Have you ever struggled with polishing titanium parts only to end up with unsatisfactory results? I know the frustration – titanium’s high strength and hardness make it incredibly challenging to achieve that perfect mirror finish. Many engineers and manufacturers give up, settling for subpar results.

To polish titanium effectively, start with progressively finer abrasives from 400 to 2000 grit, followed by buffing compounds. Use moderate pressure and maintain consistent motion. The process requires patience, but with proper technique, you can achieve a mirror-like finish.

As a manufacturing expert, I’ve refined our titanium polishing process at PTSMAKE through countless trials. I understand you might be feeling overwhelmed by the technical details, but I’ll break down our proven method into simple, actionable steps. Let me share our best practices that consistently deliver outstanding results.

Why Is Titanium So Hard To Polish?

Have you ever struggled to achieve that perfect mirror finish on titanium components? It’s frustrating when conventional polishing methods that work well on other metals leave your titanium parts looking dull and lackluster, isn’t it? The challenge becomes even more apparent when precision and aesthetics are non-negotiable.

Titanium is exceptionally difficult to polish due to its high strength-to-weight ratio, exceptional hardness, and formation of a natural oxide layer. These properties, combined with its tendency to gall and work harden during polishing, make achieving a mirror finish particularly challenging.

Understanding Titanium’s Unique Properties

Titanium’s polishing challenges stem directly from its inherent material properties. The metal’s work hardening characteristics1 make it particularly resistant to traditional polishing methods. At PTSMAKE, we’ve developed specialized techniques to overcome these challenges, especially when working with complex aerospace and medical components.

Material Structure and Composition

The difficulty in polishing titanium largely relates to its crystalline structure and chemical composition:

| Property | Characteristic | Impact on Polishing |

|---|---|---|

| Crystal Structure | Hexagonal Close-Packed (HCP) | Increases resistance to deformation |

| Surface Oxide | Self-forming TiO2 layer | Requires special handling techniques |

| Hardness | 970 MPa (Grade 5) | Demands stronger abrasives |

| Thermal Conductivity | 6.7 W/mK | Heat buildup during polishing |

The Challenge of Surface Oxidation

One of the most significant barriers to achieving a mirror finish on titanium is its rapid oxidation. Unlike other metals, titanium forms an immediate oxide layer when exposed to air. This protective layer, while excellent for corrosion resistance, presents unique challenges during the polishing process.

Heat Management During Polishing

The low thermal conductivity of titanium creates another layer of complexity:

- Excessive heat buildup during polishing

- Risk of surface discoloration

- Potential for material property changes

- Need for careful speed control

Advanced Polishing Techniques

After years of experience in precision manufacturing, I’ve identified several effective approaches:

Mechanical Polishing Methods

Progressive Grit Selection

- Start with coarser abrasives (120-180 grit)

- Gradually progress to finer grits (up to 1200)

- Final buffing with specialized compounds

Speed and Pressure Control

- Maintain consistent, moderate speeds

- Apply uniform pressure

- Use coolant when necessary

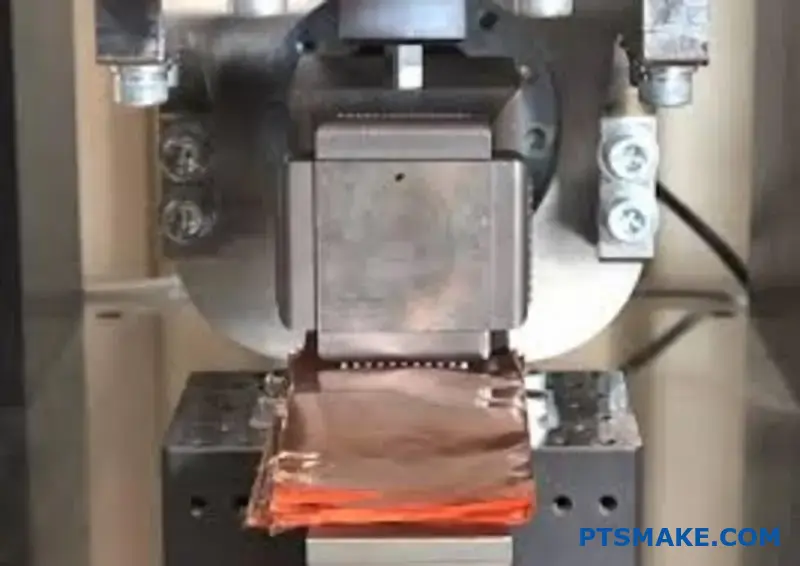

Chemical-Mechanical Polishing

The combination of mechanical and chemical processes often yields superior results:

| Process Stage | Method | Purpose |

|---|---|---|

| Pre-treatment | Chemical cleaning | Remove surface contaminants |

| Initial Polish | Mechanical abrasion | Remove major imperfections |

| Chemical Polish | Specialized solutions | Enhanced surface finish |

| Final Polish | Fine abrasives | Mirror finish achievement |

Industry-Specific Requirements

Different sectors demand varying levels of surface finish:

Aerospace Applications

- Ultra-smooth surfaces for aerodynamic efficiency

- Strict compliance with industry standards

- Critical inspection requirements

Medical Implants

- Bio-compatible finish

- Absolutely smooth surfaces

- Stringent sterilization requirements

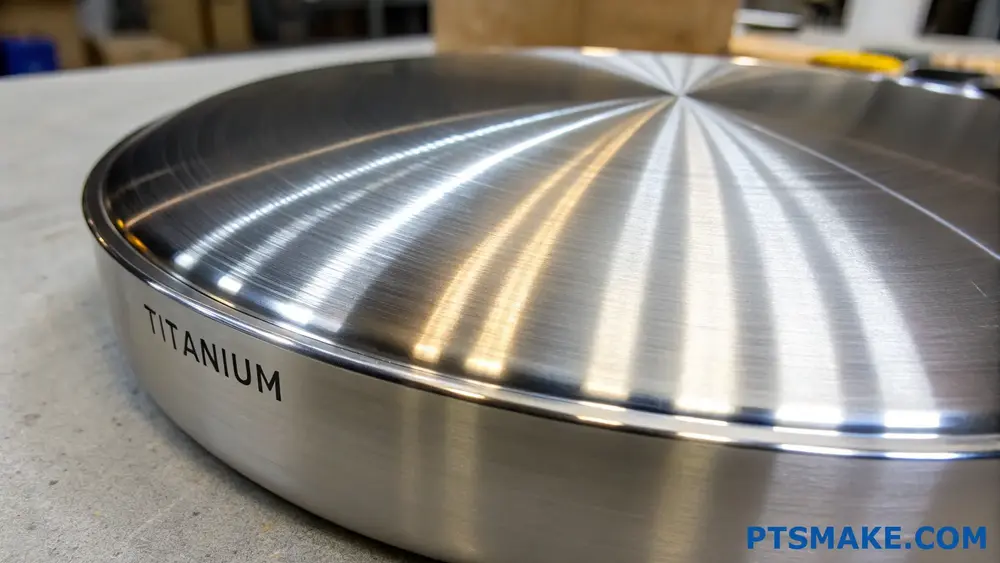

Consumer Products

- Aesthetic appeal

- Scratch resistance

- Consistent finish across batches

Quality Control Measures

At PTSMAKE, we implement rigorous quality control procedures:

Surface Finish Measurement

- Profilometer testing

- Visual inspection under controlled lighting

- Documentation of surface roughness values

Process Validation

- Regular calibration of polishing equipment

- Standardized procedures for each material grade

- Continuous monitoring of environmental conditions

The complexity of polishing titanium requires a deep understanding of material science and specialized techniques. Through careful process control and advanced methodologies, achieving the desired surface finish becomes possible, though it remains one of the more challenging aspects of titanium processing.

What Tools And Materials Are Needed To Polish Titanium Effectively?

Have you ever struggled to achieve that perfect mirror finish on titanium components? The frustration of using conventional polishing methods only to end up with uneven surfaces and lackluster results can be overwhelming. Many engineers find themselves wasting valuable time and resources on ineffective polishing techniques.

To polish titanium effectively, you’ll need specific abrasives, polishing compounds, buffing wheels, and protective equipment. The essential tools include variable speed polishers, diamond paste (ranging from 60 to 0.5 microns), microfiber cloths, and appropriate safety gear like respirators and goggles.

Essential Polishing Equipment

Power Tools Selection

The foundation of successful titanium polishing starts with choosing the right power tools. A variable-speed polisher is crucial as titanium requires different speeds at various polishing stages. I recommend using a polisher that can operate between 1,000 to 3,000 RPM. The anisotropic2 nature of titanium means we need precise control over polishing speeds to achieve optimal results.

Manual Tools Requirements

While power tools do most of the heavy lifting, manual tools are essential for detail work and finishing touches:

- Fine-grit sandpaper (400-3000 grit)

- Polishing blocks

- Hand-held burnishing tools

- Microfiber cloths

- Cotton swabs for hard-to-reach areas

Abrasive Materials

Diamond Compounds

Diamond compounds are particularly effective for titanium polishing. Here’s a recommended progression:

| Grit Size (Microns) | Application Stage | Expected Result |

|---|---|---|

| 60 | Initial cutting | Remove major imperfections |

| 30 | Secondary cutting | Surface leveling |

| 15 | Pre-polish | Initial shine development |

| 6 | Fine polish | Enhanced luster |

| 1 | Final polish | Mirror finish |

| 0.5 | Ultra-fine finish | Maximum brilliance |

Polishing Compounds

The selection of polishing compounds is crucial for achieving the desired finish:

- Aluminum oxide compounds for initial stages

- Silicon carbide for intermediate polishing

- Cerium oxide for final finishing

- Chrome oxide for specialized applications

Safety Equipment

Personal Protection

Safety should never be compromised when polishing titanium:

- Full-face shield or safety goggles

- N95 or better respirator

- Heavy-duty gloves

- Long-sleeved protective clothing

- Steel-toed boots

- Ear protection

Workspace Requirements

Your polishing area should include:

- Proper ventilation system

- Fire-resistant work surface

- Easy access to emergency equipment

- Adequate lighting

- Anti-fatigue floor mats

Supplementary Materials

Cleaning Supplies

Maintaining cleanliness throughout the process is essential:

- Industrial-grade degreaser

- Lint-free wipes

- Isopropyl alcohol

- Ultrasonic cleaner

- pH-neutral soap

Quality Control Tools

To ensure consistent results, you’ll need:

- Surface roughness tester

- Digital microscope

- LED inspection light

- Reference samples

- Documentation materials

Specialized Tools for Complex Geometries

When working with intricate titanium components, additional tools become necessary:

- Flexible polishing heads

- Extended reach attachments

- Custom-shaped polishing stones

- Miniature polishing bits

- Angle adapters

At PTSMAKE, we’ve developed specific protocols for polishing complex titanium parts used in aerospace and medical applications. Our experience has shown that investing in quality tools and materials ultimately saves time and ensures consistent results.

Material Storage and Maintenance

Proper storage of polishing materials extends their life and maintains effectiveness:

- Airtight containers for compounds

- Climate-controlled storage area

- Tool maintenance schedule

- Regular calibration of power tools

- Proper cleaning protocols

The success of titanium polishing largely depends on using the right combination of tools and materials. While the initial investment might seem substantial, quality equipment pays for itself through superior results and longer service life. Remember that each tool and material serves a specific purpose in the polishing process, and skipping or substituting any component might compromise the final result.

Can You Polish Titanium Without Professional Equipment?

Have you ever tried polishing titanium at home, only to end up with disappointing results? The stubborn surface seems to resist your efforts, leaving you frustrated and wondering if you’re doing something wrong. It’s a common challenge that can leave even experienced DIY enthusiasts scratching their heads.

Yes, you can polish titanium without professional equipment. While industrial machines provide the best results, achieving a decent finish is possible using common household items like sandpaper, polishing compounds, and basic power tools. However, the process requires patience and proper technique to achieve satisfactory results.

Understanding the Basics of Titanium Polishing

Titanium’s unique properties make it both a blessing and a challenge when it comes to polishing. The metal forms a natural passivation layer3 that protects it from corrosion but can make polishing more difficult. At PTSMAKE, we’ve refined our polishing techniques through years of working with titanium components.

Essential Tools for DIY Titanium Polishing

Before starting the polishing process, gather these basic tools:

- Sandpaper (various grits from 400 to 2000)

- Polishing compounds

- Microfiber cloths

- Electric drill or rotary tool

- Protective gear (gloves, safety glasses, dust mask)

Step-by-Step Polishing Process

1. Surface Preparation

The success of titanium polishing largely depends on proper surface preparation. Start by cleaning the surface thoroughly to remove any dirt, oils, or contaminants. Use a degreaser and ensure the surface is completely dry before proceeding.

2. Progressive Sanding

Follow this sanding sequence for optimal results:

| Grit Level | Purpose | Approximate Time |

|---|---|---|

| 400 | Remove major scratches | 10-15 minutes |

| 800 | Smooth surface | 8-10 minutes |

| 1200 | Fine smoothing | 5-8 minutes |

| 2000 | Pre-polish preparation | 3-5 minutes |

3. Polishing Technique

The key to successful titanium polishing lies in maintaining consistent pressure and movement. Work in small sections, using circular motions with your polishing tool. Keep the surface cool by frequently pausing, as excessive heat can affect titanium’s properties.

Common Mistakes to Avoid

Skipping Grit Levels

Don’t be tempted to jump from coarse to fine grits too quickly. Each step is crucial for achieving a mirror-like finish.Applying Excessive Pressure

Let the abrasives do the work. Too much pressure can create deep scratches that are difficult to remove.Neglecting Safety Precautions

Always wear appropriate protective gear. Titanium dust can be harmful if inhaled.

Advanced Tips for Better Results

Temperature Management

Monitor the surface temperature during polishing. If it becomes too hot to touch, pause and allow it to cool. At PTSMAKE, we use specialized cooling techniques in our professional processes, but for DIY projects, regular breaks work well.

Surface Pattern Considerations

Different titanium items may require different polishing patterns:

| Surface Type | Recommended Pattern | Special Considerations |

|---|---|---|

| Flat Surfaces | Linear strokes | Maintain consistent direction |

| Curved Areas | Circular motions | Follow surface contours |

| Corners | Multiple angles | Extra care needed |

Quality Assessment

To evaluate your polishing results:

Visual Inspection

- Check for consistent shine

- Look for remaining scratches

- Examine under bright light

Touch Test

- Surface should feel smooth

- No catching when running fingernail across

Alternative Methods

While traditional polishing methods work well, some alternatives include:

- Chemical polishing (requires specific safety measures)

- Electropolishing (more complex but effective)

- Hybrid approaches combining multiple techniques

Maintenance After Polishing

To maintain the polished finish:

Regular Cleaning

- Use mild soap and water

- Avoid abrasive cleaners

- Pat dry with soft cloth

Protection

- Store in dust-free environment

- Use protective covers when possible

- Handle with clean, dry hands

Remember that while DIY polishing can achieve good results, professional services like those we offer at PTSMAKE provide superior finishes for critical applications. We use precision-controlled processes and specialized equipment to ensure consistent, high-quality results.

What Safety Precautions Should Be Taken When Polishing Titanium?

Have you ever experienced the anxiety of polishing titanium without proper safety measures? The combination of fine metal particles, high-speed tools, and chemical compounds can create a hazardous environment that many engineers underestimate, putting themselves at serious risk.

When polishing titanium, essential safety precautions include wearing appropriate PPE (respirator, goggles, gloves), ensuring proper ventilation, using explosion-proof equipment, and following strict fire prevention protocols. These measures protect against metal dust, chemical exposure, and potential fire hazards.

Understanding the Risks of Titanium Polishing

Chemical Reactivity Concerns

Titanium’s high pyrophoricity4 during polishing operations requires special attention. The metal particles can spontaneously ignite when exposed to air, especially during fine polishing processes. At PTSMAKE, we’ve implemented strict safety protocols to manage these risks effectively.

Physical Hazards Protection

The polishing process generates fine particles that can be harmful when inhaled or contact skin. Personal protective equipment must be carefully selected and properly maintained:

| PPE Type | Specific Requirements | Replacement Frequency |

|---|---|---|

| Respirator | N95 or P100 rating | Every 8 hours or when breathing becomes difficult |

| Safety Goggles | Chemical splash resistant | Every 6 months or when damaged |

| Protective Gloves | Chemical resistant nitrile | Daily or when compromised |

| Face Shield | Full coverage | When scratched or damaged |

Workplace Environment Controls

Ventilation Requirements

Proper ventilation is crucial for titanium polishing operations. The system should include:

- Local exhaust ventilation with capture velocity of 100-200 feet per minute

- HEPA filtration systems for particle collection

- Regular maintenance and filter replacement schedules

- Continuous air quality monitoring

Fire Prevention Measures

Fire safety is paramount when working with titanium. Essential precautions include:

- Installing Class D fire extinguishers at accessible locations

- Maintaining dedicated disposal containers for titanium waste

- Regular cleaning to prevent dust accumulation

- Emergency response training for all personnel

Equipment and Tool Safety

Machine Maintenance Protocol

Regular equipment maintenance helps prevent accidents and ensures optimal performance:

| Maintenance Task | Frequency | Safety Impact |

|---|---|---|

| Tool Inspection | Daily | Prevents tool failure and particle projection |

| Speed Control Check | Weekly | Ensures optimal cutting conditions |

| Coolant System Review | Monthly | Prevents overheating and chemical exposure |

| Emergency Stop Testing | Quarterly | Guarantees quick response to incidents |

Safe Operating Procedures

Implementing proper operating procedures is essential:

- Start with lower speeds and gradually increase as needed

- Monitor tool temperature regularly

- Keep work area clean and organized

- Document all safety incidents and near-misses

Chemical Safety Management

Coolant Handling

Proper handling of polishing compounds and coolants requires:

- Using approved storage containers

- Regular chemical inventory checks

- Maintaining updated Safety Data Sheets (SDS)

- Training on proper mixing and disposal procedures

Waste Disposal Protocol

Proper disposal of titanium waste is crucial:

- Use designated metal waste containers

- Keep waste materials separated from other metals

- Follow local regulations for hazardous waste disposal

- Maintain proper documentation of disposal

Emergency Response Planning

First Aid Procedures

Establish clear first aid protocols:

- Eye wash stations within 10 seconds of work areas

- First aid kits specifically equipped for metal working injuries

- Trained first aid responders on each shift

- Clear evacuation routes and assembly points

Incident Response Protocol

Develop comprehensive incident response procedures:

- Emergency contact numbers clearly posted

- Regular emergency drills

- Documentation of all incidents

- Root cause analysis for prevention

Training and Documentation

Employee Training Requirements

Comprehensive training programs should include:

- Initial safety orientation

- Regular refresher courses

- Hands-on equipment training

- Emergency response procedures

- Chemical handling certification

Record Keeping

Maintain detailed records of:

- Training completion

- Equipment maintenance

- Incident reports

- Safety audits

- PPE inspections

At PTSMAKE, we’ve refined these safety protocols through years of experience in titanium processing. Our commitment to safety has resulted in an exceptional safety record while maintaining high-quality polishing results. We understand that safety isn’t just about following rules – it’s about creating a culture where everyone takes responsibility for their own safety and that of their colleagues.

How Does Titanium Polishing Affect Corrosion Resistance?

Have you ever noticed your titanium components showing early signs of corrosion despite titanium’s renowned resistance? It’s frustrating when these premium parts start degrading unexpectedly, especially in critical applications where failure isn’t an option.

Titanium polishing significantly enhances corrosion resistance by creating a smoother surface that reduces potential corrosion sites and strengthens the protective oxide layer. This process effectively minimizes the risk of localized corrosion and extends the component’s lifespan.

Understanding Surface Finish Impact on Corrosion

Surface finish quality plays a crucial role in determining how well titanium resists corrosion. When we polish titanium components at PTSMAKE, we focus on achieving specific surface roughness values that optimize corrosion resistance. The relationship between surface finish and corrosion resistance involves several key factors:

Surface Roughness Measurements

The effectiveness of titanium polishing can be quantified through various surface roughness parameters:

| Parameter | Description | Typical Range for Optimal Corrosion Resistance |

|---|---|---|

| Ra | Average Roughness | 0.1-0.4 μm |

| Rz | Maximum Height | 0.5-2.0 μm |

| Rt | Total Height | 0.8-3.0 μm |

The Science Behind Enhanced Protection

The passivation layer5 formed on titanium’s surface is what gives it excellent corrosion resistance. Through proper polishing, we can enhance this natural protection in several ways:

Oxide Layer Formation

Polishing creates ideal conditions for developing a uniform oxide layer by:

- Removing surface contaminants

- Creating consistent surface texture

- Promoting even oxygen distribution

Microscopic Benefits

At the microscopic level, polished surfaces offer:

- Reduced surface area for corrosive attacks

- Fewer crevices where corrosion can initiate

- Better resistance to pitting corrosion

Polishing Techniques and Their Effects

Different polishing methods yield varying results in terms of corrosion resistance:

Mechanical Polishing

- Uses abrasive materials in sequence

- Provides consistent surface finish

- Excellent for complex geometries

Chemical Polishing

- Removes material through chemical reactions

- Creates highly uniform surfaces

- Particularly effective for intricate parts

Electropolishing

- Combines electrical current with chemical solutions

- Produces superior surface finish

- Enhances passive layer formation

Industry-Specific Requirements

In my experience at PTSMAKE, different industries require specific surface finishes:

| Industry | Required Surface Finish | Primary Concern |

|---|---|---|

| Medical | Ra < 0.2 μm | Biocompatibility |

| Aerospace | Ra < 0.4 μm | Fatigue Resistance |

| Chemical | Ra < 0.6 μm | Chemical Resistance |

Testing and Validation Methods

To ensure polished titanium components meet corrosion resistance requirements, several testing methods are employed:

Electrochemical Testing

- Potentiodynamic polarization tests

- Electrochemical impedance spectroscopy

- Cyclic polarization measurements

Environmental Testing

- Salt spray exposure

- Humidity chamber testing

- Chemical immersion tests

Best Practices for Maintaining Corrosion Resistance

To maintain the enhanced corrosion resistance achieved through polishing:

Storage and Handling

- Keep components in controlled environments

- Avoid contact with dissimilar metals

- Use appropriate packaging materials

Regular Maintenance

- Implement cleaning protocols

- Conduct periodic inspections

- Document surface condition changes

Quality Control Measures

At PTSMAKE, we implement strict quality control measures:

| Stage | Control Measure | Purpose |

|---|---|---|

| Pre-polish | Surface inspection | Identify defects |

| During Polish | Parameter monitoring | Ensure consistency |

| Post-polish | Surface testing | Verify specifications |

Future Developments

The field of titanium polishing continues to evolve with:

- Advanced automated polishing systems

- Novel surface treatment combinations

- Improved measurement technologies

By understanding these aspects of titanium polishing and its effects on corrosion resistance, manufacturers can better protect their components and ensure longer service life. The investment in proper polishing techniques pays dividends through enhanced durability and reduced maintenance requirements.

What Are The Cost-Effective Methods For High-Volume Titanium Polishing?

Have you ever faced the challenge of polishing hundreds of titanium parts while trying to keep costs under control? The complexity of titanium polishing, combined with its time-consuming nature and high material costs, can quickly turn a profitable project into a financial burden.

Cost-effective titanium polishing for high volumes requires a combination of automated processes, optimized abrasive selection, and efficient workflow management. Key methods include mechanical polishing, electropolishing, and hybrid approaches, each offering unique advantages for different production scales.

Understanding the Economics of Titanium Polishing

When dealing with high-volume titanium polishing, the cost structure breaks down into several key components. The primary factors include labor, equipment, consumables, and time. At PTSMAKE, we’ve developed a comprehensive understanding of these elements to help optimize costs while maintaining quality.

Labor and Equipment Costs

The initial investment in polishing equipment represents a significant portion of the overall cost. Here’s a breakdown of typical equipment costs:

| Equipment Type | Initial Investment | Lifespan (Years) | Cost Per Year |

|---|---|---|---|

| Manual Systems | $5,000-15,000 | 5-7 | $1,000-3,000 |

| Semi-Automated | $20,000-50,000 | 8-10 | $2,500-6,250 |

| Fully Automated | $80,000-200,000 | 10-15 | $8,000-20,000 |

Optimizing Material Removal Rates

The efficiency of material removal directly impacts cost-effectiveness. The key lies in achieving the optimal surface roughness parameter6 while minimizing processing time. Our experience shows that combining different techniques can significantly reduce processing time.

Mechanical Polishing Strategies

Progressive Grit Sequence

- Start with coarse abrasives (80-120 grit)

- Move to medium (240-400 grit)

- Finish with fine grits (800-1200)

Pressure Control

- Maintain consistent pressure

- Use automated systems for uniform results

- Monitor wear patterns

Advanced Cost-Reduction Techniques

Batch Processing Optimization

The organization of work batches plays a crucial role in cost reduction. Here’s how we approach it:

Size-based Batching

- Group similar-sized parts

- Optimize tooling changes

- Reduce setup times

Surface Finish Requirements

- Categorize by finish specifications

- Match appropriate processes

- Minimize over-processing

Consumable Management

Proper management of polishing consumables can lead to significant cost savings:

| Consumable Type | Cost Reduction Strategy | Potential Savings |

|---|---|---|

| Abrasive Belts | Rotation System | 15-25% |

| Polishing Compounds | Controlled Application | 20-30% |

| Buffing Wheels | Maintenance Program | 10-20% |

Process Integration and Automation

Modern polishing operations benefit from integrated approaches:

Automated Material Handling

- Reduced labor costs

- Consistent processing times

- Minimized human error

Quality Control Integration

- In-line measurement systems

- Real-time process adjustment

- Reduced rework

Environmental and Safety Considerations

Cost-effective processes must also account for environmental and safety factors:

Dust Collection Systems

- Maintain clean workspace

- Protect worker health

- Recover valuable material

Waste Management

- Proper disposal procedures

- Recycling opportunities

- Regulatory compliance

Production Scale Considerations

Different production volumes require different approaches:

Small Batch Production (100-1000 pieces)

- Semi-automated systems

- Flexible tooling

- Quick changeover capability

Medium Production (1000-10000 pieces)

- Dedicated production lines

- Automated material handling

- Specialized tooling

High Volume Production (10000+ pieces)

- Fully automated systems

- Continuous flow processing

- Integrated quality control

Implementation Strategy

To successfully implement cost-effective titanium polishing:

Process Analysis

- Document current methods

- Identify bottlenecks

- Measure key metrics

Equipment Selection

- Evaluate production needs

- Consider future growth

- Calculate ROI

Training Requirements

- Operator certification

- Maintenance procedures

- Quality control methods

At PTSMAKE, we’ve successfully implemented these strategies across various production scales. Our approach focuses on balancing initial investment with long-term operational costs while maintaining the highest quality standards for our clients’ titanium components.

How To Maintain The Polish On Titanium Components Long-Term?

Have you ever admired the pristine shine of your titanium components, only to watch it fade over time? The challenge of maintaining that mirror-like finish can be frustrating, especially when these premium components represent significant investment in your projects.

Maintaining polished titanium components requires a combination of proper cleaning techniques, protective measures, and regular maintenance. The key is using pH-neutral cleaners, avoiding abrasive materials, and implementing preventive measures like protective coatings to preserve the surface finish.

Understanding the Fundamentals of Titanium Surface Care

Titanium’s unique properties make it an excellent choice for various applications, but maintaining its polished surface requires specific attention. The metal naturally forms a protective passivation layer7 that helps prevent corrosion, but this layer can be compromised by improper maintenance practices.

Regular Cleaning Protocol

Initial Inspection

- Check for surface contaminants

- Identify any scratches or damage

- Document the current condition

Cleaning Process

- Use pH-neutral cleaners

- Apply with microfiber cloths

- Avoid circular motions when wiping

Advanced Maintenance Techniques

Professional Polishing Methods

Working at PTSMAKE, I’ve developed specific techniques for maintaining titanium finishes. Here’s a comprehensive breakdown of professional polishing methods:

| Polishing Stage | Tool Type | Compound Grade | Speed (RPM) |

|---|---|---|---|

| Rough | Fabric wheel | 120-240 grit | 1500-2000 |

| Medium | Cotton wheel | 400-800 grit | 1200-1500 |

| Fine | Felt wheel | 1000+ grit | 800-1200 |

Protective Measures

The longevity of polished titanium surfaces depends heavily on protective measures:

Environmental Controls

- Maintain controlled humidity levels

- Minimize exposure to extreme temperatures

- Protect from direct sunlight when possible

Storage Solutions

- Use dedicated storage containers

- Include moisture-absorbing materials

- Maintain separation between components

Prevention of Common Issues

Surface Contamination Management

Understanding how to prevent contamination is crucial:

Material Handling

- Always wear clean gloves

- Use designated tools

- Maintain a clean work environment

Environmental Factors

- Monitor air quality

- Control dust levels

- Regulate temperature variations

Long-term Protection Strategies

In my experience at PTSMAKE, implementing these protection strategies has significantly extended the life of polished finishes:

Coating Applications

- Consider ceramic coatings

- Apply nano-protective films

- Use industrial-grade sealants

Periodic Maintenance Schedule

- Weekly visual inspections

- Monthly detailed cleaning

- Quarterly professional assessment

Advanced Troubleshooting

Common Problems and Solutions

Surface Oxidation

- Immediate cleaning with appropriate solutions

- Professional restoration if needed

- Preventive coating application

Scratch Management

- Assessment of scratch depth

- Appropriate polishing technique selection

- Prevention strategy implementation

Quality Control Measures

We at PTSMAKE implement strict quality control procedures:

| Inspection Point | Frequency | Method | Action Required |

|---|---|---|---|

| Visual Check | Daily | Direct observation | Document changes |

| Surface Testing | Weekly | Digital microscopy | Record measurements |

| Coating Integrity | Monthly | Chemical testing | Update protection |

Optimization of Maintenance Procedures

Documentation Requirements

- Maintain detailed maintenance logs

- Track environmental conditions

- Record all cleaning procedures

Training Requirements

- Proper handling techniques

- Cleaning procedure training

- Emergency response protocols

Equipment and Tools Selection

For optimal maintenance, select appropriate tools:

Essential Tools

- Microfiber cloths

- pH-neutral cleaners

- Protective gloves

- Inspection equipment

Professional Equipment

- Digital microscopes

- Surface testing tools

- Professional polishing equipment

By following these comprehensive guidelines and maintaining consistent care procedures, you can significantly extend the life of your polished titanium components. At PTSMAKE, we’ve successfully implemented these methods across numerous projects, ensuring long-lasting surface quality for our clients’ components.

What Industry Standards Apply To Titanium Polishing For Aerospace Applications?

Have you ever wondered why some titanium aerospace components shine like mirrors while others appear dull? The difference lies in the polishing standards, but navigating these requirements can be overwhelming. Many engineers struggle to meet the exact specifications, risking costly project delays and potential safety issues.

In aerospace applications, titanium polishing must comply with key standards including AMS 2700, ASTM B600, and AS9100. These standards define surface roughness requirements, material removal tolerances, and quality control procedures to ensure component performance and safety.

Understanding Core Aerospace Polishing Standards

When it comes to titanium polishing in aerospace applications, several critical standards guide the process. At PTSMAKE, we’ve implemented comprehensive systems to meet these requirements. The primary standards include:

AMS 2700 Requirements

This standard specifically addresses mechanical finishing of metals. For titanium components, it outlines:

- Surface roughness parameters

- Acceptable polishing methods

- Quality control procedures

- Documentation requirements

The standard emphasizes the importance of surface profilometry8 measurements to verify finish quality.

ASTM B600 Specifications

This standard focuses on:

- Material removal rates

- Surface integrity requirements

- Testing procedures

- Acceptance criteria

Surface Finish Requirements

Different aerospace applications require various surface finish levels:

| Application Type | Ra Value (μin) | Surface Treatment |

|---|---|---|

| Engine Components | 4-8 | Mirror Polish |

| Structural Parts | 16-32 | Standard Polish |

| Interior Components | 32-63 | Utility Finish |

Quality Control Measures

Inspection Methods

The polishing process requires rigorous quality control, including:

- Visual inspection under specific lighting conditions

- Surface roughness measurements

- Material thickness verification

- Contamination testing

Documentation Requirements

Every polishing operation must maintain:

- Process control records

- Inspection results

- Material certifications

- Operator qualifications

Environmental and Safety Standards

The polishing process must also comply with:

EPA Requirements

- Proper disposal of polishing residues

- Air quality monitoring

- Water treatment protocols

OSHA Standards

- Personal protective equipment requirements

- Ventilation specifications

- Chemical handling procedures

Material-Specific Considerations

Different titanium alloys require specific approaches:

Ti-6Al-4V Requirements

This common aerospace alloy needs:

- Controlled pressure application

- Specific polishing compound selection

- Temperature monitoring during processing

Other Titanium Alloys

Various other alloys have unique requirements:

- Beta titanium alloys need special handling

- Alpha-case prevention measures

- Specific cooling requirements

Process Validation

The polishing process must be validated through:

Initial Qualification

- First article inspection

- Process capability studies

- Operator certification

Ongoing Monitoring

- Statistical process control

- Regular calibration checks

- Periodic revalidation

Industry Specific Requirements

Different sectors within aerospace have varying standards:

Commercial Aviation

- FAA compliance requirements

- OEM specific standards

- Maintenance repair overhaul specifications

Military Applications

- Military specifications (MIL-SPEC)

- Additional security requirements

- Specialized finish requirements

Future Trends in Standards

The industry continues to evolve with:

- Increased automation requirements

- Digital documentation standards

- Enhanced traceability requirements

- Sustainable processing standards

At PTSMAKE, we maintain strict adherence to these standards while continuously updating our processes to meet emerging requirements. Our experienced team ensures that every titanium component receives the appropriate treatment according to its specific application and regulatory requirements.

The key to successful titanium polishing lies in understanding and implementing these standards effectively. Through our systematic approach and advanced quality control systems, we help our clients navigate these complex requirements while delivering consistently high-quality results.

How To Achieve Different Surface Finishes When Polishing Titanium?

Have you ever struggled to achieve the perfect surface finish on titanium components? It’s frustrating when your polishing efforts result in inconsistent finishes, unwanted scratches, or worse – dimensional inaccuracies that could compromise the entire part’s functionality.

Achieving different surface finishes on titanium requires specific techniques and tools. The process typically involves mechanical polishing, chemical polishing, or a combination of both, depending on the desired finish – from mirror-like to matte surfaces.

Understanding Titanium Polishing Fundamentals

Material Properties and Challenges

Titanium’s unique work hardening characteristics9 make it particularly challenging to polish. At PTSMAKE, we’ve developed specialized approaches to handle these challenges effectively. The material’s high strength-to-weight ratio and excellent corrosion resistance make it popular in aerospace and medical applications, but these same properties also make it difficult to achieve consistent surface finishes.

Types of Surface Finishes

There are several common surface finishes achievable on titanium:

| Finish Type | Ra Value (μm) | Common Applications | Recommended Process |

|---|---|---|---|

| Mirror | 0.01-0.05 | Medical Implants | Multi-stage mechanical + chemical |

| Satin | 0.2-0.6 | Architectural | Mechanical brushing |

| Matte | 0.8-1.6 | Industrial | Bead blasting |

| Textured | >1.6 | Aerospace | Chemical etching |

Mechanical Polishing Techniques

Manual Polishing Steps

Coarse Grinding

- Start with 80-grit abrasives

- Apply consistent pressure

- Maintain proper tool speed (1500-2000 RPM)

Fine Grinding

- Progress through 120, 240, and 400 grit

- Use cooling lubricant to prevent heat buildup

- Check surface regularly for uniformity

Final Polishing

- Use specialized titanium polishing compounds

- Apply with soft polishing wheels

- Monitor temperature carefully

Automated Polishing Systems

Modern CNC polishing machines offer several advantages:

- Consistent pressure application

- Precise control over polishing parameters

- Repeatable results across multiple parts

Chemical Polishing Methods

Chemical Bath Composition

The standard chemical polishing solution typically contains:

| Chemical Component | Concentration Range | Function |

|---|---|---|

| Hydrofluoric Acid | 10-15% | Surface etching |

| Nitric Acid | 15-20% | Oxidation control |

| Water | Balance | Solution stability |

Process Parameters

Critical factors for chemical polishing include:

- Temperature control (35-45°C)

- Immersion time (5-15 minutes)

- Agitation speed

- Bath concentration monitoring

Hybrid Finishing Approaches

Combined Mechanical-Chemical Processing

This method offers several benefits:

- Reduced processing time

- Better surface uniformity

- Enhanced corrosion resistance

- Improved dimensional control

Quality Control Measures

To ensure consistent results:

- Regular surface roughness measurements

- Visual inspection under proper lighting

- Documentation of process parameters

- Sample retention for reference

Advanced Finishing Technologies

Electropolishing Applications

Electropolishing can achieve:

- Superior smoothness

- Enhanced corrosion resistance

- Improved biocompatibility

- Consistent results

Plasma Polishing

Benefits include:

- No chemical waste

- Precise control

- Environmentally friendly

- Suitable for complex geometries

Industry-Specific Requirements

Medical Industry Standards

Medical components require:

- Biocompatible finish

- Documentation of all processes

- Validated cleaning procedures

- Regular testing protocols

Aerospace Specifications

Aerospace parts demand:

- Strict surface roughness tolerances

- Non-destructive testing

- Complete traceability

- Certified processes

Troubleshooting Common Issues

Common problems and solutions:

Orange Peel Effect

- Adjust pressure

- Modify polishing speed

- Change abrasive type

Surface Scratches

- Review grit progression

- Check tool condition

- Ensure proper lubrication

Uneven Finish

- Maintain consistent pressure

- Monitor process parameters

- Verify material condition

How To Verify Surface Quality After Polishing Titanium Parts?

Have you ever stared at a polished titanium part, wondering if it truly meets your quality standards? The anxiety of not knowing whether the surface finish will pass inspection can be overwhelming, especially when strict aerospace or medical specifications are on the line.

To verify surface quality after polishing titanium parts, you need to employ both visual inspection and quantitative measurements. This includes using surface roughness testers, optical comparators, and microscopic analysis while following industry standards like ASTM B265 for surface finish requirements.

Understanding Surface Quality Parameters

Surface quality verification for polished titanium involves multiple parameters that need careful examination. At PTSMAKE, we focus on these key aspects to ensure our clients receive parts that meet their exact specifications.

Visual Inspection Criteria

- Surface uniformity

- Absence of scratches

- Consistent shine

- No visible defects

- Color consistency

Quantitative Measurements

The profilometry10 measurements provide crucial data about surface characteristics:

| Parameter | Description | Typical Range |

|---|---|---|

| Ra | Average Roughness | 0.1-0.8 µm |

| Rz | Maximum Height | 0.5-3.0 µm |

| Rq | Root Mean Square | 0.2-1.0 µm |

Advanced Inspection Methods

Surface Roughness Testing

I recommend using calibrated surface roughness testers for accurate measurements. These devices should be regularly calibrated and operated by trained personnel. At our facility, we maintain detailed records of all measurements to ensure traceability.

Optical Analysis

Modern optical comparators and microscopes help detect:

- Surface irregularities

- Micro-scratches

- Pattern consistency

- Material defects

Industry-Specific Requirements

Different industries have varying requirements for polished titanium surfaces:

Medical Industry

- Ultra-smooth finish (Ra < 0.2 µm)

- Bio-compatible surface

- Validated cleaning processes

- Documentation requirements

Aerospace Applications

- Strict adherence to AS9100 standards

- Specific surface treatment requirements

- Stress-free surface finish

- Corrosion resistance verification

Common Quality Issues and Solutions

Surface Defects Prevention

- Proper tool selection

- Controlled pressure application

- Appropriate polishing compound selection

- Regular equipment maintenance

Quality Control Process

| Stage | Action | Documentation |

|---|---|---|

| Pre-Polish | Material inspection | Incoming QC report |

| During Polish | Process monitoring | In-process check sheet |

| Post-Polish | Final inspection | Quality certification |

Documentation Requirements

Maintaining proper documentation is crucial for quality verification:

Required Records

- Material certificates

- Process parameters

- Inspection results

- Non-conformance reports

- Corrective actions

Environmental Considerations

The inspection environment plays a crucial role in accurate measurements:

Controlled Conditions

- Temperature: 20°C ± 2°C

- Humidity: 45-55%

- Clean, dust-free environment

- Proper lighting conditions

Best Practices for Verification

To ensure consistent results, follow these guidelines:

Measurement Protocol

- Clean the surface thoroughly

- Allow temperature stabilization

- Take multiple measurements

- Document all findings

- Compare with reference standards

Quality Assurance Steps

- Regular calibration checks

- Operator training verification

- Standard operating procedures

- Quality system updates

- Continuous improvement programs

Statistical Process Control

Implementing SPC helps maintain consistent quality:

| Control Aspect | Frequency | Action Level |

|---|---|---|

| X-bar Charts | Daily | ±2σ |

| Range Charts | Per batch | Upper control limit |

| Capability Studies | Monthly | Cpk > 1.33 |

Troubleshooting Guide

When issues arise during verification:

Common Problems

- Inconsistent readings

- Equipment malfunctions

- Environmental interference

- Operator error

Corrective Actions

- Equipment recalibration

- Process adjustment

- Environmental control

- Additional training

Through implementing these comprehensive verification methods at PTSMAKE, we’ve consistently delivered high-quality polished titanium parts to our clients in medical, aerospace, and industrial sectors. Remember that successful surface quality verification requires a systematic approach combining visual inspection, quantitative measurements, and proper documentation.

Click here to learn more about work hardening and its effects on metal finishing processes. ↩

Click to learn about the crystalline structure of titanium and its impact on polishing techniques. ↩

Click here to learn about titanium’s unique protective oxide formation process. ↩

Click here to learn about the fire risks of reactive metals and prevention strategies. ↩

Click to learn more about passivation techniques that can extend your titanium components’ lifespan. ↩

Click to learn more about surface measurement techniques and their impact on cost efficiency. ↩

Click to learn about this crucial protective layer and how it affects your titanium components’ durability. ↩

Click to learn more about surface measurement techniques and their importance in aerospace applications. ↩

Click to learn more about work hardening and its impact on titanium polishing techniques. ↩

Click to learn more about surface measurement techniques and industry best practices. ↩