As a titanium anodizing expert at PTSMAKE, I’ve noticed many engineers struggle with surface treatment decisions for titanium components. The wrong choice can lead to premature wear, corrosion issues, and even part failure – problems that can derail entire projects and waste valuable resources.

Yes, titanium alloy can be anodized. This process creates a protective oxide layer on the surface, enhancing corrosion resistance and allowing for various color options depending on the voltage applied. The anodized layer also improves wear resistance and aesthetic appeal.

I want to share some insider knowledge about titanium anodizing that most manufacturers won’t tell you. At PTSMAKE, we’ve developed specific techniques that ensure consistent results across different titanium alloys. Let me explain the key factors that affect the anodizing process and how they impact your parts’ performance.

How Strong Is Titanium Compared To Steel?

When choosing materials for critical applications, I often encounter engineers struggling with the titanium versus steel dilemma. The challenge isn’t just about strength – it’s about balancing weight, cost, and durability. Many of my clients have made costly mistakes by selecting the wrong material, leading to project delays and budget overruns.

Titanium and steel both offer impressive strength, but titanium provides a superior strength-to-weight ratio. While steel is generally stronger in absolute terms, titanium is 45% lighter while maintaining comparable strength, making it ideal for aerospace and medical applications where weight reduction is crucial.

Understanding Material Properties

As a manufacturing professional, I’ve learned that comparing titanium and steel isn’t straightforward. Let’s break down their key properties to understand their strengths and limitations.

Density and Weight Considerations

The most striking difference between titanium and steel lies in their density. Titanium’s density is 4.5 g/cm³, while steel typically ranges from 7.75 to 8.05 g/cm³. This difference creates interesting opportunities when we consider the specific strength1 of each material.

Strength Comparison Metrics

When comparing these metals, we need to examine various strength parameters:

| Property | Titanium | Steel (General) | Steel (High-Strength) |

|---|---|---|---|

| Tensile Strength (MPa) | 350-1200 | 400-800 | 800-2000 |

| Yield Strength (MPa) | 250-1000 | 250-500 | 600-1800 |

| Elastic Modulus (GPa) | 110-120 | 190-210 | 190-210 |

Applications and Industry Usage

Aerospace Industry

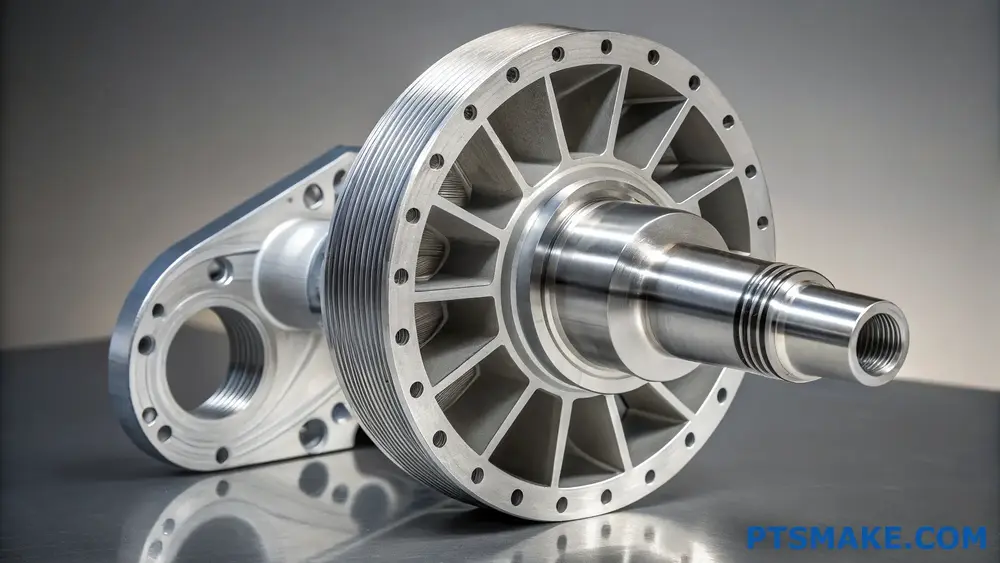

In my experience at PTSMAKE, titanium has become increasingly popular in aerospace applications. Its high strength-to-weight ratio makes it perfect for aircraft components where weight reduction is crucial. We regularly machine titanium parts for aerospace clients, particularly in structural components and engine parts.

Medical Applications

The biocompatibility of titanium makes it invaluable in medical implants. Steel, while strong, doesn’t offer the same level of biological compatibility. At PTSMAKE, we’ve developed specialized processes for manufacturing precise titanium medical components.

Environmental Factors

Corrosion Resistance

Titanium forms a protective oxide layer that provides exceptional corrosion resistance. This self-healing property gives it a significant advantage over most steels, especially in marine environments.

Temperature Performance

Both materials behave differently under temperature extremes:

| Temperature Range | Titanium Performance | Steel Performance |

|---|---|---|

| Below 0°C | Maintains strength | Becomes brittle |

| Room Temperature | Optimal performance | Optimal performance |

| Above 500°C | Oxidation concerns | Strength degradation |

Cost Considerations

Material Costs

While titanium is generally more expensive than steel, the total cost of ownership often tells a different story:

- Raw material cost: Titanium is 5-10 times more expensive

- Processing costs: Higher for titanium due to specialized equipment

- Maintenance costs: Lower for titanium due to better corrosion resistance

- Lifetime value: Often better with titanium due to durability

Manufacturing Challenges

At PTSMAKE, we’ve overcome various challenges in working with both materials:

Titanium:

- Requires specialized cutting tools

- Slower machining speeds

- More complex cooling requirements

- Higher tool wear rates

Steel:

- More straightforward machining processes

- Better tool life

- Lower processing costs

- Wider availability of processing equipment

Practical Selection Criteria

When advising clients, I consider several factors:

Application Requirements

- Load-bearing capacity needed

- Weight restrictions

- Environmental exposure

- Operating temperature range

- Cost constraints

Industry Standards

Different industries have specific requirements:

| Industry | Preferred Material | Primary Reason |

|---|---|---|

| Aerospace | Titanium | Weight savings |

| Construction | Steel | Cost-effectiveness |

| Medical | Titanium | Biocompatibility |

| Automotive | Both | Application-specific |

Future Trends

The manufacturing landscape is evolving. At PTSMAKE, we’re seeing increased demand for:

- Hybrid material solutions

- Advanced surface treatments

- Novel alloy compositions

- Improved manufacturing processes

This evolution is pushing both titanium and steel into new application areas, with each material finding its optimal use case based on specific requirements rather than general comparisons.

Does Titanium’s Strength Affect Machining Costs?

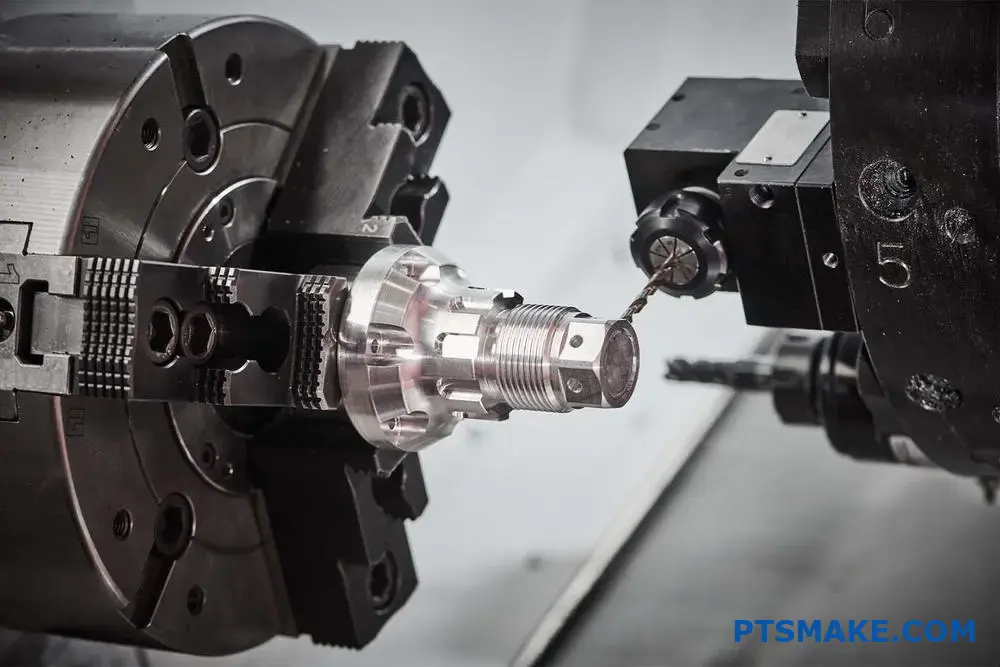

Machining titanium can be a significant challenge for many manufacturers. When clients come to me with titanium projects, they often express concerns about the high costs and long production times. The material’s exceptional strength, while beneficial for end-use applications, creates substantial obstacles during the machining process.

Yes, titanium’s strength directly impacts machining costs. Its high tensile strength and hardness require specialized cutting tools, slower machining speeds, and more frequent tool replacements. These factors typically increase machining costs by 3-5 times compared to standard steel machining.

Understanding Titanium’s Material Properties

Strength Characteristics

Titanium’s remarkable strength comes from its unique atomic structure and crystalline lattice2. I’ve observed that titanium alloys commonly used in manufacturing, such as Ti-6Al-4V, demonstrate exceptional strength-to-weight ratios. This material exhibits:

- Ultimate tensile strength: 900-1200 MPa

- Yield strength: 830-1100 MPa

- Hardness: 33-36 HRC

Heat Resistance Impact

The material’s ability to retain strength at high temperatures poses unique machining challenges. During cutting operations, temperatures can exceed 1000°C, yet titanium maintains its mechanical properties, leading to:

- Increased tool wear

- Reduced cutting speeds

- Higher power consumption

Cost Factors in Titanium Machining

Tool Wear and Replacement

Based on my experience at PTSMAKE, tool wear is one of the most significant cost drivers. Here’s a comparative analysis of tool life:

| Material | Average Tool Life (hours) | Tool Replacement Frequency | Relative Tool Cost |

|---|---|---|---|

| Mild Steel | 4-6 | Low | 1x |

| Stainless Steel | 2-4 | Medium | 2x |

| Titanium | 0.5-2 | High | 4x |

Production Time Considerations

The machining speed for titanium must be significantly reduced compared to other materials:

| Operation Type | Speed Reduction vs Steel | Impact on Production Time |

|---|---|---|

| Turning | 60-70% slower | 2.5-3x longer |

| Milling | 70-80% slower | 3-4x longer |

| Drilling | 75-85% slower | 4-5x longer |

Optimizing Titanium Machining Costs

Advanced Cutting Strategies

At PTSMAKE, we’ve implemented several strategies to optimize titanium machining:

High-Pressure Coolant Systems

- Improves heat dissipation

- Extends tool life by 40%

- Reduces cutting forces

Specialized Cutting Tools

- Carbide tools with specific geometries

- Advanced coating technologies

- Optimized rake angles

Process Parameters Optimization

The key to cost-effective titanium machining lies in finding the right balance of cutting parameters:

| Parameter | Recommended Range | Cost Impact |

|---|---|---|

| Cutting Speed | 30-60 m/min | High |

| Feed Rate | 0.1-0.3 mm/rev | Medium |

| Depth of Cut | 0.5-2.5 mm | Medium |

Economic Considerations

Cost Breakdown Analysis

Understanding the cost structure helps in making informed decisions:

Direct Costs

- Cutting tool expenses: 25-30%

- Machine operation time: 35-40%

- Coolant and consumables: 10-15%

Indirect Costs

- Setup and programming: 10-15%

- Quality control: 5-10%

- Machine maintenance: 5-8%

Long-term Cost Management

To maintain competitive pricing while ensuring quality:

Investment in Technology

- Modern CNC machines with rigid construction

- Advanced tool monitoring systems

- Automated tool changing systems

Process Optimization

- Regular tool wear monitoring

- Optimized cutting parameters

- Efficient workflow management

Quality Control Measures

- In-process inspection

- Statistical process control

- Advanced measurement techniques

The relationship between titanium’s strength and machining costs is complex but manageable with the right approach. At PTSMAKE, we’ve developed efficient processes that balance cost considerations with quality requirements. By understanding these factors and implementing appropriate strategies, we can help our clients achieve their titanium machining goals while maintaining reasonable costs.

How Does Titanium’s Fatigue Strength Impact Industrial Applications?

Manufacturers often struggle with material selection for critical components that undergo repeated stress cycles. The constant battle against metal fatigue leads to premature failures, unexpected maintenance costs, and potential safety risks in industrial applications.

Titanium’s exceptional fatigue strength makes it ideal for high-stress industrial applications, offering up to 50% higher endurance limits than steel. This superior resistance to cyclic loading enables longer component life and improved reliability in critical industrial systems.

Understanding Titanium’s Fatigue Properties

At PTSMAKE, we regularly work with titanium in critical applications where fatigue resistance is paramount. The material’s cyclic stress-strain behavior3 sets it apart from conventional metals. Here’s what makes titanium’s fatigue properties unique:

Microstructural Advantages

The hexagonal close-packed crystal structure of titanium provides inherent resistance to dislocation movement, which results in:

- Enhanced crack initiation resistance

- Slower crack propagation rates

- Better performance under variable loading conditions

Comparative Fatigue Performance

Here’s how titanium compares to other common industrial metals:

| Material | Fatigue Strength Ratio* | Typical Cycles to Failure** |

|---|---|---|

| Titanium Grade 5 | 0.8 | >10^7 |

| Stainless Steel 316 | 0.4 | 10^6 |

| Aluminum 7075 | 0.3 | 10^5 |

| Carbon Steel 1045 | 0.5 | 10^6 |

*Fatigue strength ratio = Endurance limit/Ultimate tensile strength

**Under standard testing conditions at 50% of yield strength

Industrial Applications Leveraging Titanium’s Fatigue Strength

Aerospace Components

In my experience working with aerospace clients, titanium’s fatigue properties are crucial for:

- Landing gear components

- Engine mounting brackets

- Structural airframe elements

- Turbine blades and compressor discs

Medical Implants

The biomedical industry relies heavily on titanium’s fatigue resistance for:

- Joint replacements

- Dental implants

- Bone plates and screws

- Spinal fusion devices

Chemical Processing Equipment

Our clients in the chemical processing sector value titanium for:

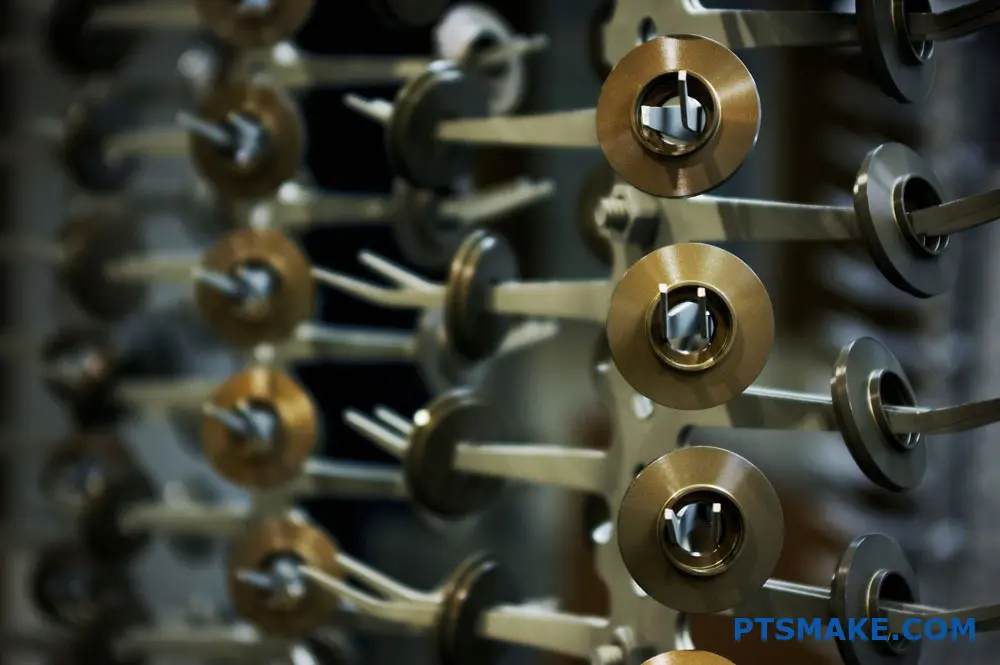

- Pump components

- Valve bodies

- Heat exchanger tubes

- Reaction vessel internals

Design Considerations for Fatigue-Critical Applications

Surface Treatment Effects

Surface conditions significantly impact fatigue performance:

- Shot peening increases fatigue strength by 15-20%

- Surface roughness must be controlled to Ra < 0.8μm

- Protective coatings can provide additional fatigue resistance

Temperature Influence

Titanium’s fatigue properties vary with temperature:

- Optimal performance range: -50°C to 350°C

- Reduced fatigue strength above 450°C

- Excellent low-temperature stability

Loading Pattern Optimization

To maximize fatigue life, consider:

- Stress concentration reduction through design

- Load distribution optimization

- Proper joint design and fastener selection

Economic Impact of Using Titanium

Cost-Benefit Analysis

While initial material costs are higher, titanium often proves more economical long-term:

- Reduced maintenance frequency

- Lower replacement rates

- Decreased downtime costs

- Extended service life

Life Cycle Considerations

Our manufacturing experience shows that titanium components typically offer:

- 2-3 times longer service life than steel alternatives

- 40% reduction in maintenance costs

- 25% decrease in total ownership costs over the component lifecycle

Quality Control and Testing Methods

To ensure optimal fatigue performance, we implement:

Non-Destructive Testing

- Ultrasonic inspection

- Radiographic testing

- Dye penetrant inspection

- Magnetic particle testing

Mechanical Testing Protocols

Standard testing procedures include:

- Rotating beam fatigue tests

- Axial loading fatigue tests

- Strain-controlled fatigue testing

- Fracture toughness evaluation

Future Trends and Developments

The industry is moving toward:

- Advanced surface treatment methods

- Hybrid material solutions

- Improved prediction models

- Automated monitoring systems

What Makes Titanium Stronger Than Aluminum In Aerospace Components?

When selecting materials for aerospace components, engineers often face a challenging decision between titanium and aluminum. The wrong choice could lead to component failure, compromised safety, and costly replacements. The aerospace industry can’t afford such risks, especially when lives are at stake.

Titanium proves stronger than aluminum in aerospace components due to its superior strength-to-weight ratio, better fatigue resistance, and higher temperature tolerance. Its unique crystal structure and alloying capabilities create a material that outperforms aluminum in demanding aerospace applications.

The Fundamental Strength Differences

Crystal Structure and Atomic Bonds

The strength difference between titanium and aluminum starts at the atomic level. Titanium’s hexagonal close-packed structure4 creates stronger interatomic bonds, resulting in better mechanical properties. I’ve observed this fundamental difference significantly impacts performance in critical aerospace applications.

Density and Strength Comparison

Understanding the strength-to-weight ratios helps explain why titanium often outperforms aluminum:

| Property | Titanium | Aluminum |

|---|---|---|

| Density (g/cm³) | 4.5 | 2.7 |

| Tensile Strength (MPa) | 900-1200 | 400-600 |

| Yield Strength (MPa) | 830-1100 | 250-500 |

| Temperature Resistance (°C) | 600 | 300 |

Performance in Aerospace Applications

Fatigue Resistance

At PTSMAKE, we’ve consistently seen titanium’s superior fatigue resistance in action. While aluminum might show signs of fatigue after 10⁵ cycles, titanium components often maintain their integrity beyond 10⁷ cycles. This makes titanium ideal for high-stress applications like landing gear and engine components.

Corrosion Resistance

Titanium forms a natural oxide layer that provides exceptional corrosion resistance. In contrast, aluminum requires additional treatments and coatings to achieve similar protection. This self-protecting characteristic makes titanium particularly valuable in marine aerospace applications.

Temperature Performance

High-Temperature Stability

One of titanium’s most significant advantages is its ability to maintain strength at elevated temperatures. While aluminum begins to lose structural integrity around 300°C, titanium remains stable up to 600°C. This makes it crucial for engine components and high-speed aircraft structures.

Thermal Expansion

Titanium’s lower coefficient of thermal expansion provides better dimensional stability:

| Material | Coefficient of Thermal Expansion (µm/m-°C) |

|---|---|

| Titanium | 8.6 |

| Aluminum | 23.1 |

Cost and Manufacturing Considerations

Material Processing

Despite titanium’s superior strength, its processing presents unique challenges. The material requires specialized equipment and expertise for machining and forming. At PTSMAKE, we’ve invested in advanced CNC machinery specifically designed for titanium processing.

Economic Factors

While titanium costs more initially, its longer service life often justifies the investment:

| Factor | Titanium | Aluminum |

|---|---|---|

| Raw Material Cost | Higher | Lower |

| Processing Cost | Higher | Lower |

| Maintenance Cost | Lower | Higher |

| Service Life | Longer | Shorter |

Application-Specific Advantages

Structural Components

In aerospace structural components, titanium’s higher strength allows for thinner wall sections, potentially offsetting its higher density. This is particularly valuable in components like wing attachments and fuselage frames.

Engine Components

For engine applications, titanium’s combination of high strength and temperature resistance makes it irreplaceable. Components like compressor blades and turbine housings benefit from titanium’s unique properties.

Weight Optimization

Despite being heavier than aluminum, titanium’s superior strength often results in lighter final components because less material is needed. This weight optimization is crucial for fuel efficiency and aircraft performance.

Future Developments

Advanced Alloys

The development of new titanium alloys continues to enhance its advantages over aluminum. These innovations focus on improving specific properties while maintaining titanium’s core strengths.

Manufacturing Technologies

Emerging technologies like additive manufacturing are making titanium processing more efficient and cost-effective. At PTSMAKE, we’re actively exploring these new manufacturing methods to optimize titanium component production.

How Does Heat Treatment Influence Titanium’s Ultimate Tensile Strength?

Understanding the impact of heat treatment on titanium’s strength is crucial for manufacturers and engineers. I’ve witnessed many projects fail due to improper heat treatment processes, resulting in compromised material properties and costly rework. The consequences of getting it wrong can be devastating, especially in critical applications like aerospace components.

Heat treatment significantly influences titanium’s ultimate tensile strength by altering its microstructure. Through controlled heating and cooling processes, heat treatment can increase titanium’s tensile strength by up to 50%, making it stronger and more suitable for demanding applications while maintaining its lightweight characteristics.

Understanding the Fundamentals of Heat Treatment for Titanium

Heat treatment is more than just heating and cooling metal. When working with titanium at PTSMAKE, we’ve developed specific processes to enhance its mechanical properties. The process involves precise control of precipitation hardening5 phases, which directly affects the material’s strength.

Temperature Control and Its Effects

The temperature range during heat treatment plays a vital role in determining the final properties of titanium. Here’s a breakdown of typical temperature ranges and their effects:

| Temperature Range (°C) | Effect on Titanium | Strength Impact |

|---|---|---|

| 480-650 | Stress Relief | Minimal increase |

| 700-850 | Solution Treatment | Moderate increase |

| 900-1000 | Beta Annealing | Significant increase |

Critical Phases of Heat Treatment Process

Solution Treatment Stage

During this phase, titanium is heated to temperatures just below its beta transus point. This process dissolves secondary phases into the primary alpha phase, creating a more uniform structure. The cooling rate from this temperature significantly influences the final strength properties.

Aging Process and Its Impact

The aging process typically follows solution treatment. This stage is where titanium develops its maximum strength through the controlled formation of fine precipitates. We’ve found that aging temperatures between 480-550°C produce optimal results for most applications.

Factors Affecting Ultimate Tensile Strength

Time-Temperature Relationship

The duration of heat treatment is as crucial as the temperature itself. Our experience shows that:

- Short treatment times may not allow complete phase transformation

- Extended treatment can lead to grain growth and reduced strength

- Optimal timing varies based on the specific titanium alloy

Cooling Rate Considerations

The cooling method significantly impacts the final strength:

| Cooling Method | Strength Impact | Typical Applications |

|---|---|---|

| Water Quenching | Highest strength | Aerospace parts |

| Air Cooling | Moderate strength | General industrial use |

| Furnace Cooling | Lower strength | Parts requiring ductility |

Industrial Applications and Strength Requirements

Different industries require varying levels of ultimate tensile strength:

Aerospace Industry Requirements

In aerospace applications, where we frequently supply components, titanium often needs to achieve ultimate tensile strengths exceeding 1000 MPa. This requires precise heat treatment protocols and rigorous quality control.

Medical Device Applications

For medical implants and devices, the focus is on achieving consistent strength while maintaining biocompatibility. Our heat treatment processes typically aim for ultimate tensile strengths between 800-900 MPa for these applications.

Quality Control and Testing Methods

To ensure consistent results, we implement various testing methods:

Tensile Testing Procedures

Regular tensile testing helps verify that heat-treated titanium meets strength requirements. Key parameters we monitor include:

- Ultimate tensile strength

- Yield strength

- Elongation percentage

- Reduction in area

Microstructure Analysis

Regular metallographic examination helps us verify:

- Grain size and distribution

- Phase composition

- Presence of unwanted precipitates

- Overall microstructure uniformity

Optimization Strategies for Maximum Strength

Based on our manufacturing experience, several strategies help optimize titanium’s ultimate tensile strength:

Process Parameter Control

- Precise temperature monitoring using calibrated thermocouples

- Controlled atmosphere to prevent contamination

- Documented heating and cooling rates

- Regular equipment calibration

Material-Specific Considerations

Different titanium alloys respond differently to heat treatment. For instance:

- Ti-6Al-4V typically achieves optimal strength around 900-950°C

- Beta titanium alloys often require more complex multi-stage treatments

- Pure titanium needs more careful temperature control to prevent grain growth

Through careful control of these parameters and processes, we can consistently achieve the desired ultimate tensile strength in titanium components, ensuring they meet or exceed customer specifications while maintaining other critical properties.

Does Titanium’s Strength-To-Weight Ratio Justify Its Cost?

Manufacturing teams often struggle with material selection, especially when it comes to titanium. The high cost makes many question its value, yet its exceptional properties make it hard to dismiss. This dilemma leads to uncertainty in decision-making and potential project delays.

The strength-to-weight ratio of titanium often justifies its cost in applications where performance and weight savings are critical, such as aerospace and medical devices. However, for general manufacturing purposes, alternative materials might offer better value depending on specific requirements.

Understanding Titanium’s True Value Proposition

When evaluating titanium’s cost-effectiveness, we must look beyond the raw material price. At PTSMAKE, I’ve observed that successful implementation of titanium in manufacturing projects requires a comprehensive analysis of several factors.

Performance Metrics That Matter

The strength of titanium is remarkable, particularly when considering its specific strength6 relative to other metals. Here’s how titanium compares to common alternatives:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Strength-to-Weight Ratio |

|---|---|---|---|

| Titanium Grade 5 | 895 | 4.43 | 202 |

| Stainless Steel 316 | 515 | 8.00 | 64 |

| Aluminum 7075 | 572 | 2.81 | 204 |

Cost Analysis Beyond Purchase Price

The true cost evaluation of titanium should consider:

Lifecycle Durability

- Corrosion resistance reduces maintenance costs

- Extended service life compared to alternatives

- Lower replacement frequency

Weight Savings Impact

- Reduced fuel consumption in transportation

- Lower shipping costs

- Easier handling during installation

Processing Requirements

- Special tooling needs

- Slower machining speeds

- Enhanced operator training

Industry-Specific Applications and Benefits

Aerospace Applications

In aerospace, where weight directly impacts fuel efficiency, titanium proves its worth. A typical commercial aircraft using titanium components can save:

- 3-5% in fuel consumption

- Reduced maintenance intervals

- Enhanced payload capacity

Medical Device Manufacturing

For medical applications, titanium’s benefits include:

- Biocompatibility

- Long-term stability

- Excellent osseointegration properties

Cost Optimization Strategies

Material Selection Optimization

Through our experience at PTSMAKE, we’ve developed effective strategies for optimizing titanium usage:

Hybrid Design Approaches

- Using titanium only in critical areas

- Combining with more cost-effective materials where possible

- Strategic placement for maximum benefit

Processing Efficiency

- Optimized cutting parameters

- Proper tool selection

- Advanced cooling techniques

Alternative Solutions Assessment

Sometimes, alternatives to titanium might be more appropriate:

| Application Type | Alternative Material | Cost Savings | Performance Impact |

|---|---|---|---|

| Non-critical components | High-strength aluminum | 40-60% | Minimal |

| Static applications | Advanced steel alloys | 50-70% | Slight reduction |

| Consumer products | Composite materials | 30-50% | Application dependent |

Making the Decision

To determine if titanium is worth the investment, consider:

Application Requirements

- Load conditions

- Environmental factors

- Service life expectations

Economic Factors

- Initial investment

- Maintenance costs

- Operational savings

Performance Criteria

- Weight restrictions

- Strength requirements

- Corrosion resistance needs

Future Considerations

The titanium landscape is evolving with:

Manufacturing Innovations

- Advanced forming techniques

- Improved machining methods

- New alloy developments

Market Trends

- Increasing availability

- Price stabilization

- Growing applications

At PTSMAKE, we’ve successfully implemented titanium solutions in various projects where the benefits clearly outweighed the costs. Our experience shows that proper analysis and application-specific evaluation are crucial for making the right choice.

How Strong Is Grade 5 Titanium Compared To Commercial Pure Grades?

When choosing titanium grades for critical applications, engineers often struggle with balancing strength requirements and cost considerations. I’ve witnessed many projects face setbacks due to incorrect grade selection, leading to component failures or budget overruns.

Grade 5 titanium (Ti-6Al-4V) demonstrates significantly higher strength compared to commercial pure grades, offering tensile strength up to 170,000 PSI versus 35,000 PSI of Grade 1. This superior strength makes it ideal for aerospace, medical, and high-performance applications.

Understanding Titanium Grade Classifications

Titanium grades are divided into several categories based on their composition and properties. At PTSMAKE, we work with various grades daily, helping clients select the most suitable option for their specific applications. The main categories include:

Commercial Pure (CP) Titanium Grades

- Grade 1: Highest purity, excellent formability

- Grade 2: Most common CP grade, balanced properties

- Grade 3: Higher strength than Grade 2

- Grade 4: Highest strength among CP grades

Alpha-Beta Alloys

Grade 5 titanium belongs to this category, featuring both alpha and beta phase structures. The microstructure7 created by this combination results in exceptional mechanical properties.

Comparative Strength Analysis

Let me break down the key strength parameters between Grade 5 and CP grades based on our manufacturing experience:

| Property | Grade 5 | Grade 1 | Grade 2 | Grade 3 | Grade 4 |

|---|---|---|---|---|---|

| Tensile Strength (PSI) | 170,000 | 35,000 | 50,000 | 65,000 | 80,000 |

| Yield Strength (PSI) | 160,000 | 25,000 | 40,000 | 55,000 | 70,000 |

| Elongation (%) | 10 | 24 | 20 | 18 | 15 |

Factors Contributing to Grade 5’s Superior Strength

Alloying Elements

The addition of 6% aluminum and 4% vanadium in Grade 5 titanium creates several advantages:

- Aluminum increases strength and reduces weight

- Vanadium improves heat treatment response

- Combined effects enhance overall mechanical properties

Heat Treatment Capabilities

Grade 5 titanium responds exceptionally well to heat treatment, unlike CP grades. At PTSMAKE, we’ve optimized our heat treatment processes to achieve:

- Improved strength-to-weight ratio

- Enhanced fatigue resistance

- Better dimensional stability

Application-Specific Strength Benefits

Aerospace Components

In aerospace applications, Grade 5’s superior strength enables:

- Lighter structural components

- Higher stress resistance

- Better fatigue performance under cyclic loading

Medical Implants

The biocompatibility combined with high strength makes Grade 5 ideal for:

- Load-bearing implants

- Surgical instruments

- Dental applications

Industrial Applications

For industrial uses, Grade 5 offers:

- Better wear resistance

- Higher temperature capability

- Improved corrosion resistance under stress

Cost-Strength Considerations

While Grade 5 titanium is more expensive than CP grades, its superior strength often results in:

- Reduced material usage due to thinner sections

- Lower maintenance costs

- Extended component life

Based on our manufacturing data at PTSMAKE, components made from Grade 5 typically show:

- 30% reduction in material volume

- 40% longer service life

- 25% lower total lifecycle costs

Manufacturing Challenges and Solutions

Working with Grade 5 titanium requires specialized expertise:

- Higher cutting forces during machining

- More frequent tool changes

- Specific cooling requirements

Our experience at PTSMAKE has led to developing optimized manufacturing processes:

- Advanced cutting strategies

- Specialized tooling selection

- Precise temperature control

Quality Control Considerations

Ensuring consistent strength properties requires:

- Regular material testing

- Strict process controls

- Advanced inspection methods

We maintain tight quality control through:

- In-house material testing

- Advanced NDT capabilities

- Comprehensive documentation

Does Welding Affect Titanium’s Structural Integrity And Strength?

I’ve seen many engineers struggle with titanium welding concerns. The fear of compromising this premium material’s properties during welding can be paralyzing, especially when working on critical components for aerospace or medical applications. The stakes are incredibly high, and any mistake could lead to catastrophic failures.

Yes, welding does affect titanium’s structural integrity and strength, but the impact varies based on the welding method and conditions. When properly executed, titanium welds can retain up to 95% of the base material’s strength, though the heat-affected zone may experience some property changes.

Understanding Titanium’s Response to Welding

At PTSMAKE, we frequently work with titanium in our precision manufacturing processes. The material’s behavior during welding is influenced by its unique metallurgical phase transformation8. When exposed to welding temperatures, titanium undergoes several crucial changes:

Temperature Effects on Titanium Properties

The heat from welding causes different zones to form:

- Fusion Zone (FZ): Where the metal melts and solidifies

- Heat Affected Zone (HAZ): Area adjacent to the weld

- Base Metal: Unaffected original material

Critical Factors Affecting Weld Quality

Atmospheric Protection

Titanium’s high reactivity with oxygen requires strict atmospheric control. We maintain these conditions:

| Protection Method | Purpose | Effectiveness |

|---|---|---|

| Inert Gas Shield | Prevents oxidation | Very High |

| Vacuum Chamber | Eliminates contamination | Excellent |

| Trailing Shield | Protects cooling weld | Good |

Welding Parameters Control

The success of titanium welding depends heavily on precise parameter control:

- Welding current and voltage

- Travel speed

- Shielding gas flow rate

- Joint preparation quality

Impact on Mechanical Properties

Strength Variations

Through extensive testing at our facility, we’ve observed these typical strength changes:

| Property | Base Metal | Welded Joint | Percentage Retention |

|---|---|---|---|

| Tensile Strength | 100% | 90-95% | High |

| Yield Strength | 100% | 85-90% | Good |

| Fatigue Strength | 100% | 80-85% | Moderate |

Microstructural Changes

The welding process affects titanium’s microstructure in several ways:

- Grain size modification

- Phase distribution changes

- Formation of new crystallographic structures

Best Practices for Maintaining Strength

Pre-Welding Preparation

Proper preparation is crucial for maintaining structural integrity:

- Surface cleaning

- Joint design optimization

- Material thickness consideration

- Tool selection and validation

Process Control Measures

In our manufacturing facility, we implement strict controls:

- Real-time monitoring systems

- Temperature control protocols

- Shielding gas purity verification

- Qualified operator supervision

Post-Weld Treatment Options

Heat Treatment

Post-weld heat treatment can help restore properties:

- Stress relief

- Grain refinement

- Property homogenization

- Strength optimization

Quality Verification

We employ multiple inspection methods:

| Method | Purpose | Detection Capability |

|---|---|---|

| X-Ray | Internal defects | High |

| Ultrasonic | Subsurface flaws | Excellent |

| Visual | Surface quality | Good |

Industry-Specific Considerations

Different sectors have varying requirements:

Aerospace Applications

- Strict certification requirements

- High-performance demands

- Zero-defect tolerance

- Regular inspection protocols

Medical Implants

- Biocompatibility maintenance

- Surface finish requirements

- Sterility considerations

- Long-term durability needs

Future Developments

The field of titanium welding continues to evolve:

- Advanced automation systems

- New shielding techniques

- Improved monitoring capabilities

- Enhanced post-weld treatments

Risk Mitigation Strategies

To ensure optimal results:

- Comprehensive procedure qualification

- Regular equipment calibration

- Environmental control systems

- Operator training programs

The key to successful titanium welding lies in understanding and controlling these various factors. At PTSMAKE, we’ve developed robust processes that ensure consistent, high-quality results in titanium welding operations, maintaining the material’s exceptional properties while meeting the most demanding industry specifications.

Click to learn how specific strength affects material selection in engineering applications. ↩

Click to learn about titanium’s unique crystal structure and its impact on machining properties. ↩

Click to learn more about stress-strain behavior and its crucial role in material selection. ↩

Click to learn more about crystal structures and their impact on material strength. ↩

Click to learn more about precipitation hardening and its crucial role in metal strengthening processes. ↩

Click to learn more about how material strength affects design choices and cost implications. ↩

Click to learn about titanium’s unique crystalline structure and its impact on material properties. ↩

Click to learn more about phase transformations in titanium welding and their practical implications. ↩