Custom Plastic Bottles & Caps Manufacturer

Our custom plastic bottle and cap solutions are designed to meet your unique specifications, combining durability, functionality, and visual appeal. With advanced molding techniques, we help your brand stand out and meet the demands of your market.

Specializing in Custom Plastic Bottles & Caps.

Food Grade Standard Meets US and EU Standards

NO MOQ

Pricing no Higher Than Standard Bottles & Caps

Empowering Brands with Unique Custom Plastic Bottles

At PTSMAKE, we specialize in crafting custom plastic bottles that make your brand stand out.

Our unique manufacturing solutions help you create a memorable brand identity, fostering recognition and customer loyalty. We believe a bottle is more than just packaging; it’s a vital part of your brand’s story.

By choosing our custom solutions, you gain a partner committed to your brand’s growth. We don’t just produce bottles; we help your brand leave a lasting impression.

Let us work together to create bottles that not only hold your products but also elevate your brand in the market.

What Sets Us Apart

Personalized options and design samples help create unique, branded packaging.

Strict quality control and certifications ensure safe, durable bottles for food or drinks.

Reliable production and quick turnaround times meet your urgent deadlines.

Clear, fair pricing with no hidden costs builds trust and value.

"Working with PTSMAKE has been a great experience. We needed custom plastic bottles and caps, and after checking several suppliers, we chose them. Their team was quick to respond and really understood our needs. They even helped refine our design to ensure functionality and cost-effectiveness.The prototyping process was smooth, with quick adjustments based on our feedback. Once production started, the quality was excellent—durable bottles and perfectly fitting caps with no leaks. They also kept us updated on progress, which made the whole process much more reliable.

Thompson, CEO, USA"

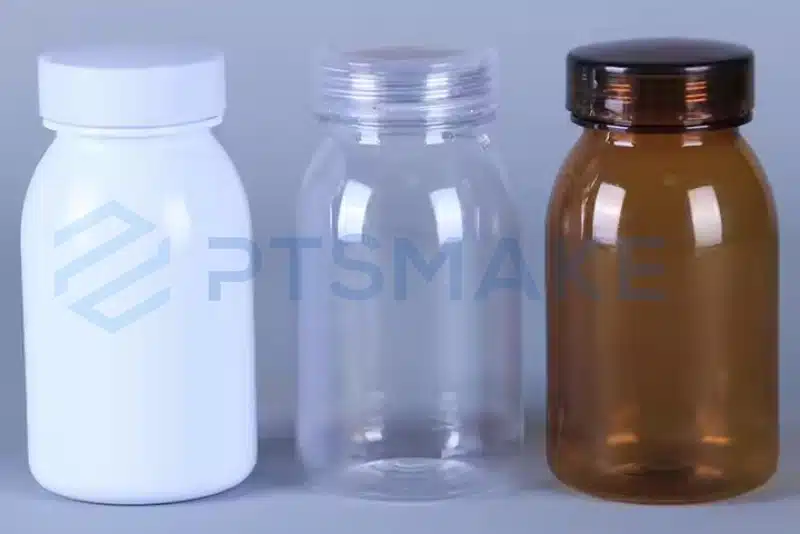

Common Types of Custom Plastic Bottles

Our product offerings include a diverse range of custom plastic bottles and caps, tailored to meet the needs of various industries. Below are 8 common types of custom plastic bottles that we provide:

Custom Plastic Bottles & Caps Design

Understanding Our Design Process

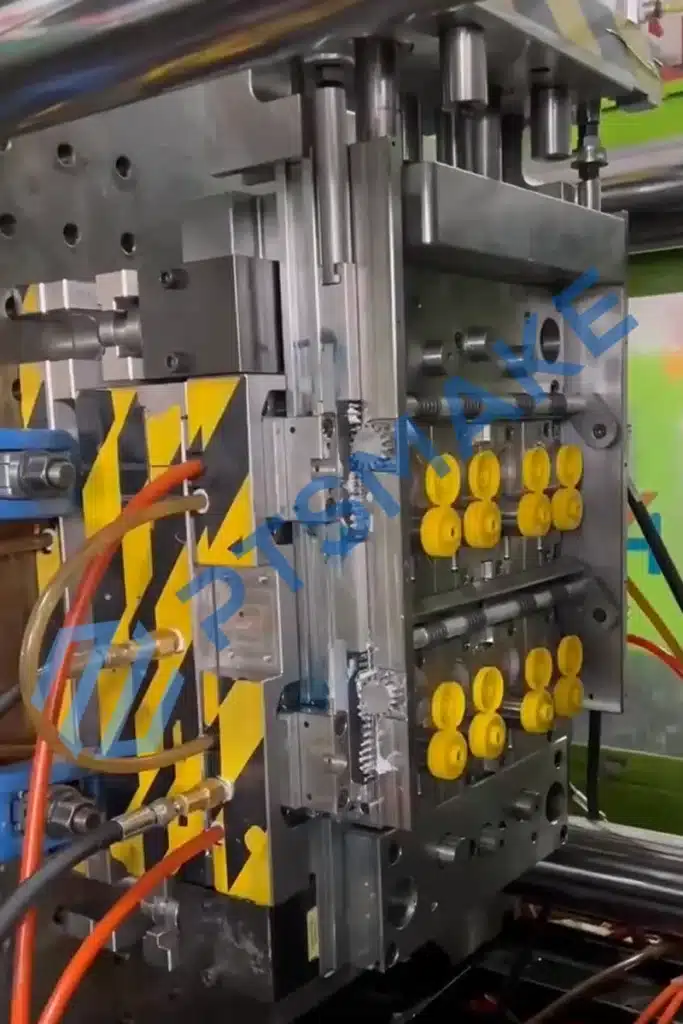

- At PTSMAKE, the foundation of our success lies in our ability to design and customize plastic bottles and caps that meet the unique needs of our clients. We believe that the design process begins with a clear understanding of our clients’ specific requirements and aspirations. Our expert design team works diligently to gather this information, conducting thorough consultations to extract insights into the desired product features, functionality, and aesthetics.

- This collaborative approach sets the stage for creating exceptional products tailored specifically to our clients’ brands. Our team leverages advanced design software, which offers state-of-the-art modeling capabilities to envision possibilities. From the initial concept, we explore a vast array of shapes, sizes, volumes, and colors that serve to not only reflect our clients’ brand identity but enhance it as well.

Prototyping for Perfection

- After establishing a strong design concept, we move to the prototyping stage, which is vital in the development of our custom products. Prototypes serve as the first tangible representation of the designs. They allow our clients to assess aspects like functionality, ease of use, and aesthetics before full-scale production begins. We understand how critical this phase is for client satisfaction, so we encourage feedback and offer modifications as necessary. Each adjustment we make is aimed at aligning the product even closer to the client’s vision and ensuring that the final outcome will exceed expectations.

- In addition, our prototyping process involves rigorous testing. We analyze various factors such as durability, usability, and performance under different conditions. This step is vital, as it allows us to uncover potential issues early, enabling both our team and our clients to address any concerns proactively before mass production begins.

Customization Options Available

- One of the aspects that differentiate us in the market is our extensive customization options. We understand that packaging plays a crucial role in marketing, branding, and product perception. Therefore, we offer a variety of customization choices that allow clients to tailor their packaging solutions precisely to their operational needs and brand identity.

- Clients can select from different bottle shapes, cap styles, and decorative elements such as labels, achieve unique finishes, or even add features such as embossed logos. Additionally, we provide a multitude of color options to ensure that every element harmonizes with the overall branding strategy. Our goal is to create unique and recognizable packaging that enhances the product inside while capturing the attention of the consumer.

Custom Plastic Bottles & Caps Minimum Order Quantity

Our Flexible MOQ Policy

- At PTSMAKE, we emphasize the importance of flexibility in our minimum order quantity (MOQ) policy. We recognize that each business operates differently, especially when it comes to budgeting and inventory management. Therefore, our MOQ is designed to cater to startups, small businesses, and large enterprises alike, ensuring that we can accommodate varying production needs without hindering progress.

- Our MOQ allows businesses to minimize their initial investment, especially when launching new products. We realize that testing the waters with smaller quantities is often wise in the world of consumer products. Clients can confidently introduce new offerings to the market while keeping costs manageable.

Benefits of Low MOQ for Startups

- Low MOQs are particularly advantageous for startups. Emerging businesses often face uncertainty related to demand and sales potential. By offering lower MOQs, we provide startups the opportunity to launch their products with less financial risk. This flexibility enables them to gauge market reactions and consumer preferences without the burden of overproducing or holding excessive inventory.

- Moreover, a focus on low MOQs allows startups to iterate on designs based on customer feedback. As they refine their offerings, we seamlessly adjust production quantities to align with changing demand and evolving market trends.

Scaling Production with Growing Businesses

- As businesses grow, the demand for their products often increases. At PTSMAKE, we stand ready to help clients scale their production volumes efficiently. Our systems are designed to accommodate growth, ensuring that as clients scale up their orders, they don’t encounter supply chain issues or delays.

- By maintaining a close working relationship, our team can forecast rising demand and plan accordingly, making necessary adjustments to production schedules in advance. This proactive approach ensures clients always have the necessary packaging materials in stock, allowing them to maintain momentum as they expand.

Request a Custom Quote Today

Get an accurate estimate for your Custom Plastic Bottle project. Let us help you meet your exact specifications.

Custom Plastic Bottles & Caps Cost

Competitive Pricing Strategy

- At PTSMAKE, we aim to provide cost-effective solutions without compromising quality. Our pricing strategy reflects a competitive yet reasonable approach that takes into account the various factors influencing overall costs, such as materials, design complexity, and the volume of the order.

- We recognize that our clients come from diverse backgrounds, and their budgeting strategies differ significantly. As such, we strive to offer pricing that appeals to both small startups and larger enterprises, providing them with pricing models that effectively align with their financial goals.

Tailored Quotes for Clients

- Every client has specific needs and requirements, which is why we provide tailored quotes based on individual project criteria. Our team engages in meaningful discussions to understand client preferences, budget constraints, and expected outcomes. Based on this information, we prepare a detailed quote that fully outlines costs associated with material choices, production timelines, and customization options.

- By being transparent in our pricing fundamental, we build trust with our clients. This also ensures that there are no hidden fees or surprises at any stage of the production process.

Bulk Discounts for Larger Orders

- For clients looking to place larger orders, we have established bulk discount options. This pricing structure encourages businesses to purchase more while enjoying significant savings. It creates an efficient purchasing model that aligns with larger operational needs and reinforces our clients’ growth strategies.

- Clients can take advantage of these bulk discounts by planning their purchasing strategies. We work closely with them to forecast future needs and ensure they can benefit from reduced prices without sacrificing the quality of their products.

Custom Plastic Bottles & Caps Production Lead Time

Overview of the Production Timeline

- Once a design is finalized, we seamlessly transition into the production cycle, which is designed to be efficient and reliable. On average, the manufacturing timeline can vary but typically falls within a few weeks, depending on the complexity of the order and the level of customization required.

- We understand that time is crucial in product launches, so we prioritize an organized manufacturing process that minimizes downtime at every step. By strategically aligning our production schedules with material availability, we can ensure that our clients receive their products as promptly as possible.

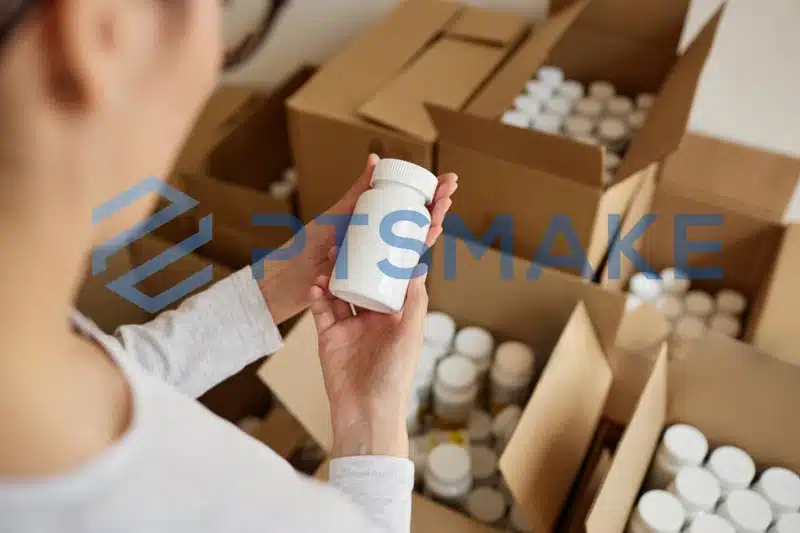

Transparent Communication Throughout Production

- Open communication is foundational to a productive partnership. Throughout the production process, our team provides consistent updates regarding order status, including any potential delays or issues. We value transparency and want our clients to feel informed and confident in our ability to deliver on our promises.

- Our project managers regularly touch base with clients, demystifying the production timeline and addressing any questions or concerns that may arise. This proactive communication helps foster long-term trust and enables clients to plan appropriately on their end.

Adapting to Challenges

- In any manufacturing environment, challenges can arise unexpectedly. Our team is well equipped to handle these challenges swiftly and effectively. Should issues emerge, we assess them immediately and present our clients with solutions. Our goal is to ensure that project timelines are adhered to without sacrificing quality.

- Issues related to material shortages, equipment failures, or unforeseen production complexities can arise. However, our agile approach and well-established contingency plans help us tackle these scenarios with confidence and maintain a steady production flow.

Custom Plastic Bottles & Caps Quality Assurance

Commitment to Quality Standards

- Quality assurance is woven into the very fabric of our business at PTSMAKE. We recognize that delivering quality plastic bottles and caps is essential for maintaining our clients’ trust and satisfaction. To achieve this, we implement comprehensive quality control measures at every stage of the manufacturing process.

- From the initial sourcing of materials to the final product testing before shipping, quality is our utmost priority. We adhere to strict protocols and standards throughout, ensuring each product aligns with our mission of providing only the highest quality packaging solutions.

Testing for Performance and Safety

- Before our custom bottles and caps are approved for sale, they undergo various performance and safety tests. We perform rigorous assessments to verify that our products meet industry standards. This meticulous testing ensures that clients receive packaging solutions that are both reliable and safe for their intended uses.

- Tests include evaluations for durability, leak resistance, and any chemical compatibility if necessary. This dedication to thorough testing not only enhances our products but also gives our clients peace of mind, bolstering their confidence in using our packaging solutions.

Strong Customer Support

- In the event that issues arise, our dedicated customer support team stands ready to assist. We handle any inquiries or concerns promptly, reinforcing our commitment to client satisfaction. Whether it’s providing additional information about our products or addressing any order-related issues, our support team is always available.

- We understand that excellent customer service plays a vital role in nurturing long-lasting partnerships. We strive to provide an experience that exceeds expectations, assuring that our clients feel valued and supported at every step of the partnership.

Custom Plastic Bottles & Caps Sustainability and Environmental Impact

The Importance of Sustainable Practices

View Details

- The significance of sustainability in manufacturing has never been clearer. At PTSMAKE, we are actively committed to adopting environmentally responsible practices. We recognize that our operations have an impact on the planet, and we take steps to mitigate that impact through sustainable initiatives.

- Our focus on sustainability is not merely a response to market trends. It is a fundamental aspect of our identity and values. We work diligently to ensure that our manufacturing processes are efficient, waste is minimized, and our carbon footprint is reduced.

Eco-Friendly Materials

View Details

- Every time we create a product, we are mindful of the materials we use. Whenever possible, we incorporate eco-friendly and recyclable materials into our custom plastic bottles and caps. This approach allows clients to choose sustainable options, aligning with their branding and corporate social responsibility initiatives.

- By offering recyclable materials, we help clients attract environmentally conscious consumers. Using sustainable packaging is increasingly vital in today’s marketplace, and PTSMAKE positions our clients as leaders in the sustainability movement.

Energy Efficiency in Production

View Details

- Our production facilities feature advanced machinery designed to operate efficiently. Energy efficiency is a critical area of focus. Lower energy consumption during production means we can deliver high-quality products while reducing our operational impact on the environment.

- We continually assess our processes to find ways to further reduce energy use. This ongoing commitment not only benefits the environment but also contributes to cost savings for our clients.

Contact Plastic Bottle Expert Today!

We look forward to the opportunity to work with you and contribute to your project’s success.

Applications of Custom Plastic Bottles & Caps

We provide custom plastic bottles and caps tailored to meet the specific needs of different industries.

Below are some industries that frequently require plastic bottles and caps:

Food and Beverage

Customer Types: Beverage manufacturers, food packagers, producers of juices, mineral water, teas, dairy products, etc.

Demand Characteristics: Require compliance with food safety standards, environmentally friendly materials, excellent sealing properties, and strong anti-counterfeiting features.

Cosmetics

Customer Types: Cosmetic brands, skincare companies, manufacturers of shampoos, shower gels, and other daily chemical products.

Demand Characteristics: Unique and attractive designs emphasizing aesthetics and user experience; packaging needs to be lightweight and leak-proof; may require UV coating or other special features.

Pharmaceutical

Customer Types: Pharmaceutical companies, health supplement manufacturers, producers of nutritional supplements.

Demand Characteristics: High standards of hygiene and safety; may need anti-counterfeiting and tamper-evident features; bottle materials and designs must comply with relevant regulations.

Cleaning and Household Goods

Customer Types: Manufacturers of household cleaners, laundry detergents, dishwashing liquids, air fresheners, etc.

Demand Characteristics: Need bottles that are corrosion-resistant, heat-resistant, and durable; designs should include leak-proof and non-slip features.

Pet Supplies

Customer Types: Manufacturers of pet food, pet care products, pet cleaning supplies.

Demand Characteristics: Fun and user-friendly designs; plastic bottles must be safe and environmentally friendly.

Automotive and Industrial Chemicals

Customer Types: Producers of automotive fluids (engine oils, antifreeze), industrial chemicals, agricultural chemicals.

Demand Characteristics: Require specialized bottles that are chemical-resistant, pressure-resistant, and impact-resistant; strict adherence to safety and compliance standards.

Personal Care

Customer Types: Manufacturers of personal hygiene products such as hand sanitizers, soaps, deodorants, lotions.

Demand Characteristics: Convenient and user-friendly packaging; focus on aesthetics and portability; bottles need to be leak-proof and easy to handle.

Sports and Health

Customer Types: Producers of energy drinks, protein shakes, dietary supplements, and fitness-related products.

Demand Characteristics: Bottles should be durable and portable with ergonomic designs; materials must be safe and compliant with health and safety standards.

Custom Plastic Bottles & Caps Materials

Selecting the Right Materials

- Material selection is one of the most vital aspects of producing high-quality custom plastic bottles and caps. The materials we utilize directly impact not just the durability and safety of the products, but also their performance in various applications. Our primary materials include PET (Polyethylene Terephthalate), HDPE (High-Density Polyethylene), and PP (Polypropylene).

- These types of plastics are known for their excellent balance of safety and functionality. PET, for example, is widely regarded in the beverage industry for its clarity and lightweight properties. HDPE offers superior chemical resistance and is often used for more durable applications. PP is known for its robustness and heat resistance, making it suitable for containers that may require sterilization.

Environmental Responsibility

- In response to growing environmental concerns, we prioritize eco-friendly practices within our material sourcing and production processes. At PTSMAKE, we actively seek recyclable materials whenever possible. This commitment helps our clients pursue sustainable packaging solutions that resonate with environmentally conscious consumers.

- By choosing materials that are not only safe but also recyclable, we enable clients to enhance their brand reputation as environmentally responsible. We understand the increasing importance of sustainability in purchasing decisions, and we strive to make it easy for clients to align with these values.

Quality Control of Materials

- Before any materials enter our production line, they undergo rigorous quality checks. This is to ensure that each type of plastic meets stringent industry standards for safety and performance. By investing in thorough inspections of incoming materials, we maintain an unwavering commitment to quality.

- These measures ensure that every bottle and cap produced is free from defects and consistently meets our high standards. Quality assurance is not an afterthought for us; it is embedded within our operational processes.

Custom Plastic Bottles & Caps Success Stories

Case Studies of Successful Collaborations

View Details

- At PTSMAKE, we pride ourselves on our track record of successful partnerships with clients across various industries. Our custom solutions have empowered businesses to achieve remarkable results, reinforcing our dedication to quality and service.

- One such success story features a beverage startup that approached us with an innovative drink concept. We collaborated closely to create a unique bottle design that both represented their brand and appealed to their target market. The successful launch of this product led to a significant increase in market visibility and sales.

Impact on Small and Large Businesses Alike

View Details

- Our successful collaborations span from small startups to large corporations. Each instance demonstrates our versatility and willingness to adapt to the unique requirements of each client. One of our larger retail partners sought to refresh their existing product line and chose PTSMAKE for our design capabilities and quick turnaround times.

- Through our collaboration, the retailer successfully reintroduced its product line with new, vibrant packaging, resulting in revitalized consumer interest and increased sales. Each success story reinforces that our custom plastic bottles and caps are built to drive results.

Building Long-Term Relationships

View Details

- At PTSMAKE, we understand that the foundation of our business is not just delivering quality products, but nurturing strong relationships with our clients. This mutual trust and respect lay the groundwork for ongoing partnerships. Many clients who experience our dedication choose to return to us for additional projects.

- Our team works diligently to ensure that these partnerships remain strong through consistent communication, responsiveness, and a commitment to quality. Building long-term relationships is at the heart of what we do, and it informs every decision we make.

Custom Plastic Bottles & Caps FAQs

What types of plastic bottles and caps do you manufacture?

We manufacture a wide range of custom plastic bottles and caps, including screw cap bottles, jar containers, child-resistant bottles, pill bottles, cosmetic bottles, flip top cap bottles, spray bottles, and rigid plastic bottles.

Can we customize the design of the bottles and caps?

Yes, we offer full customization services. You can customize the shape, size, color, and design of both the bottles and caps to meet your branding and functional requirements.

What materials do you use for your plastic bottles?

We use high-quality materials such as PET, HDPE, LDPE, and PP. All materials are food-grade and meet international safety standards.

Do you provide samples before placing an order?

Yes, we can provide samples for your evaluation. Standard samples are available, and we can also create custom samples based on your specifications.

What is your minimum order quantity (MOQ)?

Our minimum order quantity varies depending on the product and customization level. Please contact us with your specific needs for detailed information.

What is your production lead time?

Production lead time depends on the order quantity and customization requirements. Typically, it takes between 15 to 30 days after confirming all details.

How do you ensure the quality of your products?

We have strict quality control processes in place. Our team conducts inspections at every stage of production to ensure that all products meet the highest standards.

Can you produce eco-friendly or recyclable bottles?

Yes, we offer eco-friendly options. We can produce bottles using recyclable materials and can advise on the best choices for sustainability.

Do you offer printing and labeling services?

Yes, we provide printing and labeling services. We can add your logos, product information, and other designs directly onto the bottles and caps.

Can you help with the design of the bottle and cap?

Yes, our design team can assist you in creating a bottle and cap that meet your needs. We work closely with you to develop designs that align with your

Are your bottles compliant with international regulations?

Yes, our products meet international standards and regulations. We can provide certifications upon request.

Do you offer child-resistant and tamper-evident features?

Yes, we offer child-resistant caps and tamper-evident features to enhance product safety and security.

What is your pricing structure?

Pricing depends on factors like material, design, order quantity, and customization level. We provide competitive quotes based on your specific needs.

Can you handle large volume orders?

Yes, we have the capacity to handle large volume orders while maintaining high quality and timely delivery.

How do you protect our custom designs and trademarks?

We respect your intellectual property and can sign confidentiality agreements to protect your designs and trademarks.

Can you engrave our logo or text on the bottle caps?

Yes, we offer engraving services on bottle caps. We can engrave your logo or any text to enhance brand recognition and give your product a unique identity.

What labeling options do you offer, and what are IMD and IML?

We provide advanced labeling options like In-Mold Decoration (IMD) and In-Mold Labeling (IML). IMD integrates the design into the mold, resulting in durable and scratch-resistant graphics. IML places a pre-printed label inside the mold during manufacturing, creating a seamless look that becomes part of the bottle.

Can you produce multi-layer cups with multiple colors, such as three-color designs?

es, we can produce multi-layer cups featuring multiple colors, including designs with three different layers. By integrating various colored materials during the manufacturing process, we create cups with a unique and eye-catching appearance. These multi-layer cups not only enhance visual appeal but also offer options for branding and product differentiation.

Can you customize spouts and nozzles for precise dispensing?

Yes, we can customize spouts and nozzles suitable for precise dispensing, ideal for products like sauces, oils, and adhesives.

Can you produce bottles with UV protection materials?

Yes, we use materials with UV protection to safeguard light-sensitive products, helping to maintain their quality over time.

Do you offer tamper-evident features for product safety?

Yes, we provide tamper-evident seals and closures to enhance product safety and give consumers peace of mind.

Can you produce bottles and caps in specific colors?

Yes, we can produce bottles and caps in a wide range of colors. We can match specific Pantone colors to align with your branding.

What surface finishes are available for the bottles?

We offer various surface finishes, such as matte, glossy, frosted, and metallic. These finishes can enhance the aesthetic appeal of your products.