Have you ever wondered why aerospace engineers often choose titanium over steel? The decision between these two metals can make or break a project’s success. As a manufacturing expert, I’ve seen countless engineers struggle with this choice, often making costly mistakes due to misconceptions about their relative strengths.

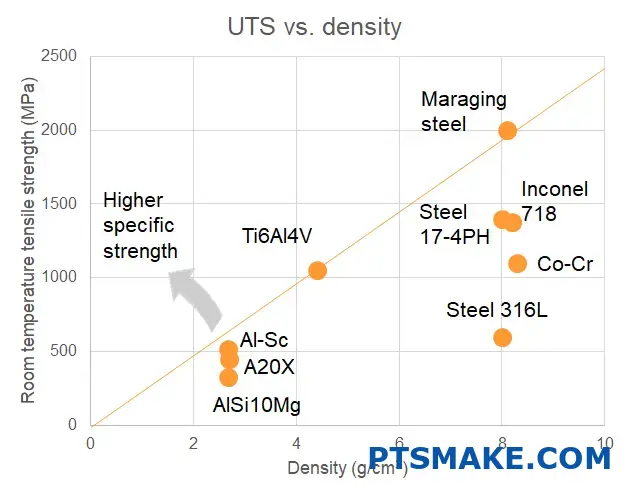

While both metals are incredibly strong, titanium and steel have different strength profiles. Titanium has a higher strength-to-weight ratio than steel, making it stronger per unit weight. However, steel generally has higher ultimate tensile strength and is more resistant to pure mechanical force.

I understand how confusing these material choices can be, especially when dealing with critical components. Having worked with both materials extensively in aerospace and medical device projects, I can tell you that the answer isn’t as straightforward as many think. Let me share some key insights about these materials that might surprise you and help you make better decisions for your next project.

Does Titanium Bend Or Break?

Have you ever wondered about the true nature of titanium’s behavior under stress? Many engineers and designers face uncertainty when choosing between titanium and other metals, especially when their projects demand both strength and flexibility. The consequences of making the wrong choice can be costly – from component failure to project delays and safety risks.

Titanium can both bend and break, depending on the applied force and conditions. It exhibits remarkable elastic properties, allowing it to bend under stress and return to its original shape. However, like all metals, it will break when subjected to forces beyond its ultimate tensile strength.

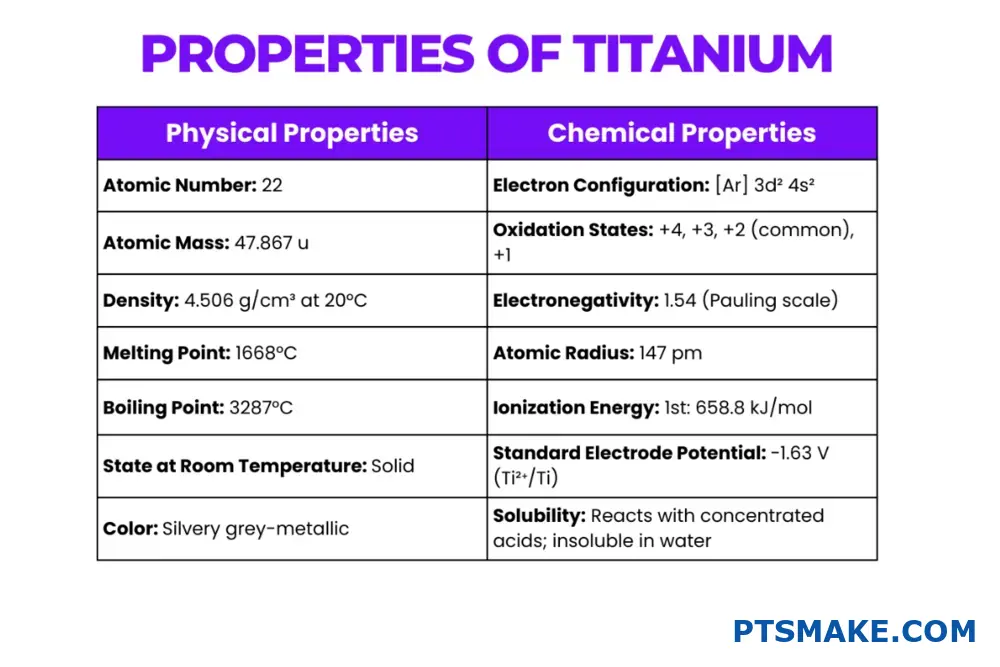

Understanding Titanium’s Physical Properties

When examining titanium’s behavior, we must first understand its fundamental properties. I’ve worked with various grades of titanium at PTSMAKE, and its elastic modulus consistently impresses our engineering team. The material’s unique characteristics make it ideal for applications requiring both strength and flexibility.

Comparative Strength Analysis

Let’s examine how titanium compares to other common metals:

| Property | Titanium | Steel | Aluminum |

|---|---|---|---|

| Density (g/cm³) | 4.5 | 7.8 | 2.7 |

| Tensile Strength (MPa) | 830-1000 | 500-800 | 200-600 |

| Elastic Modulus (GPa) | 110 | 200 | 69 |

Factors Affecting Titanium’s Behavior

Temperature Impact

Temperature plays a crucial role in titanium’s performance. At PTSMAKE, we’ve observed that titanium maintains its structural integrity across a wide temperature range, making it excellent for aerospace and medical applications. However, extreme temperatures can affect its bending characteristics:

- Room temperature: Optimal flexibility and strength

- High temperatures (>500°C): Increased ductility

- Low temperatures: Maintained strength with reduced ductility

Loading Conditions

The way force is applied significantly influences whether titanium will bend or break:

- Gradual loading allows for controlled deformation

- Sudden impact may cause brittle failure

- Cyclic loading can lead to fatigue

Real-World Applications

Aerospace Industry

In aerospace applications, titanium’s blend of strength and flexibility is invaluable. At PTSMAKE, we manufacture titanium components that must withstand:

- Extreme temperature variations

- High-stress environments

- Constant vibration

- Corrosive conditions

Medical Implants

The medical industry relies heavily on titanium’s unique properties:

- Biocompatibility

- Stress distribution similar to bone

- Excellent fatigue resistance

- Corrosion resistance

Design Considerations for Titanium Components

When designing titanium parts, several factors must be considered:

Material Grade Selection

The choice of titanium grade affects its behavior:

| Grade | Strength | Flexibility | Common Applications |

|---|---|---|---|

| Grade 1 | Moderate | Excellent | Chemical processing |

| Grade 2 | Good | Very Good | General purpose |

| Grade 5 | Excellent | Good | Aerospace, Medical |

Manufacturing Methods

Different manufacturing processes can affect titanium’s properties:

Cold Working

- Increases strength

- Reduces ductility

- Improves surface finish

Heat Treatment

- Relieves internal stresses

- Optimizes mechanical properties

- Enhances performance

Surface Treatment

- Improves wear resistance

- Enhances fatigue life

- Provides better corrosion protection

Prevention of Titanium Failure

To prevent unexpected failure, consider these key points:

- Design within material limits

- Account for environmental factors

- Implement proper quality control

- Regular maintenance and inspection

Performance Optimization

To maximize titanium’s performance:

- Proper material grade selection

- Optimal design geometry

- Appropriate manufacturing processes

- Quality control measures

This comprehensive understanding of titanium’s behavior helps engineers and designers make informed decisions. At PTSMAKE, we leverage this knowledge to provide high-quality titanium components that meet specific application requirements.

Is Titanium Flexible Or Brittle?

Have you ever wondered about titanium’s true nature when it comes to flexibility? Many engineers and designers struggle with this question, especially when choosing materials for critical applications. The confusion often leads to costly mistakes in material selection and potential project delays.

Titanium exhibits both flexible and brittle properties depending on its grade and processing. Pure titanium is relatively flexible, with good ductility and the ability to bend without breaking. However, titanium alloys can become more brittle when combined with other elements or subjected to specific heat treatments.

Understanding Titanium’s Dual Nature

Titanium’s behavior is influenced by its crystalline structure1. At PTSMAKE, we work extensively with various grades of titanium, and I’ve observed how its properties can vary significantly. Here’s a detailed breakdown of factors affecting titanium’s flexibility and brittleness:

Temperature Effects on Titanium Properties

Temperature plays a crucial role in determining titanium’s mechanical behavior. The material exhibits different characteristics at various temperature ranges:

| Temperature Range (°C) | Flexibility Characteristics | Brittleness Level |

|---|---|---|

| Below 0 | Reduced ductility | Increased brittleness |

| 0-200 | Optimal flexibility | Minimal brittleness |

| 200-400 | Moderate flexibility | Moderate brittleness |

| Above 400 | Decreased flexibility | High brittleness |

Composition Impact on Titanium Properties

The addition of alloying elements significantly affects titanium’s mechanical properties:

Alpha Titanium Alloys

These alloys maintain good flexibility at room temperature and exhibit excellent weldability. They’re commonly used in applications requiring good ductility and corrosion resistance.

Beta Titanium Alloys

These demonstrate higher strength but can be more brittle than alpha alloys. They’re often chosen for high-strength applications where some sacrifice in ductility is acceptable.

Alpha-Beta Titanium Alloys

These provide a balance between flexibility and strength, making them popular in aerospace and medical applications.

Processing Methods and Their Effects

Different processing techniques can alter titanium’s properties:

Heat Treatment

- Annealing: Increases flexibility

- Aging: Can increase strength but may reduce ductility

- Solution treating: Affects both strength and ductility

Cold Working

- Improves strength

- Can reduce ductility if excessive

- Requires careful control to maintain desired properties

Industry Applications Based on Flexibility Requirements

In my experience at PTSMAKE, we’ve worked with various industries that leverage titanium’s unique properties:

Aerospace Applications

- Landing gear components requiring both strength and flexibility

- Airframe structures needing fatigue resistance

- Engine components requiring high-temperature stability

Medical Devices

- Implants requiring biocompatibility and flexibility

- Surgical instruments needing both strength and ductility

- Dental applications requiring specific mechanical properties

Industrial Applications

- Chemical processing equipment

- Marine applications

- Sports equipment

Comparing Titanium with Other Metals

To better understand titanium’s properties, let’s compare it with other common metals:

| Metal | Flexibility Rating | Brittleness Rating | Relative Strength |

|---|---|---|---|

| Titanium | 7/10 | 4/10 | 8/10 |

| Steel | 6/10 | 5/10 | 7/10 |

| Aluminum | 8/10 | 3/10 | 5/10 |

| Copper | 9/10 | 2/10 | 4/10 |

Design Considerations for Titanium Components

When designing with titanium, several factors need consideration:

Stress Distribution

- Proper design to avoid stress concentration

- Consideration of loading conditions

- Analysis of fatigue requirements

Environmental Factors

- Temperature exposure

- Chemical exposure

- Mechanical stress levels

Manufacturing Methods

At PTSMAKE, we’ve developed specialized techniques for working with titanium:

- Precise temperature control during processing

- Specific tooling requirements

- Controlled cooling rates

Practical Tips for Working with Titanium

Based on our experience at PTSMAKE, here are key considerations:

Material Selection

- Choose the appropriate grade based on application requirements

- Consider cost versus performance requirements

- Evaluate environmental conditions

Processing Guidelines

- Maintain proper temperature control

- Use appropriate cutting tools and speeds

- Follow recommended heat treatment procedures

Quality Control

- Regular material testing

- Process monitoring

- Documentation of results

The flexibility and brittleness of titanium are not mutually exclusive properties but rather characteristics that can be controlled through proper material selection and processing. Understanding these properties helps in making informed decisions for specific applications, ensuring optimal performance and reliability in the final product.

Can You Bend Titanium?

Walking through my manufacturing facility, clients often ask me about titanium’s flexibility. They’re concerned about whether their titanium parts can withstand bending stresses without breaking. The confusion about titanium’s bendability has led to costly design mistakes and material waste.

Yes, titanium can be bent, but it requires specific conditions and techniques. While titanium has high strength comparable to steel, it maintains good ductility and can be formed when proper temperature, tools, and methods are applied. The success of bending titanium depends on factors like grade, thickness, and bending radius.

Understanding Titanium’s Physical Properties

When discussing titanium’s bendability, we must first understand its unique physical properties. Titanium exhibits remarkable work hardening characteristics, which means its strength increases as it’s deformed. At PTSMAKE, we’ve observed that this property makes titanium both challenging and rewarding to work with.

Mechanical Properties Comparison

| Property | Titanium | Steel | Aluminum |

|---|---|---|---|

| Tensile Strength (MPa) | 830-1030 | 500-800 | 230-570 |

| Yield Strength (MPa) | 760-880 | 250-600 | 95-500 |

| Elongation (%) | 10-15 | 10-25 | 10-25 |

| Density (g/cm³) | 4.5 | 7.8 | 2.7 |

Factors Affecting Titanium Bending

Several critical factors influence the success of titanium bending:

Temperature Considerations

Cold Bending (Room Temperature)

- Limited to simple shapes

- Requires greater force

- Higher spring-back effect

- Suitable for thin sections

Hot Bending (300-500°C)

- Allows more complex shapes

- Reduces required force

- Minimizes spring-back

- Better for thick sections

Material Grade Impact

Different titanium grades exhibit varying bendability:

- Grade 1: Most formable, ideal for bending

- Grade 2: Good formability, commonly used

- Grade 5 (Ti-6Al-4V): More challenging to bend

- Beta titanium: Excellent formability when heat-treated

Best Practices for Bending Titanium

In my manufacturing experience, successful titanium bending requires:

Proper Tooling Selection

- Use dedicated titanium-specific tools

- Maintain clean, smooth die surfaces

- Select appropriate bend radii

- Ensure proper lubrication

Process Controls

Speed Control

- Maintain consistent bending speed

- Avoid sudden movements

- Monitor force application

Temperature Management

- Use precise temperature control systems

- Maintain uniform heating

- Consider local heating methods

Comparing Titanium Bending Methods

Different bending methods offer various advantages:

| Method | Advantages | Limitations | Best Applications |

|---|---|---|---|

| Press Brake | High precision | Limited to simple bends | Sheet metal components |

| Roll Forming | Continuous operation | High setup costs | Long, uniform profiles |

| Hot Forming | Complex shapes possible | Requires special equipment | Aerospace parts |

| Cold Forming | No heat required | Limited bend radius | Simple components |

Industry Applications

At PTSMAKE, we’ve successfully implemented titanium bending in various sectors:

Aerospace Applications

- Engine components

- Structural elements

- Hydraulic system parts

Medical Device Manufacturing

- Implants

- Surgical instruments

- Support structures

Industrial Uses

- Chemical processing equipment

- Heat exchangers

- Marine applications

Common Challenges and Solutions

Material Spring-back

- Challenge: Titanium’s elastic recovery after bending

- Solution: Over-bending compensation and precise angle calculation

Surface Protection

- Challenge: Surface marring during forming

- Solution: Protective coatings and proper tool maintenance

Cost Considerations

- Challenge: Higher material and processing costs

- Solution: Optimized design for manufacturing and material utilization

Quality Control Measures

To ensure successful titanium bending:

Inspection Methods

- Visual inspection

- Dimensional verification

- Non-destructive testing

- Surface quality assessment

Documentation Requirements

- Material certification

- Process parameters

- Quality control records

- Traceability information

The ability to bend titanium effectively opens up numerous design possibilities while maintaining the material’s exceptional properties. Understanding these aspects ensures successful manufacturing outcomes and optimal part performance.

What Are The Pros And Cons Of Titanium?

Every manufacturer faces the challenge of selecting the right material for their projects. The wrong choice can lead to project failures, budget overruns, and compromised product performance – a nightmare scenario that keeps engineers awake at night.

Titanium stands out as a remarkable metal with impressive strength-to-weight ratio and corrosion resistance. However, it comes with high costs and specific manufacturing challenges that require careful consideration before implementation in any project.

Strength and Weight Characteristics

Unmatched Strength-to-Weight Ratio

Titanium’s most notable advantage is its exceptional strength-to-weight ratio. When working with titanium at PTSMAKE, I’ve observed that its tensile strength2 rivals that of steel while being 45% lighter. This property makes it ideal for aerospace and high-performance automotive applications where weight reduction is crucial.

Structural Stability

The metal maintains its structural integrity across a wide temperature range, from cryogenic conditions to approximately 1000°F (538°C). This stability has proven invaluable in many projects I’ve overseen, particularly in aerospace components manufacturing.

Durability Factors

Corrosion Resistance

One of titanium’s most impressive features is its natural resistance to corrosion. It forms a protective oxide layer that makes it virtually immune to natural weathering and chemical attacks. This property has made it a preferred choice for marine applications and medical implants.

Fatigue Performance

In my experience with various materials, titanium exhibits superior fatigue resistance compared to many other metals. This characteristic means parts can withstand repeated stress cycles without failing, making it excellent for:

- Aircraft components

- Medical implants

- High-performance engine parts

- Marine equipment

Cost Considerations

Here’s a detailed breakdown of titanium costs compared to other materials:

| Factor | Titanium | Steel | Aluminum |

|---|---|---|---|

| Raw Material Cost | High | Low | Medium |

| Processing Cost | Very High | Low | Medium |

| Tooling Wear | Significant | Minimal | Low |

| Maintenance Cost | Low | Medium | Low |

| Lifetime Value | Excellent | Good | Good |

Manufacturing Challenges

Complex Processing Requirements

At PTSMAKE, we’ve developed specialized procedures for titanium machining because the material requires:

- Specific cutting tools

- Controlled cutting speeds

- Proper cooling methods

- Special handling procedures

Limited Formability

The material’s high strength can make forming operations challenging. It requires:

- Higher forming forces

- Special heating procedures

- More precise tooling

- Experienced operators

Environmental Impact

Production Energy Requirements

The extraction and processing of titanium require significant energy input. However, its longevity and recyclability often offset these initial environmental costs.

Recyclability Benefits

Titanium is 100% recyclable without loss of quality. At PTSMAKE, we implement strict recycling protocols for all titanium scrap, contributing to sustainable manufacturing practices.

Application-Specific Advantages

The benefits of titanium vary by industry:

| Industry | Key Benefits | Common Applications |

|---|---|---|

| Aerospace | Weight reduction, strength | Structural components, engine parts |

| Medical | Biocompatibility, durability | Implants, surgical instruments |

| Marine | Corrosion resistance | Propellers, underwater equipment |

| Automotive | Performance, weight reduction | Racing components, valve springs |

Material Compatibility

Chemical Reactivity

While titanium’s reactivity helps form its protective oxide layer, it can also create challenges:

- Requires careful material selection for adjacent components

- Needs specific welding procedures

- May require protective coatings in certain applications

Galvanic Corrosion Considerations

When designing with titanium, we must consider its position in the galvanic series to prevent corrosion issues with other metals.

Maintenance Requirements

Regular Inspection Needs

Despite its durability, titanium components should be regularly inspected for:

- Surface condition

- Structural integrity

- Signs of wear or damage

- Proper functionality

Long-term Performance

In my experience leading projects at PTSMAKE, titanium parts often exceed their expected service life when properly maintained, offering excellent value despite higher initial costs.

Industry-Specific Considerations

Different sectors prioritize different aspects of titanium:

| Sector | Primary Concern | Secondary Consideration |

|---|---|---|

| Military | Performance | Cost |

| Commercial | Cost-effectiveness | Weight savings |

| Medical | Biocompatibility | Durability |

| Industrial | Corrosion resistance | Maintenance |

When considering titanium for your project, it’s essential to weigh these pros and cons carefully. At PTSMAKE, we help clients evaluate their specific needs and determine if titanium is the most suitable material for their application. Our expertise in titanium manufacturing ensures optimal results, whether for prototype development or full-scale production.

Why Don’t We Use Titanium Instead Of Steel?

Every time I discuss materials with clients, they often ask why we don’t just use titanium for everything. After all, isn’t titanium stronger and lighter than steel? This question reveals a common misconception in manufacturing that stronger always means better.

While titanium is indeed stronger by weight than steel and offers excellent corrosion resistance, its high cost and complex manufacturing requirements make it impractical for most applications. Steel remains the preferred choice due to its cost-effectiveness, versatility, and established manufacturing processes.

Cost Considerations in Material Selection

The primary reason titanium isn’t more widely used comes down to economics. I’ve seen this firsthand at PTSMAKE when helping clients choose materials for their projects. The metallurgical extraction3 process for titanium is significantly more complex than steel, resulting in raw material costs that can be 10-20 times higher.

Here’s a detailed cost comparison:

| Material Type | Cost per Pound (USD) | Processing Difficulty | Relative Energy Cost |

|---|---|---|---|

| Carbon Steel | $0.50-$1.00 | Low | Low |

| Stainless Steel | $2.00-$4.00 | Medium | Medium |

| Titanium | $10.00-$20.00 | High | Very High |

Manufacturing Challenges

Temperature Requirements

Titanium’s high melting point (3,034°F) requires specialized equipment and more energy compared to steel (2,500°F). This increases production costs and complexity. At PTSMAKE, we’ve invested in advanced CNC machining centers specifically designed to handle titanium, but not all manufacturers have this capability.

Tool Wear

Working with titanium causes significant tool wear due to:

- Low thermal conductivity

- Chemical reactivity at high temperatures

- High strength retention during machining

These factors lead to shorter tool life and increased manufacturing costs.

Performance Characteristics

Strength-to-Weight Ratio

While titanium has a superior strength-to-weight ratio, this advantage isn’t always necessary:

| Property | Steel | Titanium |

|---|---|---|

| Density (g/cm³) | 7.85 | 4.43 |

| Tensile Strength (MPa) | 400-2000 | 350-1200 |

| Yield Strength (MPa) | 250-1500 | 250-1000 |

Corrosion Resistance

Titanium’s exceptional corrosion resistance makes it ideal for:

- Marine environments

- Chemical processing

- Medical implants

- Aerospace applications

However, for many applications, standard steel or stainless steel provides adequate corrosion resistance at a fraction of the cost.

Environmental Impact

Energy Consumption

The production of titanium requires significantly more energy than steel:

- Titanium: 100-200 kWh/kg

- Steel: 20-30 kWh/kg

This higher energy consumption leads to:

- Increased carbon footprint

- Higher production costs

- Limited production capacity

Recyclability

Steel has a well-established recycling infrastructure, while titanium recycling is more limited and expensive.

Practical Applications

Where Titanium Excels

Titanium is the optimal choice for:

- Aerospace components

- Medical implants

- High-performance sporting goods

- Chemical processing equipment

Where Steel Remains Superior

Steel continues to dominate in:

- Construction

- Automotive manufacturing

- Industrial machinery

- Consumer products

Future Considerations

Emerging Technologies

New manufacturing methods might reduce titanium production costs:

- Advanced extraction techniques

- Improved processing methods

- Novel alloying approaches

Market Trends

The titanium market is evolving with:

- Increasing demand in medical applications

- Growing aerospace industry requirements

- Development of cost-effective processing methods

At PTSMAKE, we’ve seen increasing interest in titanium components for specialized applications, particularly in medical and aerospace sectors. However, steel remains our most requested material due to its balanced properties and cost-effectiveness.

Through careful material selection and advanced manufacturing processes, we help clients achieve optimal performance while maintaining cost-effectiveness. This often means choosing steel over titanium unless specific application requirements justify the additional cost and complexity.

How Does Titanium’s Strength-To-Weight Ratio Compare To Steel?

When choosing materials for critical engineering projects, the strength-to-weight comparison between titanium and steel often creates confusion. Many engineers and designers struggle to determine which material would provide the optimal balance of strength and weight for their specific applications.

Titanium offers a superior strength-to-weight ratio compared to steel, being 45% lighter while maintaining comparable strength. This makes titanium an excellent choice for applications where weight reduction is crucial without compromising structural integrity.

Understanding the Fundamentals of Material Properties

Material Density and Weight Considerations

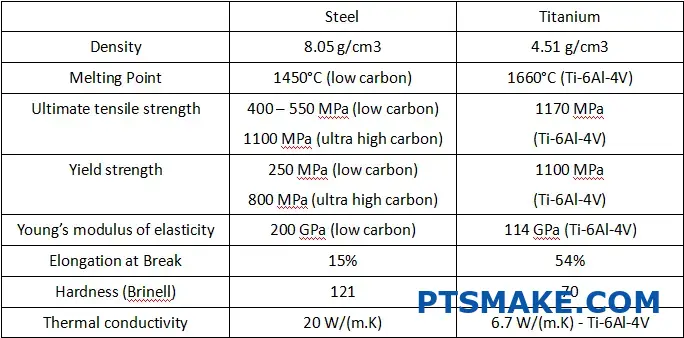

The density of titanium is approximately 4.5 g/cm³, while steel typically ranges from 7.75 to 8.05 g/cm³. This significant difference in density means that titanium components can achieve the same structural performance as steel while weighing considerably less. During my work at PTSMAKE, I’ve observed that this weight advantage becomes particularly crucial in aerospace and automotive applications where every gram matters.

Tensile Strength Analysis

When examining tensile strength, we need to consider that both materials demonstrate different characteristics under various conditions. Titanium’s ultimate tensile strength4 varies depending on the specific alloy, but generally ranges from 830 to 1,172 MPa. In comparison, standard steel grades typically offer tensile strengths between 400 and 800 MPa.

Here’s a detailed comparison of common grades:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Strength-to-Weight Ratio |

|---|---|---|---|

| Ti-6Al-4V | 4.43 | 950 | 214.4 |

| Steel 4340 | 7.85 | 855 | 108.9 |

| Ti Grade 5 | 4.45 | 895 | 201.1 |

| Steel 1045 | 7.87 | 585 | 74.3 |

Environmental Performance and Corrosion Resistance

Chemical Stability

One area where titanium clearly outperforms steel is in corrosion resistance. The natural oxide layer that forms on titanium’s surface provides exceptional protection against various corrosive environments. This makes it particularly valuable in marine applications, where steel would require additional protective coatings or frequent maintenance.

Temperature Performance

Both materials exhibit different behaviors across temperature ranges:

| Temperature Range (°C) | Titanium Performance | Steel Performance |

|---|---|---|

| -50 to 0 | Excellent ductility | Good performance |

| 0 to 400 | Stable strength | Gradual strength loss |

| 400 to 600 | Moderate strength loss | Significant strength reduction |

| Above 600 | Requires special grades | Limited application |

Cost-Benefit Analysis and Application Considerations

Manufacturing Implications

While titanium’s superior strength-to-weight ratio is attractive, it’s important to consider manufacturing challenges. At PTSMAKE, we’ve developed specialized processes for both materials:

Titanium:

- Requires controlled atmosphere during welding

- More complex machining procedures

- Higher tool wear rates

- Specialized cutting tools needed

Steel:

- More forgiving in manufacturing

- Well-established processes

- Lower tooling costs

- Broader supplier network

Industry-Specific Applications

The choice between titanium and steel often depends on specific industry requirements:

Aerospace Industry

- Critical components requiring high strength and low weight

- Fuel efficiency considerations

- High-temperature applications

Medical Industry

- Biocompatibility requirements

- Long-term implant stability

- Corrosion resistance in biological environments

Automotive Sector

- Performance vehicle components

- Weight reduction initiatives

- Structural safety requirements

Economic Considerations

Cost Analysis

The price difference between titanium and steel remains significant:

| Cost Factor | Titanium | Steel |

|---|---|---|

| Raw Material ($/kg) | 35-45 | 2-5 |

| Processing Cost | High | Moderate |

| Maintenance Cost | Low | Moderate to High |

| Lifecycle Cost | Often Lower | Variable |

Long-term Value Assessment

While the initial investment in titanium is higher, the total cost of ownership often favors titanium in specific applications due to:

- Reduced maintenance requirements

- Lower replacement frequency

- Better energy efficiency due to weight savings

- Enhanced durability in harsh environments

Future Trends and Developments

The ongoing development of new manufacturing technologies, particularly in additive manufacturing, is changing how we utilize both materials. At PTSMAKE, we’re seeing increased interest in hybrid solutions that leverage the benefits of both materials in single components.

Emerging Technologies

- Advanced alloying techniques

- Novel surface treatments

- Improved manufacturing processes

- Enhanced recycling methods

This comprehensive comparison shows that while titanium’s strength-to-weight ratio surpasses steel in many applications, the choice between the two materials depends on various factors including application requirements, environmental conditions, and economic considerations. Understanding these differences helps engineers and designers make informed decisions for their specific needs.

What Industries Benefit Most From Titanium’s Strength Over Steel?

In today’s manufacturing landscape, engineers and designers often struggle with material selection for critical applications. The choice between titanium and steel isn’t just about strength – it’s about finding the perfect balance of properties while managing costs and performance requirements.

Based on my experience working with various industries, aerospace, medical, and high-performance automotive sectors benefit most from titanium’s superior strength-to-weight ratio over steel. These industries require materials that offer exceptional performance under extreme conditions while minimizing overall weight.

Aerospace Industry: The Primary Beneficiary

Commercial Aviation

The aerospace sector stands as the largest consumer of titanium alloys, particularly in applications where the specific strength5 is crucial. I’ve observed that modern aircraft manufacturers increasingly prefer titanium over steel for:

- Engine components

- Landing gear structures

- Airframe sections

- Hydraulic systems

Space Exploration

Space vehicles and satellites require materials that can withstand extreme temperature variations and high stress. Titanium’s advantages include:

- Better thermal stability

- Higher corrosion resistance

- Reduced weight without compromising strength

- Enhanced reliability in vacuum conditions

Medical Industry: Where Biocompatibility Matters

Surgical Implants

The medical industry heavily relies on titanium for:

- Joint replacements

- Dental implants

- Bone plates and screws

- Pacemaker casings

Medical Equipment

Beyond implants, titanium proves superior to steel in:

- Surgical instruments

- Medical device components

- Sterilization equipment

Automotive Performance Sector

Racing Applications

High-performance vehicles benefit from titanium’s properties through:

| Component | Benefit Over Steel |

|---|---|

| Connecting Rods | 40% weight reduction |

| Exhaust Systems | Better heat resistance |

| Valve Springs | Higher fatigue strength |

| Suspension Components | Improved performance |

Luxury Vehicles

Premium automotive manufacturers utilize titanium in:

- Brake systems

- Engine components

- Structural reinforcements

- Performance-oriented parts

Marine Industry: Corrosion Resistance Champion

Naval Applications

The marine environment demands materials that can withstand saltwater exposure:

- Propeller shafts

- Hull components

- Underwater equipment

- Heat exchangers

At PTSMAKE, we’ve successfully manufactured numerous titanium components for marine applications, consistently delivering superior corrosion resistance compared to traditional steel parts.

Chemical Processing Industry

Processing Equipment

Titanium excels in chemical processing applications through:

- Storage tanks

- Reaction vessels

- Heat exchangers

- Piping systems

Safety Critical Components

The chemical industry benefits from titanium’s:

- Chemical inertness

- High temperature stability

- Extended service life

- Reduced maintenance requirements

Sports Equipment Manufacturing

Professional Equipment

High-end sports gear manufacturers choose titanium for:

- Tennis rackets

- Golf clubs

- Bicycle frames

- Mountain climbing equipment

Performance Benefits

Athletes benefit from titanium equipment through:

- Reduced weight

- Better vibration dampening

- Increased durability

- Enhanced performance

Energy Sector Applications

Power Generation

The energy industry utilizes titanium in:

- Steam turbine blades

- Heat exchangers

- Offshore platforms

- Geothermal wells

Alternative Energy

Renewable energy systems benefit from titanium’s properties in:

- Solar panel frames

- Wind turbine components

- Tidal energy systems

- Hydrogen fuel cells

Working with both titanium and steel at PTSMAKE has given me unique insights into their respective strengths. While steel remains essential for many applications, titanium’s superior strength-to-weight ratio makes it indispensable in industries where performance, reliability, and weight reduction are critical factors.

The choice between titanium and steel often comes down to specific application requirements, budget constraints, and performance goals. Industries that benefit most from titanium’s strength over steel are those where the material’s unique properties justify its higher cost through improved performance, longer service life, or enhanced safety features.

Through our precision manufacturing capabilities at PTSMAKE, we’ve helped countless clients across these industries optimize their material choices, ensuring they achieve the perfect balance between performance and cost-effectiveness in their applications.

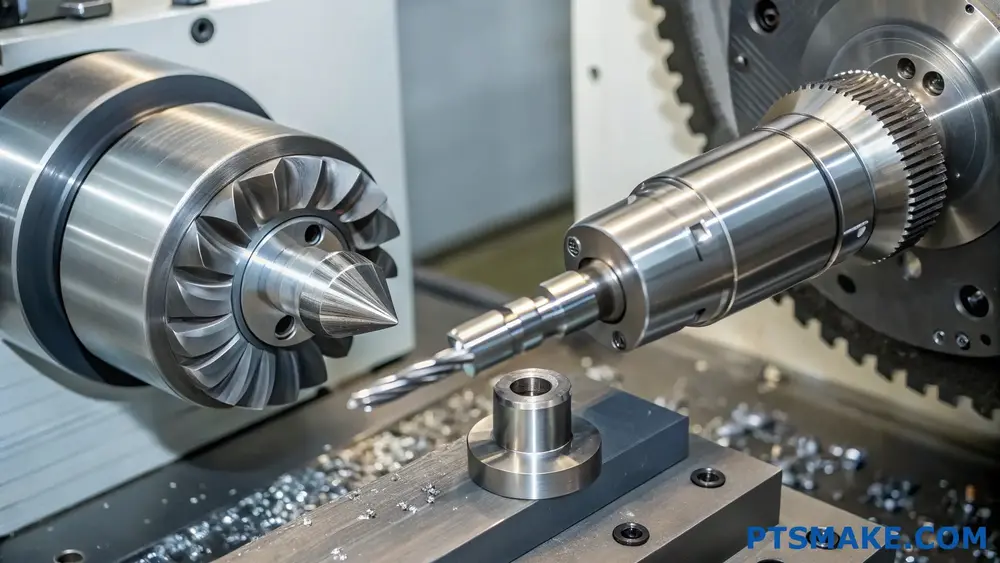

How Does Machining Titanium Compare To Steel For Precision Parts?

Machining titanium and steel for precision parts presents unique challenges that keep many manufacturers awake at night. The complexity of material properties, tooling requirements, and machining parameters can lead to costly mistakes, wasted materials, and missed deadlines.

While both materials have their merits, titanium generally offers superior strength-to-weight ratio and corrosion resistance compared to steel, but requires specialized machining techniques due to its work hardening6 properties and lower thermal conductivity.

Material Properties and Machinability

When comparing titanium and steel for precision machining, understanding their fundamental properties is crucial. I’ve observed that material characteristics significantly impact machining strategies and outcomes:

Mechanical Properties Comparison

| Property | Titanium | Steel |

|---|---|---|

| Tensile Strength | 830-1030 MPa | 370-1000 MPa |

| Density | 4.5 g/cm³ | 7.8 g/cm³ |

| Thermal Conductivity | 7.2 W/m·K | 50.2 W/m·K |

| Hardness (Brinell) | 334 HB | 150-350 HB |

Cutting Speed and Tool Life

The machining speeds for titanium are typically 60-80% slower than steel due to several factors:

- Lower thermal conductivity causing heat concentration

- Higher chemical reactivity with cutting tools

- Greater spring back effect during cutting

At PTSMAKE, we’ve developed specific protocols for machining both materials effectively:

Titanium Machining Considerations

- Requires rigid machine setups

- Demands higher coolant pressure

- Needs specialized cutting tools

- Benefits from lower cutting speeds

- Requires consistent feed rates

Steel Machining Advantages

- More forgiving cutting parameters

- Better heat dissipation

- Wider range of suitable tooling options

- Higher productivity rates

- More cost-effective tooling

Cost Implications

The cost difference between machining titanium and steel is substantial:

Raw Material Costs

| Material Type | Average Cost/lb | Relative Machining Time |

|---|---|---|

| Titanium | $35-45 | 1.8x |

| Steel | $2-15 | 1x |

Application-Specific Considerations

Different industries require different material properties:

Aerospace Applications

- Titanium: Preferred for its strength-to-weight ratio

- Steel: Used in landing gear and structural components

Medical Devices

- Titanium: Biocompatible and corrosion-resistant

- Steel: Surgical instruments and implants

Industrial Equipment

- Titanium: Corrosive environments

- Steel: General-purpose machinery

Surface Finish and Quality

Surface finish quality varies between materials:

Titanium Surface Characteristics

- Requires careful parameter control

- More challenging to achieve mirror finishes

- Superior corrosion resistance

Steel Surface Properties

- Easier to achieve desired finishes

- More predictable behavior

- Various treatment options available

Tool Selection and Management

Proper tool selection is critical for successful machining:

Titanium Tooling Requirements

- Carbide tools with specific geometries

- Higher-cost specialized coatings

- More frequent tool changes

Steel Tooling Options

- Wide range of available tools

- More standard geometries

- Lower tool replacement frequency

Production Planning Considerations

Effective production planning must account for:

Titanium Production Factors

- Longer machining cycles

- Higher tooling costs

- More complex setup requirements

Steel Production Elements

- Faster cycle times

- Lower overall costs

- More flexible scheduling options

Environmental Impact

Environmental considerations for both materials:

Titanium Environmental Aspects

- More energy-intensive machining

- Lower material waste due to cost

- Better recyclability

Steel Environmental Impact

- More efficient machining process

- Higher material availability

- Established recycling infrastructure

Best Practices for Both Materials

Through extensive experience at PTSMAKE, I’ve found these practices essential:

General Guidelines

- Maintain rigid workholding

- Use appropriate cutting fluids

- Monitor tool wear regularly

- Optimize cutting parameters

- Implement proper chip management

The choice between titanium and steel ultimately depends on specific application requirements, budget constraints, and performance needs. While steel offers cost-effectiveness and easier machinability, titanium provides superior strength-to-weight ratio and corrosion resistance. Understanding these differences helps in making informed decisions for precision part manufacturing.

Is Titanium More Corrosion-Resistant Than Steel While Maintaining Strength?

Engineers often face a challenging dilemma when selecting materials for critical applications. The choice between titanium and steel isn’t just about strength or corrosion resistance – it’s about finding the perfect balance between these properties while considering cost implications and specific application requirements.

Yes, titanium generally offers superior corrosion resistance compared to steel while maintaining excellent strength properties. Titanium’s natural oxide layer provides exceptional protection against corrosion, and its strength-to-weight ratio surpasses that of most steels, making it ideal for demanding applications where both properties are crucial.

Understanding Corrosion Resistance Properties

Working with precision manufacturing at PTSMAKE, I’ve observed that titanium’s exceptional corrosion resistance comes from its ability to form a stable passivation layer[^9] on its surface. This protective oxide film regenerates instantly when damaged, providing continuous protection against various corrosive environments.

Comparative Corrosion Performance

The corrosion resistance of titanium and steel varies significantly in different environments:

| Environment | Titanium Performance | Steel Performance |

|---|---|---|

| Saltwater | Excellent | Poor to Fair |

| Acids | Very Good | Poor |

| Alkaline Solutions | Excellent | Moderate |

| Chlorides | Excellent | Poor |

Strength Characteristics Analysis

Tensile Strength Comparison

While both materials offer impressive strength, their specific properties differ:

| Property | Titanium (Grade 5) | Stainless Steel (316) |

|---|---|---|

| Tensile Strength (MPa) | 895-930 | 515-695 |

| Yield Strength (MPa) | 828 | 205 |

| Density (g/cm³) | 4.43 | 8.0 |

Practical Applications and Industry Usage

Based on my experience at PTSMAKE, I’ve seen both materials excel in different scenarios:

Aerospace Applications

Titanium dominates in aerospace applications due to its:

- Superior strength-to-weight ratio

- Excellent fatigue resistance

- Outstanding corrosion resistance at high temperatures

- Compatibility with composite materials

Marine Environment Applications

For marine applications, corrosion resistance becomes crucial:

- Titanium shows virtually no corrosion in seawater

- Steel requires additional protective coatings

- Maintenance costs are significantly lower for titanium components

Cost-Benefit Analysis

When considering material selection, it’s essential to evaluate the total cost of ownership:

Initial Investment

- Titanium: Higher material and processing costs

- Steel: More economical initial investment

Long-term Considerations

- Maintenance requirements

- Replacement frequency

- Operational efficiency

- Weight savings benefits

Material Selection Guidelines

At PTSMAKE, we help clients make informed decisions based on:

Environmental Factors

- Operating temperature range

- Chemical exposure

- Mechanical stress levels

- Moisture exposure

Performance Requirements

- Required service life

- Weight restrictions

- Maintenance accessibility

- Safety factors

Manufacturing Considerations

The manufacturing process significantly impacts material performance:

Processing Challenges

- Titanium requires specialized machining techniques

- Steel offers more flexible manufacturing options

- Temperature control during processing is critical for both materials

At PTSMAKE, we’ve developed advanced manufacturing processes for both materials:

- Precision CNC machining capabilities

- Strict quality control measures

- Advanced surface treatment options

Future Trends and Developments

The material science field continues to evolve:

- Development of new titanium alloys

- Advanced steel compositions

- Hybrid material solutions

- Surface treatment innovations

Performance in Specific Industries

Different sectors have unique requirements:

Medical Industry

- Biocompatibility advantages of titanium

- Sterilization requirements

- Long-term implant performance

Chemical Processing

- Resistance to various chemicals

- Temperature cycling capability

- Maintenance considerations

Environmental Impact Assessment

Sustainability considerations include:

- Raw material availability

- Energy consumption during production

- Recyclability potential

- Carbon footprint

Making the Final Decision

The choice between titanium and steel should consider:

- Application requirements

- Environmental conditions

- Budget constraints

- Maintenance capabilities

- Expected service life

Through our experience at PTSMAKE, we’ve found that while titanium offers superior corrosion resistance and maintains excellent strength, the final material selection must align with specific application requirements and economic considerations. Understanding these factors helps ensure optimal material choice for each unique application.

What Cost Factors Influence Choosing Between Titanium And Steel For Manufacturing?

Many manufacturers struggle with choosing between titanium and steel for their projects. The dilemma becomes more complex when considering that selecting the wrong material could lead to excessive costs, production delays, and potential product failures.

The choice between titanium and steel depends on several cost factors including raw material prices, processing requirements, maintenance needs, and lifecycle expenses. While titanium typically has higher upfront costs, its superior durability and corrosion resistance can offer better long-term value in specific applications.

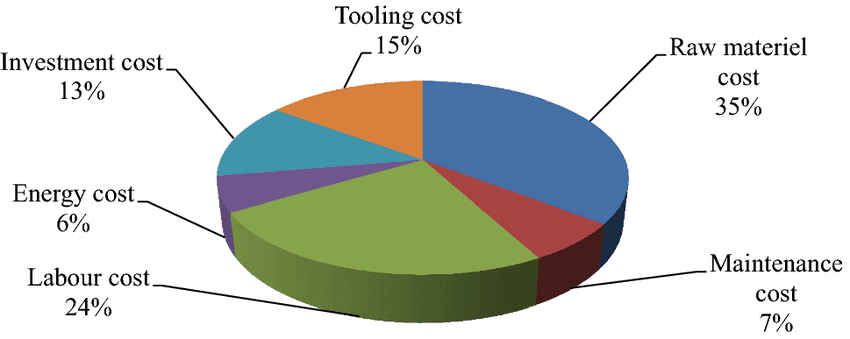

Raw Material Cost Considerations

The most immediate cost factor when comparing titanium and steel is the raw material price. I’ve observed that titanium typically costs 5-10 times more than standard steel grades. This significant price difference stems from titanium’s complex extraction process7 and limited availability. Let me break down the raw material costs:

| Material Type | Average Cost per Pound (USD) | Relative Cost Factor |

|---|---|---|

| Carbon Steel | $0.50 – $1.00 | 1x |

| Stainless Steel | $2.00 – $4.00 | 4x |

| Titanium | $7.00 – $25.00 | 15-25x |

Processing and Manufacturing Costs

Machining Expenses

At PTSMAKE, we’ve found that titanium’s hardness and low thermal conductivity make it more challenging to machine than steel. This results in:

- Slower cutting speeds

- More frequent tool replacement

- Increased machine time

- Higher labor costs

Heat Treatment Requirements

The heat treatment costs vary significantly:

- Steel typically requires simpler heat treatment processes

- Titanium often needs specialized heat treatment in controlled environments

- Additional quality control measures for titanium

Maintenance and Lifecycle Costs

Corrosion Resistance

Titanium’s superior corrosion resistance often leads to lower maintenance costs:

- Minimal need for protective coatings

- Reduced inspection frequency

- Lower replacement rates

Durability Factors

The long-term cost implications of material durability include:

- Steel may require more frequent replacement in corrosive environments

- Titanium components typically last longer in harsh conditions

- Reduced downtime for maintenance

Application-Specific Cost Considerations

Industry Requirements

Different industries have varying cost priorities:

- Aerospace: Focus on weight reduction and performance

- Medical: Emphasis on biocompatibility and longevity

- Industrial: Balance between cost and durability

Volume Production Impact

Production volume significantly affects cost calculations:

- High-volume steel production benefits from economies of scale

- Titanium becomes more cost-effective in specialized, low-volume applications

- Setup costs can be amortized better with steel for large runs

Environmental and Energy Costs

Manufacturing Energy Requirements

| Process Step | Steel Energy Cost | Titanium Energy Cost |

|---|---|---|

| Extraction | Moderate | Very High |

| Processing | Low | High |

| Recycling | Low | Moderate |

Sustainability Considerations

- Steel has well-established recycling infrastructure

- Titanium recycling is more complex but valuable

- Environmental regulations may impact future costs

Transportation and Handling Costs

Weight Considerations

The density difference affects shipping costs:

- Steel: approximately 8.0 g/cm³

- Titanium: approximately 4.5 g/cm³

- Lower weight of titanium can reduce transportation expenses

Storage Requirements

Material storage needs differ:

- Steel requires basic environmental protection

- Titanium needs more controlled storage conditions

- Inventory carrying costs vary accordingly

Risk Management Costs

Quality Control Expenses

Different inspection requirements impact costs:

- Steel typically needs standard QC procedures

- Titanium often requires more rigorous testing

- Certification costs vary by material

Insurance Considerations

Insurance costs reflect material differences:

- Higher value of titanium stock requires greater coverage

- Different liability considerations based on application

- Risk assessment impacts overall cost structure

Technology and Equipment Investment

Specialized Equipment Needs

Each material requires different processing equipment:

- Steel processing uses standard machinery

- Titanium often needs specialized equipment

- Initial investment costs vary significantly

Training Requirements

Staff expertise requirements differ:

- Steel processing requires standard training

- Titanium handling needs specialized knowledge

- Ongoing training costs vary by material

At PTSMAKE, we carefully evaluate these cost factors for each project to provide our clients with the most cost-effective solution. Whether it’s a high-volume steel production run or a specialized titanium component, we ensure that material selection aligns with both technical requirements and budget constraints.

Learn how titanium’s crystalline structure affects its flexibility and brittleness for better material choices. ↩

Learn about titanium’s tensile strength and its advantages over other materials for informed decisions. ↩

Learn about titanium’s extraction complexities and cost implications for more informed material choices. ↩

Learn about the differences in tensile strength for better material selection. ↩

Learn why specific strength is crucial in material selection for optimal performance in various industries. ↩

Understand work hardening to optimize machining processes and avoid costly mistakes in titanium parts. ↩

Learn about the costly complexities of titanium extraction and its impact on material pricing. ↩