Have you ever wondered why some machines can lift incredibly heavy loads with seemingly little effort? Many manufacturing professionals struggle with understanding the mechanics behind hydraulic systems, leading to inefficient operations and potential safety risks.

A hydraulic piston works by using fluid pressure to create force. When fluid is pumped into a cylinder, it pushes against the piston head, converting hydraulic pressure into mechanical force. This simple but powerful mechanism enables heavy lifting and precise control in various applications.

I’ve worked with countless hydraulic systems in our manufacturing facility at PTSMAKE, and I’m always amazed by their efficiency. Whether you’re designing machinery or maintaining equipment, understanding hydraulic pistons is crucial. Let me share some key insights about these fascinating components and how they can transform your manufacturing processes.

What Is A Piston In Hydraulic System?

Have you ever wondered why some hydraulic equipment suddenly loses power or fails unexpectedly? Many engineers face this challenge when their hydraulic systems underperform, often due to misunderstanding one crucial component – the piston.

A hydraulic piston is a cylindrical component that moves inside a chamber to convert fluid pressure into mechanical force. It’s the heart of hydraulic systems, working with fluid pressure to create linear motion for various industrial applications.

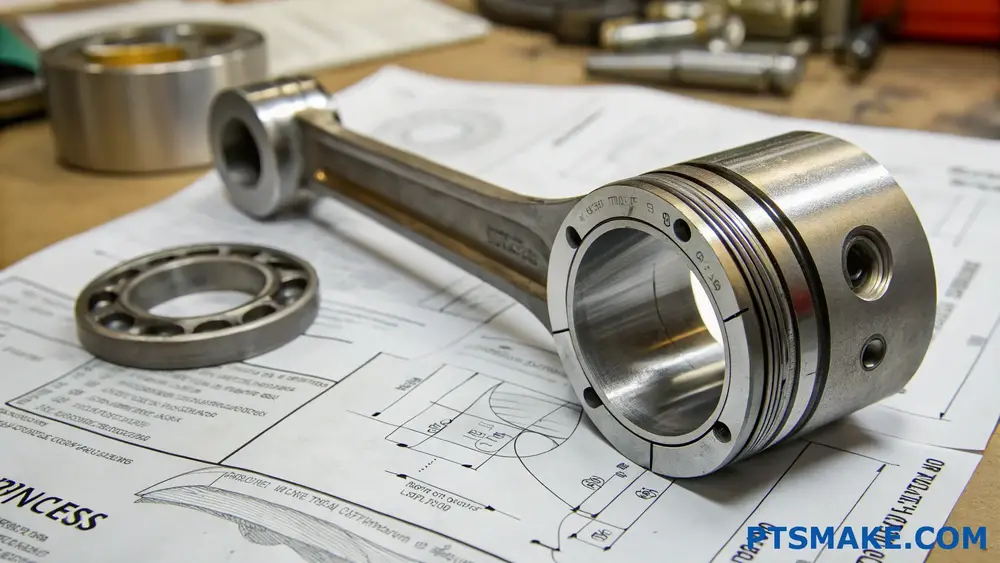

Basic Structure and Components

The basic structure of a hydraulic piston involves several key components that work together seamlessly. Let’s break down these essential parts:

Core Components

- Piston Head: The main cylindrical body

- Piston Rod: Connects to external mechanisms

- Seals: Prevents fluid leakage

- Cylinder: Houses the piston assembly

The reciprocating motion1 of these components creates the foundation for hydraulic power transmission.

Working Principle

The operation of a hydraulic piston relies on Pascal’s law, which states that pressure applied to confined fluid is transmitted equally in all directions. In practical terms:

Pressure Application

- Fluid enters the cylinder

- Pressure builds against the piston face

- Force generates mechanical movement

- Movement transfers to connected mechanisms

Types of Hydraulic Pistons

Different applications require various types of pistons. Here’s a comprehensive breakdown:

| Type | Primary Use | Advantages | Limitations |

|---|---|---|---|

| Single-acting | Simple lift operations | Cost-effective, Simple design | Limited to one-direction force |

| Double-acting | Complex machinery | Bi-directional force, More control | Higher maintenance needs |

| Telescopic | Mobile equipment | Extended reach, Compact storage | Complex sealing requirements |

| Plunger | High-pressure applications | Excellent pressure handling | Limited stroke length |

Material Selection

The choice of materials significantly impacts piston performance:

Common Materials

- Steel alloys: For high-strength applications

- Bronze: Used in wear surfaces

- Composite materials: For specialized applications

- Ceramics: For extreme conditions

In my experience at PTSMAKE, we’ve developed specialized CNC machining processes for manufacturing high-precision hydraulic pistons, ensuring optimal material selection for each application.

Performance Factors

Several key factors influence hydraulic piston performance:

Critical Parameters

Operating Pressure

- Working pressure range

- Pressure peaks

- System requirements

Temperature Considerations

- Ambient conditions

- Fluid temperature

- Material thermal expansion

Speed Requirements

- Extension rate

- Retraction velocity

- Cycle time needs

Maintenance and Care

Proper maintenance ensures optimal piston performance:

Regular Inspection Points

- Seal condition

- Surface wear

- Alignment

- Fluid cleanliness

Common Issues and Solutions

| Problem | Possible Cause | Solution |

|---|---|---|

| Leakage | Worn seals | Replace seals |

| Slow operation | Contaminated fluid | Clean system, replace fluid |

| Inconsistent movement | Air in system | Bleed air from lines |

| Excessive noise | Misalignment | Realign components |

Application Examples

Hydraulic pistons find use across various industries:

Industrial Applications

- Manufacturing equipment

- Construction machinery

- Agricultural implements

- Material handling systems

At PTSMAKE, we’ve implemented these solutions in numerous precision manufacturing projects, particularly in our CNC machining services for hydraulic components.

Design Considerations

When designing hydraulic piston systems, several factors require attention:

Key Design Elements

Load Requirements

- Static loads

- Dynamic forces

- Safety factors

Environmental Conditions

- Operating environment

- Temperature ranges

- Exposure to elements

System Integration

- Space constraints

- Power requirements

- Control systems

Future Trends

The hydraulic piston industry continues to evolve:

Emerging Technologies

- Smart sensors for condition monitoring

- Advanced materials for better efficiency

- Integrated control systems

- Eco-friendly fluid options

Our engineering team at PTSMAKE stays current with these developments, incorporating new technologies into our manufacturing processes to deliver cutting-edge solutions.

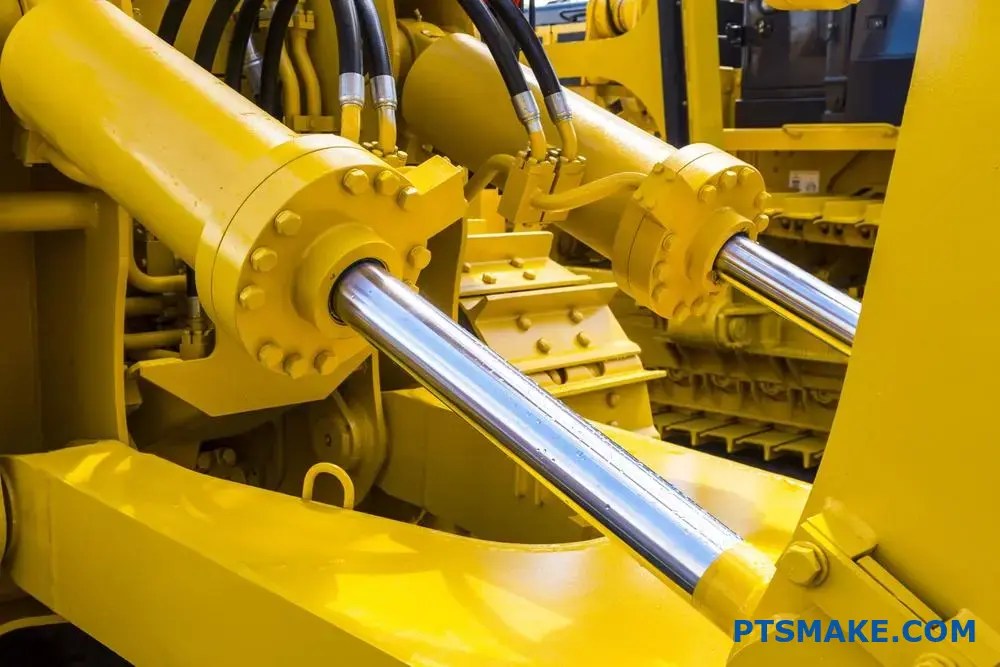

Where Are Hydraulic Pistons Used?

Have you ever watched heavy construction equipment effortlessly lift massive loads and wondered what makes it possible? Or noticed how smoothly your car’s brake pedal responds to the slightest touch? These everyday marvels hide a powerful secret that many take for granted.

Hydraulic pistons are extensively used in various applications, from construction equipment and automotive systems to manufacturing machinery and aerospace technology. They convert fluid pressure into mechanical force, enabling powerful linear motion control in equipment where high force transmission is required.

Common Applications in Heavy Equipment

Heavy machinery relies heavily on hydraulic pistons for their core operations. In my experience working with construction companies, I’ve observed several key applications:

Construction Equipment

- Excavators: The boom, arm, and bucket movements

- Bulldozers: Blade lifting and tilting mechanisms

- Cranes: Outrigger stabilization and boom extension

Agricultural Machinery

- Tractors: Three-point hitch systems

- Harvesters: Reel height adjustment

- Balers: Compression mechanisms

Automotive Applications

The automotive industry extensively uses hydraulic pistons in various systems:

Braking Systems

The master cylinder2 works with hydraulic pistons to multiply the force from your foot into significant braking power. Modern vehicles utilize this technology in:

- Anti-lock braking systems (ABS)

- Emergency brake assist

- Stability control systems

Suspension Systems

Active suspension systems employ hydraulic pistons to:

- Adjust ride height

- Control damping rates

- Enhance vehicle stability

Industrial Manufacturing

In manufacturing facilities, hydraulic pistons play crucial roles in:

Production Equipment

| Equipment Type | Piston Application |

|---|---|

| Injection Molding Machines | Material compression |

| Press Machines | Force application |

| Assembly Lines | Component positioning |

| Material Handling | Load lifting |

At PTSMAKE, we regularly integrate hydraulic systems into our precision manufacturing processes, particularly in our injection molding operations where precise force control is essential.

Safety Systems

Industrial safety equipment often relies on hydraulic pistons for:

- Emergency stops

- Safety barriers

- Machine guards

- Pressure relief systems

Aerospace Applications

The aerospace industry utilizes hydraulic pistons in:

Aircraft Systems

- Landing gear deployment

- Flight control surfaces

- Cargo door operations

- Thrust reversers

Ground Support Equipment

- Aircraft maintenance lifts

- Cargo loading systems

- Aircraft towing vehicles

Marine Applications

Ships and marine equipment employ hydraulic pistons in:

Vessel Operations

- Steering systems

- Stabilizer fins

- Cargo handling equipment

- Deck machinery

Port Equipment

- Container cranes

- Ship-to-shore transfer systems

- Dry dock operations

Building and Infrastructure

Modern buildings and infrastructure utilize hydraulic pistons in:

Vertical Transportation

- Elevator systems

- Platform lifts

- Vehicle parking systems

Civil Engineering

- Bridge mechanisms

- Lock gates

- Flood barriers

Medical Equipment

The healthcare sector relies on hydraulic pistons for:

Patient Care Equipment

- Operating tables

- Dental chairs

- Patient lifts

- Medical imaging equipment

This wide range of applications demonstrates the versatility and importance of hydraulic pistons in modern technology. At PTSMAKE, we’ve integrated hydraulic systems into various custom manufacturing solutions, particularly in our precision machining processes where accurate force control is crucial.

The reliability and power of hydraulic pistons make them indispensable in applications requiring precise force control and smooth operation. Understanding these applications helps engineers and designers make informed decisions about incorporating hydraulic systems into their projects.

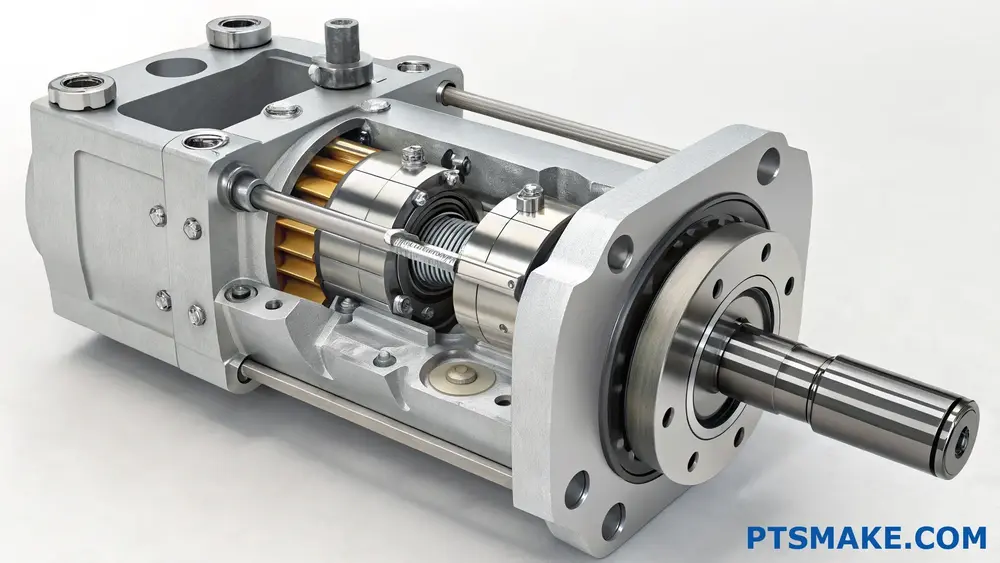

What Does A Hydraulic Piston Pump Do?

Have you ever wondered why some hydraulic systems perform flawlessly while others struggle with inconsistent pressure and frequent breakdowns? The difference often lies in one crucial component that many operators overlook until problems arise.

A hydraulic piston pump converts mechanical power into hydraulic energy by using reciprocating pistons to create flow and pressure. It draws fluid into a chamber during the intake stroke and forces it out under pressure during the discharge stroke, making it vital for various industrial applications.

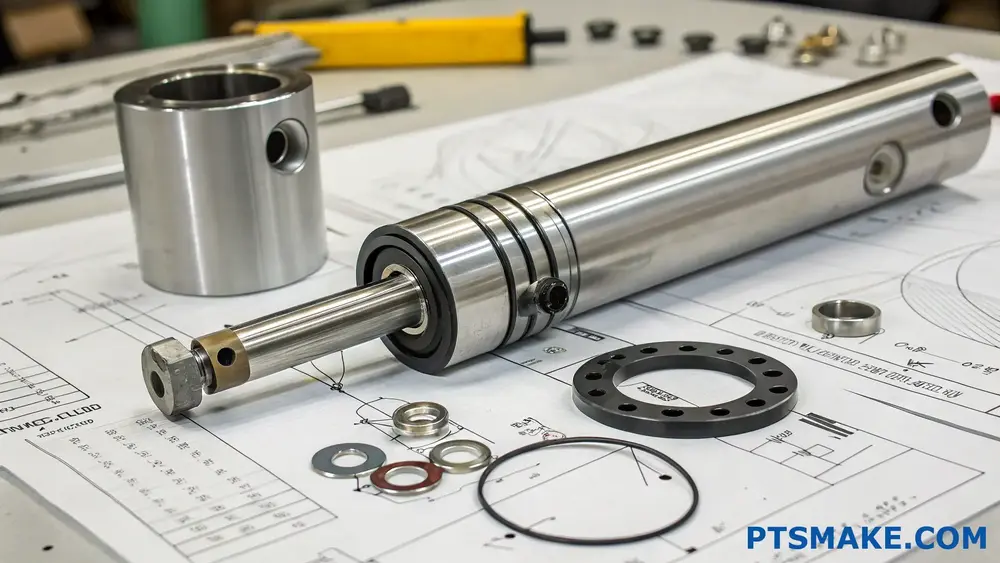

Understanding the Core Components

The effectiveness of a hydraulic piston pump relies heavily on its key components. Each part plays a specific role in the pump’s operation:

Cylinder Block

- Houses the pistons

- Provides structural support

- Contains fluid channels

- Maintains precise tolerances

Pistons and Shoes

The pistons are the workhorses of the pump, while shoes maintain contact with the swashplate. At PTSMAKE, we’ve refined our manufacturing process to achieve optimal surface finishes for these critical components.

Swashplate

This angled plate determines the pump’s displacement. The swashplate angle3 affects flow rate and pressure output.

Operating Principles

Intake Stroke

During this phase, the piston retracts, creating a vacuum that draws fluid into the cylinder. The process involves:

- Piston withdrawal

- Pressure differential creation

- Fluid intake through check valves

- Chamber filling

Discharge Stroke

The piston advances, pressurizing and expelling the fluid. This creates the hydraulic power needed for system operation.

Types of Hydraulic Piston Pumps

| Type | Advantages | Common Applications |

|---|---|---|

| Axial | High efficiency, compact design | Mobile equipment, industrial machinery |

| Radial | High pressure capability | Heavy machinery, press systems |

| Bent-axis | Excellent durability | Construction equipment, marine systems |

Performance Characteristics

Pressure Ratings

Modern hydraulic piston pumps typically operate within these ranges:

- Low pressure: 0-2000 psi

- Medium pressure: 2000-5000 psi

- High pressure: 5000+ psi

Efficiency Factors

Several elements influence pump efficiency:

- Operating temperature

- Fluid viscosity

- System pressure

- Maintenance practices

- Component quality

Applications Across Industries

The versatility of hydraulic piston pumps makes them essential in various sectors:

Manufacturing

In manufacturing facilities, these pumps power:

- CNC machines

- Hydraulic presses

- Material handling equipment

- Assembly line systems

Construction

Construction equipment relies heavily on hydraulic piston pumps for:

- Excavators

- Bulldozers

- Cranes

- Concrete pumps

Aerospace

The aerospace industry requires specialized hydraulic systems for:

- Landing gear operations

- Flight control surfaces

- Cargo door mechanisms

- Testing equipment

Maintenance Considerations

To ensure optimal performance, regular maintenance should focus on:

Daily Checks

- Fluid level monitoring

- Temperature observation

- Unusual noise detection

- Leak inspection

Scheduled Maintenance

- Fluid analysis

- Filter replacement

- Component inspection

- Performance testing

Troubleshooting Common Issues

When problems arise, systematic diagnosis is essential:

Low Pressure

- Check fluid levels

- Inspect for leaks

- Evaluate relief valve settings

- Examine pump wear

Excessive Noise

- Air in the system

- Cavitation

- Mechanical wear

- Misalignment

Overheating

- Insufficient cooling

- Fluid degradation

- System overload

- Flow restrictions

Through my experience at PTSMAKE, I’ve learned that proper component selection and maintenance are crucial for system reliability. Our precision manufacturing capabilities ensure that replacement parts meet or exceed OEM specifications.

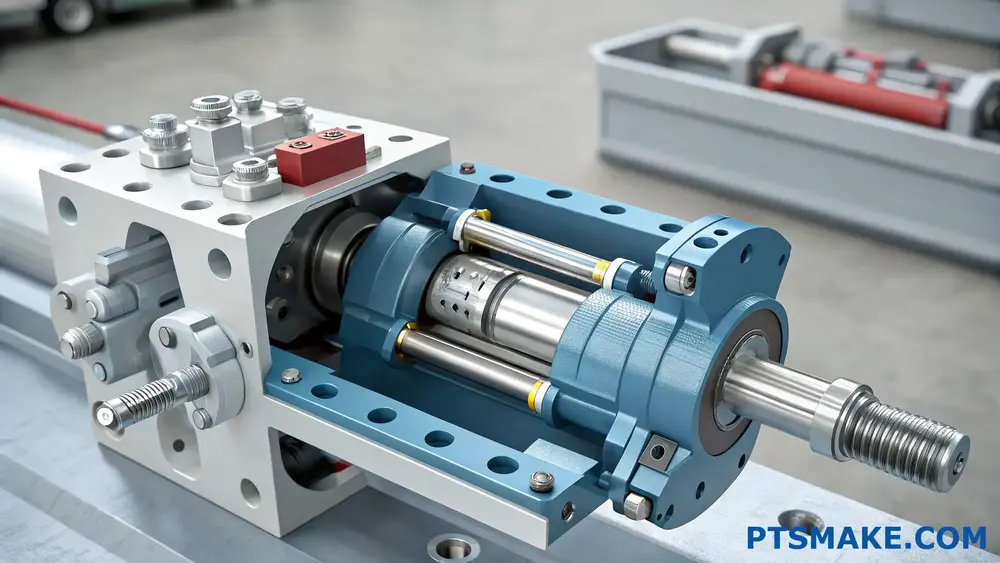

How Do You Control A Hydraulic Piston?

Have you ever struggled with inconsistent hydraulic piston movements in your machinery? It’s frustrating when your equipment jerks unexpectedly or fails to maintain precise control, potentially causing production delays and quality issues.

Controlling a hydraulic piston requires proper valve selection, pressure regulation, and flow control settings. The key components include directional control valves, pressure relief valves, and flow control valves working together with feedback systems to ensure accurate movement and positioning.

Understanding Basic Control Components

The foundation of hydraulic piston control lies in several essential components working together. Each plays a crucial role in maintaining precise movement and position control.

Directional Control Valves

Directional control valves are the primary components that determine the piston’s movement direction. These valves manage the flow path of hydraulic fluid, allowing for:

- Extension of the piston

- Retraction of the piston

- Neutral position holding

Pressure Control Systems

Pressure control is vital for safe and efficient operation. The system includes:

- Pressure relief valves for system protection

- Pressure reducing valves for specific circuit requirements

- Sequence valves for operational timing

Advanced Control Methods

Modern hydraulic systems employ sophisticated control methods to achieve precise positioning and movement control. These methods enhance system performance and reliability.

Proportional Control

Electrohydraulic proportional control4 systems offer variable control over:

| Control Parameter | Benefit | Application |

|---|---|---|

| Speed | Smooth acceleration/deceleration | Production machinery |

| Force | Precise pressure regulation | Press operations |

| Position | Accurate endpoint control | Automated systems |

Closed-Loop Control Systems

These systems provide real-time feedback for:

- Position monitoring

- Pressure regulation

- Speed adjustment

System Integration and Optimization

At PTSMAKE, we’ve implemented numerous hydraulic control systems in our manufacturing processes. Here’s what we’ve learned about optimal system integration:

Component Selection

Choosing the right components is crucial:

- Valve sizing based on flow requirements

- Sensor selection for feedback accuracy

- Controller specification for system demands

Performance Monitoring

Regular monitoring ensures optimal control:

- Pressure readings

- Temperature monitoring

- Flow rate verification

- Position accuracy checks

Troubleshooting Common Control Issues

Understanding common problems helps maintain system reliability:

Pressure-Related Issues

- Insufficient pressure causing slow movement

- Excessive pressure leading to system damage

- Pressure fluctuations affecting control accuracy

Flow Control Problems

- Irregular movement due to air in the system

- Flow restrictions causing jerky motion

- Valve response delays

Maintenance for Optimal Control

Proper maintenance ensures consistent control performance:

Regular Inspections

- Check for fluid leaks

- Inspect seals and connections

- Monitor fluid condition

- Verify sensor calibration

Preventive Maintenance Schedule

| Maintenance Task | Frequency | Impact |

|---|---|---|

| Fluid analysis | Quarterly | System longevity |

| Filter replacement | Semi-annual | Performance consistency |

| Seal inspection | Monthly | Leak prevention |

| Calibration check | Bi-annual | Control accuracy |

Safety Considerations

Safety is paramount in hydraulic piston control:

System Protection

- Install pressure relief valves

- Use accumulator systems where necessary

- Implement emergency stop systems

- Monitor system temperature

Operator Safety

- Provide proper training

- Install safety guards

- Use appropriate personal protective equipment

- Follow lockout/tagout procedures

Future Trends in Hydraulic Control

The industry is evolving with new technologies:

Digital Integration

- Smart sensors for real-time monitoring

- IoT connectivity for remote control

- Predictive maintenance capabilities

- Data analytics for performance optimization

Energy Efficiency

- Variable speed drives

- Energy recovery systems

- Smart control algorithms

- Hybrid systems

Environmental Considerations

Modern hydraulic control systems must address environmental concerns:

Eco-Friendly Solutions

- Bio-degradable hydraulic fluids

- Energy-efficient control strategies

- Leak prevention systems

- Waste reduction methods

This comprehensive approach to hydraulic piston control ensures reliable, efficient, and safe operation while meeting modern manufacturing demands.

How To Replace Hydraulic Piston Seals?

Have you ever faced a hydraulic system suddenly losing pressure or leaving messy oil leaks everywhere? The frustration of dealing with failing piston seals can bring your entire operation to a costly halt, especially when you’re in the middle of a critical project.

Replacing hydraulic piston seals requires a systematic approach: clean the work area, remove the piston, carefully extract old seals, clean all components, install new seals with proper lubrication, and reassemble following manufacturer specifications. This process ensures optimal seal performance and system reliability.

Understanding Seal Types and Their Functions

Different hydraulic systems require specific seal types based on their operating conditions. The most common seals include:

Primary Seals

- U-cup seals

- O-rings

- Step seals

- Chevron seals5

Buffer Seals

These provide additional protection and improve the overall sealing system performance. Common types include:

| Seal Type | Primary Use | Operating Pressure |

|---|---|---|

| Wiper Seals | Prevent contamination | Low pressure |

| Backup Rings | Support primary seals | High pressure |

| Guide Rings | Maintain piston alignment | Medium pressure |

Preparation Steps

Workspace Setup

- Clean and organize your workspace

- Gather necessary tools:

- Seal installation tools

- Cleaning supplies

- Calibrated torque wrench

- Manufacturer’s manual

Safety Measures

- Release all system pressure

- Lock out power sources

- Use appropriate PPE

- Document component positions

Removal Process

System Drainage

- Drain hydraulic fluid into appropriate containers

- Mark all connection points

- Remove associated piping

Piston Extraction

- Remove cylinder head

- Carefully slide out piston rod assembly

- Document seal orientation

- Mark any timing relationships

Cleaning and Inspection

Component Cleaning

- Use appropriate solvents

- Clean all metal surfaces

- Remove all debris

- Pay special attention to seal grooves

Surface Inspection

- Check for scoring

- Measure wear patterns

- Inspect chrome plating

- Verify groove dimensions

Installation Procedures

New Seal Preparation

- Verify correct seal specifications

- Lubricate seals properly

- Check seal material compatibility

- Allow for proper expansion

Installation Techniques

At PTSMAKE, we’ve developed specific techniques for seal installation that minimize damage and ensure proper fitting:

- Use appropriate installation tools

- Maintain proper alignment

- Follow manufacturer’s torque specifications

- Verify free movement after installation

Testing and Validation

Initial Testing

- Perform dry cycling tests

- Check for binding

- Verify smooth operation

- Monitor initial pressure tests

Performance Verification

| Test Parameter | Acceptable Range | Warning Signs |

|---|---|---|

| Operating Pressure | System specific | Pressure drops |

| Cycle Time | ±5% of spec | Irregular movement |

| Leakage | Zero visible leaks | Any seepage |

| Temperature | Within spec range | Excessive heat |

Maintenance Recommendations

To extend seal life and maintain optimal performance:

- Regular inspection schedules

- Proper fluid maintenance

- Temperature monitoring

- Contamination control

- Pressure monitoring

Troubleshooting Common Issues

Premature Seal Failure

- Incorrect installation

- Contamination

- Misalignment

- Temperature extremes

Performance Issues

- Pressure loss

- Erratic movement

- Excessive noise

- Temperature spikes

Best Practices for Long-term Reliability

Documentation

- Maintenance records

- Replacement dates

- Performance data

- Inspection results

Training

- Proper installation techniques

- Troubleshooting procedures

- Safety protocols

- Emergency procedures

Quality Control

- Regular system audits

- Component inspection

- Performance monitoring

- Fluid analysis

Through our experience at PTSMAKE, we’ve found that proper seal replacement isn’t just about the technical process – it’s about understanding the entire system and how each component interacts. By following these comprehensive guidelines, you can ensure reliable hydraulic system performance and minimize downtime.

How Does A Hydraulic Press With Two Pistons?

Have you ever wondered why some hydraulic presses seem more powerful than others? The difference often lies in their piston configuration. When engineers face limitations with single-piston systems, the solution might be simpler than you think.

A hydraulic press with two pistons operates based on Pascal’s law, where force applied to one piston is transferred through fluid to create a multiplied force on the second piston. This setup allows for greater force output while maintaining control and precision in industrial applications.

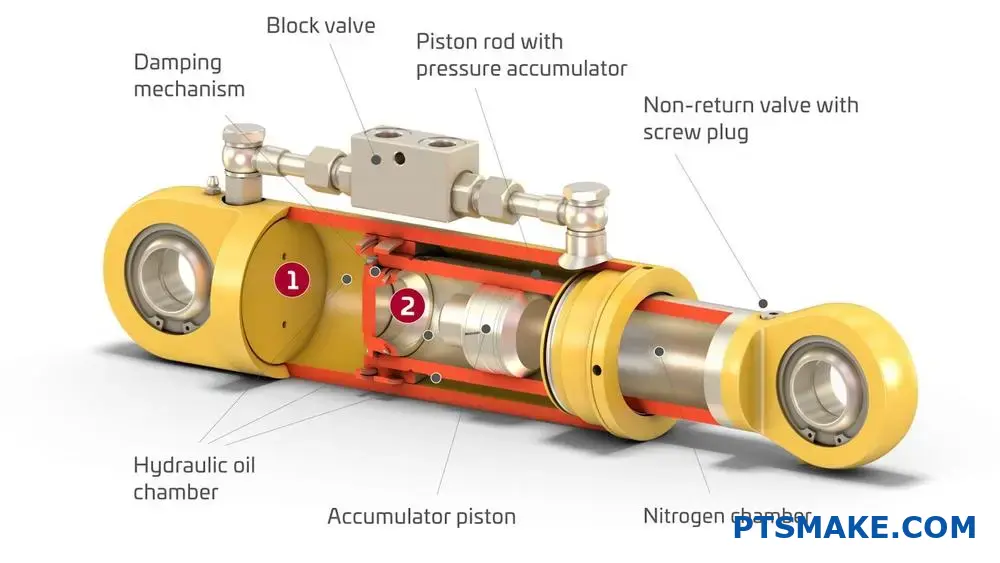

Understanding the Dual Piston Mechanism

The dual-piston hydraulic press system represents a significant advancement in fluid power technology. At PTSMAKE, we regularly incorporate this mechanism into our precision manufacturing processes. The system consists of two main pistons: an input (or primary) piston and an output (or secondary) piston, connected through a hydraulic fluid system.

Key Components of a Two-Piston System

- Primary Piston (Input)

- Secondary Piston (Output)

- Hydraulic Fluid Chamber

- Seals and Gaskets

- Control Valves

The system’s effectiveness relies heavily on the quality of these components. That’s why at PTSMAKE, we maintain strict quality control standards for all our hydraulic system parts.

Force Multiplication Principle

The force multiplication ratio6 in a two-piston system depends on the relationship between the piston areas. Here’s a simple breakdown of the mathematical relationship:

| Input Piston Area (A₁) | Output Piston Area (A₂) | Force Multiplication |

|---|---|---|

| 1 cm² | 10 cm² | 10x |

| 2 cm² | 20 cm² | 10x |

| 5 cm² | 100 cm² | 20x |

Practical Applications

In my experience working with various manufacturing processes, two-piston hydraulic presses excel in:

- Metal Forming Operations

- Precision Part Assembly

- Material Testing

- Compression Molding

Advantages of Dual Piston Configuration

The two-piston setup offers several benefits over single-piston systems:

Enhanced Force Control

- Precise pressure regulation

- Better force distribution

- Improved operational stability

Increased Efficiency

- Higher force output with lower input

- Reduced energy consumption

- More compact design

Design Considerations

When designing a two-piston hydraulic press system, several factors require careful attention:

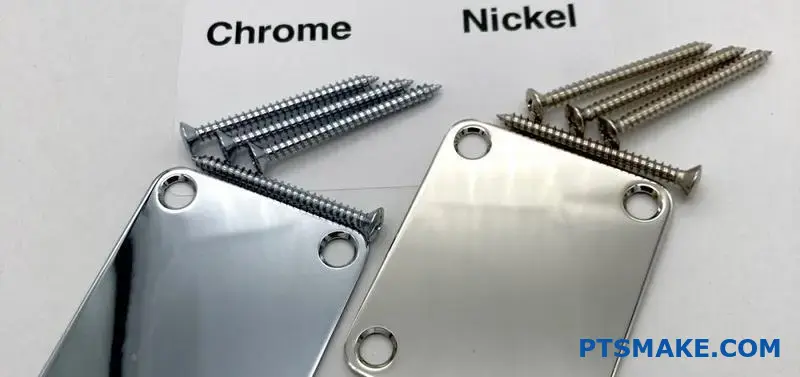

Material Selection

The choice of materials for pistons and cylinders significantly impacts performance:

Cylinder Materials:

- High-grade steel for durability

- Chrome-plated surfaces for wear resistance

- Specially treated materials for corrosion protection

Seal Materials:

- High-performance polymers

- Temperature-resistant compounds

- Wear-resistant elastomers

Maintenance Requirements

Regular maintenance ensures optimal performance:

Daily Checks:

- Fluid level monitoring

- Seal inspection

- Pressure gauge verification

Periodic Maintenance:

- Fluid replacement

- Seal replacement

- Alignment verification

Safety Considerations

Safety is paramount when operating two-piston hydraulic presses:

Pressure Relief Systems

- Emergency pressure release valves

- Automated shutdown mechanisms

- Pressure monitoring systems

Operator Protection

Physical Guards:

- Barrier systems

- Light curtains

- Emergency stop buttons

Operating Procedures:

- Clear safety protocols

- Regular training programs

- Documentation requirements

Common Troubleshooting Issues

Understanding common problems helps maintain system efficiency:

Pressure Loss:

- Seal deterioration

- Fluid leakage

- Valve malfunction

Uneven Force Distribution:

- Misalignment issues

- Worn components

- Contaminated fluid

Control Problems:

- Valve wear

- Electronic system faults

- Sensor calibration errors

Future Developments

The technology continues to evolve with:

Smart Systems Integration:

- Real-time monitoring

- Predictive maintenance

- Automated adjustments

Material Innovations:

- Advanced seal materials

- Improved fluid formulations

- Enhanced surface treatments

How To Choose The Right Material For Hydraulic Pistons?

Have you ever faced the frustrating challenge of premature hydraulic piston failure? It’s a common issue that can lead to costly downtime and repairs. Even worse, choosing the wrong material can result in catastrophic system failures when you least expect it.

Selecting the right material for hydraulic pistons requires careful consideration of factors like operating pressure, temperature, fluid compatibility, and wear resistance. The ideal material should balance mechanical properties, corrosion resistance, and cost-effectiveness while meeting specific application requirements.

Understanding Material Properties for Hydraulic Pistons

Mechanical Properties

The mechanical properties of materials play a crucial role in hydraulic piston performance. At PTSMAKE, we focus on several key properties:

- Tensile Strength: Determines the material’s ability to withstand pressure

- Hardness: Affects wear resistance and durability

- Fatigue Resistance: Critical for cyclic loading applications

- Impact Strength: Important for shock absorption

Surface Characteristics

Surface finish and coating options significantly impact piston performance. The material should maintain its tribological7 properties throughout its service life. Here’s what we consider:

- Surface Roughness

- Coating Compatibility

- Wear Resistance

- Friction Coefficient

Common Materials and Their Applications

Chrome-Plated Carbon Steel

This material offers excellent wear resistance and corrosion protection. Our experience shows it’s particularly suitable for:

| Application Type | Operating Pressure (MPa) | Temperature Range (°C) |

|---|---|---|

| General Purpose | Up to 35 | -20 to 200 |

| Heavy Duty | 35-70 | -20 to 180 |

| Extreme Duty | Above 70 | -40 to 150 |

Stainless Steel

Stainless steel provides superior corrosion resistance and is ideal for:

- Food processing equipment

- Marine applications

- Chemical processing

- Medical equipment

Bronze Alloys

Bronze materials offer unique advantages:

- Excellent self-lubricating properties

- Good thermal conductivity

- Superior wear resistance

- Compatible with various hydraulic fluids

Environmental Considerations

Temperature Effects

Temperature significantly impacts material selection:

- High temperatures can affect material strength

- Thermal expansion must be considered

- Material stability across temperature ranges

- Heat dissipation characteristics

Chemical Compatibility

Different hydraulic fluids require specific material considerations:

| Fluid Type | Recommended Materials | Special Considerations |

|---|---|---|

| Mineral Oil | Chrome-plated steel | Standard application |

| Synthetic | Stainless steel | Chemical resistance |

| Water-based | Bronze alloys | Corrosion protection |

Cost-Benefit Analysis

Initial Investment vs. Lifetime Value

When selecting materials, consider:

- Material cost per unit

- Manufacturing complexity

- Expected service life

- Maintenance requirements

Performance Optimization

To maximize ROI:

- Match material properties to application requirements

- Consider operating conditions

- Factor in maintenance costs

- Evaluate replacement frequency

Design Considerations

Load Requirements

Material selection must account for:

- Static loads

- Dynamic loads

- Impact loads

- Fatigue cycles

Size and Weight Constraints

Consider:

- Space limitations

- Weight restrictions

- Power requirements

- Efficiency targets

Testing and Validation

Material Testing Procedures

At PTSMAKE, we implement rigorous testing:

- Hardness testing

- Wear resistance evaluation

- Corrosion testing

- Fatigue testing

Quality Control Measures

Our quality control process includes:

- Material certification

- Dimensional inspection

- Surface finish verification

- Performance testing

Future Trends

Advanced Materials

Emerging options include:

- Composite materials

- Ceramic coatings

- Nano-engineered surfaces

- Smart materials

Sustainability Considerations

Modern material selection must consider:

- Environmental impact

- Recyclability

- Energy efficiency

- Carbon footprint

What Factors Affect Hydraulic Piston Lifespan?

Have you ever experienced unexpected hydraulic system failures that brought your entire production line to a halt? The frustration of dealing with premature piston wear can be overwhelming, especially when these failures lead to costly downtime and repairs.

The lifespan of a hydraulic piston is primarily influenced by operating conditions, material quality, maintenance practices, and system design. Key factors include operating temperature, fluid contamination, pressure cycles, seal condition, and proper installation methods.

Operating Environment Impact

Temperature Considerations

Operating temperature plays a crucial role in hydraulic piston longevity. When systems run at temperatures exceeding design specifications, the viscosity8 of hydraulic fluid changes dramatically, affecting lubrication and wear patterns. I recommend maintaining temperatures between 110°F to 140°F (43°C to 60°C) for optimal performance.

Pressure Cycles

Repetitive pressure cycles can lead to material fatigue. Based on my experience working with various industrial applications, systems operating under frequent high-pressure cycles require more robust maintenance schedules. Here’s a breakdown of pressure impact on lifespan:

| Pressure Range (PSI) | Expected Impact on Lifespan | Recommended Inspection Frequency |

|---|---|---|

| 0-1000 | Minimal wear | Quarterly |

| 1000-3000 | Moderate wear | Monthly |

| 3000+ | Accelerated wear | Bi-weekly |

Material Quality and Selection

Piston Material Composition

The choice of piston material significantly affects durability. At PTSMAKE, we’ve observed superior performance with chrome-plated steel pistons in high-stress applications. Different materials offer varying benefits:

- Chrome-plated steel: Excellent wear resistance

- Stainless steel: Superior corrosion resistance

- Carbon steel: Cost-effective for standard applications

- Ceramic-coated: Enhanced surface hardness

Seal Quality

High-quality seals are essential for piston longevity. Poor seal selection can result in:

- Internal leakage

- Increased friction

- Accelerated wear

- System inefficiency

Maintenance Practices

Regular Inspection Protocols

Implementing systematic inspection routines helps identify potential issues before they become critical. Key inspection points include:

- Surface wear patterns

- Seal condition

- Alignment verification

- Rod straightness

- Mounting bracket integrity

Fluid Management

Proper fluid management is crucial for extending piston life. This includes:

- Regular fluid analysis

- Contamination monitoring

- Proper filtration

- Timely fluid replacement

System Design Considerations

Load Distribution

Proper load distribution prevents uneven wear. Consider these factors:

- Alignment tolerance

- Side loading prevention

- Mount design

- Support structure integrity

Speed and Stroke Length

Operating speed and stroke length affect wear patterns:

| Speed Range | Impact on Components | Design Considerations |

|---|---|---|

| Low Speed | Minimal wear | Standard seals sufficient |

| Medium Speed | Normal wear | Enhanced lubrication needed |

| High Speed | Accelerated wear | Special seal designs required |

Installation Best Practices

Alignment Requirements

Proper alignment during installation is critical. Key points include:

- Use of alignment tools

- Torque specifications

- Mounting surface preparation

- Cleanliness protocols

Break-in Procedures

Implementing proper break-in procedures can significantly extend piston life:

- Gradual pressure increase

- Speed ramping

- Temperature monitoring

- Performance validation

Environmental Factors

Dust and Contamination

Environmental conditions significantly impact piston life:

- Use appropriate filtration systems

- Regular cleaning schedules

- Proper sealing of system components

- Environmental protection measures

Temperature Fluctuations

Managing temperature variations is essential:

- Insulation requirements

- Cooling system design

- Temperature monitoring systems

- Material expansion considerations

Modern Monitoring Solutions

Predictive Maintenance

Implementing modern monitoring solutions helps prevent failures:

- Pressure sensors

- Temperature monitoring

- Wear indicators

- Performance tracking systems

At PTSMAKE, we’ve integrated these factors into our manufacturing processes, ensuring our hydraulic components meet the highest quality standards. Our engineering team carefully considers each of these aspects when designing and producing custom hydraulic solutions for our clients.

How To Troubleshoot Hydraulic Piston Leakage Issues?

Have you ever faced the frustrating situation where your hydraulic system’s efficiency suddenly drops, only to discover fluid pooling around your piston? This common yet costly issue can halt production and create environmental hazards, leaving you searching for quick solutions.

Hydraulic piston leakage typically occurs due to worn seals, damaged cylinder walls, or improper installation. The solution involves systematic troubleshooting, including visual inspection, pressure testing, and component analysis to identify and fix the root cause effectively.

Understanding Common Causes of Hydraulic Piston Leakage

The first step in addressing hydraulic piston leakage is understanding its potential causes. When dealing with cavitation9 issues in hydraulic systems, we need to examine several key factors:

Seal-Related Issues

- Worn or damaged seals

- Incorrect seal material selection

- Improper seal installation

- Temperature-induced seal deterioration

Mechanical Problems

- Cylinder wall scoring

- Piston rod surface damage

- Misalignment issues

- Excessive wear on components

Systematic Troubleshooting Approach

At PTSMAKE, we’ve developed a comprehensive troubleshooting methodology for hydraulic piston leakage:

Step 1: Visual Inspection

- Check for visible fluid leaks

- Examine seal condition

- Inspect cylinder walls

- Assess piston rod surface

Step 2: System Analysis

Before diving deeper, consider these operational parameters:

| Parameter | Normal Range | Warning Signs |

|---|---|---|

| Operating Pressure | 2000-3000 PSI | Sudden drops or fluctuations |

| Fluid Temperature | 120-140°F | Excessive heat buildup |

| Fluid Level | Full mark | Unexplained loss |

| Cycle Time | System specific | Increased duration |

Step 3: Component Testing

Pressure Testing

- Conduct static pressure tests

- Perform dynamic cycle testing

- Monitor pressure readings

- Record any variations

Seal Inspection Protocol

- Remove seals carefully

- Check for deformation

- Measure wear patterns

- Verify material compatibility

Preventive Maintenance Strategies

Regular Maintenance Schedule

| Maintenance Task | Frequency | Critical Checks |

|---|---|---|

| Seal Inspection | Monthly | Wear patterns, elasticity |

| Fluid Analysis | Quarterly | Contamination levels, viscosity |

| Alignment Check | Semi-annually | Rod straightness, mounting |

| System Flush | Annually | Complete system cleaning |

Quality Control Measures

At PTSMAKE, we implement strict quality control measures for hydraulic components:

- Material verification

- Dimensional accuracy checks

- Surface finish inspection

- Performance testing

Advanced Diagnostic Methods

Using Modern Technology

- Thermal imaging for leak detection

- Ultrasonic testing equipment

- Digital pressure monitoring

- Vibration analysis tools

Data-Driven Decision Making

Modern hydraulic systems benefit from data analysis:

| Data Point | Analysis Method | Action Threshold |

|---|---|---|

| Pressure Drop | Trend analysis | >5% deviation |

| Temperature Rise | Real-time monitoring | >10°F increase |

| Fluid Clarity | Particle count | >ISO 4406 standard |

| Cycle Efficiency | Performance tracking | <95% nominal |

Environmental Considerations

Fluid Management

- Proper disposal procedures

- Containment systems

- Environmentally friendly fluids

- Spill response protocols

Safety Protocols

When troubleshooting hydraulic systems:

- Release system pressure

- Use appropriate PPE

- Follow lockout/tagout procedures

- Document all findings

Cost-Effective Solutions

Immediate Actions

- Temporary seal repairs

- Pressure adjustments

- Operating parameter modifications

- Emergency containment

Long-Term Investments

Consider these sustainable solutions:

| Investment | Benefit | ROI Timeline |

|---|---|---|

| Upgraded Seals | Reduced leakage | 6-12 months |

| Monitoring Systems | Early detection | 12-18 months |

| Training Programs | Better maintenance | 3-6 months |

| Quality Components | Extended life | 18-24 months |

System Optimization

Performance Enhancement

- Proper fluid selection

- Optimal operating temperatures

- Correct pressure settings

- Regular system balancing

Efficiency Improvements

- Minimize pressure drops

- Reduce heat generation

- Optimize cycle times

- Enhance control systems

Click to learn more about motion types in hydraulic systems and optimize your design. ↩

Click to learn more about master cylinder design principles and optimization techniques. ↩

Click to learn more about swashplate design and its impact on pump performance. ↩

Click here to learn advanced techniques for precise hydraulic system control and optimization. ↩

Click to learn more about specialized seal designs and their unique applications in hydraulic systems. ↩

Click to learn more about force multiplication calculations and practical applications in hydraulic systems. ↩

Click to learn more about surface interaction science in hydraulic systems. ↩

Click to learn more about fluid viscosity’s critical role in hydraulic system performance. ↩

Click to learn more about the destructive effects of cavitation in hydraulic systems and prevention methods. ↩