When choosing between titanium and steel for manufacturing projects, many engineers and designers face uncertainty. I’ve witnessed countless design meetings where teams debate the hardness properties of these metals, often making costly material selection mistakes that impact product performance.

While pure titanium is actually softer than most steel alloys, titanium can be alloyed with other elements to achieve hardness levels comparable to some steels. However, steel generally maintains superior hardness, with common steel alloys ranging from 150-330 Brinell hardness compared to titanium’s typical 70-220 Brinell range.

Let me share something interesting about these materials from my manufacturing experience at PTSMAKE. While steel might win in pure hardness, titanium offers unique advantages in strength-to-weight ratio and corrosion resistance. I’ve seen both materials excel in different applications, and the choice often depends on specific project requirements beyond just hardness.

Why Don’t We Use Titanium Instead Of Steel?

Every time I discuss materials with my clients, they often ask why we don’t use titanium more often since it’s stronger and lighter than steel. This question reveals a common misconception in manufacturing that stronger always means better. The reality is far more complex, especially when considering real-world applications and economic factors.

While titanium is indeed lighter and offers excellent corrosion resistance compared to steel, its high cost and complex manufacturing process make it impractical for most applications. Steel remains the preferred choice due to its versatility, cost-effectiveness, and established manufacturing processes.

The Cost Factor: A Significant Barrier

When we examine the cost differences between titanium and steel, the numbers tell a compelling story. The extraction process1 for titanium is significantly more complex and energy-intensive than steel production, directly impacting its market price.

| Material | Average Cost per Pound | Relative Cost |

|---|---|---|

| Carbon Steel | $0.50 – $1.00 | 1x |

| Stainless Steel | $2.00 – $4.00 | 4x |

| Titanium | $7.00 – $25.00 | 15-25x |

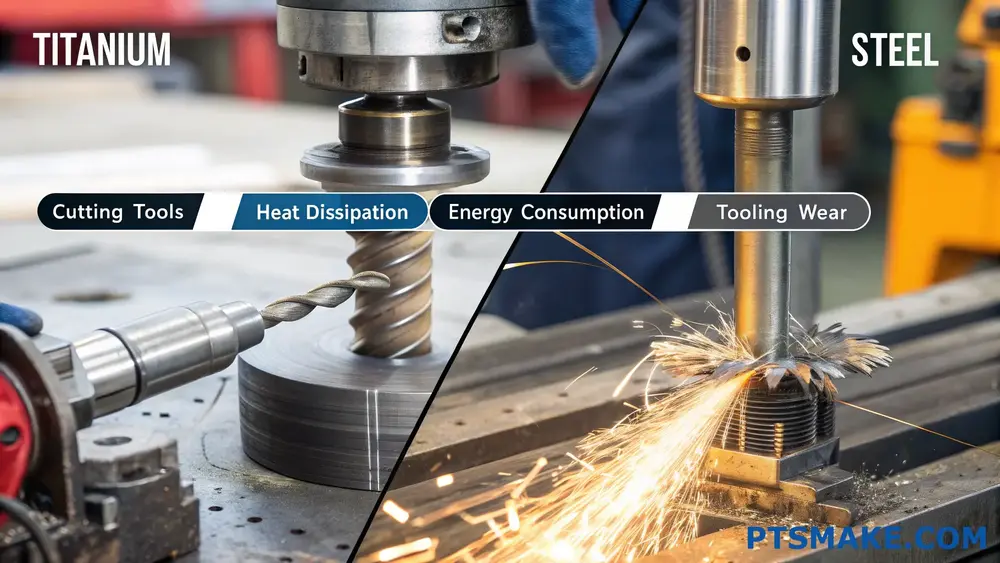

Manufacturing Challenges

Processing Complexity

At PTSMAKE, we’ve observed that titanium presents unique challenges during machining:

- Requires specialized cutting tools

- Demands slower cutting speeds

- Needs specific coolant solutions

- Shows high tool wear rates

Temperature Sensitivity

Titanium’s thermal properties create additional manufacturing hurdles:

- Poor heat dissipation during machining

- Risk of work hardening

- Higher energy consumption during processing

- Special heat treatment requirements

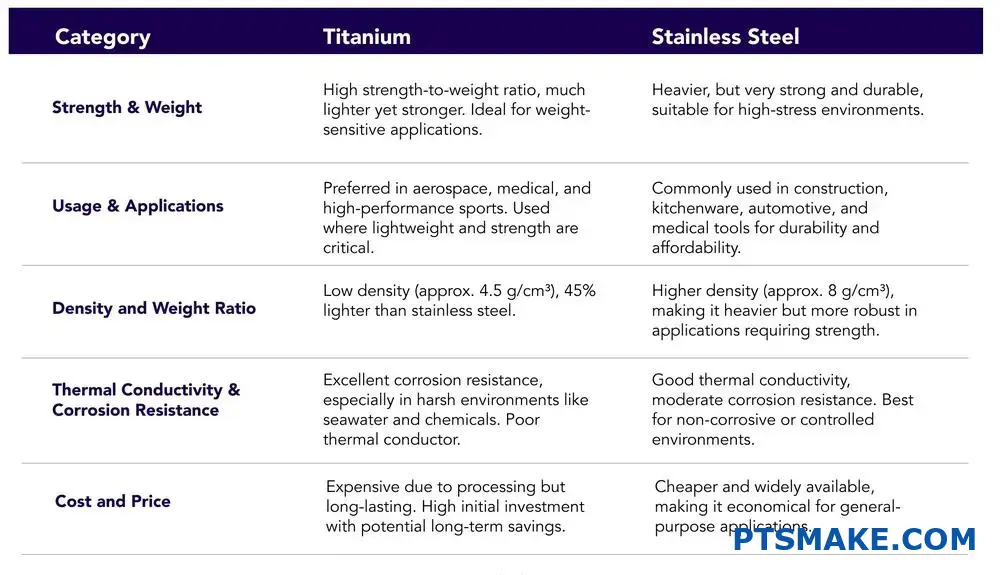

Material Properties Comparison

Strength-to-Weight Ratio

While titanium boasts an impressive strength-to-weight ratio, steel offers practical advantages:

| Property | Steel | Titanium |

|---|---|---|

| Density (g/cm³) | 7.85 | 4.51 |

| Tensile Strength (MPa) | 400-2000 | 350-1200 |

| Yield Strength (MPa) | 250-1500 | 250-1000 |

Environmental Considerations

Steel holds several environmental advantages:

- More easily recycled

- Lower energy consumption in production

- Established recycling infrastructure

- Smaller carbon footprint

Industry-Specific Applications

Aerospace and Defense

Titanium finds its niche in aerospace applications where:

- Weight savings justify the cost

- High performance is critical

- Corrosion resistance is essential

- Temperature extremes are common

Automotive and Construction

Steel dominates these sectors due to:

- Cost-effectiveness at scale

- Established manufacturing processes

- Wide availability

- Proven long-term performance

Economic Impact on Product Development

The choice between titanium and steel significantly affects product development:

- Design considerations

- Manufacturing timeline

- Project budget

- Market competitiveness

In my experience at PTSMAKE, we often guide clients toward steel solutions unless specific requirements absolutely necessitate titanium. This approach helps maintain cost-effectiveness while meeting performance requirements.

Future Outlook

The relationship between titanium and steel usage may evolve due to:

- Advancing manufacturing technologies

- New extraction methods

- Changing market demands

- Environmental regulations

Practical Considerations

When choosing between titanium and steel, consider:

- Application requirements

- Budget constraints

- Production volume

- Maintenance needs

- Environmental factors

This comprehensive analysis shows why steel remains the primary choice in most manufacturing scenarios. While titanium has its place in specialized applications, steel’s combination of properties, cost-effectiveness, and manufacturing practicality makes it the more logical choice for most applications.

Is Titanium Hard To Break?

Have you ever worried about the durability of titanium components in your critical applications? Many engineers and designers face uncertainty when choosing between titanium and other metals, especially when component failure could lead to catastrophic results. The stakes are particularly high in aerospace, medical, and high-performance machinery applications.

Titanium is remarkably difficult to break due to its high tensile strength and excellent fatigue resistance. While not indestructible, titanium’s unique combination of strength-to-weight ratio and yield strength2 makes it significantly more resistant to breaking than many other metals, including some grades of steel.

Understanding Titanium’s Breaking Resistance

Material Properties That Prevent Breaking

Titanium’s resistance to breaking comes from several key material properties:

- High Tensile Strength

- Excellent Fatigue Resistance

- Superior Crack Resistance

- Remarkable Ductility

At PTSMAKE, we regularly work with various grades of titanium, and I’ve observed these properties firsthand in numerous applications. The material’s performance consistently exceeds expectations, especially in demanding environments.

Comparative Breaking Strength

Here’s a comparison of breaking strength between titanium and other common metals:

| Material | Ultimate Tensile Strength (MPa) | Yield Strength (MPa) | Fatigue Strength (MPa) |

|---|---|---|---|

| Ti-6Al-4V | 950-1200 | 880-950 | 510-610 |

| 316L Stainless Steel | 485-680 | 170-310 | 210-250 |

| 7075-T6 Aluminum | 572 | 503 | 159 |

Factors Affecting Titanium’s Breaking Resistance

Environmental Conditions

The environment plays a crucial role in titanium’s breaking resistance:

Temperature Effects

- Maintains strength up to 600°C

- Excellent cryogenic performance

- Minimal thermal expansion

Corrosion Resistance

- Forms protective oxide layer

- Resistant to salt water

- Immune to most chemical attacks

Loading Conditions

Understanding how different loads affect titanium’s breaking resistance is essential:

Static Loads

- Excellent sustained load bearing

- High yield strength

- Good elastic deformation

Dynamic Loads

- Superior fatigue resistance

- Good impact absorption

- Excellent vibration damping

Applications Leveraging Titanium’s Breaking Resistance

Aerospace Industry

In aerospace applications, titanium’s breaking resistance is crucial:

Structural Components

- Landing gear systems

- Wing structures

- Engine mounts

Engine Components

- Turbine blades

- Compressor discs

- Exhaust systems

Medical Applications

The medical field relies heavily on titanium’s durability:

Implants

- Hip replacements

- Dental implants

- Bone plates

Surgical Instruments

- Precision tools

- Long-lasting equipment

- Sterilization-resistant components

Design Considerations for Titanium Components

Material Grade Selection

Choosing the right titanium grade is crucial for optimal breaking resistance:

Commercial Pure Grades

- Lower strength

- Better formability

- Excellent corrosion resistance

Alloyed Grades

- Higher strength

- Better heat resistance

- Enhanced mechanical properties

Manufacturing Process Impact

The manufacturing process significantly affects titanium’s breaking resistance:

Heat Treatment

- Proper annealing procedures

- Stress relief treatments

- Aging processes

Surface Finishing

- Surface quality control

- Protective coating applications

- Proper machining techniques

At PTSMAKE, we specialize in precision machining of titanium components, ensuring optimal material properties through controlled manufacturing processes. Our experience in handling various titanium grades allows us to maintain the material’s inherent breaking resistance while achieving tight tolerances and complex geometries.

Maintenance and Inspection

Regular Inspection Protocols

To maintain titanium’s breaking resistance:

Visual Inspections

- Surface condition monitoring

- Deformation checks

- Wear pattern analysis

Non-Destructive Testing

- Ultrasonic testing

- X-ray inspection

- Dye penetrant testing

Preventive Maintenance

Proper maintenance ensures long-term breaking resistance:

Surface Protection

- Regular cleaning

- Protective coating maintenance

- Contamination prevention

Load Management

- Regular stress analysis

- Load distribution optimization

- Fatigue monitoring

Through our experience at PTSMAKE, we’ve developed comprehensive quality control procedures that ensure our titanium components maintain their breaking resistance throughout their service life. Our expertise in precision manufacturing helps clients achieve optimal performance in their critical applications.

What Is Titanium Weak Against?

Many engineers and manufacturers face challenges when working with titanium. I’ve seen projects fail because they didn’t account for titanium’s vulnerabilities. Understanding these weaknesses is crucial for anyone working with this popular metal, as overlooking them can lead to costly mistakes and project delays.

While titanium is known for its exceptional strength-to-weight ratio and corrosion resistance, it has notable weaknesses against high temperatures, certain chemical compounds, and specific processing conditions. The metal can become brittle when exposed to hydrogen, react poorly with chlorine, and struggle with thermal conductivity.

Chemical Vulnerabilities of Titanium

Titanium’s remarkable strength doesn’t make it invulnerable. At PTSMAKE, we’ve observed several chemical interactions that can compromise titanium’s integrity:

Hydrogen Embrittlement

One of titanium’s most significant weaknesses is its susceptibility to hydrogen embrittlement3. This process occurs when hydrogen atoms penetrate the metal’s crystal structure, leading to:

- Reduced ductility

- Decreased tensile strength

- Increased brittleness

- Potential crack formation

Oxidation at High Temperatures

When exposed to elevated temperatures, titanium forms an oxide layer that can:

- Affect surface properties

- Reduce material strength

- Compromise dimensional accuracy

- Impact aesthetic appearance

Thermal Conductivity Limitations

Titanium’s thermal properties present unique challenges:

- Poor heat distribution

- Limited heat transfer efficiency

- Increased tooling wear during machining

- Higher processing costs

Temperature-Related Processing Issues

Working with titanium requires careful temperature control. Here’s what we’ve learned through our manufacturing experience:

| Temperature Range (°C) | Observed Effects | Manufacturing Implications |

|---|---|---|

| 20-400 | Stable performance | Standard processing possible |

| 400-600 | Oxide layer formation | Special coating needed |

| 600-800 | Increased brittleness | Limited workability |

| Above 800 | Severe oxidation | Requires inert atmosphere |

Chemical Reactivity Concerns

Titanium shows significant reactivity with:

Halogen Elements

- Chlorine gas exposure can cause severe degradation

- Fluorine compounds may trigger rapid oxidation

- Bromine and iodine can initiate surface reactions

Acid Sensitivity

While generally corrosion-resistant, titanium can be vulnerable to:

- Concentrated sulfuric acid

- Hot hydrochloric acid

- Organic acids at elevated temperatures

Processing and Fabrication Challenges

In our manufacturing facility, we’ve identified several processing-related weaknesses:

Machining Difficulties

- High tool wear rates

- Special cutting tools required

- Slower processing speeds needed

- Higher production costs

Welding Complications

Titanium welding presents unique challenges:

- Requires perfect shielding gas coverage

- High sensitivity to contamination

- Special equipment needs

- Extensive operator training required

Cost-Related Weaknesses

The economic aspects of titanium usage include:

- Higher raw material costs compared to steel

- Increased processing expenses

- Specialized handling requirements

- Extended production times

Environmental Factors

Environmental conditions can affect titanium’s performance:

Atmospheric Conditions

- High-temperature environments

- Salt-rich atmospheres

- Industrial pollutants

- UV radiation exposure

Application-Specific Limitations

Different applications face unique challenges:

| Application Type | Primary Weakness | Mitigation Strategy |

|---|---|---|

| Aerospace | Weight constraints | Optimized design |

| Medical | Biocompatibility | Surface treatment |

| Industrial | Cost factors | Alternative alloys |

| Marine | Galvanic corrosion | Isolation methods |

Design Considerations

To overcome titanium’s weaknesses, consider:

Structural Limitations

- Fatigue behavior under cyclic loading

- Stress concentration sensitivity

- Impact resistance variations

- Dimensional stability issues

Surface Treatment Requirements

- Specialized coating needs

- Surface preparation complexity

- Finish quality maintenance

- Wear resistance enhancement

In my experience at PTSMAKE, understanding these weaknesses has been crucial for successful project completion. We’ve developed specialized processes to address these challenges, ensuring our titanium components meet the highest quality standards. By carefully considering these limitations during the design and manufacturing phases, we can help our clients achieve optimal results while minimizing potential issues.

How Does Titanium’s Hardness Affect CNC Machining Processes?

CNC machining titanium presents significant challenges for manufacturers worldwide. The material’s exceptional hardness, while beneficial for end-use applications, creates complexities in machining processes, leading to increased tool wear, longer production times, and higher costs.

Titanium’s hardness significantly impacts CNC machining through increased tool wear, reduced cutting speeds, and specific cooling requirements. These factors directly affect machining strategies, tool selection, and overall production efficiency in manufacturing processes.

Understanding Titanium’s Hardness Characteristics

Titanium’s unique properties stem from its crystalline structure4, which contributes to its exceptional strength-to-weight ratio. In my experience working with various metals at PTSMAKE, I’ve observed that titanium’s hardness characteristics differ significantly from other common materials.

Comparing Titanium with Other Common Materials

| Material | Brinell Hardness (HB) | Relative Machinability |

|---|---|---|

| Titanium Grade 5 | 334 | Poor |

| Stainless Steel 316 | 149 | Moderate |

| Aluminum 6061 | 95 | Excellent |

| Tool Steel | 560 | Fair |

Impact on Cutting Tools and Parameters

Tool Wear Considerations

Working with titanium requires careful attention to tool selection and maintenance. At PTSMAKE, we’ve optimized our processes to manage the accelerated tool wear that occurs when machining titanium. The material’s high strength and low thermal conductivity cause tools to deteriorate faster than when working with other metals.

Cutting Speed Adjustments

The hardness of titanium necessitates slower cutting speeds compared to other materials:

- Recommended cutting speed: 30-60 m/min

- Feed rate reduction: 20-40% compared to steel

- Depth of cut: Limited to prevent tool damage

Cooling and Heat Management Strategies

Coolant Selection

The proper coolant strategy is crucial when machining titanium. I recommend using:

- High-pressure coolant systems

- Oil-based cutting fluids for better lubrication

- Advanced cooling techniques like cryogenic cooling

Temperature Control Methods

Maintaining optimal temperature during machining is essential:

- Regular coolant flow checks

- Strategic pause points in machining cycles

- Temperature monitoring systems

Specialized Machining Techniques

Tool Path Optimization

At PTSMAKE, we employ specific tool path strategies for titanium:

- Trochoidal milling patterns

- Reduced engagement angles

- Optimized entry and exit moves

Machine Settings Adaptation

Proper machine settings are crucial for successful titanium machining:

- Increased spindle rigidity requirements

- Enhanced vibration dampening

- Precise tool holder selection

Quality Control Considerations

Surface Finish Management

Achieving desired surface finishes requires:

- Regular tool condition monitoring

- Appropriate cutting parameter selection

- Advanced surface measurement techniques

Dimensional Accuracy

Maintaining tight tolerances involves:

- Regular machine calibration

- Temperature-controlled environment

- Precise measurement protocols

Economic Implications

Cost Factors

The hardness of titanium affects various cost elements:

- Higher tool replacement frequency

- Increased machining time

- Enhanced cooling system requirements

Production Planning

Effective planning must account for:

- Extended cycle times

- Higher tool inventory needs

- Additional quality control steps

Best Practices and Recommendations

Tool Selection Guidelines

Based on our experience at PTSMAKE, optimal results come from:

- Carbide tools with specific coatings

- Rigid tool holders

- Appropriate tool geometries for titanium

Process Optimization Strategies

Success in titanium machining requires:

- Regular process monitoring

- Continuous improvement protocols

- Operator training programs

Industry Applications and Future Trends

The challenges of machining titanium continue to drive innovation in:

- Advanced cutting tool materials

- Improved machining strategies

- New cooling technologies

Our team at PTSMAKE stays current with these developments to provide the best possible solutions for our clients’ titanium machining needs.

Environmental and Safety Considerations

When working with titanium, proper safety measures include:

- Adequate ventilation systems

- Proper chip management

- Fire prevention protocols

The hardness of titanium significantly impacts every aspect of the CNC machining process, from tool selection to final quality control. Understanding these effects is crucial for successful manufacturing outcomes.

Can Titanium Replace Steel In High-Stress Industrial Applications?

Steel has dominated industrial applications for centuries, but concerns about weight, corrosion, and environmental impact are pushing manufacturers to seek alternatives. The challenge lies in finding materials that can match steel’s strength while offering better performance in specific applications.

Titanium can replace steel in certain high-stress industrial applications, particularly where weight reduction, corrosion resistance, and biocompatibility are crucial. However, its high cost and specific processing requirements make it more suitable for specialized applications rather than universal steel replacement.

Understanding Material Properties

When comparing titanium and steel for high-stress applications, we need to examine several key properties. I’ve observed that many engineers focus solely on strength, overlooking other crucial factors. Let’s break down these properties in detail:

Strength-to-Weight Ratio

Titanium’s most significant advantage is its exceptional specific strength5. While steel typically has higher absolute strength, titanium’s lower density gives it a superior strength-to-weight ratio. This makes it particularly valuable in:

- Aerospace components

- High-performance automotive parts

- Marine equipment

- Medical implants

Corrosion Resistance Comparison

Based on my experience at PTSMAKE, I’ve seen how corrosion resistance can be a game-changer in material selection. Here’s a comparative analysis:

| Property | Titanium | Steel |

|---|---|---|

| Salt Water Resistance | Excellent | Poor to Moderate |

| Chemical Resistance | Very High | Moderate |

| Surface Oxidation | Forms protective oxide layer | Requires coating |

| Maintenance Needs | Minimal | Regular |

Cost and Manufacturing Considerations

Economic Factors

The cost difference between titanium and steel remains significant:

- Raw material costs (titanium is 5-10 times more expensive)

- Processing requirements

- Tooling wear and maintenance

- Production time and complexity

Manufacturing Challenges

At PTSMAKE, we’ve developed specialized processes for both materials. Here are key manufacturing considerations:

Processing Requirements

| Aspect | Titanium | Steel |

|---|---|---|

| Machining Speed | Slower | Faster |

| Tool Wear | Higher | Lower |

| Heat Treatment | Complex | Well-established |

| Welding Difficulty | High | Moderate |

Application-Specific Considerations

Aerospace Industry

Titanium excels in aerospace applications due to:

- High temperature resistance

- Fatigue strength

- Weight savings

- Compatibility with composite materials

Medical Applications

The biomedical industry particularly benefits from titanium’s:

- Biocompatibility

- Non-toxic properties

- Similar elasticity to human bone

- Excellent osseointegration

Industrial Processing

In chemical processing and marine applications, titanium offers:

- Superior acid resistance

- Zero contamination risk

- Extended equipment life

- Reduced maintenance costs

Environmental Impact

Sustainability Factors

The environmental comparison between titanium and steel includes:

- Energy consumption during production

- Recyclability potential

- Lifetime carbon footprint

- Waste reduction through longer service life

Long-term Environmental Benefits

While titanium production requires more energy initially, its benefits include:

- Reduced fuel consumption in transport applications

- Lower maintenance requirements

- Longer service life

- Complete recyclability

Future Trends and Innovations

Emerging Technologies

New developments are making titanium more viable:

- Improved manufacturing processes

- Advanced alloy development

- Cost reduction strategies

- Novel applications

Market Evolution

The titanium market is evolving with:

- Increasing demand in emerging sectors

- Development of hybrid materials

- New processing technologies

- Growing focus on sustainability

At PTSMAKE, we’ve successfully implemented titanium solutions in various high-stress applications, particularly in aerospace and medical components. While titanium cannot completely replace steel in all applications, it offers compelling advantages in specific scenarios where its unique properties justify the higher cost.

The decision between titanium and steel ultimately depends on:

- Application requirements

- Budget constraints

- Performance expectations

- Environmental considerations

- Maintenance needs

For high-stress industrial applications requiring exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility, titanium often proves to be the superior choice despite its higher initial cost.

How Does Titanium’s Corrosion Resistance Compare To Steel?

Metal corrosion poses a significant challenge across numerous industries, leading to billions in maintenance costs and potential safety hazards. When critical components fail due to corrosion, it can result in devastating consequences, from production delays to catastrophic structural failures.

Titanium generally offers superior corrosion resistance compared to steel due to its naturally forming protective oxide layer. While steel can rust in moisture and harsh environments, titanium maintains its integrity even in demanding conditions like saltwater exposure and chemical processing.

Understanding the Science Behind Corrosion Resistance

The exceptional corrosion resistance of titanium stems from its ability to form a stable passivation layer6 on its surface. This self-healing oxide film forms spontaneously when exposed to oxygen, creating an extremely thin but highly effective barrier against corrosive attacks. In my experience working with various metals, I’ve observed that this protective layer reforms almost instantly if damaged, providing continuous protection.

Chemical Composition and Environmental Factors

The relationship between material composition and corrosion resistance can be better understood through this comparison:

| Property | Titanium | Steel |

|---|---|---|

| Oxide Layer | TiO2 (highly stable) | Fe2O3 (unstable) |

| Formation Speed | Immediate | Gradual |

| Layer Stability | Self-healing | Deteriorates |

| pH Resistance | 0-14 | 4-12 |

Performance in Different Environments

Marine Applications

In seawater environments, titanium shows remarkable resistance to corrosion. At PTSMAKE, we’ve manufactured numerous marine components, and I can confirm that titanium consistently outperforms steel in saltwater conditions. The metal shows virtually no deterioration even after extended exposure, while steel requires significant protective measures.

Chemical Processing Industry

When it comes to chemical processing applications, titanium’s corrosion resistance truly shines. The metal maintains its integrity in environments where even stainless steel might fail:

| Environment | Titanium Performance | Steel Performance |

|---|---|---|

| Chlorine | Excellent | Poor |

| Oxidizing Acids | Very Good | Fair to Poor |

| Organic Acids | Excellent | Variable |

| Alkaline Solutions | Excellent | Moderate |

Cost-Benefit Analysis

Initial Investment vs. Long-term Value

While titanium’s upfront cost is higher than steel, its superior corrosion resistance often results in lower lifetime costs:

- Reduced maintenance requirements

- Longer service life

- Lower replacement frequency

- Minimal downtime for repairs

Industry-Specific Applications

Different industries require varying levels of corrosion resistance:

| Industry | Recommended Material | Reasoning |

|---|---|---|

| Aerospace | Titanium | High strength-to-weight ratio, excellent corrosion resistance |

| Chemical Processing | Titanium | Superior chemical resistance |

| Construction | Steel with coating | Cost-effective for most applications |

| Marine | Titanium or Special Steel | Depends on exposure level and budget |

Temperature Effects on Corrosion Resistance

The relationship between temperature and corrosion resistance is crucial:

High-Temperature Performance

Titanium maintains its corrosion resistance at elevated temperatures, while steel’s protective properties may deteriorate. At PTSMAKE, we’ve developed specialized titanium components for high-temperature applications where steel would typically fail.

Low-Temperature Behavior

In cryogenic conditions, titanium’s corrosion resistance remains stable, while some steels become brittle and more susceptible to corrosion-related failures.

Maintenance Requirements

The maintenance needs for both materials differ significantly:

| Aspect | Titanium | Steel |

|---|---|---|

| Inspection Frequency | Annual | Quarterly |

| Surface Treatment | Rarely needed | Regular coating |

| Cleaning Requirements | Minimal | Regular |

| Repair Frequency | Very low | Moderate to high |

Future Developments and Innovations

The field of corrosion resistance continues to evolve:

Emerging Technologies

- Advanced surface treatments

- New alloy compositions

- Hybrid materials

- Smart coatings with self-reporting capabilities

Industry Trends

The demand for corrosion-resistant materials is growing, particularly in:

- Renewable energy systems

- Medical devices

- Advanced manufacturing

- Sustainable infrastructure

Making the Right Choice

When selecting between titanium and steel, consider:

- Environmental exposure conditions

- Service life requirements

- Maintenance capabilities

- Budget constraints

- Safety considerations

At PTSMAKE, we assist clients in making informed decisions based on these factors, ensuring optimal material selection for their specific applications. Our expertise in both titanium and steel manufacturing allows us to provide comprehensive guidance for various industrial needs.

What Industries Prefer Titanium Over Steel For Precision Components?

Many manufacturers struggle to choose between titanium and steel for their precision components. The wrong material choice can lead to component failure, reduced performance, and wasted resources. These challenges become even more critical in high-stakes industries where failure isn’t an option.

The aerospace, medical, automotive, and marine industries often prefer titanium over steel for precision components due to its superior strength-to-weight ratio, excellent corrosion resistance, and biocompatibility. Despite higher costs, titanium’s unique properties make it invaluable for specific applications.

Material Properties Comparison

Understanding the fundamental differences between titanium and steel helps explain why certain industries favor titanium. The metallurgical composition7 of these materials directly affects their performance in various applications.

Strength-to-Weight Ratio

Titanium’s exceptional strength-to-weight ratio makes it particularly valuable for weight-sensitive applications. While steel is generally stronger, titanium offers comparable strength at roughly half the weight. This characteristic becomes crucial in applications where every gram matters.

| Property | Titanium | Steel |

|---|---|---|

| Density (g/cm³) | 4.5 | 7.8 |

| Tensile Strength (MPa) | 950 | 700-1000 |

| Weight Efficiency | High | Moderate |

Industry-Specific Applications

Aerospace Industry

In aerospace applications, titanium components are essential for:

- Engine components requiring high heat resistance

- Structural elements where weight reduction is critical

- Landing gear components exposed to extreme stress

At PTSMAKE, we’ve manufactured numerous titanium components for aerospace clients, consistently meeting their stringent requirements for precision and reliability.

Medical Industry

The medical sector heavily relies on titanium for:

- Surgical instruments requiring exceptional durability

- Implants and prosthetics

- Dental applications

The material’s biocompatibility and resistance to bodily fluids make it indispensable in medical applications.

Automotive Performance Sector

High-performance automotive applications include:

- Valve springs and retainers

- Connecting rods

- Exhaust systems

These components benefit from titanium’s superior strength and reduced weight, enhancing vehicle performance.

Cost Considerations and ROI

Initial Investment vs. Long-term Benefits

| Factor | Titanium | Steel |

|---|---|---|

| Raw Material Cost | Higher | Lower |

| Maintenance Requirements | Minimal | Moderate |

| Lifespan | Extended | Standard |

| Replacement Frequency | Less frequent | More frequent |

Manufacturing Challenges and Solutions

Precision Machining Considerations

Working with titanium requires specialized expertise and equipment. Key factors include:

- Proper cutting speeds and feeds

- Appropriate tooling selection

- Temperature control during machining

Our facility at PTSMAKE maintains advanced CNC machines specifically calibrated for titanium machining, ensuring optimal results.

Quality Control Measures

Maintaining quality in titanium components requires:

- Advanced inspection techniques

- Strict material certification

- Comprehensive testing protocols

Environmental Impact

Sustainability Factors

- Lower replacement frequency reduces waste

- Energy efficiency in long-term applications

- Recyclability potential

Emerging Applications

New Industries Adopting Titanium

- Renewable energy sector

- Marine applications

- Sports equipment manufacturing

Future Trends

The demand for titanium components continues to grow in:

- Electric vehicle manufacturing

- Space exploration

- Advanced robotics

Selection Criteria Guide

Application Assessment Factors

Consider these key points when choosing between titanium and steel:

- Operating environment conditions

- Weight requirements

- Budget constraints

- Performance expectations

I’ve observed that successful material selection often depends on a thorough understanding of these factors combined with practical application experience.

Industry Standards and Certifications

Quality Assurance

Essential certifications include:

- ISO 9001:2015

- AS9100D for aerospace

- ISO 13485 for medical devices

At PTSMAKE, we maintain these certifications to ensure our titanium components meet industry standards.

Given my experience in precision manufacturing, I’ve seen titanium consistently outperform steel in applications where weight reduction, corrosion resistance, and biocompatibility are crucial. While steel remains valuable for many applications, titanium’s unique properties make it irreplaceable in specific industries despite its higher cost.

The decision between titanium and steel ultimately depends on your specific application requirements. For precision components in demanding industries, titanium often proves to be the superior choice, offering long-term benefits that outweigh its initial cost.

Remember that the key to successful titanium injection molding lies in careful material selection, precise process control, and regular monitoring of all production parameters. With proper expertise and equipment, manufacturers can effectively overcome the challenges posed by titanium’s hardness and produce high-quality injection molded parts.

The extraction process, known as the Kroll process, is a complex metallurgical procedure used to produce titanium metal from titanium tetrachloride. ↩

Defines material’s elastic limit for structural integrity assessment ↩

Explains material failure mechanism; helps prevent structural degradation in titanium components. ↩

Explains material behavior for optimized machining processes and improved component performance. ↩

Explains titanium’s advantage in weight-sensitive applications through strength-to-weight metrics. ↩

Explains titanium’s self-healing oxide layer crucial for corrosion resistance. Helps in material selection decisions. ↩

Explains material performance factors. Helps optimize component design choices. ↩