What Are Aluminum Channel Extrusions?

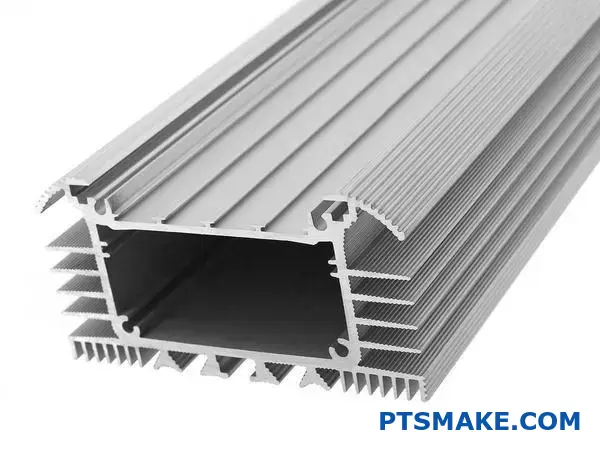

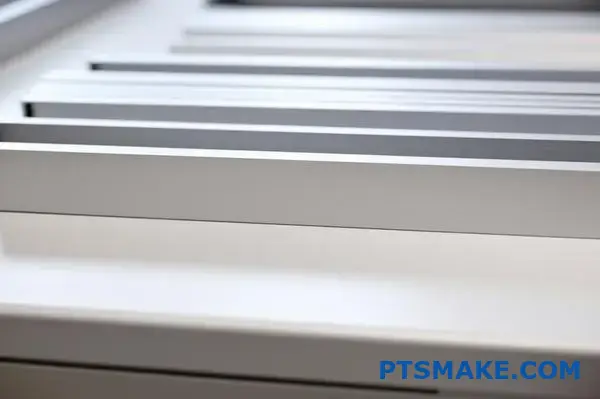

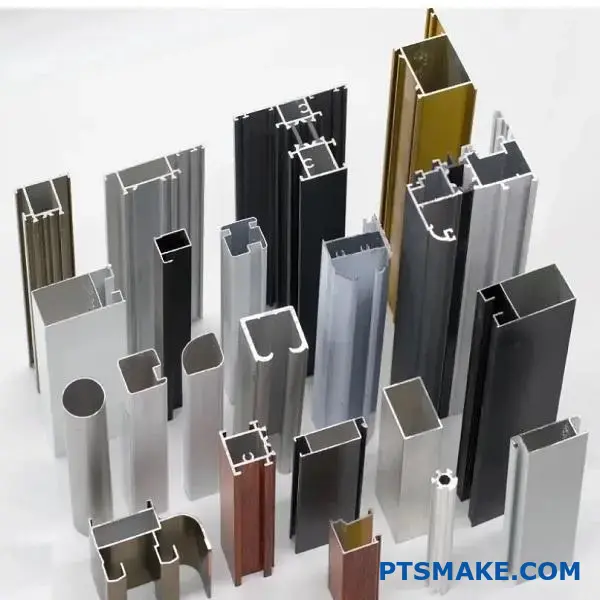

Ever look closely at window frames, LED light housings, or even structural frameworks and notice those distinct U-shaped or C-shaped metal pieces? Many of these are aluminum channel extrusions, versatile components found in countless applications around us. But what exactly makes them so useful?

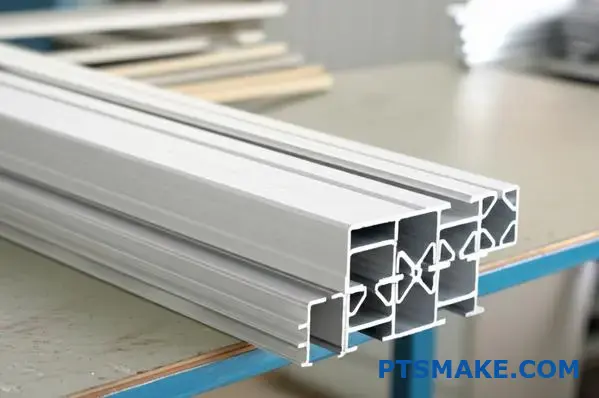

Aluminum channel extrusions are defined as linear profiles, commonly with a U or C cross-section featuring sharp 90-degree corners. They are produced by pushing heated aluminum alloy, typically 6063, through a shaped die, resulting in lightweight yet structurally sound components.

Let’s break down what makes these profiles unique. The term "extrusion" refers to the manufacturing process itself – think of it like squeezing toothpaste from a tube, but using heated aluminum and immense pressure to force it through a die (a specialized tool with a cutout) shaped like the desired cross-section. This process is incredibly efficient for creating long, continuous shapes with consistent profiles.

The Significance of the "Channel" Shape

The defining feature is the "channel" – typically a U-shape or C-shape. Unlike tubes (hollow) or bars (solid), channels have an opening along one side. This geometry provides several advantages:

- Structural Support: The perpendicular flanges provide rigidity against bending forces along the channel’s length.

- Mounting & Enclosure: The channel creates a natural housing or mounting point for other components, like glass panels, wiring, or LED strips.

- Joining: The flat surfaces and defined edges make joining multiple extrusions or attaching other parts relatively straightforward.

Why Use 6063 Aluminum Alloy?

While various aluminum alloys exist, 6063 is a very common choice for aluminum channel extrusions, and for good reason. It belongs to the 6000 series, which uses magnesium and silicon as primary alloying elements. This combination gives 6063 alloy:

- Excellent extrudability, meaning it flows well through complex die shapes.

- Good surface finish characteristics, making it ideal for decorative applications.

- Good corrosion resistance, suitable for many indoor and outdoor uses.

- Responsiveness to heat treatment for increased strength if needed.

- Suitability for finishing processes like anodizing1 or powder coating, enhancing durability and appearance.

In projects at PTSMAKE, we often recommend 6063 for applications where both aesthetics and functional performance are important.

Key Properties Summarized

Here’s a quick look at the core benefits offered by aluminum channel extrusions, particularly those made from 6063 alloy:

| Proprietà | Descrizione |

|---|---|

| Leggero | Reduces overall weight in assemblies, easing handling and installation. |

| Rapporto forza-peso | Offers significant structural integrity relative to its low density. |

| Resistenza alla corrosione | Naturally forms a protective oxide layer; can be further enhanced. |

| Lavorabilità | Easily cut, drilled, or machined for customization. |

| Finitura superficiale | Provides a smooth surface suitable for various finishing treatments. |

| Riciclabilità | Aluminum is highly recyclable without loss of quality. |

These properties combined make aluminum channel extrusions a go-to solution across diverse industries, from construction and architecture to electronics and automotive manufacturing. They represent a smart balance of form, function, and manufacturability.

Key Benefits for Engineering Applications

Engineers constantly seek materials that balance performance, weight, and durability. How can one component offer structural support without adding excessive bulk, resist environmental decay, and even help manage heat? Aluminum channel extrusions often provide the answer.

Aluminum channel extrusions deliver a powerful combination of high strength-to-weight ratio, excellent corrosion resistance, and efficient thermal conductivity. This unique blend of properties makes them exceptionally versatile and valuable for a wide range of demanding engineering applications where structural integrity is paramount.

Let’s delve deeper into why these benefits are so crucial in engineering design and how they translate into practical advantages. Understanding these core properties helps explain why aluminum channel extrusions are frequently specified for complex projects.

Elevato rapporto resistenza/peso

One of the most significant advantages of aluminum is its low density combined with its potential for high strength, especially when alloyed correctly. This results in an excellent strength-to-weight ratio2. For engineers, this means:

- Reduced Overall Mass: Components can be designed to meet structural requirements with significantly less weight compared to materials like steel. This is critical in automotive, aerospace, and robotics, where lower weight translates to fuel efficiency or improved performance.

- Easier Handling and Installation: Lighter components simplify logistics, assembly processes, and reduce the load on supporting structures.

- Structural Efficiency: Engineers can achieve robust designs without the penalty of excessive weight, allowing for more innovative and streamlined solutions. At PTSMAKE, we often see this benefit leveraged in automation equipment framing and structural supports.

Eccellente resistenza alla corrosione

Aluminum naturally forms a thin, tough layer of aluminum oxide on its surface when exposed to air. This passive oxide layer provides inherent protection against corrosion in many common environments.

- Durata: This resistance extends the lifespan of components, especially in outdoor or moderately humid conditions. Alloys like 6063, commonly used for these extrusions, offer good general corrosion resistance.

- Low Maintenance: The natural protection reduces the need for frequent protective coatings, although treatments like anodizing or powder coating can be applied for enhanced protection in harsher environments (like coastal areas) or for specific aesthetic requirements.

- Material Integrity: Prevents degradation that could compromise the structural integrity or functionality of the part over time.

Effective Thermal Conductivity

Aluminum is a good conductor of heat, approximately half as conductive as copper but significantly lighter and less costly.

- Dissipazione del calore: This property makes aluminum channel extrusions ideal for applications requiring heat management, such as housings for LED lighting, enclosures for electronic components, and heat sinks. The channel shape itself can sometimes aid in convective cooling.

- Temperature Stability: Helps maintain operational temperature ranges for sensitive equipment. Based on material specifications, aluminum alloys maintain their properties well across a reasonable range of temperatures.

Versatilità di applicazione

The combination of these properties, along with the efficiency of the extrusion process, makes aluminum channels incredibly versatile. Their adaptability is evident across numerous engineering fields:

| Area di applicazione | Example Use Cases | Key Benefit Leveraged |

|---|---|---|

| Structural Framing | Machine bases, automation cells, support structures | Strength-to-weight, Modularity |

| Electronics Enclosures | Housings for power supplies, controls, LED fixtures | Thermal conductivity, Shielding |

| Architettonico | Window/door frames, curtain wall mullions, trim | Corrosion resistance, Aesthetics |

| Automotive & Transport | Body structure components, trim, roof rack systems | Lightweight, Strength |

| Prodotti di consumo | Appliance frames, furniture components, display stands | Aesthetics, Durability |

This adaptability allows engineers to use a standardized profile type for a wide array of functional requirements, simplifying design and procurement. Working with a partner like PTSMAKE ensures you select the optimal profile and alloy, like the versatile aluminum channel extrusions, tailored to your specific engineering challenge.

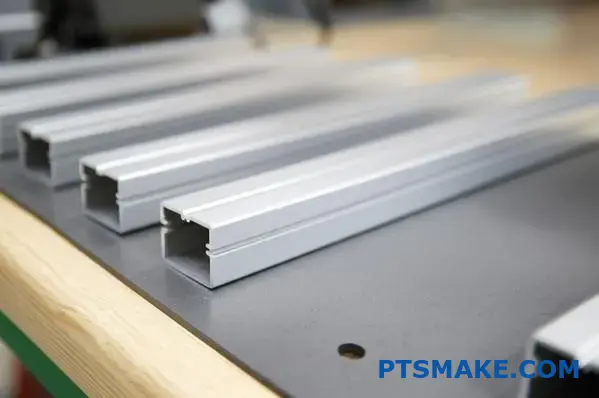

Common Types and Dimensions

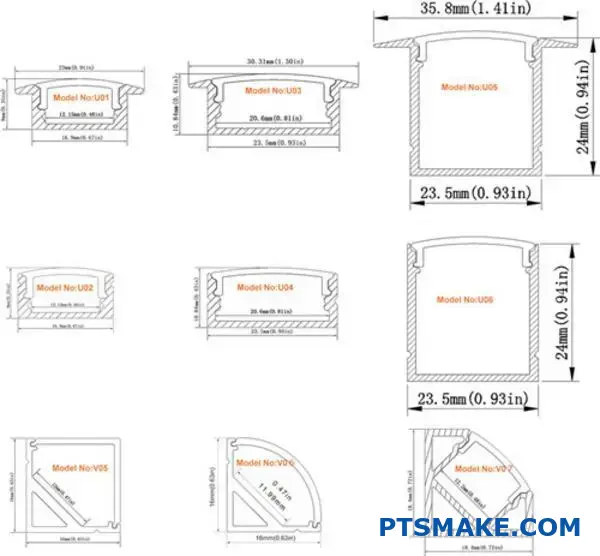

Ever noticed how those aluminum channels used in window frames look slightly different from the ones in heavy-duty shelving? That’s because aluminum channel extrusions come in various shapes and sizes, each tailored for specific jobs. Let’s explore the most common options available.

Aluminum channel extrusions typically feature U-channel or C-channel profiles, essential for structural and architectural uses. Standard dimensions often range from 1/2" to 3" in width and 1/16" to 1/4" in thickness, though customization allows for virtually any required size.

When selecting aluminum channel extrusions for a project, understanding the common types and their typical dimensions is crucial. While customization is always an option, especially when working with a partner like PTSMAKE, starting with standard profiles can often streamline the design and procurement process.

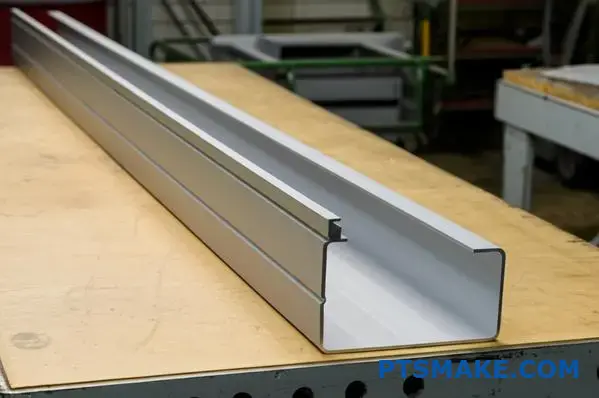

Channel Shapes: U vs. C

The two most prevalent shapes you’ll encounter are U-channels and C-channels. While similar, they have distinct characteristics:

- U-Channels: These typically feature two parallel flanges (legs) perpendicular to a flat base, forming a ‘U’ shape. They are often used for edge protection, tracks, framing, and general structural support where internal mounting isn’t the primary focus.

- C-Channels: Also known as architectural channels, these resemble U-channels but often have sharper inside corners or slightly different leg proportions. They are frequently used in window and door frames, trim, enclosures, and applications where components might be mounted within the channel.

The choice between U and C often depends on the specific load-bearing requirements and how the channel needs to integrate with other parts.

Standard Size Ranges

Manufacturers offer aluminum channel extrusions in a variety of standard sizes. These common dimensions provide readily available options for many applications:

- Width: This typically refers to the overall width across the base of the channel. Standard widths commonly range from 1/2 inch up to 3 inches, but larger structural channels exist.

- Leg Height: The height of the flanges or legs is another key dimension.

- Wall Thickness: This dimension significantly impacts strength and rigidity. Common thicknesses range from a lighter 1/16 inch (approx 1.6mm) to a more robust 1/4 inch (approx 6.35mm). Thicker walls provide greater structural integrity but add weight and cost. Based on our experience with client projects, selecting the appropriate wall thickness is critical for performance.

Understanding Dimensions & Tolerances

When specifying aluminum channel extrusions, clarity on dimensions is key. Here are the primary measurements:

| Dimensione | Descrizione | Typical Range (Example) |

|---|---|---|

| Overall Width | The widest measurement across the channel base. | 1" – 3" |

| Leg Height | The length of the perpendicular flange(s). | 1/2" – 1-1/2" |

| Spessore della parete | The thickness of the aluminum material itself. | 1/16" – 1/4" |

| Inside Corners | Can be sharp (architectural) or radiused (structural). | Varies by profile |

It’s also important to consider manufacturing tolerances, which define the allowable variation in these dimensions.

Customization: Beyond Standard Sizes

While standard profiles cover many needs, the real power of extrusion lies in customization. If your project requires a unique shape, non-standard dimensions, or specific features, creating a custom profile is entirely feasible. This involves designing and producing a unique extrusion die3 – the tool that shapes the aluminum. At PTSMAKE, we frequently collaborate with clients to develop custom aluminum channel extrusions tailored precisely to their application, ensuring optimal fit and function, from prototype to production runs. This flexibility allows engineers and designers to achieve innovative solutions not possible with off-the-shelf components.

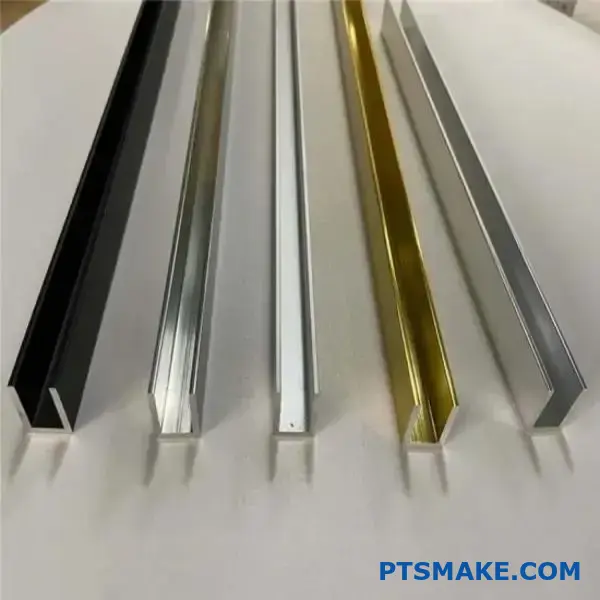

Opzioni di finitura della superficie

Thinking about aluminum channel extrusions? The raw metal look is just the starting point. The finish you choose significantly impacts both how it looks and how long it lasts. Let’s explore why this choice matters more than you might think.

Surface finishes for aluminum channel extrusions aren’t merely cosmetic; they significantly enhance durability and functionality. Options like anodizing or painting provide crucial corrosion resistance and aesthetic appeal, adding value while maintaining the part’s original dimensions.

When aluminum extrusions leave the die, they have what’s called a "mill finish." This is the natural appearance of the aluminum, often showing faint lines from the extrusion process. While it’s the most basic option, it offers minimal protection against scratches, weathering, or corrosion, especially in demanding environments. For many applications, further treatment is necessary.

Mill Finish: The Starting Point

Mill finish is essentially untreated aluminum.

- Appearance: Natural metallic look, can have slight variations or extrusion lines.

- Protection: Minimal. Aluminum forms a natural oxide layer, offering some basic corrosion resistance, but it’s easily scratched or stained.

- Best Use: Applications where aesthetics are not critical, cost is the primary driver, or the part will be finished later (e.g., painted on-site).

Anodizing: Durability and Color

Anodizing is a popular choice for enhancing aluminum channel extrusions. It’s an processo elettrochimico4 that thickens the natural oxide layer on the aluminum surface. This creates a very hard, durable, and corrosion-resistant finish that’s integrated with the metal itself, not just a coating on top.

Key Benefits of Anodizing

- Enhanced Durability: Significantly improves scratch and wear resistance.

- Superior Corrosion Resistance: Ideal for outdoor use or harsher conditions.

- Color Options: While clear anodizing retains a metallic look, dyes can be introduced during the process to achieve various colors. Common choices include:

- Clear: Enhances the natural aluminum appearance.

- Black: Provides a sleek, modern look.

- Bronze/Gold Tones: Often used in architectural applications.

- Dimensional Stability: A properly controlled anodizing process adds only a minimal thickness, preserving the part’s original dimensions – crucial for tight tolerance assemblies. At PTSMAKE, we ensure our finishing partners maintain strict process control.

Painting and Powder Coating: Versatility in Color

For the widest range of color options and specific protective needs, painting or powder coating are excellent alternatives.

- Liquid Paint: Can be matched to virtually any color specification. Requires proper surface preparation for good adhesion.

- Rivestimento in polvere: Electrostatically applied powder is cured under heat, forming a tough, uniform layer. It’s generally more durable than liquid paint and environmentally friendlier (no VOCs).

Considerations for Paint/Powder Coat

- Color Choice: Nearly limitless.

- Protection: Offers good corrosion protection. Durability varies based on the type of paint/powder and application quality.

- Potential Issues: Unlike anodizing, these are surface coatings that can chip or scratch if subjected to heavy impact or abrasion.

Here’s a quick comparison:

| Tipo di finitura | Beneficio primario | Appearance Options | Durata | Fattore di costo |

|---|---|---|---|---|

| Mill Finish | Lowest Cost | Natural Metallic | Basso | Basso |

| Anodizzazione | Durability, Corrosion Res. | Clear, Black, Metallics | Alto | Medio |

| Paint/Powder | Widest Color Range | Unlimited Colors | Medio-Alto | Medio-alto |

Choosing the right finish depends on your application’s specific needs – balancing aesthetics, environmental exposure, durability requirements, and budget. We often help clients navigate these options to find the perfect match for their aluminum channel extrusions project.

Custom Fabrication Capabilities

Think standard aluminum channel extrusions cover all bases? What if your project demands more precision, unique mounting holes, or specific bends? Standard profiles are just the beginning; unlocking the full potential often requires custom fabrication tailored to your needs.

Custom fabrication for aluminum channel extrusions involves secondary processes like precise cutting, drilling, tapping, and bending. These tailor standard profiles to meet exact project specifications, ensuring perfect fit and enhanced functionality for specialized applications.

While standard aluminum channel extrusions offer a great starting point, many projects require modifications to meet specific design requirements. Simply ordering stock lengths rarely suffices for complex assemblies or applications demanding high precision. At PTSMAKE, we understand that the real value often comes from transforming these standard profiles into application-ready components. This involves a range of fabrication capabilities.

Precision Cutting and Drilling

Standard extrusions typically come in long lengths. The most basic fabrication step is cutting them to the precise lengths needed for your assembly. But it goes beyond simple cuts.

- Tight Tolerance Cutting: Achieving exact lengths with clean, square cuts is essential, especially when multiple pieces need to fit together seamlessly.

- Drilling and Tapping: Mounting hardware, connecting components, or allowing passage for wiring often requires precisely located holes. We can drill clearance holes, tap threads for fasteners, or create complex hole patterns based on your CAD files. Accurate hole placement is critical to avoid assembly issues caused by tolerance stack-up5.

Bending and Forming

Sometimes, a straight channel isn’t enough. Applications might require curves or specific angles not achievable directly through extrusion.

- Custom Bends: We can carefully bend aluminum channel extrusions to create curved sections or specific angles, essential for architectural elements, custom enclosures, or unique structural supports. Controlling the bending process is key to maintaining the profile’s integrity.

- Forming Operations: Minor forming operations can alter the profile slightly, perhaps to create a lip or notch for better integration with other parts.

Welding and Assembly

For more complex structures, individual fabricated channels might need to be joined.

- Saldatura: Aluminum requires specialized welding techniques (like TIG or MIG) due to its thermal properties and oxide layer. Properly welded joints provide strong, permanent connections for building frames or complex assemblies from aluminum channel extrusions.

- Mechanical Assembly: Alternatively, channels can be joined using fasteners, brackets, or specialized connectors. We can pre-drill holes to facilitate easier on-site assembly or even supply pre-assembled units.

Here’s how custom fabrication adds value compared to using standard profiles alone:

| Caratteristica | Standard Extrusion Limitation | Custom Fabrication Benefit |

|---|---|---|

| Lunghezza | Standard stock lengths (e.g., 6m) | Cut to exact required length, minimizes waste |

| Montaggio | No pre-drilled holes | Precise holes/threads for easy mounting/assembly |

| Shape | Straight profiles only | Custom bends and angles possible |

| Joining | Requires on-site work | Pre-welded or pre-drilled for easier final assembly |

| Fit & Function | May require adjustments | Ensures components meet tight tolerances for function |

In past projects at PTSMAKE, integrating these custom fabrication steps early in the design phase has saved our clients significant time and effort during final assembly. By providing components that are ready to integrate, we help streamline their production processes.

Popular Industry Applications

Ever wonder how intricate robotic arms move so smoothly or how sleek display shelves seem to float? Often, the hidden framework relies on aluminum channel extrusions. Their versatility is astonishing, making them unsung heroes in countless products and structures we interact with daily.

Aluminum channel extrusions are indispensable in diverse sectors, including robotics, retail displays, sliding systems, and electronics. Their precision, light weight, and structural integrity make them ideal for applications ranging from automotive components to fine architectural trim, meeting demanding functional and aesthetic needs.

The unique combination of properties offered by aluminum channel extrusions makes them a preferred choice across a wide spectrum of industries. Their adaptability allows engineers and designers to leverage their strengths for specific functional requirements. Let’s explore some of the most prominent application areas.

Robotica e automazione

In the fast-paced world of robotics and factory automation, every gram counts. Aluminum channel extrusions provide the perfect balance of strength and low weight needed for building structural frames.

- Framing Systems: They form the backbone for robotic cells, automated assembly lines, and machine guards. The channels allow for easy mounting of sensors, actuators, and other components.

- Linear Motion Guides: The precise geometry of the channels makes them suitable for creating tracks or guides for moving parts.

In past projects at PTSMAKE, we’ve supplied precisely cut and finished aluminum channel extrusions for complex robotic assemblies where tight tolerances were critical for performance.

Architectural and Construction

Architects and builders value aluminum channel extrusions for both functional and aesthetic reasons.

- Window and Door Frames: C-channels are commonly used here, providing structural support and a clean look. Their corrosion resistance is a major plus for exterior applications.

- Curtain Walling: Larger extrusions form the mullions and transoms in glass curtain wall systems.

- Trim and Finishing: Used for decorative trim, corner guards, and creating reveals or shadow lines.

- Sliding Door Systems: U-channels often serve as the tracks for sliding glass doors or partitions, ensuring smooth operation.

Electronics and Lighting

The need for heat dissipation and durable enclosures makes aluminum a natural fit for electronics.

- Electronic Enclosures: Channels can form part of housings for power supplies, control units, and other sensitive equipment, offering physical protection and EMI shielding potential.

- LED Lighting Fixtures: Many linear LED fixtures use aluminum channel extrusions as the housing. This not only protects the LED strip but also acts as a heat sink, crucial for LED longevity and performance – a key aspect of thermal management6.

- Heat Sinks: Custom or standard channel profiles are often designed specifically to maximize surface area for dissipating heat from electronic components.

Retail Fixtures and Displays

In retail environments, aesthetics and modularity are key.

- Shelving Systems: Extrusions form the uprights and supports for adjustable shelving.

- Display Cases and Stands: Used to create frames for glass cases, product displays, and sign holders. Their clean lines and finish options complement modern retail design.

- Framing for Graphics: Channels provide a simple way to frame fabric graphics or rigid panels used in signage and exhibits.

Here’s a quick summary of common applications:

| Industry Sector | Applicazione comune | Key Reason for Use |

|---|---|---|

| Robotics & Automation | Machine Frames, Linear Guides | Lightweight, Strength, Modularity |

| Architettonico | Window/Door Frames, Trim, Sliding Tracks | Corrosion Resistance, Aesthetics, Precision |

| Electronics & Lighting | Enclosures, LED Housings, Heat Sinks | Thermal Conductivity, Protection, Lightweight |

| Retail & Display | Shelving, Display Frames, Sign Holders | Aesthetics, Modularity, Ease of Assembly |

| Automotive | Trim Components, Roof Rack Systems | Lightweight, Strength, Corrosion Resistance |

The adaptability of aluminum channel extrusions, combined with options for customization and finishing, ensures their continued relevance across these and emerging industrial applications. Whether it’s for a complex machine or a simple architectural detail, these profiles offer a reliable and efficient solution.

Guida alla selezione dei materiali

Choosing the right aluminum channel extrusion seems simple, but pick incorrectly, and you could face performance issues or unnecessary costs. How do you navigate the options to ensure your project succeeds from the start?

Selecting the ideal aluminum channel extrusion involves carefully considering the specific aluminum alloy (like 6061 vs. 6063), the mechanical load it must bear, the environmental conditions it will face, and how it will be joined to other components.

Making the right choice upfront is crucial for ensuring the longevity and effectiveness of your design. Let’s break down the key factors you need to evaluate when specifying aluminum channel extrusions for your application. Neglecting any of these can lead to suboptimal results or even premature failure.

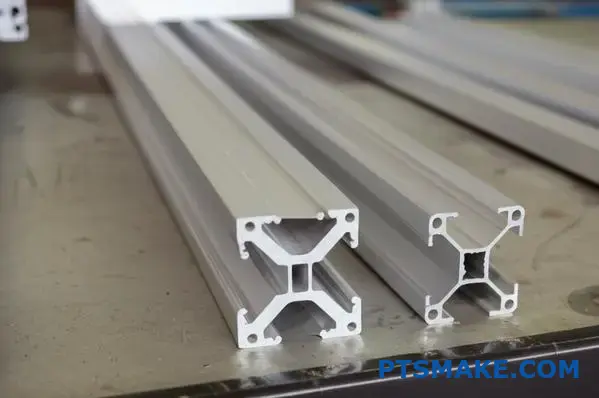

Alloy Type: 6061 vs. 6063

The aluminum alloy is perhaps the most fundamental choice. The two most common alloys for channel extrusions are 6061 and 6063, each with distinct advantages:

- 6063 Alloy: Often called the "architectural alloy," 6063 offers excellent extrudability (allowing for complex shapes), a great surface finish suitable for anodizing, and good corrosion resistance. It’s ideal for window frames, trim, and applications where appearance is important. However, its strength is moderate compared to 6061.

- 6061 Alloy: This alloy offers higher strength and better machinability than 6063. It’s often chosen for structural applications requiring greater load-bearing capacity, such as machine framing, supports, and transportation components. Its surface finish is generally not as smooth as 6063 straight from the die.

Here’s a quick comparison based on typical properties:

| Caratteristica | 6063 Alloy | 6061 Alloy |

|---|---|---|

| La forza | Moderato | Più alto |

| Extrudability | Eccellente | Buono |

| Finitura superficiale | Eccellente | Buono |

| Resistente alla corrosione. | Buono | Buono |

| Saldabilità | Buono | Buono |

| Uso tipico | Architectural, Trim | Structural, Machine |

Choosing between them depends heavily on whether strength or finish/formability is the primary driver for your aluminum channel extrusions.

Requisiti di carico

How much weight or stress will the channel need to support? This directly influences the required profile shape and wall thickness.

- Integrità strutturale: For applications bearing significant loads, a thicker wall or a profile with more robust flanges (like some structural C-channels) might be necessary. Using an alloy like 6061 can also provide the needed strength.

- Deflection: Consider not just the ultimate failure point, but also how much the channel might bend (deflect) under load. A stiffer profile (thicker walls, taller flanges) minimizes deflection. In past projects at PTSMAKE, we often use basic simulations to help clients verify if a chosen profile meets their deflection criteria.

Esposizione ambientale

Where will the aluminum channel extrusion be used?

- Indoor/Controlled: Mill finish 6063 might suffice in dry, stable indoor environments where aesthetics are secondary.

- Outdoor/Moderate: Anodized 6063 is a common choice, offering good protection against weather and UV exposure.

- Harsh Conditions: For coastal areas (salt spray) or industrial environments with chemical exposure, a more robust finish like powder coating or a higher grade of anodizing might be essential. Even 6061 offers good corrosion resistance, but enhancing it with a finish is usually wise for demanding outdoor use.

Joining Methods

How will the channels connect to each other or to other parts?

- Mechanical Fasteners: Most aluminum alloys, including 6061 and 6063, are easily drilled and tapped for bolts or screws. The channel shape provides flat surfaces for secure connections.

- Saldatura: Both 6061 and 6063 are weldable, but require specific techniques (TIG/MIG) and filler materials. The heat-affected zone near the weld will have reduced strength, particularly in heat-treated alloys like 6061-T6. The Saldabilità7 consideration might influence alloy choice if extensive welding is planned.

- Specialized Connectors: Many modular framing systems use custom connectors designed for specific extrusion profiles, simplifying assembly.

Considering these factors systematically helps narrow down the options and ensures you select the aluminum channel extrusions that provide the best combination of performance, longevity, and cost-effectiveness for your specific needs. Consulting with an experienced supplier like PTSMAKE can also provide valuable guidance tailored to your project.

Installation and Assembly Best Practices

You’ve selected the perfect aluminum channel extrusions for your project. Now, how do you ensure they perform flawlessly once assembled? Proper installation is not just a final step; it’s crucial for unlocking their full potential and ensuring long-term structural integrity.

Maximize the structural integrity and lifespan of your aluminum channel extrusions assembly by using compatible fasteners, ensuring precise alignment, and carefully considering thermal expansion effects. Following these essential best practices prevents costly issues down the line.

Putting aluminum channel extrusions together might seem straightforward, but overlooking key details can compromise the entire assembly. Based on our experience helping clients at PTSMAKE optimize their designs, focusing on a few core areas during installation makes a significant difference. Let’s delve into the specifics.

Choose Compatible Fasteners

The fasteners holding your aluminum channel extrusions together are critical. Using the wrong type or material can lead to failure or corrosion.

- Material Matters: Always use fasteners compatible with aluminum. Stainless steel fasteners (grades 304 or 316) are excellent choices as they minimize the risk of corrosione galvanica8 where dissimilar metals interact. Coated steel fasteners can also work, but ensure the coating is intact. Avoid using zinc-plated or uncoated carbon steel fasteners directly with aluminum, especially in damp conditions.

- Type and Size: Select fasteners (screws, bolts, rivets) appropriate for the load requirements and the channel’s thickness. Ensure the fastener length and diameter provide adequate grip without damaging the extrusion. Sometimes, specialized connectors designed for specific extrusion profiles offer the easiest and most secure assembly.

Maintain Precise Alignment

Proper alignment is essential for both structural integrity and functionality. Misaligned channels can introduce stress points, affect load distribution, and look unprofessional.

- Use Tools: Employ tools like levels, squares, and jigs or fixtures during assembly to ensure channels are correctly positioned relative to each other and the overall structure.

- Sequential Tightening: When connecting multiple extrusions, loosely fit all fasteners first. This allows for minor adjustments. Once everything is correctly aligned, tighten the fasteners sequentially, often working from the center outwards, to the recommended torque specifications. This helps distribute clamping force evenly.

Account for Thermal Expansion

Aluminum expands and contracts with temperature changes more significantly than steel. Ignoring this can cause problems, especially in long assemblies or outdoor applications.

- Allow for Movement: In long runs, consider incorporating expansion joints or using slotted holes for fasteners rather than simple round holes. This allows the aluminum channel extrusions to expand and contract without buckling or stressing the joints.

- Temperature During Installation: Be mindful of the ambient temperature during installation, especially if assembling very long sections or components with tight tolerances that interface with other materials.

Here’s a quick reference table for common installation pitfalls and how to avoid them:

| Potential Issue | Best Practice Solution | Perché è importante |

|---|---|---|

| Joint Corrosion | Use stainless steel or compatible coated fasteners | Prevents galvanic corrosion, ensures longevity |

| Loose Connections | Tighten fasteners to specified torque | Maintains structural rigidity, avoids rattles |

| Component Misalignment | Use alignment tools (levels, jigs); tighten evenly | Ensures proper load distribution, function |

| Thermal Buckling | Design in expansion gaps or slotted holes | Prevents stress and deformation from temp changes |

By carefully considering fasteners, alignment, and thermal movement, you ensure your aluminum channel extrusions assembly performs reliably for years to come. These practices, drawn from numerous successful projects, form the foundation of quality installation.

Learn more about anodizing and how it improves aluminum’s surface properties. ↩

Understand how this ratio impacts material selection in engineering design. ↩

Explore how extrusion dies shape aluminum profiles for custom designs. ↩

Discover the science behind anodizing and how it creates a durable oxide layer on aluminum. ↩

Understand how controlling tolerances impacts final assembly fit and function. ↩

Learn how effective heat dissipation impacts electronic component lifespan and reliability. ↩

Explore how alloy composition affects the ease and quality of welding aluminum extrusions. ↩

Learn about preventing metal degradation when dissimilar metals contact in an electrolyte. ↩