Have you ever received a machined shaft that didn’t quite fit your assembly? It’s frustrating when dimensional inaccuracies cause delays and rework. I’ve seen many engineers struggle with poorly machined shafts that lead to premature wear and equipment failure.

A shaft in machining is a cylindrical component designed to transmit power and rotational motion in mechanical systems. It’s typically manufactured through turning operations on a lathe, where material is removed to achieve specific diameters, lengths, and surface finishes.

I’ve helped many customers optimize their shaft designs and manufacturing processes. The key aspects we need to consider include material selection, tolerance requirements, and surface finish specifications. Let me share some essential insights about shaft machining that will help you avoid common pitfalls.

What Are Different Types of Shafts?

Have you ever found yourself puzzled by the variety of shafts in mechanical systems? Many engineers face this challenge when selecting the right shaft for their projects, often discovering that choosing the wrong type can lead to costly failures and system inefficiencies.

A shaft is a rotating machine element that transmits power from one component to another. Different types include drive shafts, transmission shafts, countershafts, and spindle shafts, each designed for specific applications and load requirements.

Understanding Shaft Classifications

Based on Power Transmission Method

Power transmission shafts can be categorized into several types based on how they transfer power:

Transmission Shafts

These shafts transmit power between the source and the machine absorbing power. The most common example is the shaft connecting an electric motor to a gearbox. When designing transmission shafts, the focus is on both torsional strength and rigidity.

Spindle Shafts

Commonly found in machine tools, spindle shafts are a crucial component that holds the cutting tool or workpiece. At PTSMAKE, we frequently manufacture high-precision spindle shafts for CNC machines, where runout1 tolerance is critical for achieving accurate machining results.

Drive Shafts

These shafts transfer power from one location to another, often at an angle. Automotive drive shafts are perfect examples, connecting the transmission to the differential.

Based on Shape and Design

Different shaft shapes serve various purposes:

| Shape Type | Characteristics | Common Applications |

|---|---|---|

| Straight | Uniform diameter throughout | General power transmission |

| Stepped | Multiple diameter sections | Machine tools, gear assemblies |

| Splined | External or internal grooves | Automotive transmissions |

| Hollow | Tubular construction | Lightweight applications |

Material Selection Considerations

The choice of shaft material significantly impacts performance:

Carbon Steel Shafts

- AISI 1040-1050: Moderate strength applications

- AISI 4140-4150: Higher strength requirements

- AISI 8620: Case-hardened applications

Stainless Steel Shafts

In my experience at PTSMAKE, we often recommend stainless steel shafts for:

- Corrosive environments

- Food processing equipment

- Medical devices

- Marine applications

Load Bearing Characteristics

Understanding load types is crucial for shaft design:

Torsional Loads

- Primary consideration in power transmission

- Affects shaft diameter calculations

- Requires careful material strength analysis

Bending Loads

- Created by transverse forces

- Influenced by shaft length and support

- Critical in determining shaft deflection

Combined Loads

Most real-world applications involve both torsional and bending loads, requiring comprehensive design considerations.

Manufacturing Methods

At PTSMAKE, we employ various manufacturing techniques:

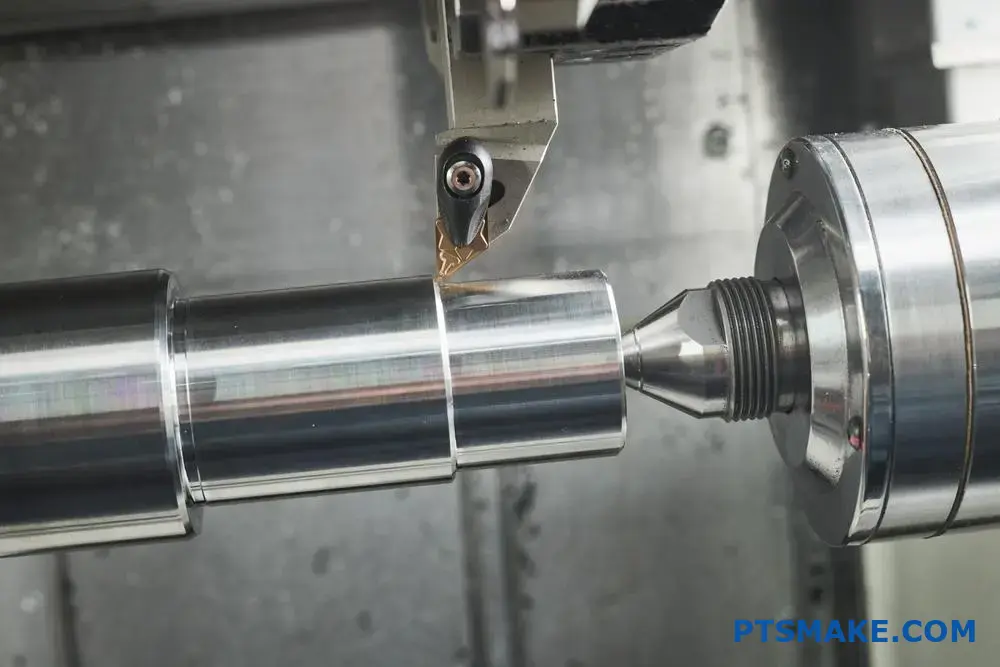

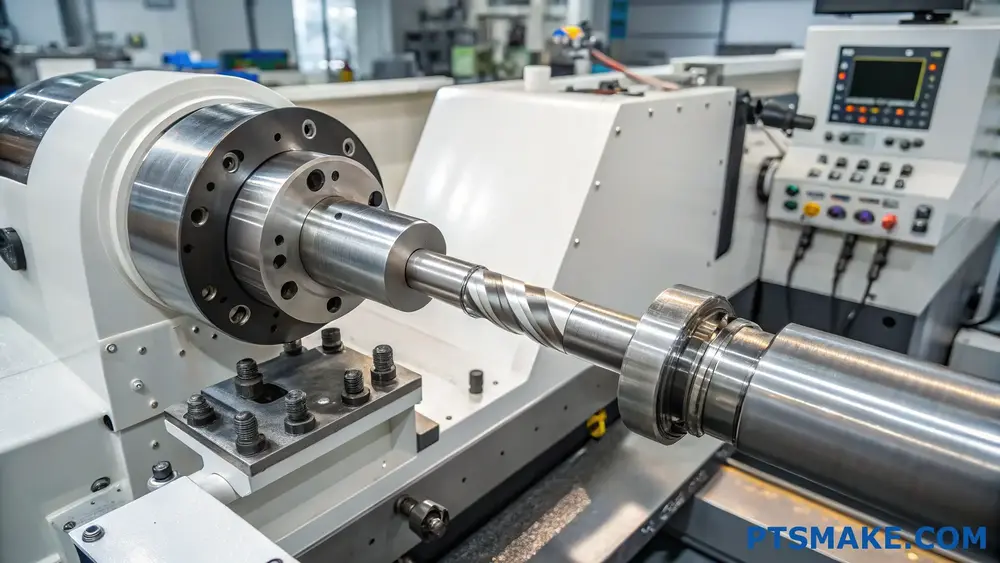

CNC Turning

- Precise diameter control

- Excellent surface finish

- Complex profile capabilities

Grinding

- For high-precision requirements

- Post-heat treatment finishing

- Tight tolerance achievement

Heat Treatment

- Surface hardening

- Core strength enhancement

- Wear resistance improvement

Quality Control Measures

Essential quality checks include:

Dimensional Inspection

- Diameter measurements

- Runout verification

- Length confirmation

Material Testing

- Hardness testing

- Surface finish inspection

- Non-destructive testing when required

Application-Specific Considerations

Different industries require specific shaft characteristics:

Aerospace

- Lightweight materials

- High strength-to-weight ratio

- Strict quality requirements

Automotive

- Durability under varying loads

- Cost-effective solutions

- Mass production capability

Industrial Machinery

- Heavy-duty applications

- Long service life

- Maintenance considerations

Through these comprehensive classifications and considerations, engineers can better understand and select the appropriate shaft type for their specific applications. At PTSMAKE, we’ve developed expertise in manufacturing various shaft types, ensuring optimal performance across different industries and applications.

What Is a Shaft Designed For?

Have you ever wondered why some mechanical components fail unexpectedly, causing costly downtime and repairs? The heart of this issue often lies in misunderstanding shaft design requirements, leading to premature wear, unexpected breakdowns, and reduced equipment efficiency.

A shaft is a rotating machine element designed to transmit power and torque between different mechanical components. It serves as a crucial support for rotating elements like gears, pulleys, and flywheels while maintaining proper alignment and bearing loads during operation.

Understanding Fundamental Shaft Functions

Power Transmission

The primary function of a shaft is to transmit power from one point to another. This involves handling various types of loads, including:

- Torsional loads from rotary motion

- Bending loads from connected components

- Axial loads from thrust forces

- Combined loads during operation

The shaft’s ability to handle these loads depends on its stress distribution2 patterns and material properties.

Load-Bearing Capabilities

Shafts must support various mechanical elements while maintaining:

- Proper alignment

- Rotational stability

- Minimal deflection

- Structural integrity

Design Considerations for Optimal Performance

Material Selection

The choice of material significantly impacts shaft performance. Here’s a comparison of common shaft materials:

| Material Type | Advantages | Best Applications |

|---|---|---|

| Carbon Steel | Cost-effective, good strength | General purpose machinery |

| Alloy Steel | Higher strength, better wear resistance | Heavy-duty equipment |

| Stainless Steel | Corrosion resistant, clean operation | Food processing, chemical industries |

| Tool Steel | Excellent wear resistance | High-precision machinery |

Geometric Features

The shaft’s geometry plays a crucial role in its functionality:

Diameter variations

- Stepped sections for component mounting

- Gradual transitions to minimize stress concentration

- Optimal sizing for load distribution

Surface features

- Keyways for securing components

- Splines for torque transmission

- Thread sections for fastening

Critical Speed Considerations

When designing shafts, we must account for:

- Operating speeds

- Natural frequencies

- Vibration characteristics

- Dynamic balance requirements

Manufacturing Aspects

At PTSMAKE, we emphasize precise machining techniques to ensure shaft quality:

Precision Machining Requirements

Dimensional accuracy

- Typical tolerances: ±0.001 inch for critical features

- Surface finish requirements: 32-63 microinches

- Roundness control within 0.0005 inch

Surface Treatment

- Heat treatment for improved strength

- Surface hardening for wear resistance

- Coating applications for specific environments

Quality Control Measures

Inspection procedures

- Dimensional verification

- Runout measurements

- Material certification

- Hardness testing

Documentation requirements

- Manufacturing drawings

- Inspection reports

- Material certificates

- Heat treatment records

Application-Specific Considerations

Different industries require specialized shaft designs:

Automotive Applications

- High-speed operation

- Varying load conditions

- Strict balance requirements

- Durability standards

Industrial Machinery

- Continuous operation

- Heavy load capacity

- Maintenance accessibility

- Environmental considerations

Precision Equipment

- High accuracy requirements

- Minimal vibration

- Special material needs

- Critical surface finish

Maintenance and Reliability

To ensure long-term performance:

Regular inspection schedule

- Visual checks for wear

- Alignment verification

- Bearing condition monitoring

- Vibration analysis

Preventive maintenance

- Lubrication requirements

- Component replacement intervals

- Performance monitoring

- Documentation practices

With proper design, manufacturing, and maintenance, shafts can provide reliable service throughout their intended lifecycle. The key is understanding the specific application requirements and implementing appropriate design features to meet these needs.

Where Are Shafts Used?

Have you ever wondered why shafts seem to be everywhere in mechanical systems? From your car’s drivetrain to industrial machinery, these seemingly simple components play crucial roles, yet many engineers struggle to identify the optimal applications for different shaft types.

Shafts are essential mechanical components used in rotating equipment to transmit power and motion. They’re found in automotive transmissions, industrial machinery, power generation equipment, machine tools, and various other applications where rotary motion or power transmission is required.

Common Applications of Shafts

Automotive Industry

The automotive sector extensively uses shafts in various components. Drive shafts transfer power from the engine to the wheels, while camshafts control valve timing in engines. At PTSMAKE, I’ve machined countless precision shafts for automotive applications, where torsional rigidity3 is crucial for optimal performance.

Industrial Machinery

Manufacturing equipment relies heavily on shaft systems. Conveyor systems, pumps, and industrial mixers all incorporate different types of shafts. These components often require specific material properties and precise dimensional tolerances to function correctly.

Power Generation

In power plants, shafts play vital roles in turbines and generators. These applications demand extremely high precision due to the high speeds and loads involved. The shafts must maintain perfect balance and alignment to prevent vibration and ensure efficient power generation.

Types of Shafts Based on Applications

| Shaft Type | Primary Use | Key Characteristics |

|---|---|---|

| Drive Shafts | Power transmission | High torque capacity, balanced design |

| Countershafts | Speed/direction change | Compact, multiple gear mounting |

| Splined Shafts | Variable position power transmission | Enhanced torque capacity, sliding capability |

| Flexible Shafts | Power transmission in non-linear paths | Bendable, maintains torque capacity |

Aerospace Applications

The aerospace industry demands some of the most precise shaft applications. These components must be lightweight yet incredibly strong, often machined from exotic materials like titanium alloys. Our CNC machining capabilities at PTSMAKE are particularly suited for these high-precision requirements.

Critical Design Considerations

Material Selection

The choice of material significantly impacts shaft performance:

- Carbon steel: Common in general applications

- Stainless steel: Corrosion-resistant environments

- Alloy steel: High-stress applications

- Titanium: Aerospace and lightweight applications

Surface Finish Requirements

Surface finish plays a crucial role in shaft performance:

- Running surfaces require specific roughness values

- Bearing seats need precise dimensional control

- Surface treatment may be necessary for wear resistance

Manufacturing Methods

CNC Turning

Modern CNC turning centers offer superior precision for shaft manufacturing. This process allows for:

- Tight tolerances (often within ±0.001")

- Excellent surface finish

- Complex feature integration

- High production efficiency

Grinding Operations

Post-machining grinding often ensures:

- Superior surface finish

- Precise diameter control

- Improved roundness

- Enhanced wear resistance

Quality Control Measures

Inspection Methods

Quality control for shafts includes:

- Dimensional verification

- Roundness checking

- Surface finish measurement

- Material hardness testing

- Straightness verification

Application-Specific Requirements

High-Speed Applications

High-speed shafts require special consideration:

- Dynamic balancing

- Special material selection

- Precise alignment features

- Specific surface finish requirements

Heavy-Duty Applications

For heavy-duty use:

- Enhanced material properties

- Larger safety factors

- Special heat treatment

- Additional surface hardening

Future Trends in Shaft Applications

The evolution of shaft applications continues with:

- Integration of smart sensors

- Use of advanced materials

- Enhanced surface treatments

- Improved design optimization

- Integration with IoT systems

Through our experience at PTSMAKE, we’ve observed increasing demand for precision-machined shafts across various industries. Our advanced CNC machining capabilities allow us to meet these evolving requirements while maintaining the highest quality standards.

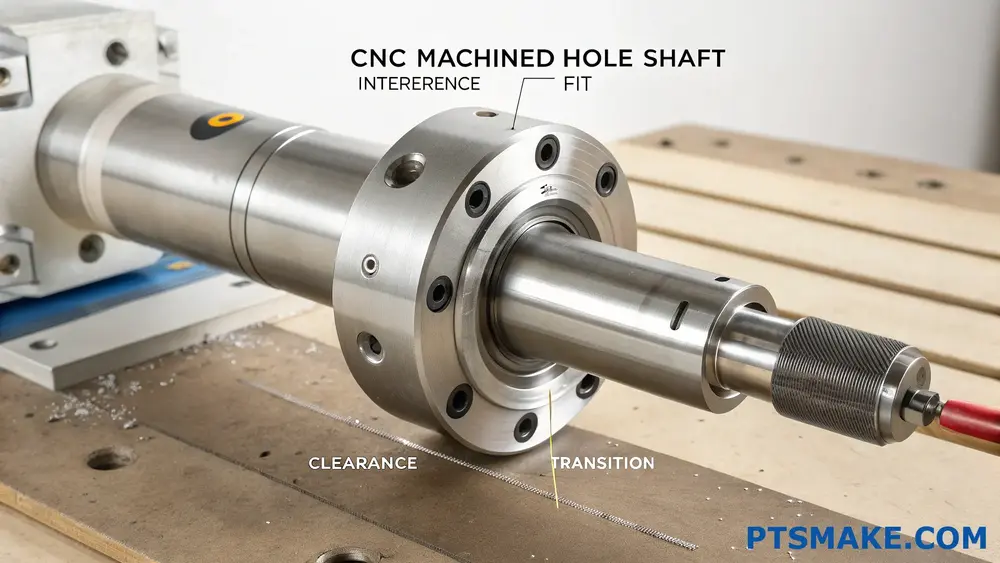

How to Do Hole Shaft Fit for CNC Machining?

Have you ever faced the frustrating challenge of mismatched hole-shaft fits in your machining projects? The headache of parts that won’t assemble properly, or worse, components that wear out prematurely due to incorrect fitting can be a costly nightmare.

Understanding hole-shaft fit in CNC machining is crucial for achieving precise component assembly. It involves selecting the right tolerance class and ensuring proper dimensioning to create functional mechanical connections between mating parts.

Understanding Tolerance Classes

The foundation of successful hole-shaft fits lies in understanding tolerance classes. These standardized classifications help ensure consistent dimensional metrology4 across manufacturing processes. At PTSMAKE, we follow both ISO and ANSI standards to maintain global compatibility.

Common Tolerance Classes for Holes:

| Tolerance Class | Typical Application | Accuracy Level |

|---|---|---|

| H7 | General machinery | Standard precision |

| H6 | Precision equipment | High precision |

| H5 | Instrument parts | Very high precision |

Common Tolerance Classes for Shafts:

| Tolerance Class | Typical Application | Accuracy Level |

|---|---|---|

| f7 | Sliding fits | Standard precision |

| h6 | Location fits | High precision |

| k6 | Light press fits | Interference fit |

Types of Fits and Their Applications

Clearance Fits

These fits provide space between the shaft and hole, allowing for movement. I recommend clearance fits for components that need regular assembly and disassembly, such as bearings or bushings that require lubrication.

Transition Fits

Transition fits offer minimal clearance or slight interference. They’re ideal for parts that need precise positioning but occasional disassembly. Our clients often use these fits for locating pins and semi-permanent assemblies.

Interference Fits

Also known as press fits, these connections create a strong bond between components. At PTSMAKE, we carefully control the machining process to achieve the exact interference required for permanent assemblies.

Critical Factors in Hole-Shaft Fit Manufacturing

Surface Finish Requirements

The surface finish significantly impacts fit quality. Here’s what we consider:

- Ra value for sliding fits: 0.8-1.6 µm

- Ra value for interference fits: 0.4-0.8 µm

- Surface pattern orientation for optimal performance

Material Considerations

Different materials require different approaches:

- Thermal expansion coefficients

- Material hardness and wear resistance

- Environmental factors affecting fit stability

Best Practices for CNC Machining Fits

Pre-Production Planning

- Review engineering drawings thoroughly

- Verify tolerance stack-ups

- Consider thermal effects during machining

Manufacturing Process Control

- Regular tool wear monitoring

- Temperature-controlled environment

- In-process measurement verification

Quality Verification

- Use precision measuring instruments

- Document all critical dimensions

- Perform assembly tests when applicable

Common Challenges and Solutions

Temperature Effects

Temperature variations can significantly impact fit accuracy. We maintain strict temperature control in our manufacturing facility to ensure consistent results.

Tool Wear Compensation

Regular tool condition monitoring and compensation adjustments help maintain accuracy throughout production runs.

Material Specific Challenges

Different materials present unique challenges:

- Aluminum: Thermal expansion consideration

- Steel: Tool wear management

- Plastics: Dimensional stability control

Measuring and Verification Methods

Measurement Tools Selection

| Tool Type | Application | Accuracy Level |

|---|---|---|

| Micrometers | External dimensions | ±0.001mm |

| Bore gauges | Internal dimensions | ±0.002mm |

| CMM | Complex geometries | ±0.001mm |

Quality Control Procedures

- First article inspection

- Regular in-process checks

- Final dimensional verification

- Fit testing when applicable

Cost Optimization Strategies

When designing hole-shaft fits, consider these cost-saving approaches:

- Select appropriate tolerance classes based on functional requirements

- Optimize machining sequences

- Use standard sizing where possible

- Consider alternative manufacturing methods

Troubleshooting Guide

Common issues and solutions:

- Inconsistent fits: Check machine calibration

- Poor surface finish: Review cutting parameters

- Size variations: Monitor environmental conditions

- Assembly difficulties: Verify measuring equipment calibration

How to Design a Shaft in Machine Design?

Have you ever struggled with shaft design failures that led to costly machine breakdowns? Or perhaps you’ve faced challenges in determining the right material and dimensions for your shaft components? These issues can turn a seemingly straightforward design task into a complex engineering puzzle.

A well-designed shaft requires careful consideration of load conditions, material selection, and dimensional accuracy. The design process involves analyzing stress distributions, calculating safety factors, and ensuring proper alignment with mating components while meeting specific application requirements.

Understanding Key Design Parameters

Load Analysis

The first step in shaft design is understanding the various loads it will encounter. During my work at PTSMAKE, I’ve learned that comprehensive load analysis is crucial for reliable shaft performance. This includes:

- Torsional loads from power transmission

- Bending moments from transverse forces

- Axial loads from thrust forces

- Combined stresses from multiple load types

Material Selection Criteria

Material selection plays a vital role in shaft performance. The material must possess adequate yield strength5 and other essential properties:

| Property | Importance | Common Requirements |

|---|---|---|

| Tensile Strength | High | 350-1000 MPa |

| Fatigue Resistance | Critical | >107 cycles |

| Hardness | Moderate | 150-300 HB |

| Machinability | Important | Good to Excellent |

Design Considerations for Different Applications

Industrial Machinery

For industrial applications, I recommend focusing on:

- Rigidity requirements

- Environmental factors

- Maintenance accessibility

- Cost considerations

Precision Equipment

When designing shafts for precision equipment, consider:

- Dimensional stability

- Surface finish requirements

- Thermal expansion characteristics

- Vibration dampening needs

Critical Design Elements

Stress Concentration

Key areas requiring attention include:

- Keyways and splines

- Shoulder fillets

- Groove locations

- Thread details

Size and Tolerance Specifications

| Feature | Typical Tolerance | Notes |

|---|---|---|

| Diameter | ±0.025mm | Critical surfaces |

| Roundness | 0.01mm | Running surfaces |

| Concentricity | 0.02mm | Multiple diameters |

| Surface Finish | Ra 0.4-1.6 | Load-bearing areas |

Manufacturing Considerations

Machining Process Selection

At PTSMAKE, we’ve refined our shaft manufacturing processes to ensure optimal results:

- CNC turning for primary shaping

- Grinding for precise surfaces

- Heat treatment timing

- Surface finishing methods

Quality Control Measures

Essential quality checks include:

- Dimensional verification

- Material certification

- Hardness testing

- Surface finish inspection

- Runout measurements

Design Optimization Tips

Cost Reduction Strategies

- Standardize dimensions where possible

- Minimize complex features

- Consider manufacturing capabilities

- Use readily available materials

Performance Enhancement

To maximize shaft performance:

- Optimize stress distribution

- Implement adequate safety factors

- Consider dynamic balancing requirements

- Plan for proper lubrication

Implementation Guidelines

Documentation Requirements

Proper documentation should include:

- Detailed drawings with tolerances

- Material specifications

- Surface finish requirements

- Heat treatment parameters

- Assembly instructions

Testing Protocols

Before final approval:

- Static load testing

- Dynamic balance checking

- Dimensional verification

- Material property confirmation

- Assembly fit verification

Maintenance and Service Life

Preventive Maintenance

Regular maintenance should focus on:

- Bearing condition monitoring

- Alignment checks

- Lubrication schedule

- Wear inspection

- Vibration analysis

Life Cycle Considerations

Design for optimal service life by:

- Anticipating wear patterns

- Planning for replacements

- Considering environmental factors

- Implementing protection features

The success of shaft design lies in the careful balance of these various elements. At PTSMAKE, we’ve consistently achieved excellent results by following these guidelines while maintaining close communication with our clients throughout the design and manufacturing process. This comprehensive approach ensures that our shaft designs meet both immediate performance requirements and long-term reliability goals.

What Materials Are Best Suited for Shafts Machining in High-Stress Environments?

Have you ever faced a situation where your shaft components failed unexpectedly under high stress? The consequences can be devastating – from costly equipment downtime to potential safety hazards. Many engineers struggle to select the right materials that can withstand extreme conditions while maintaining precision.

For high-stress shaft machining applications, alloy steels like 4140 and 4340 are optimal choices due to their excellent combination of strength, toughness, and machinability. These materials offer superior fatigue resistance and can maintain dimensional stability under extreme conditions.

Understanding Material Properties for High-Stress Shafts

When selecting materials for shaft machining in high-stress environments, several critical properties must be considered. The material must possess adequate yield strength6 while maintaining good machinability. At PTSMAKE, we carefully evaluate these properties to ensure optimal performance:

Key Material Properties for Shaft Applications

| Property | Description | Importance |

|---|---|---|

| Tensile Strength | Resistance to breaking under tension | Critical for load-bearing capacity |

| Hardness | Resistance to surface deformation | Affects wear resistance |

| Fatigue Resistance | Ability to withstand cyclic loading | Prevents premature failure |

| Machinability | Ease of material removal | Impacts manufacturing cost |

Top Material Choices for High-Stress Shafts

1. Alloy Steel 4140

This material offers an excellent balance of strength and toughness. Its chromium and molybdenum content provides:

- Enhanced hardenability

- Good wear resistance

- Excellent fatigue strength

- Superior torsional strength

2. Alloy Steel 4340

A premium choice for highly stressed applications, 4340 provides:

- Higher strength than 4140

- Better impact resistance

- Superior fatigue properties

- Excellent deep hardening capabilities

3. Stainless Steel 17-4 PH

For corrosive environments, this precipitation-hardening stainless steel offers:

- Exceptional corrosion resistance

- High strength

- Good dimensional stability

- Excellent wear properties

Material Selection Considerations

Operating Environment Factors

The operating environment significantly influences material selection:

- Temperature variations

- Exposure to corrosive elements

- Presence of lubricants

- Ambient humidity levels

Load Characteristics

Understanding load patterns is crucial:

- Static vs. dynamic loading

- Impact loading frequency

- Torsional stress requirements

- Bending moment considerations

Manufacturing Considerations

The manufacturing process plays a vital role in achieving desired properties:

Heat Treatment Options

| Treatment Type | Benefits | Applications |

|---|---|---|

| Quenching | Increases hardness | High-wear areas |

| Tempering | Improves toughness | Impact-resistant parts |

| Normalizing | Enhances machinability | General purpose |

Surface Finishing Requirements

Different applications require specific surface finishes:

- Ground surfaces for bearing fits

- Polished surfaces for sealing areas

- Rougher finishes for better lubrication retention

Cost-Effectiveness Analysis

When selecting materials, consider:

- Raw material costs

- Machining time and complexity

- Heat treatment requirements

- Expected service life

- Maintenance needs

At PTSMAKE, we help customers balance these factors to achieve optimal cost-effectiveness without compromising performance. Our experience in shaft machining allows us to recommend materials that provide the best value for specific applications.

Quality Control Measures

To ensure consistent performance:

- Material certification verification

- Hardness testing at multiple points

- Non-destructive testing when required

- Dimensional accuracy verification

- Surface finish measurement

Future Trends in Shaft Materials

The industry is witnessing several developments:

- Advanced composite materials

- Hybrid material solutions

- Surface treatment innovations

- Smart materials with monitoring capabilities

How to Ensure Precision and Quality in Shafts Machining Processes?

Have you ever received shafts that failed to meet your specifications, leading to assembly issues or project delays? It’s frustrating when machined shafts show inconsistent dimensions or poor surface finish, especially when these issues aren’t apparent until final assembly.

Quality control in shafts machining requires a systematic approach combining proper tooling, precise measurements, and stringent inspection protocols. By implementing comprehensive quality assurance measures throughout the manufacturing process, manufacturers can consistently produce high-precision shafts that meet exact specifications.

Understanding Critical Quality Parameters

Dimensional Accuracy

Maintaining tight tolerances is crucial for shaft manufacturing. At PTSMAKE, we focus on achieving tolerances as precise as ±0.005mm for critical dimensions. This level of accuracy ensures proper fit and function in assemblies. The key factors affecting dimensional accuracy include:

- Machine tool calibration

- Temperature control during machining

- Tool wear compensation

- Proper workpiece fixturing

Surface Quality Requirements

Surface finish directly impacts shaft performance and longevity. The surface roughness7 requirements typically vary based on application:

| Application Type | Ra Value (μm) | Common Usage |

|---|---|---|

| General Purpose | 1.6 – 3.2 | Basic power transmission |

| Precision | 0.4 – 1.6 | Motor shafts |

| High Precision | 0.1 – 0.4 | Aerospace components |

Process Control Measures

Material Selection and Verification

Proper material selection is fundamental to shaft quality. We implement:

- Material certification verification

- Hardness testing before machining

- Grain structure analysis when needed

- Chemical composition confirmation

Machining Parameters Optimization

The following parameters require careful control:

Cutting Speed

- Match to material properties

- Consider surface finish requirements

- Account for tool life optimization

Feed Rate

- Balance between productivity and surface quality

- Adjust for different operations

- Monitor cutting forces

Depth of Cut

- Control for thermal effects

- Maintain dimensional stability

- Optimize for tool life

Quality Inspection Protocol

In-Process Inspection

Regular checks during machining help prevent defects:

- Dimensional verification at critical stages

- Surface roughness monitoring

- Roundness measurements

- Tool wear inspection

Final Inspection Methods

We employ comprehensive final inspection techniques:

Geometric Features

- Straightness measurement

- Roundness verification

- Concentricity checking

Surface Quality

- Visual inspection

- Surface roughness measurement

- Material defect detection

Advanced Quality Assurance Techniques

Statistical Process Control

Implementing SPC helps maintain consistent quality:

| Control Aspect | Monitoring Method | Action Threshold |

|---|---|---|

| Diameter Variation | X-bar charts | ±2σ |

| Surface Finish | Individual value charts | Upper control limit |

| Tool Wear | Run charts | Tool life threshold |

Documentation and Traceability

Maintaining detailed records ensures quality consistency:

- Material certifications

- Process parameters

- Inspection results

- Non-conformance reports

- Corrective actions taken

Environmental Controls

Temperature control plays a crucial role in precision machining:

Shop Floor Environment

- Temperature: 20°C ±1°C

- Humidity: 45-55%

- Air filtration

- Vibration isolation

Material Stabilization

- Temperature equalization before machining

- Proper storage conditions

- Handling procedures

Continuous Improvement Practices

Our commitment to quality involves:

Regular Process Audits

- Monthly performance reviews

- Equipment calibration checks

- Operator training assessment

Technology Updates

- New measurement methods

- Advanced cutting tools

- Process automation opportunities

Problem Prevention Strategies

To maintain consistent quality:

Preventive Maintenance

- Regular machine calibration

- Tool condition monitoring

- Coolant system maintenance

Operation Standards

- Detailed work instructions

- Quality checkpoints

- Operator training programs

At PTSMAKE, we’ve integrated these quality control measures into our shaft machining processes, resulting in a defect rate below 0.1% and customer satisfaction exceeding 98%. Our systematic approach ensures that each shaft meets or exceeds specifications, providing reliable performance in our clients’ applications.

What Surface Treatments Improve Durability in Shafts Machining?

Have you ever received shaft components that failed prematurely despite meeting all dimensional specifications? It’s frustrating when surface degradation leads to component failure, especially when the machining process seemed perfect. This challenge can severely impact your product’s reliability and maintenance costs.

Surface treatments for machined shafts are critical for enhancing durability. Key methods include nitriding, carburizing, induction hardening, and chromium plating. These processes create harder, wear-resistant surfaces while maintaining the shaft’s core properties, significantly extending component lifespan and performance.

Understanding Surface Treatment Fundamentals

When it comes to shaft machining, surface treatment isn’t just an optional step – it’s a crucial process that determines the component’s longevity. The primary goal is to enhance the surface properties while maintaining the core material’s characteristics. At PTSMAKE, we’ve refined our surface treatment processes to ensure optimal results for various applications.

Types of Surface Treatments

Thermal Treatments

- Induction Hardening: Creates a hard outer layer while keeping the core relatively ductile

- Case hardening8: Produces a hard surface layer through carbon diffusion

- Flame Hardening: Provides localized surface hardening for specific wear areas

Chemical Treatments

| Treatment Type | Benefits | Typical Applications |

|---|---|---|

| Nitriding | High surface hardness, improved wear resistance | Gear shafts, crankshafts |

| Carburizing | Enhanced fatigue strength, wear resistance | Drive shafts, camshafts |

| Nitrocarburizing | Combined benefits of nitriding and carburizing | Heavy-duty industrial shafts |

- Mechanical Treatments

| Process | Advantages | Best Used For |

|---|---|---|

| Shot Peening | Improves fatigue resistance | High-stress applications |

| Burnishing | Better surface finish, compressive stress | Precision components |

| Cold Rolling | Enhanced surface hardness, better finish | Bearing surfaces |

Selecting the Right Treatment

The selection of surface treatment depends on several factors:

Material Considerations

- Carbon content of the base material

- Desired case depth

- Core properties requirements

- Cost constraints

Application Requirements

- Operating environment

- Load conditions

- Speed requirements

- Maintenance expectations

Process Control and Quality Assurance

At PTSMAKE, we maintain strict process control measures:

Critical Parameters

- Temperature control during treatment

- Treatment time optimization

- Environmental conditions monitoring

- Post-treatment inspection protocols

Quality Verification Methods

- Surface hardness testing

- Case depth measurement

- Microstructure analysis

- Dimensional verification

Industry-Specific Applications

Different industries require specific surface treatment approaches:

Automotive Industry

- Crankshafts: Typically require induction hardening

- Camshafts: Often treated with nitriding

- Drive shafts: Usually undergo carburizing

Aerospace Applications

- Landing gear components: Shot peening plus chrome plating

- Turbine shafts: Special heat treatment combinations

- Actuator shafts: Precision surface hardening

Industrial Machinery

- Heavy equipment shafts: Deep case hardening

- High-speed spindles: Precision grinding with surface treatment

- Power transmission shafts: Combined thermal and chemical treatments

Cost-Benefit Analysis

When considering surface treatments, evaluate:

Direct Costs

- Treatment process expenses

- Equipment investment

- Material costs

- Labor requirements

Long-term Benefits

- Extended component life

- Reduced maintenance needs

- Improved performance

- Lower replacement frequency

Environmental Considerations

Modern surface treatment processes must address:

Sustainability Factors

- Energy consumption

- Chemical usage

- Waste management

- Environmental compliance

Green Alternatives

- Low-temperature processes

- Environmentally friendly chemicals

- Waste reduction methods

- Energy-efficient equipment

At PTSMAKE, our surface treatment facilities are equipped with state-of-the-art technology to ensure both quality results and environmental responsibility. We continuously invest in research and development to improve our processes and meet evolving industry standards.

Future Trends

The field of surface treatment is evolving with:

Emerging Technologies

- Plasma-based treatments

- Nano-surface modifications

- Hybrid processing methods

- Smart coating systems

Industry 4.0 Integration

- Real-time process monitoring

- Automated quality control

- Data-driven optimization

- Predictive maintenance capabilities

What Are the Key Considerations for Cost-Effective Shafts Machining at Scale?

Have you ever faced the challenge of balancing quality and cost when scaling up shaft production? Many manufacturers struggle with maintaining precision while keeping costs manageable, especially when production volumes increase and deadlines tighten.

Cost-effective shaft machining at scale requires careful consideration of material selection, production workflow optimization, quality control systems, and automated processes. Success depends on balancing these elements while maintaining tight tolerances and surface finish requirements.

Material Selection Strategies

The foundation of cost-effective shaft machining starts with smart material choices. When selecting materials, we need to consider both machinability and durability. At PTSMAKE, we’ve developed a systematic approach to material selection that balances cost with performance requirements.

Common Materials for Shaft Production

| Material Type | Machinability Rating | Cost Factor | Best Applications |

|---|---|---|---|

| Carbon Steel | High | Low | General purpose shafts |

| Stainless Steel | Medium | Medium | Corrosion-resistant applications |

| Alloy Steel | Medium-High | Medium-High | High-stress applications |

| Aluminum | Very High | Low-Medium | Light-duty shafts |

Production Workflow Optimization

Optimizing the production workflow is crucial for achieving cost-effectiveness in batch production9. A well-designed workflow reduces setup times and minimizes material waste.

Setup Time Reduction Techniques

- Standardized tooling arrangements

- Pre-set tool configurations

- Digital work instructions

- Quick-change fixtures

Quality Control Integration

Implementing robust quality control systems helps prevent costly rework and ensures consistent output. Our approach includes:

In-Process Inspection Methods

- Automated diameter checks

- Surface roughness monitoring

- Geometric tolerance verification

- Real-time data collection

Advanced Machining Technologies

Modern CNC technology plays a vital role in achieving cost-effective production. Key considerations include:

Machine Selection Criteria

- Spindle speed capabilities

- Tool change time

- Axis precision

- Power requirements

- Maintenance costs

Surface Finish Considerations

The quality of surface finish directly impacts both functionality and production costs. We focus on:

Surface Treatment Options

| Treatment Type | Cost Impact | Benefits | Applications |

|---|---|---|---|

| Grinding | Medium-High | High precision | Critical surfaces |

| Polishing | Medium | Improved appearance | Aesthetic requirements |

| Shot peening | Low-Medium | Enhanced fatigue life | Stress-critical parts |

Tool Management Strategies

Effective tool management significantly impacts production costs. Consider:

- Tool life monitoring

- Cutting parameter optimization

- Insert rotation schedules

- Coolant management

Production Planning Considerations

Efficient production planning helps maintain cost-effectiveness through:

Batch Size Optimization

- Setup cost analysis

- Material handling efficiency

- Equipment utilization

- Inventory management

Cost Control Measures

To maintain profitability while scaling production, implement:

- Regular cost analysis reviews

- Supplier relationship management

- Waste reduction programs

- Energy efficiency initiatives

Automation Integration

Incorporating automation can significantly reduce labor costs and improve consistency:

Automation Opportunities

- Material handling systems

- Robotic loading/unloading

- Automated measurement

- Digital process monitoring

Training and Skill Development

Investing in operator training yields long-term cost benefits through:

- Reduced error rates

- Improved setup efficiency

- Better problem-solving capabilities

- Enhanced equipment utilization

At PTSMAKE, we’ve successfully implemented these strategies to deliver high-quality shaft machining services while maintaining competitive pricing. Our approach combines technical expertise with practical experience to achieve optimal results for our clients.

How to Choose a Reliable Supplier for Custom Shafts Machining Projects?

Have you ever received precision shafts that didn’t meet your specifications, causing production delays and budget overruns? Or worse, dealt with a supplier who disappeared when quality issues arose? These scenarios can turn your manufacturing project into a nightmare.

Choosing a reliable supplier for custom shafts machining requires evaluating their technical capabilities, quality control systems, communication efficiency, and track record. The ideal partner should demonstrate expertise in precision machining, maintain consistent quality standards, and provide responsive customer service.

Evaluating Technical Capabilities

Machinery and Equipment Assessment

A supplier’s machining capabilities directly impact the quality of your custom shafts. At PTSMAKE, we understand that modern CNC machines with volumetric compensation10 systems are essential for achieving tight tolerances.

Key equipment considerations include:

| Equipment Type | Importance | Impact on Quality |

|---|---|---|

| CNC Lathes | Critical | Dimensional accuracy |

| Grinding Machines | High | Surface finish |

| CMM Equipment | Essential | Quality verification |

| Material Testing | Important | Material integrity |

Material Processing Expertise

The supplier should demonstrate comprehensive knowledge of various materials commonly used in shaft manufacturing, including:

- Stainless steel

- Carbon steel

- Alloy steel

- Aluminum alloys

Quality Control Systems

Documentation and Certification

Look for suppliers with:

- ISO 9001:2015 certification

- Industry-specific certifications

- Documented quality procedures

- Regular audit records

Inspection Methods

Quality control should include:

- First article inspection

- In-process checks

- Final dimensional verification

- Surface finish measurement

- Material certification

Communication and Response Time

Project Management Capabilities

Effective communication includes:

- Dedicated project managers

- Regular progress updates

- Technical consultation

- Quick response to inquiries

Digital Infrastructure

Modern suppliers should offer:

- Online ordering systems

- Real-time production tracking

- Digital documentation

- CAD/CAM capabilities

Cost and Value Assessment

Pricing Structure

Consider these factors:

- Material costs

- Manufacturing time

- Setup charges

- Quantity discounts

- Shipping options

Value-Added Services

Look for suppliers offering:

- Design optimization suggestions

- Material selection assistance

- Assembly services

- Inventory management

Production Capacity and Lead Times

Manufacturing Flexibility

The supplier should demonstrate:

- Ability to handle varying order volumes

- Quick changeover capabilities

- Multiple machine availability

- Backup production plans

Lead Time Management

Evaluate:

- Standard lead times

- Rush order capabilities

- On-time delivery record

- Production scheduling efficiency

Sample and Prototype Services

Prototype Development

A reliable supplier should offer:

- Rapid prototyping options

- Material alternatives

- Design feedback

- Cost-effective solutions

Sample Evaluation Process

Look for:

- Free or low-cost samples

- Quick turnaround times

- Detailed inspection reports

- Performance testing capabilities

Post-Production Support

Quality Guarantee

Ensure the supplier provides:

- Clear warranty terms

- Defect resolution process

- Replacement policies

- Quality documentation

Technical Support

Valuable support includes:

- Installation guidance

- Troubleshooting assistance

- Performance optimization

- Maintenance recommendations

Geographic Location and Logistics

Shipping Capabilities

Consider:

- International shipping experience

- Packaging methods

- Transportation partners

- Custom clearance expertise

Location Advantages

Evaluate:

- Time zone differences

- Communication barriers

- Cultural understanding

- Local regulations

Industry Experience and References

Market Presence

Look for:

- Years in business

- Industry recognition

- Client testimonials

- Project portfolio

Reference Checks

Verify:

- Past project success

- Customer satisfaction

- Problem resolution

- Long-term relationships

Financial Stability

Business Health Indicators

Assess:

- Credit ratings

- Financial statements

- Investment in equipment

- Growth trajectory

Click to learn about shaft runout measurement and its impact on machining precision. ↩

Click to learn more about stress analysis techniques for optimal shaft design. ↩

Click to learn more about how torsional rigidity affects shaft performance and selection. ↩

Click to learn advanced measurement techniques for precise manufacturing tolerances. ↩

Click to learn more about material yield strength calculations and optimization techniques. ↩

Click to learn more about yield strength calculations and their impact on shaft design. ↩

Click to learn more about surface measurement techniques and their impact on shaft performance. ↩

Click to learn about advanced hardening techniques that can double your shaft’s lifespan. ↩

Click to learn how batch production strategies can optimize your manufacturing costs. ↩

Click to learn about advanced machining compensation techniques for superior accuracy. ↩