When sourcing plastic materials, I often hear engineers using "Delrin" and "POM" interchangeably. This confusion can lead to costly mistakes in material selection and potentially impact the final product’s performance.

While Delrin and POM are related, they’re not exactly the same. Delrin is DuPont’s trademark name for their POM homopolymer, while POM (Polyoxymethylene) is the generic name for a family of engineering thermoplastic materials.

I want to clarify something important here. Many engineers I work with initially think these materials are completely interchangeable, but there are subtle differences that can significantly impact your project’s success. Understanding these distinctions is crucial for making informed material choices for your applications, and I’ll explain why.

What Kind Of Plastic Is Delrin?

Have you ever struggled to choose the right plastic material for your precision parts? In the world of engineering plastics, making the wrong choice can lead to premature part failure, costly replacements, and production delays that could seriously impact your project timeline.

Delrin, also known as Polyoxymethylene (POM), is a high-performance engineering thermoplastic known for its exceptional strength, stiffness, and dimensional stability. It belongs to the acetal family of plastics and offers excellent wear resistance, low friction, and good machinability.

Chemical Composition and Structure

The unique properties of Delrin stem from its molecular structure. When we look at its composition, Delrin consists of alternating methylene groups (-CH2-) connected by oxygen atoms, forming a homopolymer1 chain. This structure gives Delrin its characteristic strength and stability.

Basic Chemical Properties

- Molecular Formula: (-CH2O-)n

- Density: 1.41-1.43 g/cm³

- Melting Point: 175°C (347°F)

- Glass Transition Temperature: -60°C (-76°F)

Key Material Properties

At PTSMAKE, we regularly work with Delrin for various precision parts. Here are the main properties that make it stand out:

Mechanical Properties

- High tensile strength

- Superior fatigue resistance

- Excellent creep resistance

- Good impact resistance

- Low friction coefficient

Physical Properties

- Outstanding dimensional stability

- Low moisture absorption

- Good electrical insulation

- Chemical resistance to many solvents

- Natural lubricity

Common Grades and Classifications

Delrin comes in various grades, each optimized for specific applications:

| Grade Type | Key Features | Typical Applications |

|---|---|---|

| Standard Grades | Basic mechanical properties | General purpose parts |

| High Performance | Enhanced strength and stiffness | Precision gears, bearings |

| UV Stabilized | Better weather resistance | Outdoor applications |

| Food Grade | FDA compliant | Food processing equipment |

Manufacturing Methods

In my experience at PTSMAKE, we primarily process Delrin through:

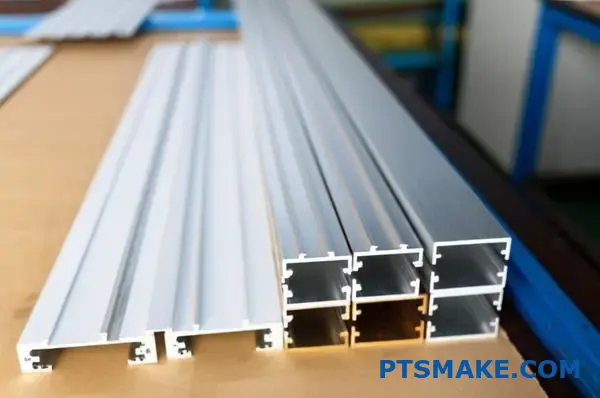

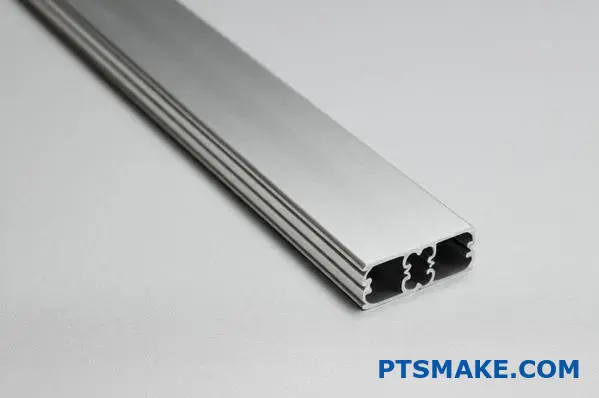

CNC Machining

- Excellent machinability

- Tight tolerances achievable

- Complex geometries possible

- Smooth surface finish

Injection Molding

- Good flow characteristics

- Minimal shrinkage

- Consistent part quality

- High volume production capability

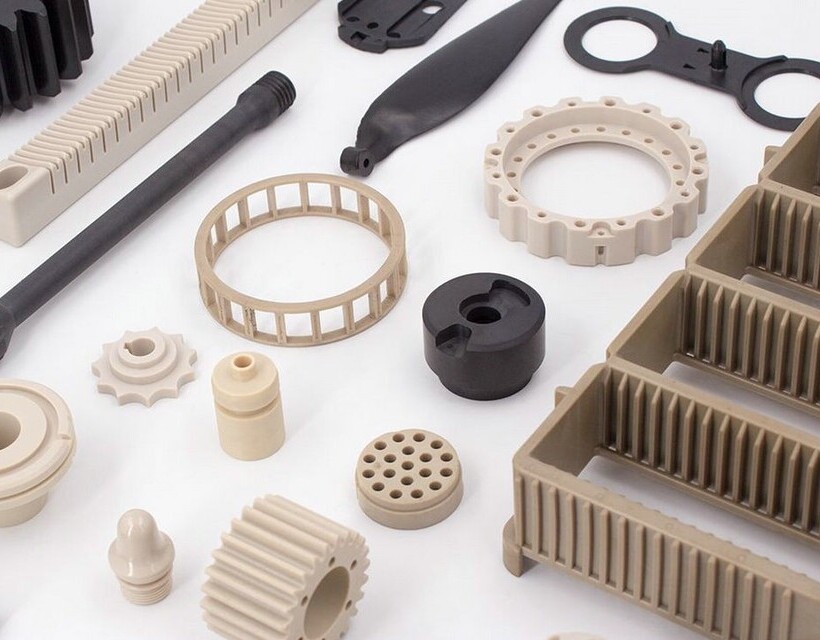

Applications Across Industries

Delrin finds extensive use in various industries:

Automotive

- Fuel system components

- Interior mechanisms

- Belt tensioners

- Door lock systems

Consumer Electronics

- Smartphone components

- Laptop hinges

- Camera mechanisms

- Audio equipment parts

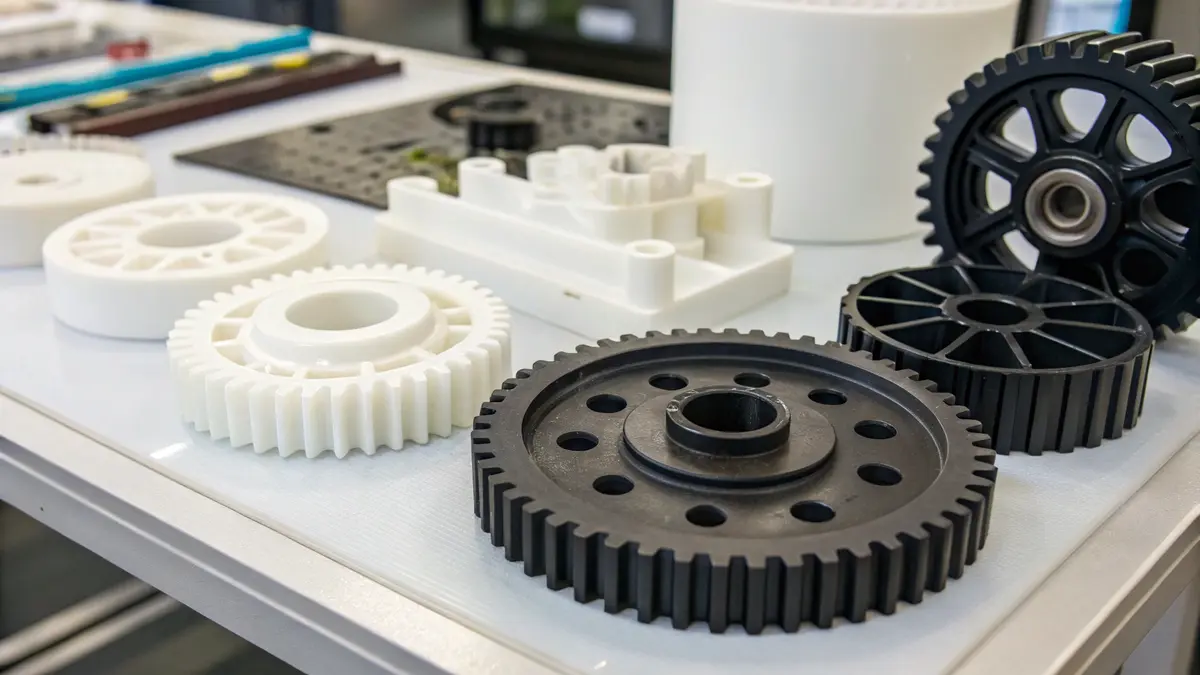

Industrial Equipment

- Conveyor components

- Pump parts

- Valve bodies

- Precision gears

Medical Devices

- Surgical instruments

- Drug delivery devices

- Dental applications

- Laboratory equipment

Performance Comparison

Let’s compare Delrin with other common engineering plastics:

| Property | Delrin | Nylon | PEEK | PET |

|---|---|---|---|---|

| Strength | High | Medium | Very High | Medium |

| Cost | Moderate | Low | High | Low |

| Chemical Resistance | Good | Fair | Excellent | Good |

| Wear Resistance | Excellent | Good | Excellent | Fair |

Design Considerations

When designing parts with Delrin, consider these factors:

Material Selection

- Operating temperature requirements

- Chemical exposure conditions

- Load-bearing requirements

- Cost constraints

Manufacturing Guidelines

- Wall thickness uniformity

- Draft angles for molded parts

- Gate locations

- Cooling considerations

At PTSMAKE, we’ve successfully manufactured countless precision components using Delrin. The material’s versatility and reliability make it an excellent choice for many engineering applications. Our experience with both CNC machining and injection molding of Delrin allows us to optimize part design and manufacturing processes for optimal performance.

Why Is Delrin So Expensive?

The rising cost of Delrin has become a significant concern for manufacturers and engineers. I’ve noticed many clients struggling with budget constraints when sourcing this material, especially when prices keep climbing year after year. The situation becomes even more challenging when projects require large quantities of Delrin parts.

Delrin’s high price is primarily due to its complex manufacturing process, superior mechanical properties, and the increasing demand from various industries. The material requires specialized production facilities, strict quality control, and premium raw materials, all contributing to its elevated cost structure.

Raw Material Production Complexity

Advanced Polymerization Process

The production of Delrin, or polyoxymethylene (POM), involves a sophisticated polymerization2 process. This process requires precise control of temperature, pressure, and chemical conditions. At PTSMAKE, we’ve observed that the complexity of this process significantly impacts the final material cost.

Quality Control Requirements

The manufacturing of Delrin demands rigorous quality control measures:

| Quality Parameter | Control Requirement | Impact on Cost |

|---|---|---|

| Molecular Weight | Strict monitoring | High |

| Crystallinity | Precise control | Medium |

| Thermal Stability | Continuous testing | High |

| Chemical Purity | Advanced filtration | Very High |

Market Dynamics

Supply Chain Factors

The global supply chain for Delrin raw materials faces several challenges:

- Limited number of qualified manufacturers

- Transportation costs for specialized handling

- Storage requirements for maintaining material properties

- Inventory management complexities

Industry Demand Patterns

Different sectors contribute to the high demand for Delrin:

| Industry | Usage Volume | Price Sensitivity |

|---|---|---|

| Automotive | Very High | Medium |

| Electronics | High | High |

| Medical | Medium | Low |

| Aerospace | Low | Very Low |

Technical Advantages That Justify the Cost

Superior Mechanical Properties

Delrin’s exceptional characteristics make it worth the investment:

- High tensile strength and stiffness

- Excellent fatigue resistance

- Low friction coefficient

- Outstanding dimensional stability

Long-term Cost Benefits

While initial material costs are high, Delrin often provides better value over time:

- Reduced maintenance requirements

- Extended component lifespan

- Lower replacement frequency

- Minimal lubrication needs

Processing Requirements

Specialized Equipment Needs

Manufacturing Delrin parts requires specific machinery and tooling:

- Temperature-controlled processing equipment

- Wear-resistant tooling

- Precise cooling systems

- Advanced quality control instruments

Technical Expertise

The processing of Delrin demands skilled operators and engineers who understand:

- Material behavior during processing

- Optimal processing parameters

- Quality control procedures

- Troubleshooting techniques

Cost Optimization Strategies

Design Optimization

At PTSMAKE, we help clients optimize their designs to reduce material usage while maintaining performance:

- Wall thickness optimization

- Strategic placement of ribs and supports

- Part consolidation opportunities

- Material selection alternatives where appropriate

Production Efficiency

We implement various strategies to manage costs:

- Batch size optimization

- Process automation

- Scrap reduction

- Efficient tooling design

Environmental Considerations

Sustainability Impact

Environmental factors affecting Delrin’s cost include:

- Energy-intensive production processes

- Environmental compliance requirements

- Recycling challenges

- Waste management costs

Regulatory Compliance

Meeting environmental regulations adds to the cost:

- Emissions control equipment

- Waste treatment systems

- Documentation requirements

- Certification processes

Future Price Trends

Market Outlook

Several factors suggest continued price pressure:

- Growing demand from emerging industries

- Raw material availability

- Energy cost fluctuations

- Technology advancement requirements

Innovation Impact

Ongoing research and development may affect future pricing:

- New production methods

- Alternative materials development

- Process efficiency improvements

- Quality enhancement techniques

This comprehensive analysis shows why Delrin commands premium pricing in the market. While the cost may seem high initially, the material’s superior properties and long-term benefits often justify the investment for critical applications. At PTSMAKE, we work closely with our clients to optimize designs and processes, ensuring they get the best value from their Delrin components while maintaining the highest quality standards.

Is Delrin The Same As Teflon?

When working with engineering plastics, I often encounter confusion from clients about Delrin and Teflon. Many believe these materials are interchangeable, leading to costly design mistakes and project delays. The misunderstanding becomes even more problematic when critical components fail due to incorrect material selection.

Delrin and Teflon are distinctly different engineering plastics. While Delrin (POM) is a thermoplastic known for its high strength and stiffness, Teflon (PTFE) is renowned for its low friction and non-stick properties. Each material serves unique purposes in engineering applications.

Physical Properties and Chemical Composition

The fundamental differences between these materials start at the molecular level. Delrin, also known as Polyoxymethylene (POM), features a highly crystalline structure that gives it exceptional mechanical properties. In contrast, Teflon’s polytetrafluoroethylene3 structure creates its unique non-stick characteristics.

Material Structure Comparison

| Property | Delrin (POM) | Teflon (PTFE) |

|---|---|---|

| Chemical Structure | (-CH2O-)n | (-CF2-CF2-)n |

| Crystallinity | 75-85% | 92-98% |

| Density (g/cm³) | 1.41-1.43 | 2.13-2.20 |

| Melting Point (°C) | 175 | 327 |

Performance Characteristics

At PTSMAKE, I’ve worked with both materials extensively in various manufacturing projects. Here’s what makes each unique:

Mechanical Properties

Delrin Strengths

- High tensile strength (63-70 MPa)

- Excellent fatigue resistance

- Superior dimensional stability

- Good wear resistance

- High stiffness

Teflon Advantages

- Extremely low friction coefficient (0.1)

- Outstanding chemical resistance

- Excellent thermal stability

- Non-stick properties

- Self-lubricating

Application Differences

Based on my manufacturing experience, these materials serve different purposes:

Delrin Best Uses

- Precision mechanical parts

- Gears and bearings

- Automotive components

- Consumer electronics

- Medical devices

Teflon Optimal Applications

- Non-stick coatings

- Chemical processing equipment

- Electrical insulation

- Bearings and seals

- Medical implants

Cost and Processing Considerations

The manufacturing process significantly impacts material selection:

Processing Methods

| Manufacturing Process | Delrin | Teflon |

|---|---|---|

| Injection Molding | Excellent | Limited |

| Machining | Good | Excellent |

| Compression Molding | Not Common | Common |

| Extrusion | Good | Excellent |

Temperature and Environmental Factors

Understanding environmental limitations is crucial:

Temperature Performance

| Temperature Range | Delrin | Teflon |

|---|---|---|

| Maximum Continuous Use (°C) | 82-105 | 260 |

| Minimum Service Temperature (°C) | -40 | -200 |

| Heat Deflection Temperature (°C) | 115 | 55 |

Industry-Specific Considerations

In my experience at PTSMAKE, material selection often depends on industry requirements:

Automotive Industry

- Delrin: Fuel system components, window systems

- Teflon: Engine seals, brake system components

Medical Industry

- Delrin: Surgical instruments, dental applications

- Teflon: Implants, pharmaceutical processing equipment

Electronics Industry

- Delrin: Connectors, spring elements

- Teflon: Cable insulation, printed circuit boards

Maintenance and Longevity

The materials differ significantly in maintenance requirements:

Long-term Performance

| Aspect | Delrin | Teflon |

|---|---|---|

| Chemical Resistance | Good | Excellent |

| UV Resistance | Fair | Excellent |

| Wear Resistance | Excellent | Good |

| Moisture Absorption | Low | None |

Through my work at PTSMAKE, I’ve observed that proper material selection significantly impacts project success. While both Delrin and Teflon are excellent engineering plastics, they serve different purposes and shouldn’t be considered interchangeable. Understanding these differences helps ensure optimal performance and longevity in your applications.

I always recommend conducting thorough material testing and consulting with experts before making final material selections. At PTSMAKE, we provide comprehensive material selection guidance and manufacturing solutions to help you make the best choice for your specific application needs.

Does DuPont Still Own Delrin?

When manufacturing engineers and procurement managers search for Delrin suppliers, they often face uncertainty about its current ownership. The market confusion stems from DuPont’s various corporate restructurings and spin-offs over the years, leaving many wondering about the authentic source of this critical engineering material.

No, DuPont no longer owns Delrin. Since 2019, DuPont’s former Performance Materials division, including Delrin, has been operated by Celanese Corporation following a $11 billion acquisition deal. Celanese now manufactures and distributes Delrin acetal homopolymer resins globally.

The Journey of Delrin Ownership

The history of Delrin ownership reflects the dynamic nature of the chemical industry. As someone deeply involved in precision manufacturing, I’ve witnessed the evolution of this material’s ownership firsthand. The timeline of ownership changes helps us understand the current situation better:

Historical Timeline

| Year | Major Event | Impact on Delrin |

|---|---|---|

| 1956 | Initial Development | DuPont introduces Delrin |

| 2015 | DowDuPont Merger | Combined chemical operations |

| 2019 | DuPont Spin-off | Performance Materials division separated |

| 2022 | Celanese Acquisition | Complete transfer of ownership |

Impact on Manufacturing Industry

The transfer of Delrin ownership to Celanese has brought several changes to the manufacturing landscape. The material’s polymerization4 process remains consistent, but there have been subtle shifts in:

Supply Chain Dynamics

- Distribution networks have been reorganized

- New quality control protocols implemented

- Updated certification processes established

- Modified pricing structures introduced

Product Development and Innovation

At PTSMAKE, we’ve adapted to these changes while maintaining our high-quality injection molding services. The transition has actually opened up new opportunities for innovation in Delrin applications:

- Enhanced material grades for specific industries

- Improved processing guidelines

- New technical support systems

- Expanded application possibilities

Market Response and Quality Assurance

The market’s response to the ownership change has been largely positive. As a manufacturer working extensively with Delrin, I can confirm that Celanese has maintained the material’s renowned qualities:

Quality Parameters

- Mechanical properties remain consistent

- Chemical resistance standards upheld

- Thermal stability specifications maintained

- Processing characteristics preserved

Future Outlook and Industry Implications

The future of Delrin under Celanese ownership looks promising. Based on current market trends and our experience at PTSMAKE, we anticipate:

Short-term Developments

- Increased material availability

- More specialized grades for specific applications

- Enhanced technical support

- Competitive pricing structures

Long-term Industry Impact

- Greater innovation in material properties

- Expanded global distribution networks

- More sustainable manufacturing processes

- Improved end-user support systems

Practical Considerations for Manufacturers

For manufacturers and engineers working with Delrin, the ownership change requires attention to several key aspects:

Material Specification Updates

- Review material certifications

- Update supplier documentation

- Verify quality control processes

- Confirm compliance requirements

Supply Chain Adjustments

- Evaluate new distribution channels

- Assess lead time changes

- Review pricing structures

- Update supplier agreements

At PTSMAKE, we’ve successfully navigated these changes while maintaining our high standards in precision manufacturing. Our experience with both DuPont and Celanese Delrin has enabled us to provide consistent quality in our injection molding services.

Technical Support and Resources

The transition has brought changes to technical support structures. Manufacturers should be aware of:

Available Resources

- Updated material datasheets

- New processing guidelines

- Technical consultation services

- Quality assurance documentation

Industry Compliance

While ownership has changed, Delrin’s core specifications and industry certifications remain intact. This includes:

- FDA compliance for food-grade applications

- ISO certifications

- Industry-specific standards

- Environmental regulations

The ownership transition from DuPont to Celanese represents a significant shift in the industry, but one that has been managed effectively to maintain product quality and reliability. As a manufacturing professional, I’ve observed that the material’s fundamental characteristics and performance capabilities remain unchanged, ensuring continuity for manufacturers and end-users alike.

What Plastic Is Similar To Delrin?

Finding the right plastic material for your project can be overwhelming. With countless options available, identifying alternatives to Delrin that offer similar properties while potentially being more cost-effective or better suited for specific applications can feel like searching for a needle in a haystack.

Several plastics share properties similar to Delrin, with POM-C (Polyoxymethylene Copolymer) being the closest alternative. It offers comparable strength, wear resistance, and machinability, making it an excellent substitute in many engineering applications.

Understanding POM-C as a Delrin Alternative

POM-C stands out as the primary alternative to Delrin due to its nearly identical molecular structure. At PTSMAKE, I’ve worked extensively with both materials, and their similarities in terms of mechanical properties are remarkable. The main difference lies in their crystallization5 process, which affects their dimensional stability slightly.

Key Properties Comparison

| Property | Delrin (POM-H) | POM-C |

|---|---|---|

| Tensile Strength | 70 MPa | 65 MPa |

| Hardness (Rockwell M) | 94 | 90 |

| Melting Point | 175°C | 165°C |

| Chemical Resistance | Excellent | Very Good |

| Cost | Higher | Lower |

Other Notable Alternatives

Nylon (PA6 and PA66)

Nylon serves as another viable alternative to Delrin, particularly in applications where impact resistance is crucial. While working with various clients at PTSMAKE, I’ve noticed that Nylon often outperforms Delrin in terms of:

- Impact resistance

- Flexibility

- Cost-effectiveness

- Wear resistance in wet conditions

PEEK (Polyether Ether Ketone)

PEEK represents a high-performance alternative, albeit at a higher price point. It excels in:

- Higher temperature resistance

- Superior chemical resistance

- Better wear properties

- Enhanced strength characteristics

Application-Specific Alternatives

Automotive Applications

For automotive components, I’ve found that these materials often serve as excellent Delrin alternatives:

- Glass-filled POM-C

- Impact-modified PBT

- Reinforced PA66

Medical Applications

In medical device manufacturing, these alternatives have proven successful:

- Medical-grade PEEK

- USP Class VI POM-C

- Medical-grade PPSU

Cost Considerations

| Material | Relative Cost (1-10) | Performance Rating (1-10) |

|---|---|---|

| Delrin | 7 | 8 |

| POM-C | 6 | 8 |

| Nylon | 5 | 7 |

| PEEK | 10 | 9 |

Manufacturing Considerations

When selecting a Delrin alternative, manufacturing processes play a crucial role. At PTSMAKE, we consider several factors:

Machining Properties

- Tool wear

- Surface finish requirements

- Dimensional stability

- Heat generation during processing

Injection Molding Characteristics

- Mold shrinkage

- Gate location options

- Cooling requirements

- Cycle time optimization

Environmental Impact

Recyclability Comparison

| Material | Recyclability | Environmental Impact |

|---|---|---|

| Delrin | Moderate | Medium |

| POM-C | Good | Medium |

| Nylon | Excellent | Low |

| PEEK | Limited | High |

Performance in Specific Environments

Understanding environmental factors is crucial when selecting alternatives:

High Temperature Applications

- PEEK excels in high-temperature environments

- PPS offers good temperature resistance

- Modified POM-C maintains stability

Chemical Exposure

- POM-C shows excellent chemical resistance

- PEEK provides superior chemical resistance

- Modified Nylon offers good chemical resistance

Quality Control Considerations

When working with Delrin alternatives, proper quality control measures are essential:

- Dimensional stability monitoring

- Moisture content testing

- Mechanical property verification

- Visual inspection protocols

Decision-Making Framework

To help select the right Delrin alternative, consider:

- Application requirements

- Environmental conditions

- Cost constraints

- Manufacturing processes

- Quality requirements

Through my experience at PTSMAKE, I’ve found that successful material selection often depends on carefully balancing these factors rather than focusing solely on material properties. We maintain comprehensive material databases and testing capabilities to help clients make informed decisions about Delrin alternatives.

By understanding these alternatives and their specific characteristics, you can make an informed decision that best suits your application requirements while potentially reducing costs or improving performance. Each alternative offers unique advantages, and the key lies in matching these benefits to your specific needs.

Does Delrin Break Easily?

Are you concerned about the durability of Delrin for your critical engineering applications? Many designers and engineers face sleepless nights worrying about material failure, especially when their projects demand both strength and precision.

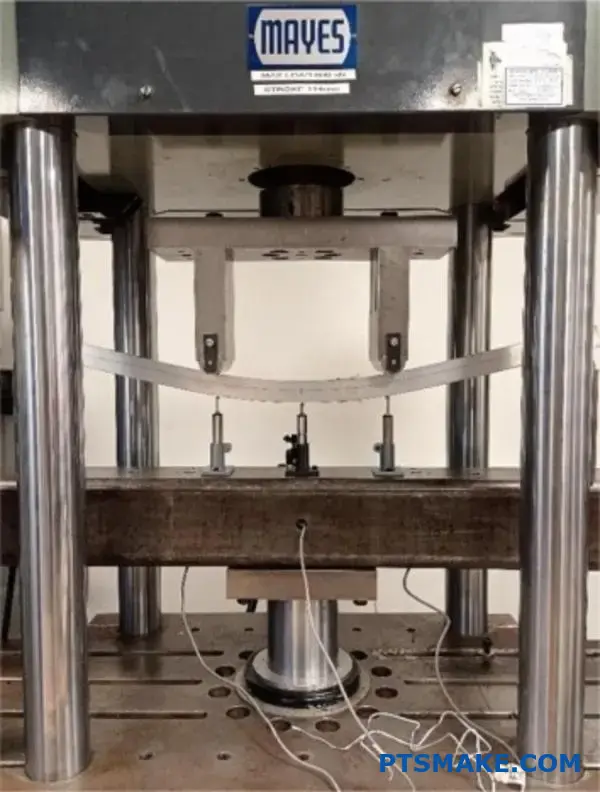

Delrin doesn’t break easily under normal conditions. It offers exceptional mechanical strength, fatigue resistance, and dimensional stability. With a tensile strength ranging from 8,000 to 10,000 PSI, Delrin is one of the most durable engineering plastics available for precision parts.

Understanding Delrin’s Break Resistance

At PTSMAKE, I’ve observed that Delrin’s break resistance is directly related to its unique molecular structure. The material exhibits homopolymer crystallization6, which provides superior mechanical properties. This crystalline structure creates a robust framework that resists breaking under various conditions.

Factors Affecting Delrin’s Break Resistance

Several key factors influence how well Delrin resists breaking:

- Temperature Exposure

- Chemical Environment

- Load Type and Duration

- Manufacturing Quality

- Design Considerations

Comparative Strength Analysis

Let’s examine how Delrin compares to other common engineering plastics:

| Material | Tensile Strength (PSI) | Impact Resistance (ft-lb/in) | Temperature Resistance (°F) |

|---|---|---|---|

| Delrin | 8,000-10,000 | 1.0-2.0 | -40 to 180 |

| Nylon 6 | 7,000-8,000 | 0.8-1.5 | -40 to 170 |

| PEEK | 14,000-16,000 | 1.6-3.0 | -40 to 480 |

| POM-C | 7,500-9,000 | 0.9-1.8 | -40 to 160 |

Breaking Mechanisms and Prevention

Impact Resistance

Delrin demonstrates excellent impact resistance due to its high crystallinity. At PTSMAKE, we’ve successfully implemented Delrin in various high-impact applications, from automotive components to industrial machinery parts.

Fatigue Resistance

One of Delrin’s standout features is its exceptional fatigue resistance. The material can withstand repeated stress cycles without significant degradation, making it ideal for:

- Gear mechanisms

- Bearing components

- Moving parts

- High-cycle applications

Chemical Resistance

The material’s resistance to chemicals plays a crucial role in preventing degradation and subsequent breaking. Delrin maintains its structural integrity when exposed to:

- Most solvents

- Neutral chemicals

- Weak acids

- Automotive fluids

Design Considerations for Break Prevention

Proper Wall Thickness

To optimize break resistance, consider these wall thickness guidelines:

- Minimum wall thickness: 0.040 inches

- Recommended thickness: 0.060-0.120 inches

- Maximum thickness: 0.250 inches

Stress Distribution

Even stress distribution is crucial for preventing breaks. Implementation of proper design features includes:

- Rounded corners

- Gradual transitions

- Reinforcement ribs

- Uniform wall thickness

Manufacturing Impact on Break Resistance

The manufacturing process significantly influences Delrin’s break resistance. At PTSMAKE, we employ:

- Precise temperature control during molding

- Optimal cooling rates

- Proper gate locations

- Quality material handling procedures

Quality Control Measures

To ensure maximum break resistance, we implement:

- Material certification checks

- In-process monitoring

- Post-production testing

- Dimensional verification

Real-World Applications

Delrin’s break resistance makes it ideal for:

Industrial Applications

- Conveyor components

- Precision bushings

- Industrial fasteners

- Machine parts

Consumer Products

- High-end appliance parts

- Sports equipment components

- Electronic device housings

- Automotive interior components

Environmental Factors

Understanding environmental influences helps predict and prevent breaking:

Temperature Effects

- Optimal performance range: 32°F to 180°F

- Reduced strength at elevated temperatures

- Increased brittleness at low temperatures

Moisture Impact

- Limited moisture absorption

- Stable dimensional properties

- Consistent mechanical performance

Long-Term Performance

For sustained break resistance:

- Regular maintenance inspection

- Proper loading conditions

- Environmental control

- Periodic part replacement when needed

Professional Recommendations

As a manufacturing professional, I recommend:

- Thorough material selection analysis

- Comprehensive design review

- Proper manufacturing process control

- Regular quality assurance testing

Through these various aspects, it’s clear that Delrin’s break resistance is exceptional when properly designed, manufactured, and applied. At PTSMAKE, we continue to push the boundaries of what’s possible with this versatile material, ensuring our clients receive components that meet or exceed their durability requirements.

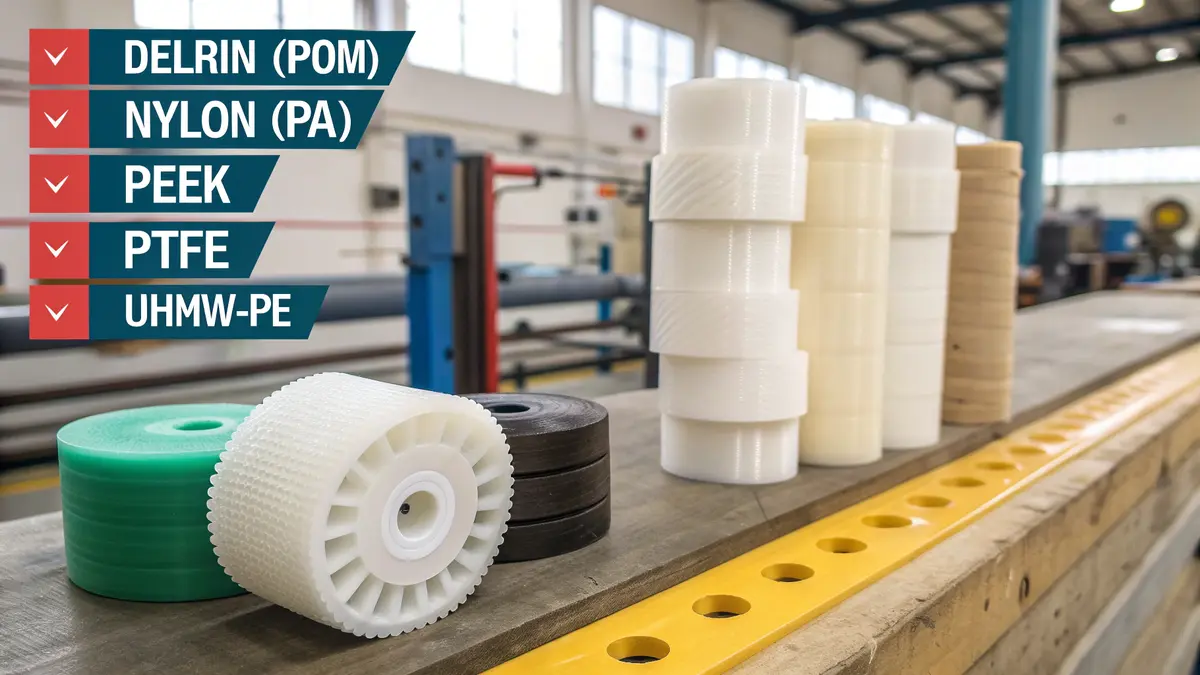

What Material Is Equivalent To Delrin?

Finding alternative materials to Delrin can be challenging when you need specific mechanical properties for your projects. I’ve seen many engineers struggle to identify suitable replacements, often leading to project delays and increased costs due to limited material options.

The closest equivalents to Delrin (POM) are Nylon (PA), PEEK, PTFE, and UHMW-PE. Each material offers similar mechanical properties but with varying strengths in different applications. The best choice depends on specific requirements like chemical resistance, temperature range, and cost considerations.

Understanding Delrin and Its Properties

Before exploring alternatives, it’s essential to understand what makes Delrin unique. Delrin, also known as acetal homopolymer, is a high-performance engineering plastic known for its excellent mechanical properties. The material’s crystalline structure7 provides outstanding dimensional stability and wear resistance.

Key Properties of Delrin:

- High tensile strength and stiffness

- Excellent fatigue resistance

- Low friction coefficient

- Good dimensional stability

- Chemical resistance

- Easy to machine

Comparable Materials and Their Characteristics

Nylon (PA)

Nylon serves as one of the most common alternatives to Delrin. At PTSMAKE, we frequently recommend Nylon for various applications due to its versatility.

Key advantages of Nylon include:

- Better impact resistance than Delrin

- Higher heat resistance

- More cost-effective

- Superior wear properties

PEEK (Polyether Ether Ketone)

PEEK represents a high-end alternative with exceptional properties:

| Property | PEEK vs Delrin |

|---|---|

| Temperature Resistance | Superior (up to 260°C vs 180°C) |

| Chemical Resistance | Better |

| Cost | Significantly higher |

| Wear Resistance | Excellent |

| Machining Difficulty | More challenging |

PTFE (Polytetrafluoroethylene)

PTFE offers unique characteristics that make it suitable for specific applications:

- Lowest coefficient of friction

- Excellent chemical resistance

- Wide temperature range

- FDA compliant

UHMW-PE (Ultra-High-Molecular-Weight Polyethylene)

This material provides an economical alternative with specific advantages:

| Property | UHMW-PE Characteristics |

|---|---|

| Impact Strength | Excellent |

| Wear Resistance | Very Good |

| Chemical Resistance | Good |

| Cost | Lower than Delrin |

| Weight | Lighter |

Application-Specific Comparisons

Automotive Applications

In automotive components, where precision and durability are crucial, different materials show varying performance:

- Delrin: Ideal for fuel system components

- Nylon: Better for under-hood applications

- PEEK: Perfect for high-temperature environments

- PTFE: Excellent for bearing applications

- UHMW-PE: Suitable for wear plates and guides

Medical Applications

For medical devices, material selection becomes even more critical:

- Delrin: Commonly used in surgical instruments

- PEEK: Preferred for implantable devices

- PTFE: Ideal for non-stick applications

- Nylon: Used in disposable medical tools

Industrial Equipment

Based on my experience at PTSMAKE, industrial applications require careful material selection:

| Application | Recommended Material | Reason |

|---|---|---|

| Gears | Delrin/Nylon | Excellent wear resistance |

| Bearings | PTFE/PEEK | Low friction |

| Conveyor Components | UHMW-PE | Cost-effective wear resistance |

| Precision Parts | Delrin/PEEK | Dimensional stability |

Cost Considerations and Value Analysis

Understanding the cost implications helps in making informed decisions:

- PEEK: 5-7x more expensive than Delrin

- PTFE: 2-3x more expensive than Delrin

- Nylon: Similar or slightly less expensive

- UHMW-PE: Generally less expensive

Environmental Factors and Sustainability

Different materials have varying environmental impacts:

- Recyclability potential

- Energy consumption during production

- End-of-life disposal considerations

- Carbon footprint

Making the Right Choice

To select the right Delrin alternative, consider:

- Operating temperature requirements

- Chemical exposure conditions

- Mechanical load requirements

- Cost constraints

- Regulatory compliance needs

At PTSMAKE, we guide our clients through this selection process by analyzing these factors comprehensively. This ensures optimal material selection for each specific application while maintaining cost-effectiveness and performance requirements.

Machining and Processing Considerations

Different materials require different machining approaches:

- Tool selection

- Cutting speeds and feeds

- Cooling requirements

- Post-processing needs

Through our experience in precision manufacturing, we’ve developed specific protocols for each material to ensure optimal results.

What Is The Cost Of Delrin Material?

When sourcing Delrin material for manufacturing projects, determining the exact cost can be challenging. Price fluctuations, market conditions, and varying supplier quotes often leave engineers and procurement managers confused and frustrated.

Delrin material typically costs between $3 to $8 per pound for standard grades, with specialty grades ranging from $10 to $15 per pound. The final price depends on grade quality, order quantity, market conditions, and supplier relationships.

Understanding Delrin Material Cost Components

The cost of Delrin material is influenced by several key factors that create its molecular composition8. Let me break down these components to help you make informed purchasing decisions.

Raw Material Base Price

The foundation of Delrin pricing starts with the base material cost. At PTSMAKE, we source high-quality Delrin from certified suppliers to ensure consistent quality. The base price typically includes:

- Resin production costs

- Manufacturing overhead

- Quality control processes

- Initial processing fees

Grade Quality Impact on Price

Different grades of Delrin command different prices based on their properties:

| Grade Type | Price Range ($/lb) | Common Applications |

|---|---|---|

| Standard Grade | 3-8 | General purpose parts |

| Medical Grade | 12-15 | Medical devices |

| High-Performance | 10-13 | Precision components |

| UV-Stabilized | 8-11 | Outdoor applications |

Volume-Based Pricing Structure

Order quantity significantly affects the per-unit cost of Delrin material:

Bulk Purchase Benefits

- Large orders (1000+ lbs): 15-20% discount

- Medium orders (500-999 lbs): 10-15% discount

- Small orders (100-499 lbs): 5-10% discount

Market Factors Affecting Delrin Costs

Supply Chain Influences

The global supply chain impacts Delrin pricing through:

- Transportation costs

- Import/export regulations

- Regional availability

- Market demand fluctuations

Economic Factors

Several economic conditions affect pricing:

- Oil prices (raw material source)

- Currency exchange rates

- Manufacturing capacity

- Global economic conditions

Additional Cost Considerations

Processing Requirements

The final cost often includes:

- Material preparation

- Special handling

- Custom packaging

- Quality certification costs

Quality Certification Expenses

| Certification Type | Additional Cost (%) | Purpose |

|---|---|---|

| ISO compliance | 5-8 | Quality assurance |

| Medical grade | 10-15 | Healthcare applications |

| FDA approval | 12-18 | Food contact |

| Custom testing | 8-12 | Specific requirements |

Cost Optimization Strategies

At PTSMAKE, we help our clients optimize their Delrin material costs through:

Strategic Purchasing

- Long-term supply agreements

- Volume consolidation

- Market timing optimization

- Supplier relationship management

Material Selection Optimization

- Application-specific grade selection

- Alternative material evaluation

- Design optimization support

- Waste reduction strategies

Regional Price Variations

Different regions have varying price structures:

| Region | Price Range ($/lb) | Contributing Factors |

|---|---|---|

| North America | 4-9 | Local production |

| Europe | 5-10 | Import costs |

| Asia | 3-8 | Manufacturing proximity |

| Other regions | 6-12 | Transportation costs |

Future Price Trends

Based on market analysis and industry expertise, we anticipate:

- Steady price increases of 2-3% annually

- Continued impact of raw material costs

- Growing demand in emerging markets

- Technology advancements affecting production costs

Value-Added Services Impact

Additional services can affect the final cost:

- Custom cutting and sizing

- Special packaging requirements

- Technical support services

- Quality documentation

Cost-Saving Recommendations

To optimize your Delrin material costs:

- Plan purchases strategically

- Consider bulk ordering

- Evaluate grade requirements carefully

- Maintain strong supplier relationships

- Monitor market conditions

Through PTSMAKE’s expertise in material sourcing and manufacturing, we help clients navigate these cost factors effectively. Our global supply network and industry relationships enable us to secure competitive pricing while maintaining high-quality standards.

What Is Another Name For Delrin?

Finding the right plastic material for your project can be confusing when the same material goes by different names. Many engineers and designers struggle with this terminology challenge, which can lead to costly mistakes in material selection and procurement.

Delrin is the DuPont trade name for Polyoxymethylene (POM), also commonly known as acetal. This engineering thermoplastic offers exceptional mechanical properties, dimensional stability, and wear resistance, making it ideal for precision parts.

Understanding the Different Names of Delrin

In my experience working with various manufacturing projects, I’ve noticed that material naming conventions often cause confusion. Let me clarify the different names associated with Delrin:

Common Trade Names

The material we know as Delrin is marketed under various trade names by different manufacturers:

| Manufacturer | Trade Name |

|---|---|

| DuPont | Delrin |

| Ticona | Celcon |

| BASF | Ultraform |

| KEP | Kepital |

| Polyplastics | Duracon |

Chemical Composition and Structure

Polyacetal homopolymer9 forms the basis of Delrin, giving it unique properties that set it apart from other engineering plastics. At PTSMAKE, we often recommend this material for its exceptional performance in demanding applications.

Key Properties of Delrin/POM

Mechanical Properties

- High tensile strength

- Excellent fatigue resistance

- Low friction coefficient

- Superior wear resistance

- Good dimensional stability

Chemical Properties

The material demonstrates remarkable resistance to:

- Most solvents

- Chemical compounds

- Fuel and hydrocarbons

- Hot water exposure

Applications Across Industries

Automotive Components

- Fuel system components

- Interior trim parts

- Gears and bearings

- Door lock systems

Consumer Electronics

- Mobile phone components

- Laptop hinges

- Camera parts

- Electronic housings

Industrial Equipment

- Conveyor components

- Pump parts

- Valve bodies

- Industrial gears

Manufacturing Considerations

Machining Guidelines

When machining Delrin at our PTSMAKE facilities, we follow specific guidelines:

- Use sharp cutting tools

- Maintain moderate cutting speeds

- Provide adequate cooling

- Ensure proper chip evacuation

Injection Molding Parameters

Based on our extensive molding experience:

| Parameter | Recommended Range |

|---|---|

| Melt Temperature | 180-215°C |

| Mold Temperature | 80-120°C |

| Injection Pressure | 70-120 MPa |

| Drying Time | 2-4 hours |

Material Selection Criteria

Performance Requirements

- Load-bearing capacity needed

- Operating temperature range

- Chemical exposure conditions

- Wear resistance requirements

Cost Considerations

- Material cost per unit

- Processing costs

- Tool wear factors

- Production volume impact

Quality Control Measures

At PTSMAKE, we implement rigorous quality control procedures:

Testing Methods

- Dimensional inspection

- Hardness testing

- Impact resistance evaluation

- Chemical resistance verification

Documentation Requirements

- Material certificates

- Process parameters

- Quality control reports

- Traceability records

Environmental Impact

Sustainability Aspects

- Recyclability potential

- Energy consumption in processing

- Waste reduction strategies

- Environmental compliance

Industry Standards and Compliance

Relevant Standards

- ISO 9001 certification

- ASTM testing methods

- RoHS compliance

- FDA approvals (where applicable)

Comparison with Alternative Materials

| Property | Delrin/POM | Nylon | PEEK |

|---|---|---|---|

| Cost | Moderate | Low | High |

| Strength | High | Medium | Very High |

| Chemical Resistance | Excellent | Good | Excellent |

| Heat Resistance | Good | Good | Excellent |

Troubleshooting Common Issues

Processing Problems

- Warpage control

- Dimensional stability

- Surface finish quality

- Gate location optimization

Material Storage

- Temperature control

- Humidity management

- Inventory rotation

- Contamination prevention

Through our experience at PTSMAKE, we’ve developed effective solutions for these common challenges, ensuring consistent quality in our manufacturing processes.

Which Plastic Is Also Called Teflon?

The confusion around plastic names can be overwhelming for engineers and manufacturers. With numerous trade names, chemical formulas, and industry terminology, it’s challenging to keep track of which plastic is which, especially when it comes to high-performance materials like Teflon.

Teflon is the trademarked brand name for Polytetrafluoroethylene (PTFE), a synthetic fluoropolymer of tetrafluoroethylene. This versatile plastic is known for its non-stick properties, high heat resistance, and chemical inertness, making it invaluable in both industrial applications and consumer products.

The Chemical Composition of PTFE

PTFE’s unique properties stem from its molecular structure. The material consists of carbon and fluorine atoms forming a strong bond that creates a fluoropolymer10 structure. This composition gives PTFE its exceptional characteristics:

Molecular Structure Benefits

- Strong carbon-fluorine bonds

- Regular crystalline structure

- Low surface energy

- High molecular weight

Key Properties That Make PTFE Special

Temperature Resistance

PTFE can withstand temperatures from -200°C to +260°C without degrading. This remarkable temperature range makes it ideal for various applications:

| Temperature Range | Application Examples |

|---|---|

| -200°C to 0°C | Cryogenic equipment seals |

| 0°C to 150°C | Non-stick cookware |

| 150°C to 260°C | Industrial bearings |

Chemical Resistance

One of PTFE’s most valuable properties is its resistance to almost all chemicals. In my experience at PTSMAKE, we’ve seen PTFE perform exceptionally well in aggressive chemical environments where other plastics fail.

Industrial Applications of PTFE

Manufacturing Industry

- Bearings and bushings

- Seals and gaskets

- Conveyor belts

- Machine components

Chemical Processing

- Pipeline linings

- Valve components

- Pump parts

- Chemical storage containers

Medical and Food Industry Applications

The FDA has approved PTFE for food contact and medical applications due to its:

- Non-toxic nature

- Bio-compatibility

- Easy sterilization

- Chemical inertness

Comparing PTFE with Other High-Performance Plastics

Here’s how PTFE stacks up against other common engineering plastics:

| Property | PTFE | PEEK | POM (Delrin) |

|---|---|---|---|

| Max Temperature | 260°C | 250°C | 180°C |

| Chemical Resistance | Excellent | Good | Good |

| Wear Resistance | Good | Excellent | Excellent |

| Cost | High | Very High | Moderate |

Processing Methods for PTFE

Ram Extrusion

This process involves:

- Compressing PTFE powder

- Heating to sintering temperature

- Cooling under controlled conditions

- Final machining to specifications

Compression Molding

At PTSMAKE, we’ve optimized our compression molding process for PTFE components, ensuring:

- Uniform density

- Minimal voids

- Excellent dimensional stability

- Superior mechanical properties

Maintenance and Care of PTFE Components

To maximize the lifespan of PTFE parts:

- Avoid mechanical scratching

- Clean with appropriate solvents

- Store at moderate temperatures

- Prevent exposure to direct UV light

Environmental Considerations

While PTFE offers exceptional performance, it’s important to consider:

- Recycling challenges

- End-of-life disposal

- Environmental impact

- Sustainable alternatives

Quality Control Measures

At PTSMAKE, we implement strict quality control procedures for PTFE products:

- Material certification

- Dimensional inspection

- Surface finish testing

- Performance validation

Cost Considerations and ROI

When evaluating PTFE for your application, consider:

- Initial material costs

- Processing expenses

- Maintenance requirements

- Lifetime value

- Replacement frequency

Future Developments in PTFE Technology

Current research focuses on:

- Modified PTFE grades

- Improved processing methods

- Enhanced mechanical properties

- Sustainable manufacturing

Common Misconceptions About PTFE

It’s important to address some common misunderstandings:

- PTFE is not just for cookware

- It’s more than a coating material

- High cost is offset by longevity

- Processing limitations can be overcome

Through our work at PTSMAKE, we’ve helped numerous clients select and implement PTFE solutions that perfectly match their requirements. The key is understanding both the material’s capabilities and limitations to make informed decisions about its application in specific scenarios.

How Does Delrin Perform In High-Temperature Environments?

Working with engineering plastics can be challenging, especially when dealing with high-temperature applications. Many manufacturers struggle to find materials that maintain their structural integrity and performance under elevated temperatures, leading to costly failures and production delays.

Delrin exhibits stable performance in high-temperature environments up to 180°F (82°C) for continuous use, maintaining its mechanical properties and dimensional stability. However, its performance gradually declines as temperatures approach its melting point of 347°F (175°C).

Temperature Resistance Characteristics

Delrin, also known as polyoxymethylene (POM), displays remarkable thermal properties that make it suitable for various high-temperature applications. I’ve observed that its crystalline structure provides excellent dimensional stability even as temperatures rise. The material’s behavior can be categorized into different temperature ranges:

Short-Term Temperature Exposure

During my work with clients in automotive and industrial sectors, I’ve found that Delrin can withstand short-term exposure to temperatures up to:

| Temperature Range | Duration | Performance Impact |

|---|---|---|

| 180-220°F (82-104°C) | 24-48 hours | Minimal property changes |

| 220-280°F (104-138°C) | 2-4 hours | Moderate softening |

| 280-347°F (138-175°C) | < 1 hour | Significant property degradation |

Mechanical Properties at Elevated Temperatures

The material’s crystallinity11 plays a crucial role in maintaining its mechanical properties under heat stress. Based on my testing experience at PTSMAKE, I’ve documented these key performance aspects:

Tensile Strength Retention

- At room temperature: 100% baseline strength

- At 150°F (65°C): 85-90% strength retention

- At 180°F (82°C): 70-75% strength retention

Dimensional Stability

Heat can affect Delrin’s dimensional accuracy, but proper design considerations can minimize this impact:

| Temperature Range | Linear Expansion Rate | Design Consideration |

|---|---|---|

| 70-120°F (21-49°C) | 0.00022 inch/inch/°F | Standard tolerances acceptable |

| 120-180°F (49-82°C) | 0.00025 inch/inch/°F | Enhanced tolerances needed |

Applications in High-Temperature Environments

Through our manufacturing experience at PTSMAKE, we’ve successfully implemented Delrin in various high-temperature applications:

Automotive Components

- Engine compartment components

- Transmission parts

- Cooling system components

Industrial Equipment

- Hot water system components

- Heat exchanger parts

- Processing equipment components

Design Considerations for High-Temperature Use

To ensure optimal performance, consider these design factors:

Material Grade Selection

- Standard grades for moderate temperatures

- High-temperature grades for demanding applications

- Reinforced grades for enhanced stability

Thermal Management Strategies

Heat Dissipation

- Incorporate cooling fins when possible

- Allow for adequate airflow

- Consider thermal barriers

Stress Distribution

- Design for uniform heat distribution

- Avoid sharp corners that concentrate stress

- Include expansion joints where necessary

Performance Optimization Techniques

To maximize Delrin’s performance in high-temperature environments, I recommend:

Surface Treatment Options

- Annealing for improved stability

- Surface finishing for reduced friction

- Coating applications for additional protection

Assembly Considerations

- Use appropriate clearances for thermal expansion

- Select compatible fastening methods

- Consider thermal cycling effects

Material Limitations and Alternatives

While Delrin performs well in many high-temperature applications, it’s important to recognize its limitations:

Temperature Thresholds

| Condition | Maximum Temperature | Duration |

|---|---|---|

| Continuous Use | 180°F (82°C) | Indefinite |

| Intermittent Use | 250°F (121°C) | < 24 hours |

| Peak Exposure | 347°F (175°C) | Minutes |

At PTSMAKE, we often recommend alternative materials when applications exceed these limits:

- PEEK for higher temperature requirements

- PPS for chemical resistance at elevated temperatures

- Modified POM grades for specific performance needs

Testing and Validation Procedures

To ensure reliable performance, we implement comprehensive testing:

Thermal Analysis Methods

- Differential Scanning Calorimetry (DSC)

- Thermogravimetric Analysis (TGA)

- Heat Deflection Temperature Testing

Quality Assurance

- Dimensional stability monitoring

- Mechanical property verification

- Long-term performance testing

Through careful material selection and proper design implementation, Delrin can effectively serve in high-temperature environments within its specified limits. Understanding these performance characteristics enables successful application in demanding thermal conditions while maintaining the material’s beneficial properties.

What Are The Best Practices For Machining Delrin Parts?

Machining Delrin parts can be challenging due to their unique material properties. Many engineers struggle with issues like dimensional instability, tool wear, and surface finish problems. I’ve seen projects delayed and costs increase due to improper machining techniques, causing frustration for both manufacturers and clients.

The best practices for machining Delrin parts include using sharp cutting tools, maintaining appropriate speeds and feeds, ensuring proper cooling, and implementing specific design considerations. These practices help achieve optimal results while preventing common issues like material deformation and poor surface finish.

Understanding Delrin’s Material Properties

Delrin, also known as acetal homopolymer, exhibits unique characteristics that directly influence machining strategies. The material’s crystallinity12 affects its behavior during machining operations. I’ve found that understanding these properties is crucial for successful machining:

Key Material Characteristics

- Low friction coefficient

- High mechanical strength

- Excellent dimensional stability

- Good wear resistance

- Natural lubricity

Cutting Tool Selection and Preparation

The success of Delrin machining heavily depends on proper tool selection. At PTSMAKE, we’ve developed specific guidelines for tool selection:

Recommended Tool Types

| Tool Type | Application | Recommended Geometry |

|---|---|---|

| End Mills | General milling | 2-4 flutes, 30° helix angle |

| Drills | Hole making | 118° point angle, polished flutes |

| Face Mills | Surface finishing | High positive rake angle |

| Reamers | Precision holes | Straight flute, 45° chamfer |

Optimal Cutting Parameters

Speed and Feed Rates

Proper cutting parameters are essential for achieving high-quality results:

| Operation | Surface Speed (SFM) | Feed Rate (IPR) |

|---|---|---|

| Turning | 300-1000 | 0.004-0.012 |

| Milling | 400-1200 | 0.003-0.010 |

| Drilling | 200-400 | 0.005-0.015 |

Cooling and Temperature Control

Temperature management is crucial when machining Delrin. Here’s why:

- Prevents material softening

- Maintains dimensional accuracy

- Improves surface finish

- Extends tool life

Cooling Methods

- Flood coolant

- Compressed air

- Mist cooling systems

- Cryogenic cooling for specialized applications

Design Considerations for Machinability

Wall Thickness Requirements

I recommend following these guidelines for wall thickness:

- Minimum wall thickness: 0.040 inches

- Optimal wall thickness: 0.125 inches or greater

- Maximum thickness variation: 25% within same feature

Feature Design Guidelines

- Avoid sharp corners (use minimum 0.015" radius)

- Design self-supporting structures

- Consider shrinkage allowance

- Plan for proper fixturing points

Surface Finish Optimization

To achieve excellent surface finish:

Recommended Practices

- Use high-speed finishing passes

- Maintain sharp cutting edges

- Apply consistent cutting pressure

- Consider post-machining treatments

Quality Control Measures

Implementing proper quality control is essential:

Inspection Methods

- Dimensional verification

- Surface roughness testing

- Visual inspection for defects

- Material property validation

Common Machining Issues and Solutions

Problem-Solution Matrix

| Issue | Cause | Solution |

|---|---|---|

| Poor surface finish | Dull tools | Replace or sharpen tools |

| Dimensional inaccuracy | Thermal expansion | Proper cooling implementation |

| Tool wear | Incorrect speeds | Adjust cutting parameters |

| Chipping | Improper support | Improve workpiece fixturing |

Advanced Machining Techniques

At PTSMAKE, we employ several advanced techniques:

High-Speed Machining

- Reduced heat generation

- Better surface finish

- Increased productivity

- Enhanced dimensional accuracy

Specialized Fixturing

- Custom workholding solutions

- Multiple setup reduction

- Improved repeatability

- Enhanced part stability

Cost Optimization Strategies

To maintain cost-effectiveness:

- Optimize tool life

- Minimize material waste

- Reduce setup times

- Implement efficient processes

Environmental Considerations

Sustainable Practices

- Proper chip recycling

- Coolant management

- Energy-efficient machining

- Waste reduction strategies

Can Delrin Be Recycled Or Repurposed After Use?

The growing concern about plastic waste has left many engineers and manufacturers wondering about the recyclability of engineering plastics like Delrin. As landfills continue to fill up and environmental regulations tighten, finding sustainable solutions for used Delrin components has become a pressing challenge.

Yes, Delrin can be recycled and repurposed. Through mechanical recycling processes, used Delrin parts can be ground into pellets and reprocessed. However, the material’s properties may degrade after recycling, making it more suitable for less demanding applications.

Understanding Delrin’s Recycling Potential

Chemical Composition and Recyclability

Delrin, also known as polyoxymethylene (POM), possesses unique chemical properties that affect its recyclability. The material undergoes a process called depolymerization13 during recycling, which can impact its mechanical properties. At PTSMAKE, we’ve observed that proper sorting and processing methods are crucial for successful recycling.

Types of Recycling Methods

There are several methods to recycle Delrin:

Mechanical Recycling

- Grinding into smaller particles

- Melting and reforming

- Blending with virgin material

Chemical Recycling

- Depolymerization

- Chemical breakdown

- Recovery of base materials

Best Practices for Delrin Recycling

Collection and Sorting

For effective recycling, proper collection and sorting are essential. Here’s a breakdown of the process:

| Step | Description | Key Considerations |

|---|---|---|

| Collection | Gathering used Delrin parts | Ensure parts are clean and separated |

| Sorting | Separating Delrin from other plastics | Use proper identification methods |

| Cleaning | Removing contaminants | Avoid chemical contamination |

| Storage | Proper storage before processing | Maintain dry conditions |

Processing Guidelines

The recycling process must follow specific guidelines to maintain quality:

Temperature Control

- Optimal processing temperature

- Careful monitoring during melting

- Cooling rate management

Contamination Prevention

- Remove metal inserts

- Separate different grades

- Clean thoroughly

Applications for Recycled Delrin

Primary Uses

Recycled Delrin finds applications in various industries:

Automotive Components

- Non-critical parts

- Interior components

- Secondary assemblies

Industrial Applications

- Material handling equipment

- Low-stress components

- Protective covers

Quality Considerations

When using recycled Delrin, consider these factors:

| Property | Virgin Material | Recycled Material |

|---|---|---|

| Tensile Strength | High | Slightly reduced |

| Impact Resistance | Excellent | Good |

| Dimensional Stability | Very good | Acceptable |

| Chemical Resistance | Excellent | Good |

Environmental Impact and Benefits

Sustainability Advantages

Recycling Delrin offers several environmental benefits:

Reduced Landfill Waste

- Less plastic in landfills

- Lower environmental impact

- Conservation of resources

Energy Savings

- Reduced production energy

- Lower carbon footprint

- Resource efficiency

Economic Benefits

The economic advantages of recycling Delrin include:

Cost Reduction

- Lower material costs

- Reduced waste disposal fees

- Energy savings

Market Opportunities

- Growing demand for recycled materials

- New business opportunities

- Compliance with regulations

Future Trends and Innovations

Emerging Technologies

New technologies are improving Delrin recycling:

Advanced Sorting Systems

- Automated identification

- Improved separation

- Higher purity yields

Enhanced Processing Methods

- Better quality control

- Improved property retention

- More efficient systems

Industry Developments

The industry continues to evolve:

Circular Economy Integration

- Closed-loop systems

- Improved collection networks

- Better recycling infrastructure

Market Growth

- Increasing demand

- New applications

- Expanding opportunities

What Industries Commonly Use Delrin Components?

Finding the right material for manufacturing precision components can be challenging. Many engineers and product designers struggle to identify materials that offer the perfect balance of strength, durability, and cost-effectiveness for their specific applications.

Delrin components are widely used across multiple industries due to their exceptional mechanical properties, chemical resistance, and dimensional stability. From automotive and electronics to medical devices and consumer products, these versatile components serve crucial roles in various applications.

Automotive Industry Applications

The automotive sector heavily relies on Delrin components for both interior and exterior applications. I’ve observed that modern vehicles contain numerous Delrin parts, particularly in areas requiring high wear resistance and low friction properties.

Key Automotive Applications

- Gear systems and bearings

- Door locking mechanisms

- Fuel system components

- Window regulators

- Steering column components

The tribological properties of Delrin make it especially suitable for these applications, as it provides excellent wear resistance and low friction without requiring additional lubrication.

Medical Device Manufacturing

In the medical industry, Delrin’s biocompatibility and sterilization capabilities make it an ideal choice for various medical devices and equipment.

Common Medical Applications

- Surgical instruments

- Drug delivery devices

- Diagnostic equipment components

- Medical device housings

- Laboratory equipment parts

Electronics and Consumer Electronics

The electronics industry benefits from Delrin’s electrical insulation properties and dimensional stability. At PTSMAKE, we frequently manufacture Delrin components for:

| Application Type | Key Benefits | Common Uses |

|---|---|---|

| Connectors | High strength, electrical insulation | Cable management systems |

| Housing Components | Dimensional stability | Device enclosures |

| Switch Components | Wear resistance | Toggle mechanisms |

| Terminal Blocks | Chemical resistance | Power distribution |

Industrial Equipment and Machinery

The industrial sector represents one of the largest markets for Delrin components. Based on our manufacturing experience at PTSMAKE, these parts are crucial in:

Manufacturing Equipment

- Conveyor system components

- Assembly line mechanisms

- Packaging machinery parts

- Industrial automation components

Heavy Machinery

- Bearing housings

- Wear plates

- Guide rails

- Bushings

Aerospace and Defense Applications

The aerospace industry demands materials that offer reliability under extreme conditions. Delrin components serve various purposes in:

- Control system components

- Interior cabin fittings

- Ground support equipment

- Satellite components

- Navigation system housings

Food Processing Equipment

Delrin’s FDA compliance makes it suitable for food processing equipment. Common applications include:

| Component Type | Application Area | Key Advantage |

|---|---|---|

| Conveyor Parts | Food Transport | Chemical Resistance |

| Mixing Equipment | Food Preparation | Wear Resistance |

| Packaging Systems | Product Handling | Low Friction |

| Storage Solutions | Food Storage | Durability |

Consumer Products and Appliances

The consumer goods sector extensively uses Delrin components in:

Home Appliances

- Washing machine components

- Dishwasher parts

- Coffee maker mechanisms

- Small appliance gears

Sports Equipment

- Bicycle components

- Fitness equipment parts

- Sporting good accessories

- Recreation equipment

Renewable Energy Sector

The growing renewable energy sector increasingly utilizes Delrin components in:

- Solar panel mounting systems

- Wind turbine components

- Energy storage systems

- Power distribution equipment

Having worked with numerous industries at PTSMAKE, I’ve noticed that the versatility of Delrin makes it indispensable across these diverse applications. Our manufacturing capabilities allow us to produce precise Delrin components that meet the specific requirements of each industry, whether it’s high-volume production for automotive applications or specialized components for medical devices.

The trend toward lightweight, durable materials continues to drive the adoption of Delrin components across industries. At PTSMAKE, we maintain strict quality control measures and leverage advanced manufacturing technologies to ensure our Delrin components meet or exceed industry standards.

For companies considering Delrin components for their applications, it’s crucial to partner with experienced manufacturers who understand the material’s properties and processing requirements. This ensures optimal performance and longevity of the final products while maintaining cost-effectiveness in production.

How Does Delrin Compare To Nylon In Wear Resistance?

Engineers often face challenges when selecting the right material for parts that require high wear resistance. I’ve seen many projects fail due to incorrect material choices, leading to premature wear, increased maintenance costs, and production downtime.

Delrin generally shows superior wear resistance compared to Nylon due to its higher mechanical strength, lower friction coefficient, and better dimensional stability. However, the specific application requirements, operating conditions, and cost considerations should guide the final material selection.

Understanding Wear Resistance Fundamentals

At PTSMAKE, we frequently work with both materials in our precision manufacturing processes. The tribological properties14 of these materials play a crucial role in their wear performance. Let me break down the key factors that influence wear resistance:

Surface Hardness

Delrin typically exhibits higher surface hardness than Nylon, which contributes to its better wear resistance. The harder surface helps prevent material loss during sliding contact and abrasive conditions.

Friction Coefficient

One of Delrin’s notable advantages is its naturally low coefficient of friction. This characteristic results in:

- Less heat generation during operation

- Smoother movement in sliding applications

- Reduced wear on mating surfaces

Moisture Absorption

Nylon’s higher moisture absorption rate can affect its dimensional stability and wear characteristics. Here’s a comparative analysis:

| Property | Delrin | Nylon |

|---|---|---|

| Moisture Absorption (24h) | 0.25% | 1.5-3.0% |

| Dimensional Change | Minimal | Moderate |

| Performance Stability | High | Variable |

Performance Under Different Operating Conditions

Temperature Effects

Based on my experience with numerous manufacturing projects, temperature significantly impacts wear resistance:

Low Temperature (-40°C to 0°C)

- Delrin maintains better dimensional stability

- Nylon becomes more brittle

Room Temperature (20°C to 25°C)

- Both materials perform well

- Delrin shows slightly better wear characteristics

Elevated Temperature (60°C to 82°C)

- Delrin retains strength better

- Nylon’s wear resistance decreases more rapidly

Load Bearing Capacity

The wear resistance under different loads varies significantly:

| Load Condition | Delrin Performance | Nylon Performance |

|---|---|---|

| Light Load (<1 MPa) | Excellent | Very Good |

| Medium Load (1-5 MPa) | Very Good | Good |

| Heavy Load (>5 MPa) | Good | Fair |

Application-Specific Considerations

Speed and Motion Type

Different motion types affect wear patterns:

Rotary Motion

- Delrin excels in gears and bearings

- Better for high-speed applications

Linear Motion

- Both materials perform well

- Delrin preferred for precision movements

Intermittent Motion

- Both materials suitable

- Delrin shows better long-term wear resistance

Environmental Factors

The operating environment plays a crucial role:

Chemical Exposure

- Delrin: Better resistance to hydrocarbons

- Nylon: Superior resistance to certain chemicals

Moisture Presence

- Delrin: Maintains properties better

- Nylon: Properties can vary significantly

Cost-Performance Analysis

When considering wear resistance versus cost:

| Aspect | Delrin | Nylon |

|---|---|---|

| Initial Cost | Higher | Lower |

| Maintenance Cost | Lower | Variable |

| Lifetime Value | Better | Good |

| Replacement Frequency | Less Frequent | More Frequent |

Real-World Applications

At PTSMAKE, we’ve successfully implemented both materials in various applications:

Automotive Components

- Delrin: Ideal for precision bushings and gears

- Nylon: Suitable for less critical wear applications

Industrial Equipment

- Delrin: Preferred for high-precision automation components

- Nylon: Good for general-purpose applications

Consumer Products

- Delrin: Used in high-end products requiring durability

- Nylon: Suitable for cost-sensitive applications

Optimization Strategies

To maximize wear resistance:

Surface Treatment

- Consider surface finishing options

- Evaluate coating possibilities

Design Optimization

- Incorporate proper clearances

- Account for thermal expansion

Lubrication Considerations

- Determine if lubrication is needed

- Select compatible lubricants

Making the Final Decision

The choice between Delrin and Nylon should consider:

Operating Requirements

- Speed and load conditions

- Temperature range

- Environmental factors

Economic Factors

- Initial material cost

- Expected service life

- Maintenance requirements

Design Parameters

- Dimensional stability needs

- Precision requirements

- Assembly considerations

Through these considerations and my experience at PTSMAKE, I’ve found that while both materials have their place, Delrin generally offers superior wear resistance in demanding applications. However, Nylon remains a cost-effective choice for less critical wear situations.

What Surface Finishes Work Best With Delrin?

Working with Delrin can be tricky when it comes to surface finishes. Many engineers struggle to achieve the desired aesthetic and functional properties. I’ve seen projects delayed and costs increase because of improper surface finish selections, leading to parts that don’t meet specifications or fail prematurely.

The best surface finishes for Delrin include bead blasting, polishing, and light texturing. These finishes enhance both aesthetics and functionality while maintaining the material’s inherent properties. Each finish serves specific purposes, from reducing friction to improving appearance.

Understanding Delrin’s Surface Properties

Delrin, also known as acetal homopolymer, has unique characteristics that influence its surface finish options. Its crystalline structure15 makes it naturally slippery and self-lubricating. At PTSMAKE, we’ve found that this property affects how different surface treatments interact with the material.

Natural Surface Characteristics

- Low friction coefficient

- Good wear resistance

- Moisture resistance

- Dimensional stability

Common Surface Finish Options

Bead Blasting

Bead blasting creates a uniform matte finish on Delrin surfaces. This process involves propelling fine glass beads at high pressure against the material surface. I recommend this finish when you need:

- Enhanced grip properties

- Uniform appearance

- Light texture without aggressive patterns

- Masked minor surface imperfections

Polishing Techniques

Manual and mechanical polishing can achieve different gloss levels on Delrin parts. Here’s a breakdown of common polishing methods:

| Polishing Method | Surface Roughness (Ra) | Best Applications | Cost Factor |

|---|---|---|---|

| Manual Buffing | 0.2-0.4 μm | Aesthetic parts | Medium |

| Diamond Polish | 0.1-0.2 μm | High-precision components | High |

| Mechanical Polish | 0.3-0.6 μm | Production parts | Low |

Texturing Options

Light Texturing

Light texturing works particularly well with Delrin due to its molecular structure. Common patterns include:

- Leather grain

- Stipple

- Random matte

- Fine geometric patterns

Medium Texturing

Medium texturing requires careful consideration with Delrin:

- Ensures proper material flow

- Maintains dimensional accuracy

- Provides better grip properties

- Enhances aesthetic appeal

Surface Finish Selection Criteria

When selecting a surface finish for Delrin parts, consider these factors:

Functional Requirements

- Friction requirements

- Wear resistance needs

- Chemical exposure

- Operating environment

Aesthetic Considerations

- Visual appearance

- Touch and feel

- Brand consistency

- End-user expectations

Special Considerations

Temperature Effects

Surface finishes must account for Delrin’s thermal properties:

- Thermal expansion

- Heat dissipation

- Operating temperature range

- Processing temperature limits

Chemical Compatibility

Different surface treatments may affect chemical resistance:

- Solvent exposure

- Cleaning agent compatibility

- Environmental factors

- Chemical processing requirements

Quality Control Measures

To ensure consistent surface finish quality, we at PTSMAKE implement:

Inspection Methods