What Are Rubber Rollers & Their Essential Functions

Ever wondered what keeps your printer running smoothly or how fragile materials move through complex manufacturing lines without damage? The unsung heroes behind these daily miracles are hiding in plain sight – rubber rollers.

Rubber rollers are specialized cylindrical components featuring elastomeric coverings that serve critical functions across countless industries. These versatile tools enable precise material handling while providing the perfect balance of grip, pressure, and protection needed for efficient manufacturing operations.

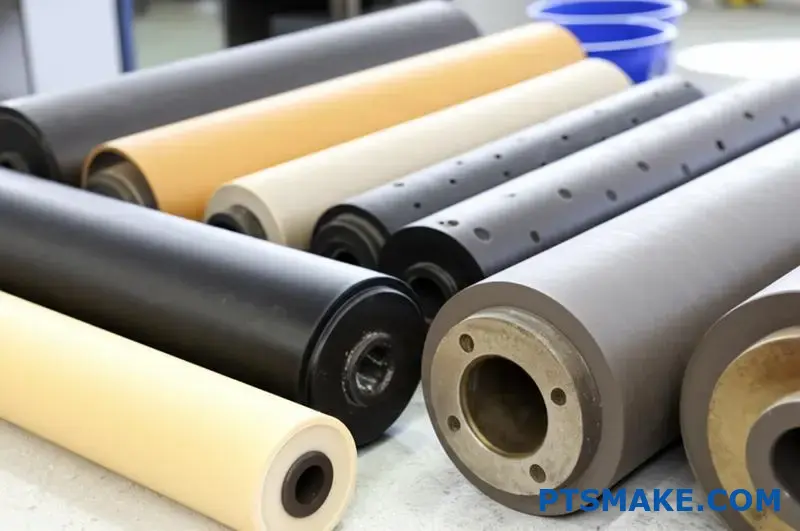

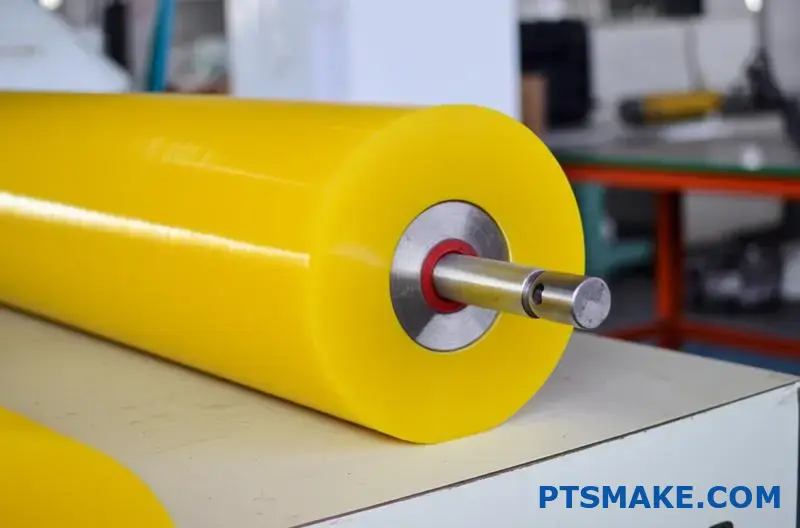

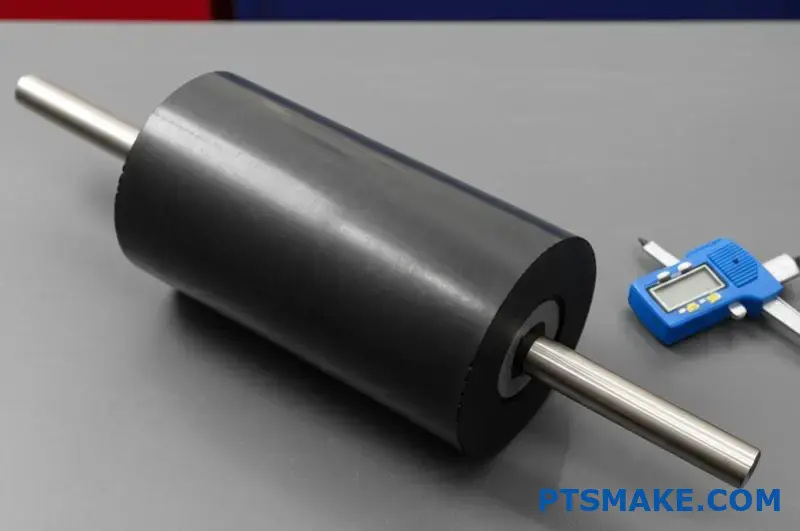

The Anatomy of a Rubber Roller

Rubber rollers might seem simple at first glance, but their construction involves careful engineering to meet specific application requirements. A typical rubber roller consists of several key components:

- Core: Usually made from metal (steel or aluminum) or sometimes plastic for lightweight applications

- Elastomeric Covering: The rubber or polymer material that gives the roller its functional properties

- End Shafts: Allow the roller to be mounted and rotated within machinery

- Optional Components: Bearings, seals, or specialized coatings for specific applications

The selection of materials for each component depends entirely on the intended use. In my work at PTSMAKE, I’ve seen how critical proper material selection is for ensuring optimal performance and longevity.

Types of Rubber Roller Materials

The elastomeric covering is what truly defines a rubber roller’s capabilities. Different materials offer varying levels of hardness, chemical resistance, temperature tolerance, and other properties.

Common Rubber Roller Materials

| Material | Key Properties | Common Applications |

|---|---|---|

| Natural Rubber | High friction, excellent elasticity, good tear resistance | Paper handling, textile processing |

| Neoprene | Good chemical resistance, moderate oil resistance | Food processing, printing |

| EPDM | Outstanding weather resistance, excellent electrical insulation | Outdoor equipment, electrical applications |

| Silicone | Extreme temperature resistance, non-stick properties | Food processing, medical equipment |

| Polyurethane | High abrasion resistance, load-bearing capacity | Heavy material handling, industrial printing |

The durometer1 of the rubber covering is another crucial specification. This measurement of hardness typically ranges from 20A (very soft) to 90A (firm) for most applications.

Key Functions of Rubber Rollers in Industry

Rubber rollers perform numerous essential functions across various industries. Their versatility makes them indispensable in modern manufacturing processes.

Material Transport and Conveyance

One of the most common applications of rubber rollers is moving materials through processing equipment. The elastomeric surface provides:

- Controlled friction for reliable material movement

- Gentle handling to prevent damage to sensitive materials

- Consistent speed and tension control

- Ability to accommodate variations in material thickness

In printing presses, for example, precision rubber rollers ensure paper moves through at exact speeds without slipping or tearing, maintaining perfect registration of colors.

Compression and Lamination

Rubber rollers excel at applying uniform pressure across surfaces, making them ideal for:

- Laminating multiple layers together

- Removing air bubbles between materials

- Creating consistent adhesion between surfaces

- Compressing materials to specific thicknesses

Surface Finishing and Coating

The controlled contact provided by rubber rollers makes them perfect for applying finishes and coatings:

- Even distribution of inks, adhesives, or coatings

- Controlled penetration depth of treatments

- Uniform coverage without streaking or pooling

- Gentle application to prevent substrate damage

Material Processing

In many manufacturing operations, rubber rollers directly participate in transforming materials:

- Squeezing water from textiles

- Pressing pulp in paper manufacturing

- Embossing patterns into surfaces

- Stretching or calendering materials to specific dimensions

Industry-Specific Applications

Rubber rollers have become essential components across numerous industries, each with specialized requirements:

Printing and Publishing

In the printing industry, rubber rollers transfer ink, move paper, and apply pressure in various processes. The demands are exceptionally precise, as even minor variations can cause visible defects.

Food Processing

Food-grade rubber rollers process everything from dough to meat products. Here at PTSMAKE, we ensure these rollers meet strict FDA compliance standards and can withstand frequent sanitization.

Textiles and Fabric

The textile industry relies on rubber rollers for dyeing, pressing, and finishing fabrics without causing damage to delicate materials.

Packaging and Converting

Modern packaging lines use rubber rollers to guide materials, apply adhesives, and create seals with perfect consistency even at high speeds.

By understanding the essential functions of rubber rollers, manufacturers can select the optimal specifications for their particular applications, ensuring efficient operations and high-quality output.

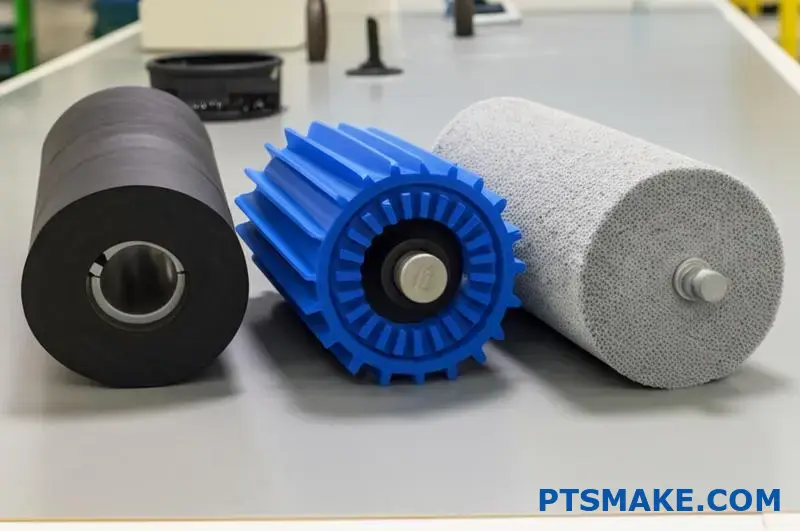

Types of Rubber Rollers: Solid, Finned & Durasoft®

When it comes to industrial efficiency, the difference between success and failure often hinges on components you rarely see – like rubber rollers. These unassuming workhorses quietly determine whether your production line runs smoothly or grinds to a costly halt.

The rubber roller market offers three distinct primary styles to address various industrial needs: solid rollers providing unmatched durability, finned rollers delivering enhanced grip capabilities, and specialized Durasoft® no-crush rollers engineered specifically for handling delicate materials without causing damage.

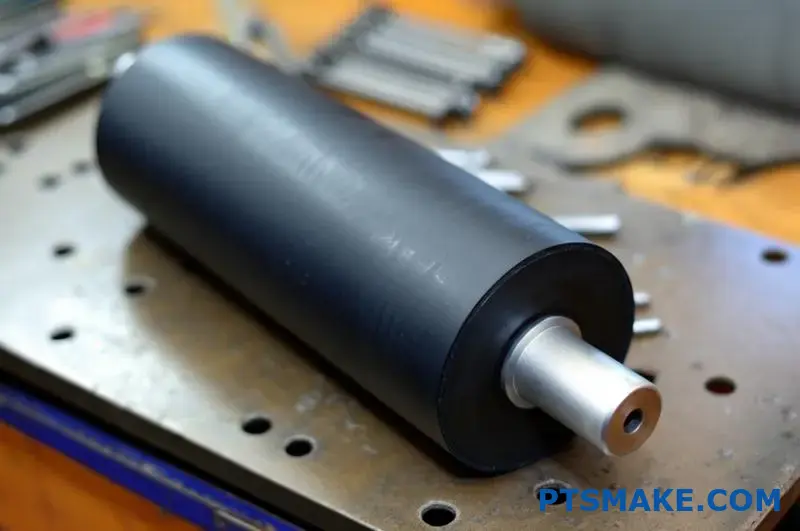

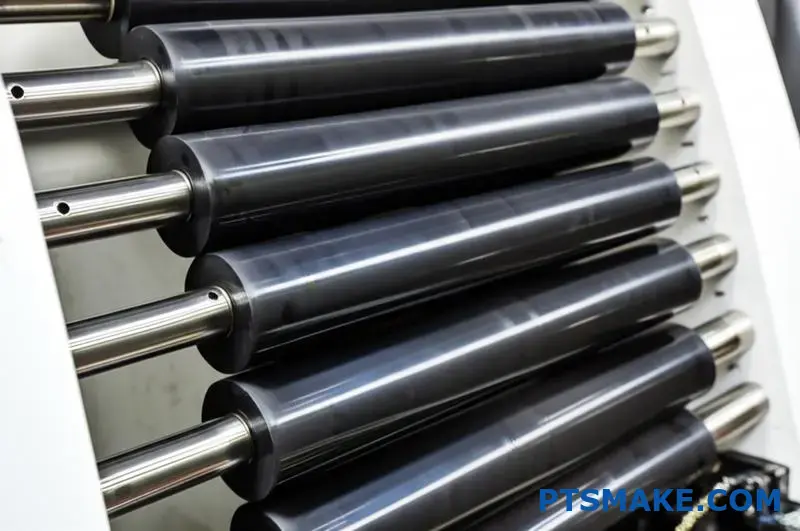

Solid Rubber Rollers: The Industry Workhorses

Solid rubber rollers represent the traditional and most widely used option in the industry. These rollers feature a continuous rubber covering over a metal core, providing consistent surface contact across the entire roller width.

Key Characteristics of Solid Rubber Rollers

Solid rollers excel in applications requiring durability and reliability. Their seamless construction minimizes potential failure points and provides excellent load distribution capabilities.

The uniformity of solid rollers makes them particularly well-suited for:

- Consistent material feeding

- Even pressure application

- Smooth material transport

- Applications requiring precise nip pressure

Material Options for Solid Rollers

The effectiveness of a solid rubber roller largely depends on the elastomer material selected. Having worked with countless manufacturers to solve material handling challenges, I’ve seen firsthand how crucial proper material selection is.

| Material Type | Hardness Range | Key Advantages | Common Applications |

|---|---|---|---|

| Natural Rubber | 30-80A | High friction, excellent rebound | Paper handling, general conveying |

| EPDM | 40-90A | Weather/ozone resistance, color stability | Outdoor applications, UV exposure environments |

| Neoprene | 40-80A | Oil resistance, moderate chemical resistance | Light oil environments, moderate chemical exposure |

| Silicone | 20-80A | Extreme temperature range, FDA compliance | Food processing, high/low temperature applications |

| Polyurethane | 20-95A | Exceptional wear resistance, oil tolerance | High-abrasion environments, heavy material handling |

The choice between these materials depends on your specific application requirements including environmental factors, material properties, and processing conditions.

Finned Rubber Rollers: Enhanced Grip Solutions

Finned rubber rollers feature a series of raised ridges or fins across their surface. This design dramatically changes how the roller interacts with materials being processed.

Benefits of Finned Rubber Roller Design

The distinctive finned pattern provides several advantages over solid rollers in certain applications:

- Increased Surface Area: The fins effectively multiply the contact surface, enhancing grip capabilities.

- Improved Air Release: The channels between fins allow air to escape when bringing materials together.

- Enhanced Traction: The raised profile provides better grip on difficult materials.

- Reduced Material Slippage: The textured surface minimizes slipping especially with smooth materials.

Optimal Applications for Finned Rollers

These rollers particularly excel in:

- Sheet feeding operations

- Label application systems

- Material separation processes

- Applications with smooth or glossy materials

- Environments requiring enhanced material grip

The fin pattern can be customized based on application needs. Some common configurations include:

- Straight fins (perpendicular to roller axis)

- Spiral fins (for lateral material movement)

- Crosshatch patterns (for maximum grip)

- Diamond patterns (balanced grip and release)

Maintenance Considerations for Finned Rollers

One notable aspect of finned rollers is their cleaning regimen2, which differs from solid rollers. The spaces between fins can collect debris over time, potentially affecting performance. In production environments where contamination is a concern, establishing a regular cleaning schedule is essential to maintain optimal function.

Durasoft® No-Crush Rollers: Delicate Material Specialists

Durasoft® represents a specialized rubber roller technology designed specifically for handling fragile or easily damaged materials. These rollers feature a proprietary construction that combines firm support with an ultra-soft surface layer.

The Unique Construction of Durasoft® Rollers

What makes Durasoft® technology remarkable is its dual-layer design:

- A firm inner layer providing structural integrity and dimensional stability

- An extremely soft outer layer that conforms to delicate materials without applying excessive pressure

This configuration delivers the seemingly contradictory benefits of support strength and gentle handling in a single roller.

Primary Applications for Durasoft® Technology

Durasoft® rollers are the optimal choice for:

- Medical device manufacturing

- Electronics assembly

- Optical film handling

- Delicate textile processing

- Thin film lamination

- Food handling of fragile products

Performance Advantages of Durasoft® Rollers

The specialized construction of these rollers provides several notable benefits:

- Prevention of material deformation or crushing

- Reduced risk of surface marking or scratching

- Ability to handle materials of varying thicknesses simultaneously

- Elimination of air entrapment during lamination processes

- Extended material lifespan through reduced handling stress

At PTSMAKE, I’ve implemented Durasoft® rollers in several precision manufacturing applications where material integrity was absolutely critical. The results consistently demonstrated improved quality outcomes and reduced material waste compared to traditional roller technologies.

Selecting the Right Roller Type for Your Application

The choice between solid, finned, and Durasoft® rollers should be based on a thorough analysis of your specific application requirements. Consider these key factors:

- Material Properties: What are you handling? Delicate materials may require Durasoft®, while standard materials might work well with solid rollers.

- Grip Requirements: Need enhanced traction? Finned rollers provide superior grip for difficult materials.

- Processing Speed: Higher speeds may benefit from specific roller designs to maintain consistent contact.

- Environmental Conditions: Temperature, humidity, and chemical exposure all influence optimal roller selection.

- Maintenance Considerations: Some roller types require more frequent maintenance than others.

By carefully evaluating these factors, you can select the roller technology that provides optimal performance for your specific application, ensuring efficient operation and high-quality output.

Material Options: Neoprene, Nitrile & Polyurethane

Have you ever wondered why some rubber rollers last for years in harsh environments while others fail within months? The secret lies not in the manufacturing process, but in the material selection that happens long before production begins.

Choosing the right material for rubber rollers is perhaps the most critical decision affecting their performance. Neoprene, nitrile, and polyurethane each offer distinct advantages that can dramatically impact durability, functionality, and application suitability in your specific operating conditions.

Understanding Material Properties and Performance

When selecting materials for rubber rollers, we need to consider several critical factors that will determine their effectiveness in specific applications. Each material has unique characteristics that make it suitable for particular environments and requirements.

Neoprene: The Flame-Resistant Workhorse

Neoprene (polychloroprene) has earned its reputation as a versatile and reliable material for rubber rollers across numerous industries. Its combination of properties makes it particularly valuable in challenging environments.

Key Properties of Neoprene Rollers

Neoprene offers an impressive balance of physical properties that make it suitable for many applications:

- Temperature Range: Effective from -40°F to +200°F (-40°C to +93°C)

- Flame Resistance: Inherently self-extinguishing

- Weather Resistance: Excellent resistance to ozone, UV, and weathering

- Chemical Compatibility: Good resistance to many chemicals and moderate oils

- Hardness Range: Typically available in 40-90 Shore A

Ideal Applications for Neoprene

In my experience working with manufacturers across various sectors, I’ve found neoprene to be particularly effective in:

- Printing industry applications where fire safety is paramount

- Outdoor equipment exposed to weather elements

- Applications requiring moderate chemical resistance

- Paper processing and textile handling

One notable limitation is that neoprene tends to have lower tear strength compared to some alternatives, which can be a factor in applications with high mechanical stress.

Nitrile: The Oil-Resistant Specialist

Nitrile rubber (NBR or acrylonitrile-butadiene rubber) excels in environments where oil resistance is critical. This petroleum-resistant material has become indispensable in many industrial applications.

Key Properties of Nitrile Rollers

Nitrile offers several advantages that make it valuable for specific applications:

- Oil Resistance: Exceptional resistance to petroleum-based oils and fuels

- Temperature Range: Typically effective from -30°F to +250°F (-34°C to +121°C)

- Non-Marring Properties: Leaves minimal marks on contacted surfaces

- Abrasion Resistance: Good resistance to wear and abrasion

- Chemical Compatibility: Excellent with many industrial chemicals

| Material | Oil Resistance | Temperature Range | Abrasion Resistance | Cost Factor |

|---|---|---|---|---|

| Neoprene | Moderate | -40°F to +200°F | Good | Medium |

| Nitrile | Excellent | -30°F to +250°F | Good | Medium-High |

| Polyurethane | Good | -30°F to +180°F | Excellent | High |

Ideal Applications for Nitrile

Nitrile rubber rollers particularly shine in:

- Automotive and aerospace manufacturing where oil exposure is common

- Food processing equipment requiring oil resistance

- Manufacturing environments with hydraulic systems nearby

- Applications where non-marking properties are essential

The main drawback of nitrile is its limited resistance to aromatic hydrocarbons and its tendency to degrade when exposed to strong oxidizing agents or ozone.

Polyurethane: The Abrasion-Resistant Powerhouse

Polyurethane elastomers represent the premium tier of rubber roller materials, offering exceptional mechanical properties that outperform most conventional rubbers.

Key Properties of Polyurethane Rollers

Polyurethane delivers an impressive set of characteristics:

- Abrasion Resistance: Up to 5-10 times more resistant than natural rubber

- Load-Bearing Capacity: Exceptional compression strength and recovery

- Tear Resistance: Superior resistance to cuts, tears, and chunking

- Hardness Range: Extremely versatile range from 10 Shore A to 70 Shore D

- Oil Resistance: Good resistance to aliphatic hydrocarbons and many oils

Ideal Applications for Polyurethane

The superior mechanical properties of polyurethane make it ideal for:

- Heavy material handling with high load requirements

- Applications with abrasive materials that quickly wear other elastomers

- High-speed operations requiring dimensional stability

- Precision applications needing exact tolerances

- Environments where extended service life justifies higher initial cost

Making the Right Material Selection

Selecting the optimal material for rubber rollers requires balancing several factors including operating environment, performance requirements, and budget constraints. Here’s a systematic approach I’ve developed over years of working with manufacturers:

Environmental Considerations

Start by evaluating the conditions your rollers will face:

- Temperature Exposure: Will the rollers operate in extreme heat or cold?

- Chemical Contact: What substances will contact the rollers during operation?

- Moisture Levels: Will the rollers be exposed to water, steam, or high humidity?

- UV/Ozone Exposure: Will the rollers be used outdoors or near electrical equipment?

Mechanical Requirements

Next, consider the physical demands on the rollers:

- Load Requirements: How much weight or pressure will the rollers bear?

- Speed of Operation: Will the rollers operate at high speeds?

- Abrasion Factors: Will the rollers contact abrasive materials?

- Precision Needs: How tight are the tolerance requirements?

Application-Specific Factors

Finally, consider any special requirements for your application:

- Food Safety: Does the application require FDA-compliant materials?

- Static Concerns: Is electrostatic discharge3 a concern in your application?

- Noise Reduction: Are noise dampening properties needed?

- Color Requirements: Are there specific color needs for visual identification?

In my work at PTSMAKE, I’ve found that most applications don’t have a single "perfect" material. Instead, the best choice represents a carefully considered compromise that prioritizes the most critical performance factors for that specific use case.

For instance, while polyurethane offers superior abrasion resistance, its higher cost may not be justified for applications where rollers aren’t subjected to highly abrasive materials. Conversely, trying to save money by using neoprene in an oil-immersed application will likely result in premature failure and higher long-term costs.

By thoroughly analyzing your specific requirements and understanding the unique properties of each material option, you can select rubber rollers that deliver optimal performance and longevity for your particular application.

Mounting Solutions & Hardware Configurations

Ever wondered what makes the difference between a rubber roller that performs flawlessly and one that constantly fails? The secret often lies not in the roller itself, but in how it’s mounted to your machinery.

Proper mounting solutions for rubber rollers are critical engineering decisions that directly impact operational efficiency, maintenance requirements, and product quality. Each mounting style serves specific functional needs while addressing unique installation constraints in different industrial applications.

The Critical Role of Proper Roller Mounting

When designing or upgrading machinery that utilizes rubber rollers, the mounting configuration deserves careful consideration. The right mounting solution ensures optimal performance, reduces maintenance requirements, and extends the service life of both the roller and the host equipment.

Roller-Only Configurations

The simplest mounting approach is the roller-only configuration, where the rubber roller is the primary component without additional hardware assemblies. This setup is typically used where the roller functions as a simple contact surface.

Advantages of Roller-Only Setups

- Maximum simplicity with minimal components

- Cost-effective solution for basic applications

- Easier replacement during maintenance

- Reduced weight in mobile equipment

Typical Applications

Roller-only configurations excel in applications like:

- Guide rollers in conveyor systems

- Pressure applicators in non-motorized equipment

- Contact surfaces in manual operations

- Temporary installations and testing setups

Bearing Mounts for Free Rotation

When rollers need to rotate freely with minimal friction, bearing mounts are the preferred solution. These configurations incorporate precision bearings that enable smooth rotation even under significant loads.

Types of Bearing Mounting Systems

- Internal Bearings: Housed within the roller core itself

- External Bearing Blocks: Mounted on the shaft ends outside the roller body

- Pillow Block Bearings: Free-standing units that support the roller assembly

- Flange-Mounted Bearings: Allow surface mounting to machine frames

| Bearing Mount Type | Load Capacity | Installation Complexity | Maintenance Access | Space Requirements |

|---|---|---|---|---|

| Internal Bearings | Moderate | Simple | Limited | Minimal |

| External Bearing Blocks | High | Moderate | Excellent | Moderate |

| Pillow Block Bearings | Very High | Complex | Excellent | Significant |

| Flange-Mounted Bearings | High | Moderate | Good | Moderate |

Considerations for Bearing Selection

The selection of appropriate bearings involves several factors:

- Speed Rating: Maximum RPM the bearing can safely sustain

- Load Capacity: Both radial and axial loading considerations

- Environmental Conditions: Exposure to moisture, dust, or chemicals

- Temperature Range: Operational temperatures affect lubrication requirements

- Precision Requirements: Tolerance needs for the application

In high-precision applications, I often recommend using sealed bearings with permanent lubrication to minimize maintenance and prevent contamination that could affect roller performance.

Threaded Stud Mounts for Fixed Installations

For applications where the roller needs to be firmly secured in a fixed position, threaded stud mounts provide an excellent solution. These configurations feature threaded posts extending from one or both ends of the roller.

Key Benefits of Threaded Stud Mounts

- Secure, vibration-resistant installation

- Precise positioning capabilities

- Space-efficient mounting in tight areas

- Easy removal for maintenance or replacement

- Ability to create adjustable pressure systems

Implementation Varieties

Threaded stud mounts come in several configurations:

- Single-End Studs: One threaded post, allowing cantilever mounting

- Double-End Studs: Threaded posts at both ends for maximum stability

- Spring-Loaded Studs: Incorporate spring tension for controlled pressure

- Adjustable Threaded Mounts: Allow for precise roller positioning

When implementing threaded stud mounts at PTSMAKE, we pay particular attention to the stress concentration at the junction between the stud and the roller core. This transition point requires proper engineering to prevent failures under load.

Shaft Mounts for Drive Systems

When rubber rollers need to be powered or need to transfer power themselves, shaft mounting systems are essential. These configurations connect the roller to motors or other drive mechanisms.

Drive System Integration Options

- Direct Drive Coupling: The roller shaft connects directly to a motor

- Belt or Chain Drives: Power transfer via belts or chains

- Gear Drives: For applications requiring torque multiplication or speed reduction

- Clutched Connections: Allow engagement/disengagement during operation

Critical Design Factors

When designing shaft-mounted drive systems, several factors require careful consideration:

- Torque Requirements: Sufficient power to overcome operational resistance

- Speed Control: Maintaining consistent RPM under varying loads

- Shaft Alignment: Proper alignment to prevent premature bearing wear

- Vibration Damping: Minimizing operational vibration

- Emergency Stopping: Safety mechanisms for rapid shutdown

In one challenging project, we implemented a keyway system4 for a client’s high-torque application where previous setups had failed due to shaft slippage. This modification provided the necessary torque transfer capability while maintaining quick disassembly for maintenance.

Specialized Mounting Solutions for Unique Applications

Beyond the standard mounting configurations, several specialized solutions address particular operational requirements.

Quick-Change Mounting Systems

For production environments where minimizing downtime is critical, quick-change mounting systems allow rapid roller replacement without extensive disassembly.

Key features include:

- Tool-free removal mechanisms

- Self-aligning components

- Pre-loaded tensioning systems

- Color-coded or keyed parts to prevent incorrect installation

Adjustable Pressure Mounts

Some applications require variable pressure between rollers or between a roller and another surface. Adjustable pressure mounts incorporate:

- Spring-loaded mechanisms

- Pneumatic or hydraulic cylinders

- Lever systems with mechanical advantage

- Electronic pressure control systems

Cantilevered Mounts for Special Access

When access to one end of a roller path is limited or when rollers need to be changed from one side only, cantilevered mounting solutions provide the answer. These specialized configurations support the roller from a single end while maintaining stability and proper alignment.

Floating Mounts for Automatic Alignment

In applications with slight misalignments or where materials of varying thickness must be accommodated, floating mount systems allow the roller to self-adjust. These mounts incorporate:

- Spherical bearings that permit angular movement

- Spring-centered positioning systems

- Pivot points with controlled degrees of freedom

- Self-adjusting tensioners

Selecting the Optimal Mounting Solution

The process of choosing the right mounting configuration should follow a systematic approach:

- Define Functional Requirements: Identify exactly what the roller needs to accomplish

- Assess Operational Environment: Consider factors like temperature, contamination, and space constraints

- Determine Maintenance Needs: Factor in how frequently the roller will need servicing

- Evaluate Load Characteristics: Analyze both static and dynamic loading scenarios

- Consider Future Adaptability: Allow for potential changes in production requirements

By carefully evaluating these factors, you can select a mounting solution that not only meets current needs but also provides flexibility for future requirements.

Through years of designing rubber roller systems for various industries, I’ve found that the mounting solution often makes as much difference to overall system performance as the roller material itself. Even the highest quality rubber roller will fail prematurely if improperly mounted for its application.

Industry-Specific Rubber Roller Applications

Have you ever watched a newspaper being printed at lightning speed or marveled at how delicate fabrics move through complex textile machines without a single snag? Behind these manufacturing marvels lies an unsung hero – the humble rubber roller.

Rubber rollers serve as the critical interface between machinery and materials across countless industries, each with unique demands. From distributing ink with micrometer precision in printing to safely conveying food products while meeting strict regulatory standards, these versatile components adapt to specialized industry requirements.

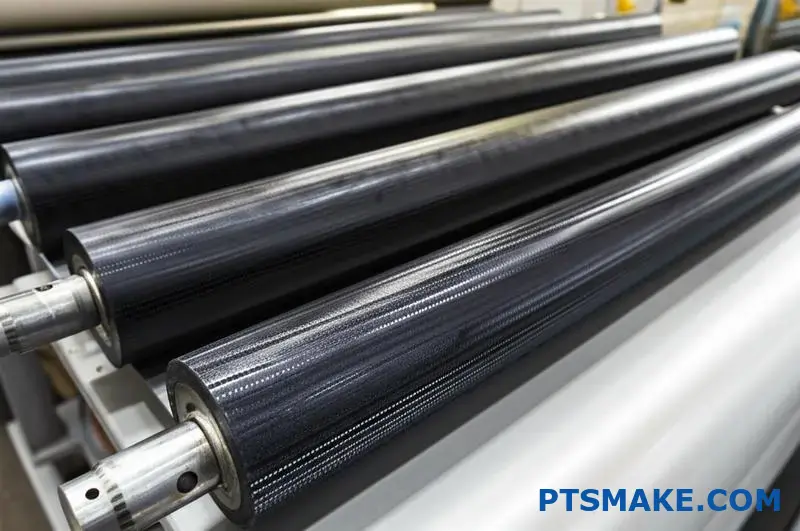

The Printing and Graphics Industry: Precision Ink Distribution

The printing industry has perhaps the most demanding requirements for rubber rollers of any sector. Here, rubber rollers must perform with extraordinary precision while handling a variety of materials and chemical compounds.

Ink Distribution Systems

In offset printing presses, rubber rollers form complex ink distribution trains that transform thick, tacky ink into microscopically thin, uniform films. These systems require:

- Precise durometer (hardness) specifications for optimal ink transfer

- Chemical resistance to withstand aggressive solvents in inks

- Dimensional stability to maintain perfect registration

- Consistent surface characteristics even after millions of impressions

The rubber compounds used must balance grip, release, and durability while maintaining precise geometrical tolerances. At PTSMAKE, we’ve found that specialized EPDM compounds often provide the ideal balance for modern UV-curable inks, while traditional oil-resistant nitrile compounds work best with conventional inks.

Paper Handling and Transport

Beyond ink transfer, rubber rollers in printing equipment also manage paper movement through the press. These transport rollers must:

- Provide sufficient friction without marking delicate papers

- Maintain consistent speed to prevent registration errors

- Accommodate various paper stocks from thin sheets to heavy cardstock

- Resist buildup of paper dust and coating particles

Digital Printing Applications

Modern digital printing systems rely heavily on specialized rubber rollers for paper transport, fusing systems, and maintenance stations. In high-speed inkjet systems, precision rubber rollers maintain exact paper positioning to ensure accurate droplet placement, often requiring tolerances measured in microns rather than millimeters.

The Packaging Industry: Material Movement Excellence

The packaging industry presents a unique set of challenges for rubber roller applications, with demands ranging from high-speed film handling to precise adhesive application.

Flexible Packaging Processes

In flexible packaging production, rubber rollers serve critical functions including:

- Nipping rollers for lamination processes

- Tension control for consistent material feed

- Corona treatment to improve surface adhesion

- Adhesive application for multi-layer constructions

The materials processed often include metallized films, thin plastics, and specialty coatings that require gentle handling with precise pressure control.

Converting Operations

Converting operations transform raw materials into finished packaging products through processes like slitting, die-cutting, and folding. In these applications, rubber rollers must:

- Provide exact pressure for clean cutting operations

- Maintain precise web tension throughout the process

- Accommodate rapid changeovers between different materials

- Resist cutting oils and lubricants used in the machinery

One particularly challenging converting application I’ve worked on involved high-speed die-cutting of pressure-sensitive labels where the rubber roller compound needed to resist both the adhesive from the labels and the cutting lubricants while maintaining perfect dimensional stability at speeds exceeding 300 meters per minute.

Manufacturing and Assembly Lines: Controlled Material Movement

In general manufacturing environments, rubber rollers facilitate the controlled movement of components and materials through production processes.

Automated Assembly Systems

Modern assembly lines utilize rubber rollers for:

- Precise positioning of components

- Gentle handling of finished surfaces

- Controlled acceleration and deceleration of parts

- Interface between automated systems and work pieces

The automotive industry, in particular, relies heavily on specialized rubber rollers in their assembly operations. These rollers must handle everything from raw sheet metal to painted body panels without causing damage or deformation.

Electronic Component Manufacturing

The electronics industry presents perhaps the most demanding cleanliness requirements for rubber rollers. In semiconductor and circuit board manufacturing, rubber rollers must:

- Be free from particulate generation

- Resist static electricity buildup

- Maintain precise dimensions in controlled environments

- Withstand specialized cleaning agents used in clean rooms

For these applications, specially formulated silicone and EPDM compounds with antistatic properties5 often provide the best combination of performance characteristics.

Food Processing: Safety and Sanitation First

The food processing industry combines mechanical demands with stringent regulatory requirements, creating unique challenges for rubber roller applications.

FDA and Regulatory Compliance

Rubber rollers used in food processing must meet strict FDA requirements regarding:

- Material formulation and extractables

- Resistance to cleaning and sanitizing agents

- Ability to withstand high-temperature washing

- Surface characteristics that prevent bacterial harborage

At PTSMAKE, we specialize in food-grade rubber compounds that maintain their performance properties even after thousands of cleaning cycles with aggressive sanitizing agents.

Specific Food Processing Applications

Different food products require specialized roller characteristics:

| Food Product Type | Key Roller Requirements | Recommended Materials |

|---|---|---|

| Bakery Products | Heat resistance, non-stick properties | Silicone, specialized EPDM |

| Meat Processing | Resistance to fats and proteins, sanitizability | FDA-compliant nitrile |

| Dairy Products | Resistance to butterfat, low temperature performance | Food-grade neoprene |

| Frozen Foods | Low-temperature flexibility, non-brittle performance | Specialty polyurethane |

Steel Processing: Heavy-Duty Performance

Steel mills and metal processing facilities represent the extreme end of rubber roller applications, with extraordinary demands for durability and heat resistance.

Hot Rolling Applications

In hot rolling mills, rubber rollers must function in proximity to steel at temperatures that can exceed 1800°F (982°C). These applications require:

- Specialized heat-resistant compounds

- Water-cooling systems integrated into the roller design

- Exceptional compression resistance

- Ability to withstand thermal cycling

While the rubber rollers don’t directly contact the hot steel, they often function in pinch roll and guide systems where ambient temperatures regularly exceed 200°F (93°C).

Coil Processing Lines

In steel coil processing (pickling, coating, slitting, etc.), rubber rollers must:

- Resist highly corrosive acids and processing chemicals

- Handle extreme weights and pressures

- Maintain consistent surface characteristics despite harsh conditions

- Provide reliable traction on oily or wet steel surfaces

Textile Manufacturing: Gentle Yet Precise Handling

The textile industry presents a fascinating contrast of requirements – rollers must be gentle enough to handle delicate fabrics yet durable enough to withstand continuous operation.

Dyeing and Finishing

In textile dyeing and finishing operations, rubber rollers must:

- Resist aggressive dyes and chemical treatments

- Apply precise, uniform pressure for consistent results

- Operate in high-humidity and high-temperature environments

- Prevent marking or distorting delicate fabrics

Weaving and Knitting Preparation

Before fabrics are woven or knitted, yarns undergo numerous processes where rubber rollers control tension and positioning. These specialized rollers require:

- Precise groove patterns for yarn alignment

- Consistent surface characteristics to prevent yarn breakage

- Ability to handle thousands of individual yarn strands simultaneously

- Resistance to fiber fragments and processing oils

In my work with textile manufacturers, I’ve found that specialized rubber compounds with exactly tailored durometer ratings are critical for achieving the perfect balance between grip and gentle handling required for modern high-speed textile machinery.

By understanding the specific requirements of each industry, manufacturers can select rubber roller specifications that optimize performance, extend service life, and improve product quality in their particular applications.

<

Durometer Selection & Performance Characteristics

Have you ever wondered why some rubber rollers grip materials perfectly while others slip unexpectedly? Or why certain rollers wear out in weeks while similar-looking ones last for years? The secret lies in a critical specification that too many engineers overlook – the durometer.

The durometer (Shore hardness) of rubber rollers is the key determinant of their functional performance, with measurements ranging from 20-95 Shore A. This single specification controls compression characteristics, grip capabilities, and wear resistance – ultimately defining whether a roller will excel or fail in your specific application.

Understanding Durometer and its Impact on Roller Performance

Durometer is the industry-standard measurement of a rubber compound’s hardness or resistance to indentation. For rubber rollers, this specification is typically measured on the Shore A scale, which ranges from extremely soft (around 20A) to very firm (95A). Beyond this range, materials enter the realm of hard plastics rather than elastomers.

How Durometer Is Measured

The Shore durometer test measures how deeply a standardized indenter penetrates the rubber surface under controlled conditions. The less the indenter penetrates, the higher the durometer reading. This simple test reveals crucial information about how the rubber will perform under actual operating conditions.

For rubber rollers specifically, the measurement is typically taken directly on the roller surface after manufacturing. At PTSMAKE, we perform multiple measurements at different points around the roller circumference and across its width to ensure consistent hardness throughout the entire component.

Durometer Ranges and Their Applications

The full durometer spectrum can be divided into several functional ranges, each suited to specific applications:

| Durometer Range | Classification | Typical Applications | Compression Characteristics |

|---|---|---|---|

| 20-40 Shore A | Soft | Material feeding, high-grip applications, delicate material handling | High deformation, maximum contact area |

| 45-65 Shore A | Medium | General purpose, printing applications, textile processing | Moderate deformation, good grip/wear balance |

| 70-85 Shore A | Medium-Hard | Heavy material transport, moderate abrasion environments | Limited deformation, improved durability |

| 85-95 Shore A | Hard | High abrasion environments, precision nip applications | Minimal deformation, maximum wear resistance |

The selection of the appropriate durometer depends entirely on the specific requirements of your application. In my years designing roller systems, I’ve found that durometer selection is often more critical to application success than even the base material selection.

How Durometer Affects Roller Compression

The compression characteristics of a rubber roller are directly related to its durometer rating. This relationship impacts several key performance factors.

Compression Set and Recovery

Compression set refers to a roller’s ability to return to its original dimensions after being compressed. Lower durometer rollers (softer) typically exhibit greater compression set over time, meaning they may not fully recover their original shape after prolonged compression.

This is particularly important in applications where rollers remain in contact under pressure for extended periods. For instance, in a printing press that sits idle over weekends, soft rollers might develop temporary flat spots where they contact other surfaces.

Recovery time also varies with durometer. Softer compounds recover more slowly than harder ones, which can affect performance in high-speed operations where the roller must repeatedly compress and recover.

Load Distribution and Footprint

The "footprint" or contact area of a roller against another surface varies inversely with durometer. Softer rollers create larger contact areas as they deform under pressure, while harder rollers maintain smaller, more defined contact regions.

This relationship has significant implications for applications like:

- Nip pressure applications: Softer rollers distribute pressure over larger areas, reducing PSI at any given point

- Material feeding: Softer rollers conform better to irregular surfaces, providing more consistent grip

- Precision coating: Harder rollers maintain more precise contact areas for controlled application

In one particularly challenging project, we replaced a client’s 85A durometer rollers with 55A versions, which solved persistent material slippage issues by increasing the contact area by nearly 40% without changing applied pressure.

Grip and Traction Characteristics

Perhaps the most immediately noticeable impact of durometer is on a roller’s grip capabilities. This relationship follows a generally inverse correlation – softer rollers typically provide greater grip than harder ones.

The Durometer-Grip Relationship

Softer rollers (20-40A) conform more readily to surface irregularities in materials being handled, creating:

- Larger contact areas

- Better microlevel surface engagement

- Improved friction through mechanical interlocking

- Enhanced grip on smooth or slippery materials

Harder rollers (70-95A) maintain their shape under load, offering:

- Reduced material deformation

- More consistent and predictable contact pressure

- Decreased hysteresis6 energy losses

- Improved dimensional stability under load

Application-Specific Grip Requirements

Different applications have vastly different grip requirements:

- Sheet feeding systems typically benefit from softer durometers (30-50A) to maximize grip on individual sheets

- Web tension systems often utilize medium durometers (50-70A) to balance grip with minimal material deformation

- Driven transport systems may require harder durometers (70-85A) to minimize slippage between roller and drive system

Durometer’s Impact on Wear Resistance

Durometer significantly impacts a roller’s resistance to wear and its overall service life. This relationship is generally proportional – harder compounds typically offer greater wear resistance than softer ones.

Abrasion Resistance Across the Durometer Spectrum

Harder rubber compounds (85-95A) demonstrate superior resistance to:

- Surface abrasion from material movement

- Cutting and chunking from sharp materials

- Dimensional changes from continuous operation

Softer compounds (20-40A) are more susceptible to:

- Progressive wear from material friction

- Surface damage from abrasive materials

- Permanent deformation under sustained loads

This difference becomes particularly important in applications where rollers contact abrasive materials like paper with fillers, textiles with sizing compounds, or any process involving particulates.

Service Life Considerations

When engineering rubber roller systems, we often need to balance grip requirements (favoring softer durometers) against wear resistance (favoring harder durometers). This tradeoff is fundamental to roller design.

For applications requiring both characteristics, several approaches can be effective:

- Dual-durometer rollers: Combining a softer outer layer with a harder inner layer

- Textured surfaces: Adding patterns to harder compounds to increase grip

- Specialized compounds: Using additives that improve grip without reducing durometer

- Composite rollers: Incorporating different materials in specific roller sections

Selecting the Optimal Durometer for Your Application

Choosing the right durometer involves analyzing several key factors:

Material Characteristics

Consider the materials your rollers will process:

- Delicate or easily damaged materials generally require softer rollers

- Abrasive materials typically demand harder compounds

- Materials with irregular surfaces often need softer durometers for consistent contact

- High-value materials justify premium roller compounds that optimize handling characteristics

Operational Parameters

Evaluate your specific operating conditions:

- Higher speeds generally benefit from higher durometers with faster recovery

- Greater loads typically require harder compounds to resist deformation

- Continuous operation favors harder compounds with better wear resistance

- Intermittent operation may allow softer compounds for improved grip

Environmental Factors

Environmental conditions can significantly impact durometer selection:

- Higher temperatures generally require harder initial durometers (as heat often softens rubber)

- Exposure to oils or solvents may alter effective durometer over time

- High humidity can affect some compounds’ surface characteristics

- UV exposure can harden some rubber compounds prematurely

By carefully considering these factors, you can select the optimal durometer that provides the perfect balance of compression characteristics, grip capabilities, and wear resistance for your specific application requirements.

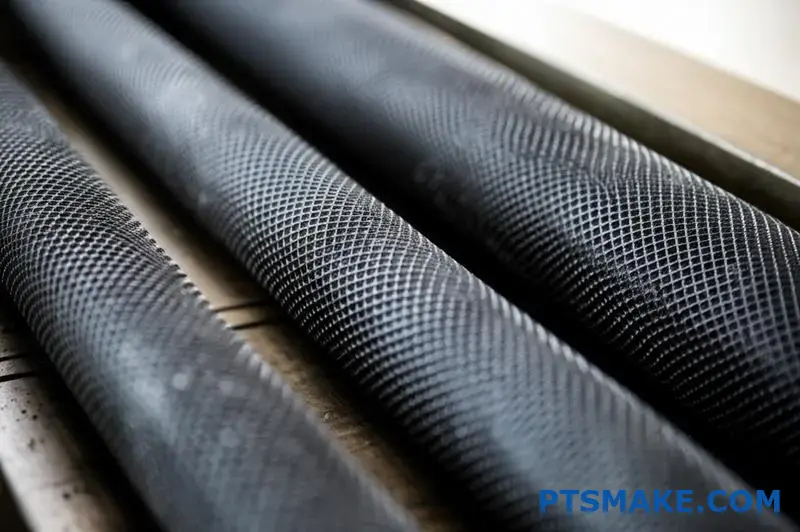

Advanced Features: Crowns, Contours & Specialty Finishes

Have you ever wondered why some manufacturing lines run flawlessly for years while others constantly battle with material tracking issues and inconsistent product quality? The secret often lies in the specialized design features of their rubber rollers that most people never notice.

Advanced rubber roller designs incorporate sophisticated engineering elements like crowned profiles for automatic tracking correction, contoured shapes tailored to specific material properties, and specialized surface finishes that optimize grip, release, and processing capabilities across diverse industrial applications.

Understanding the Importance of Advanced Roller Geometry

Modern manufacturing demands precision and consistency that standard cylindrical rollers often can’t deliver. Advanced geometric features transform basic rubber rollers into specialized tools that actively solve common processing problems.

Crowned Roller Profiles: Self-Correcting Material Tracking

One of the most valuable advanced features in rubber roller design is the crowned profile – a subtle yet incredibly effective modification where the roller diameter is slightly larger in the center than at the edges.

How Crowned Profiles Function

The crowned shape creates a natural tracking mechanism that automatically centers materials as they pass over the roller. The physics behind this self-correcting action is fascinating:

- When material begins to drift off-center, it encounters the declining diameter of the roller

- This creates differential tension across the material width

- The higher tension on one side naturally pulls the material back toward the roller’s center

- This continuous correction happens without any sensors or control systems

In high-speed web handling operations, a properly designed crown can eliminate tracking problems that would otherwise require complex electronic guidance systems.

Crown Design Considerations

Not all crowned rollers are created equal. The crown profile must be carefully engineered based on:

- Material properties (elasticity, thickness, width)

- Operating speeds

- Tension requirements

- Wrap angle around the roller

- Environmental conditions

The crown "height" (difference between center and edge diameters) typically ranges from 0.001" to 0.015" (0.025mm to 0.38mm) depending on application requirements. For particularly wide webs or sensitive materials, compound crowns with multiple radius sections may be necessary.

Contoured Roller Shapes: Material-Specific Designs

Beyond simple crowning, some applications benefit from more complex contoured shapes designed for specific material interactions.

Common Contour Designs

| Contour Type | Profile Description | Typical Applications | Key Benefits |

|---|---|---|---|

| Hourglass | Concave profile with narrower middle | Thick, stiff materials | Improved tracking, reduced edge stress |

| Barrel | Convex profile (standard crown) | Thin, flexible materials | Self-centering, improved tension distribution |

| Step | Multiple diameter sections | Layered or edge-sensitive materials | Controlled tension zones, precise alignment |

| Tapered | Gradual diameter change from end to end | Specialized guiding applications | Directed material movement, intentional offset |

| Compound | Multiple curves or transitions | Complex material paths | Optimized handling for varying widths or materials |

In my experience at PTSMAKE, contoured rollers have solved persistent problems that no other approach could address. For instance, we created a custom step-contoured roller for a client processing delicate foil laminates that eliminated edge wrinkling issues they had struggled with for years.

Specialized Surface Finishes for Enhanced Performance

While profile geometry shapes how materials track across a roller, the surface finish determines how the material directly interacts with the roller at the microscopic level.

Grooved Surface Patterns

Grooved patterns cut into the roller surface serve several critical functions depending on their design:

Straight Grooves

Straight grooves running parallel to the roller axis are commonly used to:

- Allow air escape during high-speed operations, preventing air entrapment

- Provide channels for moisture or process fluids to flow

- Create controlled slip in certain areas of the roller

- Enhance grip on smooth or slippery materials

The groove spacing, depth, and profile must be precisely matched to the application. In paper handling, for example, narrow, shallow grooves may be ideal, while fabric processing might require wider, deeper channels.

Spiral Grooves

Spiral or helical groove patterns introduce lateral forces that can:

- Actively direct materials toward one side of the roller

- Counter natural drift tendencies in certain materials

- Create mixing or spreading effects in coating applications

- Provide more uniform air release across the entire roller width

The pitch of the spiral (angle relative to the roller axis) determines the strength of the lateral force applied to the material.

Diamond and Crosshatch Patterns

More complex groove patterns like diamond or crosshatch configurations offer:

- Multi-directional grip enhancement

- Superior air release capabilities

- Reduced material contact area for processing tacky substances

- Improved release characteristics for adhesive materials

These patterns are particularly valuable in converting operations where materials may have inherent directional properties that affect their handling characteristics.

Textured Surface Finishes

Beyond grooves, various textured finishes can be applied to rubber roller surfaces to achieve specific performance characteristics:

Microembossed Textures

Microembossing creates tiny, precisely formed patterns on the roller surface that:

- Control the exact amount of coating applied to materials

- Create controlled air release without full channels

- Provide precise friction characteristics

- Impart specific patterns to processed materials

Modern laser engraving7 technology allows for incredible precision in these micropatterns, with features as small as 10 microns possible on some rubber compounds.

Sandblasted and Media-Blasted Finishes

Controlled abrasive blasting creates random surface textures that:

- Provide consistent, non-directional grip

- Reduce sensitivity to material alignment

- Offer excellent release properties for tacky materials

- Create semi-matte finishes on processed materials

The texture depth and pattern can be controlled by the blast media size, hardness, pressure, and exposure time during the finishing process.

Polished Smooth Finishes

Some applications require exceptionally smooth roller surfaces that:

- Transfer perfect impressions in printing applications

- Maintain absolute flatness in laminating operations

- Provide extremely uniform pressure distribution

- Eliminate pattern transfer to sensitive materials

Achieving truly smooth finishes requires special compounds and multi-stage polishing processes to create surfaces with roughness measurements below 0.5μm Ra.

Hybrid Roller Technologies

The most advanced rubber roller solutions often combine multiple features to address complex application requirements.

Multi-Durometer Constructions

Rollers with different hardness zones across their surface can provide:

- Varying compression characteristics across the roller width

- Controlled deflection profiles under load

- Different friction zones for specific material sections

- Optimized handling for materials with varying properties

These constructions are particularly valuable in wide-web converting operations processing composite materials with different edge and center characteristics.

Segmented Roller Designs

Some advanced applications benefit from segmented rollers where:

- Different sections can rotate at different speeds

- Sections can be individually replaced if damaged

- Various materials or finishes can be combined in one roller

- Custom handling solutions can be created for complex materials

I’ve implemented segmented designs for clients processing multi-lane materials where each lane required different handling characteristics, saving them from needing multiple processing lines.

Temperature-Controlled Roller Systems

The most sophisticated rubber roller systems incorporate temperature control to:

- Maintain consistent rubber properties despite ambient temperature changes

- Create specific temperature zones across the roller width

- Provide heating or cooling to process materials

- Ensure consistent performance in variable operating conditions

These advanced roller systems represent the cutting edge of material handling technology, delivering precision and consistency that was impossible with earlier roller designs.

By incorporating these advanced features – crowned profiles, contoured shapes, and specialized finishes – manufacturers can solve challenging material handling problems, improve product quality, and increase production efficiency beyond what would be possible with standard roller designs.

Maintenance, Replacement & Customization Options

Ever struggled with unexpected production line stoppages due to rubber roller failures? These costly disruptions aren’t just frustrating – they’re often completely preventable with the right maintenance approach and timely replacement strategy.

Maximizing rubber roller performance requires a proactive three-pronged approach: implementing systematic maintenance routines, recognizing when resurfacing or replacement is necessary, and selecting customized configurations with specific dimensions, materials, and surface treatments optimized for your exact application requirements.

The Critical Importance of Proper Roller Maintenance

Rubber rollers represent a significant investment in your production equipment, and their condition directly impacts product quality and operational efficiency. Establishing proper maintenance protocols can dramatically extend service life while ensuring consistent performance.

Cleaning Procedures for Different Roller Materials

Different elastomer materials require specific cleaning approaches to prevent damage while effectively removing contaminants:

| Material | Recommended Cleaners | What to Avoid | Cleaning Frequency |

|---|---|---|---|

| Natural Rubber | Mild soap and water | Petroleum solvents, strong acids | Weekly or after material changes |

| Neoprene | Mild detergents, isopropyl alcohol | Ketones, strong oxidizers | Bi-weekly or when visibly soiled |

| Nitrile | Most common solvents, detergents | Strong acids, esters | Monthly or when performance changes |

| EPDM | Mild soap solutions, alkaline cleaners | Petroleum oils, aromatic solvents | Weekly in dusty environments |

| Polyurethane | Mild detergents, some solvents | Concentrated acids, MEK | After each production run |

| Silicone | Warm water, mild soap, isopropyl alcohol | Concentrated caustics | Daily in food processing applications |

When cleaning, always use soft cloths or non-abrasive pads to avoid scratching the roller surface. For stubborn residues, soaking rather than scrubbing is generally preferred to preserve surface integrity.

Inspection and Preventive Maintenance Schedules

Regular inspection is the cornerstone of effective roller maintenance. Based on my experience at PTSMAKE, I recommend establishing a schedule that includes:

Daily Visual Checks

- Look for visible damage, cuts, or gouges

- Check for material buildup or contamination

- Observe for any unusual wear patterns

- Listen for unusual sounds during operation

Weekly Physical Inspections

- Measure durometer at multiple points (using a portable durometer gauge)

- Check for any dimensional changes

- Inspect bearing operation if applicable

- Verify proper alignment in the machine

Monthly Comprehensive Assessments

- Measure TIR (Total Indicated Runout) with a dial indicator

- Check for proper crown profile maintenance

- Inspect for chemical damage or swelling

- Evaluate overall roller condition against baseline measurements

Documentation is essential – maintain records of all inspections, noting any changes over time. This historical data often reveals gradual degradation patterns that can help predict failure before it occurs.

Storage and Handling Best Practices

Proper storage of spare rollers and handling during maintenance significantly impact roller lifespan:

Temperature Control: Store rubber rollers at moderate temperatures (50-70°F/10-21°C) whenever possible. Extreme temperatures can permanently alter rubber properties.

Light Protection: Shield rollers from direct sunlight and UV exposure, which can cause ozone cracking and premature aging.

Position Rotation: Rotate stored rollers regularly (at least monthly) to prevent flat spots and permanent deformation.

Support Distribution: Store rollers either standing on end (for shorter rollers) or supported evenly across their entire length to prevent bending or core deflection.

Contact Avoidance: Prevent contact with oils, solvents, and other chemicals even during storage. Even vapor exposure can damage some compounds.

When removing or reinstalling rollers during maintenance, always lift evenly from both ends to prevent core bending, and avoid impact or dropping that can damage both the rubber covering and the metal core.

Recognizing When to Resurface or Replace

Even with excellent maintenance, rubber rollers eventually require resurfacing or complete replacement. Understanding when to take these steps helps maximize roller value while preventing quality issues.

Key Indicators of Rubber Roller Deterioration

Several observable conditions signal when a roller needs attention:

Surface Damage Signs

- Glazing: Shiny, hardened surface areas indicating heat damage

- Cracking: Visible fractures in the rubber surface (often ozone-related)

- Chunking: Missing pieces of rubber covering

- Grooving: Unintended channels worn into the surface

- Flat spots: Areas of uneven wear causing vibration during rotation

Operational Symptoms

- Inconsistent product quality

- Visible tracking problems in web materials

- Increased noise or vibration

- Reduced grip or material slippage

- Uneven pressure application

- Bearing noise or excessive heat

Measurement Indicators

- Durometer changes exceeding ±5 points from original specification

- TIR (runout) exceeding application tolerance

- Loss of crown profile dimensions

- Dimensional changes in diameter or length

When these indicators appear, prompt action can often save the roller through resurfacing rather than requiring complete replacement.

Resurfacing vs. Recovery Options

The terms "resurfacing" and "recovery" represent different levels of roller refurbishment:

Resurfacing involves removing a minimal amount of the existing rubber to restore the original surface characteristics. This process typically removes 0.010"-0.030" (0.25-0.76mm) of material and is suitable when:

- Surface damage is shallow

- The base rubber remains in good condition

- Dimensional changes are minimal

- Original geometric profiles need to be restored

Recovery (or recovering) involves stripping the old rubber completely and applying a new covering. This more extensive process is necessary when:

- Damage extends deep into the rubber layer

- The compound has chemically degraded

- Significant dimensional changes have occurred

- A different rubber compound is desired

The economics generally favor resurfacing when possible, as it preserves more of the original investment. However, recovery often provides a roller that’s effectively new at 60-70% of the cost of complete replacement.

Cost-Benefit Analysis of Repair vs. Replacement

When deciding between resurfacing, recovery, or complete replacement, consider these factors:

| Factor | Resurfacing | Recovery | Complete Replacement |

|---|---|---|---|

| Initial Cost | 20-40% of new | 60-70% of new | 100% |

| Processing Time | 1-3 days typically | 3-7 days | 7-14 days (if custom) |

| Resulting Quality | Good for minor issues | Equivalent to new | New condition |

| Roller Core Reuse | Yes | Yes | No |

| Potential for Redesign | Limited | Substantial | Complete |

| Typical Lifespan | 60-80% of new | Nearly equal to new | 100% |

At PTSMAKE, we often recommend recovery when a roller has been resurfaced twice previously, as core fatigue can become a factor after multiple resurfacing operations. For critical applications where even minor quality variations cannot be tolerated, replacement may be the only acceptable option despite higher costs.

Customization Options for Application-Specific Performance

The true value of rubber rollers lies in their ability to be customized for exact application requirements. Understanding available customization options helps you specify rollers that deliver optimal performance.

Dimensional Customizations

Basic dimensional specifications include:

- Overall Length: The total roller length, including any shaft extensions

- Face Length: The covered portion that contacts materials

- Diameter: The outer diameter of the rubber covering

- Core Diameter: The size of the internal metal or composite core

- Covering Thickness: The rubber layer depth (affects compression properties)

- End Configurations: Bearing journals, drive connections, mounting provisions

Beyond these basics, dimensional customizations may include:

- Crown Profile: The convex profile that aids web tracking (typically 0.010"-0.030" crown height)

- Runout Tolerance: The allowable deviation from perfect roundness (often specified as TIR)

- Balance Grade: For high-speed applications, balancing reduces vibration

- Shaft Extensions: Custom lengths and features for mounting and drive systems

Material Selection for Specific Environmental Factors

Material selection should consider the specific conditions under which the roller will operate:

Temperature Considerations

- Sub-freezing environments may require special low-temperature compounds

- High-temperature applications might need silicone or specialized EPDM formulations

- Thermal cycling environments benefit from compounds with minimal hardness change across temperature ranges

Chemical Exposure

- Acid/alkali exposure requires different compound selections

- Solvent resistance varies dramatically between compounds

- Oil and hydraulic fluid resistance is particularly strong in nitrile formulations

- Food-grade applications need FDA-compliant materials

Mechanical Requirements

- High-load applications benefit from higher durometer polyurethane

- High-speed operations need compounds with low heat buildup

- Vibration damping requirements favor natural rubber and some EPDM formulations

- Abrasive environments demand wear-resistant compounds like polyurethane

Surface Treatment and Finish Options

The roller surface finish directly affects its interaction with processed materials:

Standard Finishes

- Ground Finish: Standard machined surface with moderate roughness

- Polished: Smooth surface for applications requiring minimal texture transfer

- RMS Specified: Surface roughness defined by specific measurement parameters

Enhanced Grip Options

- Microgrooves: Shallow patterned grooves for enhanced traction

- Media Blasting: Creates consistent textured surfaces

- Chemical Etching: Produces microscopically textured surfaces for specific grip characteristics

Specialized Functional Treatments

- Plasma Treatments: Alter surface energy for improved wetting or release properties

- Non-stick Coatings: Applied over rubber for release applications

- Conductive Treatments: Reduce static buildup in sensitive applications

- Anti-microbial Additives: For food processing and pharmaceutical applications

Each of these customization options can be combined and fine-tuned to create rubber rollers that perform exceptionally well in their intended applications. In my work at PTSMAKE, I’ve found that the most successful roller specifications come from collaborative discussions where both application requirements and material limitations are thoroughly understood.

By implementing proper maintenance protocols, recognizing when resurfacing or replacement is needed, and leveraging available customization options, manufacturers can maximize the performance and lifespan of their rubber rollers while optimizing production efficiency and product quality.

Learn more about durometer scales and how they affect rubber roller performance in material handling applications. ↩

Discover our specialized cleaning solutions for maintaining optimal roller performance in high-demand environments. ↩

Learn how proper material selection can prevent static buildup that damages sensitive electronics. ↩

Discover how proper keyway design can significantly enhance torque transfer capabilities while maintaining serviceability in high-demand applications. ↩

Learn about specialized compounds that prevent static buildup while maintaining precise material handling capabilities in sensitive electronic applications. ↩

Discover how hysteresis effects influence rubber roller performance and how proper durometer selection can minimize energy losses in high-speed applications. ↩

Explore how precision laser engraving creates microscopic surface patterns that optimize material handling in high-speed processing applications. ↩