What Are T-Slot Aluminum Profiles & Their Key Benefits

Ever wondered how complex industrial frames, machine guards, or custom workstations are built so quickly and precisely? It often involves a surprisingly simple yet ingenious building block. Let’s explore this versatile component that has revolutionized structural assembly in many industries.

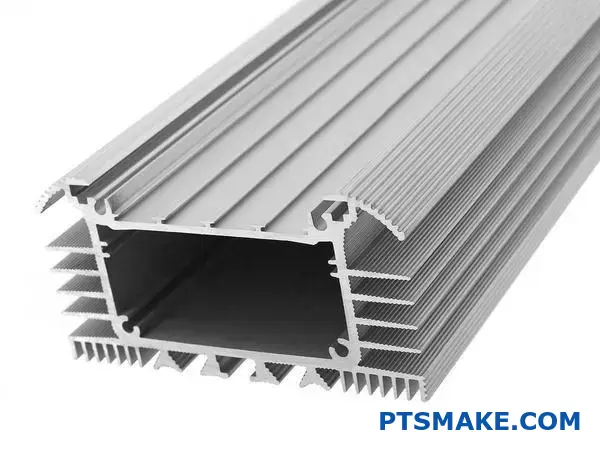

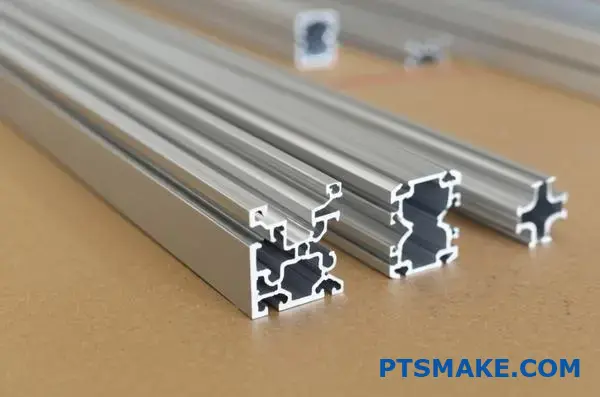

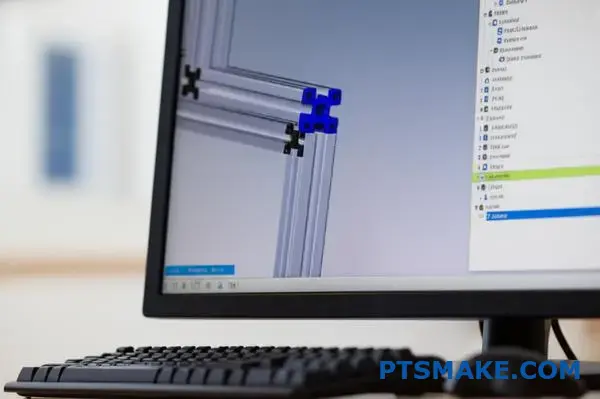

T-slot aluminum profiles are extruded aluminum shapes featuring distinctive T-shaped channels along their lengths. These slots are designed to easily accept specialized fasteners and accessories, making them fundamental for building highly modular and adaptable structures across countless industrial and commercial applications.

T-slot aluminum profiles, often just called aluminum extrusions or 80/20 (after a popular brand), are essentially structural LEGOs for engineers and builders. Understanding their makeup and benefits is key to unlocking their potential in your projects.

The Anatomy of a T-Slot Profile

At its core, a t slot aluminum profile starts as a billet of aluminum alloy (typically from the 6000 series, like 6061 or 6063). This billet is heated and forced through a shaped die using an extrusion1 process. This process shapes the aluminum into long lengths with the characteristic T-shaped slot(s) running continuously along one or more faces. Think of it like squeezing toothpaste from a tube, but with metal and much higher pressures.

The critical feature is the "T" slot itself. This precisely shaped channel is designed to capture the head of a special nut (often called a T-nut) or bolt head. Once inserted into the slot, the fastener can slide along the length until it’s in the desired position. Tightening the bolt then locks the fastener, and whatever it’s holding, securely in place. This simple mechanism is the foundation of the system’s modularity.

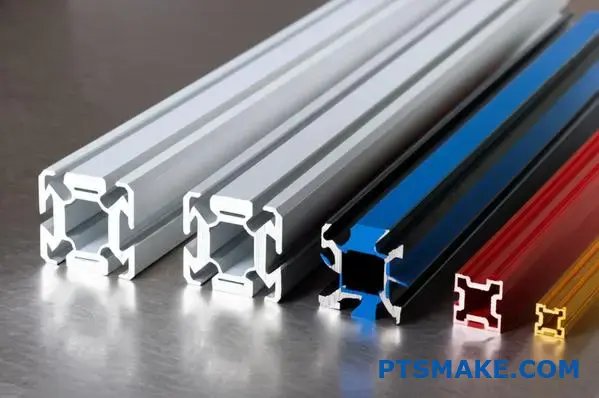

While the concept is simple, these profiles come in a vast array of shapes, sizes, and slot configurations. You’ll find square profiles, rectangular ones, profiles with rounded edges, and even specialized shapes for specific functions. They are often categorized by a metric series (like 20mm, 30mm, 40mm, 45mm series) or fractional inch dimensions, indicating the basic size of the profile square. Most profiles also receive a surface treatment, typically anodizing. This electrochemical process creates a hard, corrosion-resistant oxide layer that also provides a clean, aesthetic finish, usually in clear (silver) or black.

Why Choose Aluminum for These Profiles?

Aluminum is the material of choice for these profiles for several compelling reasons.

Lightweight Strength

Aluminum offers an exceptional strength-to-weight ratio. It’s significantly lighter than steel but still provides substantial structural integrity for a wide range of applications. In past PTSMAKE projects involving automated systems and robotics, minimizing frame weight was crucial for performance and motor sizing. Using aluminum profiles allowed us to achieve the required rigidity without adding unnecessary mass. This makes aluminum ideal for machine frames, guarding, motion systems, and any structure where weight is a consideration.

Resistenza naturale alla corrosione

Aluminum naturally forms a thin, tough layer of aluminum oxide when exposed to air. This layer protects the metal underneath from further oxidation and corrosion. When combined with anodizing, the corrosion resistance becomes even better, making aluminum profiles suitable for use in diverse environments, from cleanrooms to factory floors, without needing paint or other protective coatings (though coatings can be applied for specific needs).

Riciclabilità

Aluminum is highly recyclable without losing its quality. This makes aluminum profiles a more sustainable choice compared to some other materials, aligning with growing environmental considerations in manufacturing and design.

The Core Advantage: Modularity and Flexibility

The single biggest advantage of the t slot aluminum profile system is its incredible modularity and flexibility. The T-slots allow components to be attached anywhere along the profile length.

This contrasts sharply with traditional framing methods like welding steel. Welding creates permanent joints, requires specialized skills and equipment, can introduce heat distortion, and makes modifications difficult and time-consuming. With T-slot profiles, assembly is fast and straightforward using simple hand tools. No welding, grinding, or painting is required on-site.

More importantly, structures built with these profiles are inherently adaptable. Need to move a sensor mount? Loosen the bolts, slide it over, and retighten. Need to add a new support beam or expand the frame? Cut a new piece of profile and bolt it on. This ability to easily modify, reconfigure, or even completely disassemble and reuse the components is invaluable. It allows designs to evolve, accommodates changes in production processes, and significantly extends the useful life of the structure. For our clients at PTSMAKE, this means the framing solutions we help design can adapt as their needs change, saving them significant time and money compared to rebuilding welded structures.

Key Benefits Driving Adoption

Beyond modularity, several other benefits make t slot aluminum profile systems popular.

Reduced Assembly Time & Cost

The simplicity of the connection system drastically reduces assembly time. Using standard profiles and fasteners eliminates much of the custom fabrication work associated with welded frames. Faster assembly translates directly to lower labor costs and quicker project completion times. Based on our experience, assembly using T-slots can be significantly faster than comparable welded structures.

High Precision and Alignment

The extrusion process itself yields profiles with consistent dimensions and straightness. The slots act as natural guides, ensuring that attached components are accurately aligned. This is critical for applications like machine bases, linear motion guides, measurement fixtures, and automation frameworks where precision is paramount.

Clean and Aesthetic Appearance

Anodized aluminum profiles offer a clean, modern, and professional look right out of the box. The slots can sometimes be used to conceal wiring or air lines using special cover strips, further enhancing the neat appearance. This makes them suitable not just for industrial settings but also for lab environments, retail displays, museum exhibits, and furniture.

Common Applications Showcase Versatility

The flexibility of t slot aluminum profile systems means they are used across a vast spectrum of applications. Here are just a few examples:

| Area di applicazione | Descrizione | Key Benefit Utilized |

|---|---|---|

| Machine Guarding | Creating robust safety enclosures and barriers around operating machinery. | Modularity, Strength |

| Workstations & Benches | Building custom ergonomic workstations, test benches, and lab furniture. | Flexibility, Ease |

| Automation Frames | Constructing the structural skeletons for robotic cells and automated equipment. | Precision, Strength |

| Material Handling Racks | Designing custom storage solutions, flow racks, and carts. | Modularity, Load Capacity |

| Display Booths | Creating lightweight, reusable trade show displays and retail fixtures. | Aesthetics, Reusability |

| Linear Motion Systems | Providing the structural base for linear guides, actuators, and gantries. | Precision, Straightness |

| Enclosures & Cabinets | Building custom enclosures for electronics or environmental control. | Flexibility, Aesthetics |

The specific profile series (e.g., 20 series vs. 45 series) and wall thickness chosen will depend heavily on the load requirements, desired rigidity, and budget for the specific application. Heavier-duty profiles offer greater strength and stiffness for demanding structural tasks. Choosing the right profile is a key step in the design process.

Common Applications Across Manufacturing Industries

Walk through almost any modern manufacturing facility, R&D lab, or even a sophisticated workshop. You’ll likely see structures built with a surprisingly versatile material, often hiding in plain sight. What allows for such rapid, precise construction?

T-slot aluminum profiles are incredibly versatile, forming the backbone for safety guarding, machine frames, workstations, automation systems, and clean room structures. Their adaptability shines in both rapid prototyping and full-scale production environments.

The beauty of the t slot aluminum profile system lies in its adaptability. It’s like a high-tech erector set for industry. You might hear people refer to it using brand names like 80/20, which is a popular manufacturer of these systems, but the core concept is the standardized T-slot extrusion. This simple design unlocks applications across countless manufacturing scenarios, from one-off prototypes to high-volume production lines. At PTSMAKE, we often see the high-precision CNC machined parts or injection molded components we produce being integrated into structures built with these profiles by our clients. Its utility spans a wide range of needs.

Safety Guarding and Enclosures

One of the most common uses for t slot aluminum profile systems is creating safety guards around machinery. Protecting personnel from moving parts, robotic arms, or process hazards is critical for compliance and worker safety. T-slot profiles make building robust, custom-sized enclosures straightforward. You can easily incorporate clear polycarbonate or wire mesh panels into the slots to maintain visibility while ensuring protection. The modularity is a huge advantage here. If a machine layout changes or access points need modification, adjusting a T-slot guard is far simpler and quicker than cutting and re-welding a steel cage. You just loosen the connectors, reposition elements, and retighten. This adaptability saves significant downtime and cost.

Machine Frames and Structural Bases

Building the core frame for industrial machinery, automation equipment, or test fixtures is another key application. T-slot aluminum profiles offer a great balance of strength, stability, and precision. Unlike welded steel frames, there’s no heat distortion introduced during assembly, ensuring better dimensional accuracy, which is vital for mounting precision components like linear rails or measurement devices. The inherent straightness of the extrusions helps maintain alignment. Furthermore, the assembly speed is a major factor. In our experience helping clients integrate the parts we manufacture at PTSMAKE, using t-slot framing often cuts assembly time by 30-50% compared to traditional welded steel structures. This efficiency accelerates project timelines significantly. While standard profiles offer good rigidity, careful design, including appropriate bracing and profile selection (e.g., heavier series like 40 or 45), is necessary for high-load or high-vibration applications.

Custom Workstations and Ergonomic Solutions

Manufacturing environments demand efficient and ergonomic workstations. T-slot profiles excel at creating customized solutions. Whether it’s an assembly bench, an inspection station, a packing table, or a specialized lab setup, you can design and build exactly what’s needed. The T-slots make it incredibly easy to add accessories like tool holders, monitor arms, shelving, lighting fixtures, parts bins, and power strips exactly where they are needed. This level of customization supports lean manufacturing principles by optimizing workflow and improves worker comfort and productivity by tailoring the station height and layout. The clean, anodized finish also contributes to a professional and organized work environment.

Automation Systems and Robotics Integration

The rise of automation relies heavily on flexible structural systems. T-slot aluminum profiles are fundamental in constructing frames for robotic cells, conveyor systems, linear motion guides, gantries, and automated test equipment. The high strength-to-weight ratio of aluminum is beneficial, especially for dynamic systems where minimizing inertia is important. The precision of the slots ensures accurate mounting and alignment of critical automation components like actuators, sensors, and cameras. Many of the complex, high-precision parts we produce through CNC machining at PTSMAKE are destined for such automated systems, often mounting directly onto these versatile aluminum frames. The ease of modification allows automation cells to be reconfigured or expanded as production needs evolve.

Clean Rooms and Controlled Environments

Specific industries like electronics, pharmaceuticals, and medical device manufacturing require clean room environments. T-slot aluminum profiles, particularly those with smooth surfaces and anodized finishes, are well-suited for these applications. Aluminum is inherently corrosion-resistant, and the anodized layer enhances this, preventing particle shedding. The smooth surfaces are easy to wipe down and keep clean. When designing for clean rooms, careful consideration must be given to the profile shape (avoiding designs that trap contaminants) and the sealing of joints. Additionally, selecting materials with low outgassing2 properties might be necessary for ultra-sensitive applications to prevent contamination of processes or products. The ability to construct controlled environment enclosures without welding (which introduces contaminants) is a significant advantage.

Versatility from Prototype to Production

A key takeaway is the system’s scalability. The same t slot aluminum profile system used to quickly build a proof-of-concept prototype in an R&D lab can be scaled up for full production lines. Engineers can rapidly iterate designs during development using standard components. Once finalized, the bill of materials can be easily generated for larger quantities. This seamless transition reduces design transfer time and ensures consistency between development and production phases.

Here’s a quick summary of common applications:

| Area di applicazione | Why T-Slot Aluminum Profiles are Chosen | Example Use Case |

|---|---|---|

| Safety Guarding | Modularity, Ease of Customization, Strength, Panel Integration | Machine perimeter fencing |

| Machine Frames | Precision, Stability, Faster Assembly vs. Welding, No Distortion | Base for CNC routers or 3D printers |

| Custom Workstations | Ergonomics, Accessory Integration, Flexibility, Cleanliness | Electronic assembly bench |

| Sistemi di automazione | Strength-to-Weight, Precision Alignment, Reconfigurability | Robot cell framework, Conveyor stand |

| Clean Rooms | Corrosion Resistance, Ease of Cleaning, Smooth Surface | Support structures inside labs |

| Prototyping / R&D | Speed of Assembly, Ease of Modification, Reusability | Test rig for new mechanism |

The adaptability and wide range of available profiles and accessories make t slot aluminum profile systems a go-to solution for countless structural challenges across diverse manufacturing industries.

Technical Specifications & Material Properties

Ever wondered how to guarantee your t-slot aluminum profile structure won’t buckle under pressure? Choosing the right profile involves more than just aesthetics; it demands a look into the technical details. Let’s explore the specifications that ensure strength and reliability in your builds.

Key technical specifications for t slot aluminum profiles include their dimensional series (like 20mm or 40mm), the specific material properties of the aluminum alloy (typically 6063-T6), and crucial engineering data such as load capacities and moment of inertia for accurate structural design.

Understanding these technical details is the difference between a robust, reliable structure and one that might fail unexpectedly. When we design solutions or provide precision parts at PTSMAKE that integrate with these framing systems, knowing the specs is non-negotiable.

Understanding Profile Dimensions & Series

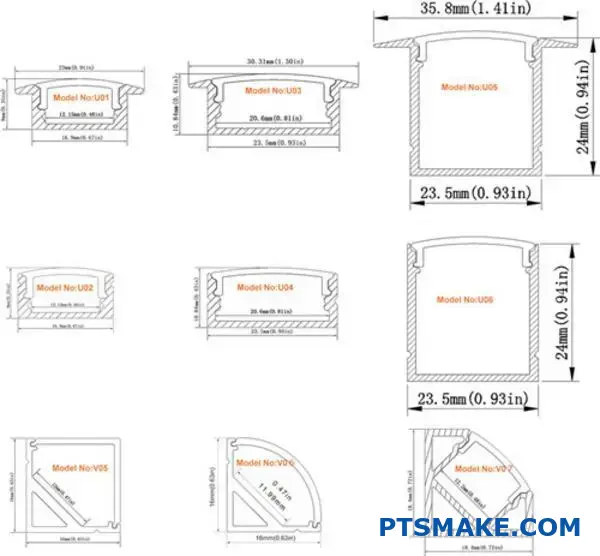

T-slot aluminum profiles aren’t one-size-fits-all. They come in standardized series, typically defined by the primary dimension of the profile’s cross-section, usually in millimeters (e.g., 20 Series, 30 Series, 40 Series, 45 Series) or sometimes fractional inches. A "40 Series" profile, for instance, generally means the main body is 40mm x 40mm.

- Series Size: Directly relates to the overall strength and the size of the T-slot itself. Larger series generally mean higher strength and larger slots compatible with heavier-duty fasteners.

- Slot Width: Determines the type and size of T-nuts and bolts that can be used. Consistency is key; mixing series in a single structure usually requires adapter plates or specialized connectors.

- Wall Thickness: Profiles within the same series can have different wall thicknesses ("light" vs. "heavy" duty). Thicker walls increase weight but significantly boost strength and rigidity.

- Shape Variations: Beyond basic squares, you’ll find rectangles (e.g., 40×80), profiles with rounded corners, profiles with more or fewer slots, and specialized shapes for specific functions like mounting panels.

Choosing the right series depends entirely on the application’s load requirements, the span of the beams, and the desired rigidity. For simple guards or light frames, a 20 or 30 series might suffice. For machine bases or heavy structures, 40, 45, or even larger series are common. Profiles are typically sold in standard lengths but can be easily cut to custom sizes for specific project needs.

The Workhorse Material: 6063-T6 Aluminum

The most common alloy used for t slot aluminum profiles is 6063. It offers an excellent combination of extrudability (allowing for complex shapes with tight tolerances), a good surface finish (ideal for anodizing), and adequate strength for the vast majority of framing applications. It’s often specified with a T6 temper.

What does "T6 temper" signify? It means the aluminum has undergone a specific heat treatment process:

- Solution Heat Treatment: Heating the aluminum to a specific high temperature to dissolve alloying elements into the base metal.

- Quenching: Rapidly cooling the aluminum to lock these elements in a supersaturated state.

- Artificial Aging: Reheating the aluminum to a lower temperature for a set time. This precipitates the alloying elements, significantly increasing the material’s strength and hardness.

Key Material Properties of 6063-T6

Understanding these properties helps in engineering calculations and material selection:

- Tensile Strength (Ultimate): Typically around 241 MPa (35,000 psi). This is the maximum stress the material can withstand while being stretched or pulled before breaking.

- Tensile Strength (Yield): Around 214 MPa (31,000 psi). This is the stress at which the material begins to deform plastically (permanently). Designing below the yield strength is crucial for structural integrity.

- Hardness: Often measured on the Brinell scale (around 73 HB). This relates to resistance to indentation and surface wear.

- Modulus of Elasticity: Approximately 68.9 GPa (10,000 ksi). This measures the material’s stiffness or resistance to elastic deformation under load. A key factor in deflection calculations.

- Resistenza alla corrosione: 6063 offers good natural corrosion resistance, which is further enhanced by anodizing – the standard surface finish for most t slot aluminum profiles.

- Lavorabilità: Generally considered good, allowing for easy cutting, drilling, and tapping for assembly or customization.

While 6061-T6 is another common structural aluminum alloy with slightly higher strength, 6063-T6 is often preferred for extrusions due to its better formability into complex profile shapes and superior surface finish characteristics.

Load Capacity & Structural Integrity

How much weight can a specific t slot aluminum profile hold? There’s no single answer. The load capacity depends heavily on:

- Profile Selection: Larger series and thicker walls mean higher capacity.

- Beam Length (Span): Longer unsupported spans drastically reduce capacity.

- Load Type: A concentrated point load is more demanding than a uniformly distributed load.

- Support Conditions: How the beam is supported (fixed at both ends, cantilevered, etc.) significantly impacts its strength and deflection.

Manufacturers typically provide load tables or charts in their catalogs. These tables give allowable loads (often based on a maximum deflection limit, like L/200, meaning the deflection won’t exceed 1/200th of the beam’s length) for specific profiles under defined loading and support conditions. It’s crucial to consult these tables for the specific profile you intend to use. Remember, minimizing deflection (bending) is often just as important as preventing outright failure, especially in precision applications like machine bases or linear motion systems. Based on project data collected over time at PTSMAKE, using the manufacturer’s load data correctly prevents most common structural issues.

The Engineer’s Friend: Moment of Inertia

For more complex loading scenarios, longer spans, or applications demanding high stiffness, relying solely on basic load tables might not be sufficient. This is where understanding the Moment of Inertia3 becomes essential. In simple terms, Moment of Inertia (often denoted as ‘I’) is a geometric property of a cross-section that measures its resistance to bending. The higher the Moment of Inertia, the stiffer the beam and the less it will deflect under a given load.

- Importance: It’s a critical value used in standard beam deflection and stress calculation formulas. Engineers use it to predict how a structure will behave under load.

- Ix and Iy: Because T-slot profiles are often not symmetrical (especially rectangular ones), they have different Moments of Inertia depending on the axis of bending (typically denoted as Ix and Iy). A profile will be much stiffer when bending occurs around the axis with the higher Moment of Inertia. Manufacturers always provide both Ix and Iy values for each profile in their technical data.

- Applicazione: When designing frames, especially those with longer unsupported sections or significant loads, performing basic beam calculations using the Moment of Inertia is highly recommended to ensure the structure meets stiffness requirements and stays well within safe stress limits.

Below is a simplified comparison illustrating how properties scale with profile size:

| Proprietà | Unità | Typical 20×20 Profile | Typical 40×40 Profile (Light) | Typical 40×40 Profile (Heavy) |

|---|---|---|---|---|

| Peso | kg/m | ~0.48 | ~1.35 | ~1.85 |

| Moment of Inertia Ix | cm4 | ~0.68 | ~7.8 | ~11.5 |

| Moment of Inertia Iy | cm4 | ~0.68 | ~7.8 | ~11.5 |

| Section Modulus Zx | cm3 | ~0.68 | ~3.9 | ~5.7 |

| Section Modulus Zy | cm3 | ~0.68 | ~3.9 | ~5.7 |

(Note: Values are approximate and vary slightly by manufacturer and specific profile design. Always refer to manufacturer data.)

As you can see, doubling the profile dimension from 20mm to 40mm increases the Moment of Inertia (stiffness) by more than tenfold! This highlights the significant impact of choosing the right profile series based on engineering requirements.

By understanding these technical specifications – dimensions, material properties (like those of 6063-T6), load limits, and the significance of Moment of Inertia – you can confidently select and design t slot aluminum profile structures that are safe, efficient, and perfectly suited for their intended purpose.

Assembly Methods & Connection Hardware Options

Ever wondered how those sleek, strong aluminum frames snap together seemingly like magic, without a single weld? The secret lies in clever connection methods and specialized hardware. Let’s dive into how you actually build with t-slot aluminum profiles.

Assembling t slot aluminum profile structures relies on various connection techniques using T-nuts, brackets, connectors, and fasteners. These methods allow for strong, rigid joints comparable to welding but offer the significant advantages of easy modification and reconfiguration.

The beauty of the t-slot system is its modularity, which hinges entirely on how the pieces connect. Unlike welded structures that are permanent and require specialized skills, assembling t slot aluminum profile frames is more like using an industrial-grade construction set. It’s fast, clean, and remarkably versatile. At PTSMAKE, we often provide high-precision machined components that mount onto these frames, so understanding the assembly is crucial for seamless integration.

The Foundation: T-Nuts and Fasteners

The heart of the connection system is the T-nut. These specially shaped nuts are designed to slide into the T-slot of the profile and then rotate 90 degrees to lock into place under the slot’s shoulders.

How T-Nuts Work

- Insertion: Depending on the type, the T-nut is either slid in from the profile end or dropped/rolled directly into the slot face.

- Positioning: It slides freely along the slot until it reaches the desired connection point.

- Tightening: A standard bolt (typically a socket head cap screw) is inserted through the component being attached (like a bracket or another profile’s access hole) and threaded into the T-nut. As the bolt tightens, it pulls the T-nut securely against the internal shoulders of the slot, creating a strong, friction-based connection.

Common T-Nut Varieties

- Standard T-Nuts: Require sliding in from an open profile end. Most economical but less convenient if ends are blocked.

- Roll-In/Drop-In T-Nuts: Can be inserted anywhere along the slot length, often featuring a spring-loaded ball or set screw to hold them in position before tightening. More convenient for modifications or additions.

- Pre-Set T-Nuts: Similar to roll-in but designed to stay put more firmly before final tightening.

The choice of bolt depends on the T-nut thread size (M4, M5, M6, M8 are common for metric profiles) and the required strength. Washers are sometimes used to distribute the load, especially when connecting softer materials or oversized holes.

Essential Brackets for Strength and Alignment

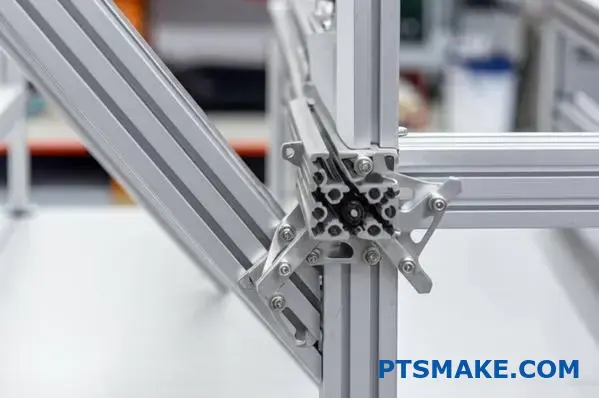

While T-nuts provide the anchor point, brackets are often used to create strong, aligned joints between profiles, especially for corner connections.

Corner Brackets (Gussets)

These are the workhorses for creating 90-degree connections. They typically feature holes aligned with the T-slots on both profiles being joined.

- Tipi: Come in various sizes and strengths, from simple die-cast brackets for light loads to heavy-duty machined or extruded gussets with reinforcing ribs for maximum rigidity.

- Funzione: They significantly increase the stiffness and strength of the corner joint, preventing racking or twisting. Alignment tabs are often included to ensure the profiles sit perfectly perpendicular.

Joining Plates

Used to connect profiles end-to-end or side-by-side (parallel).

- End Connectors: Plates that bridge the gap between two abutting profiles, often secured with T-nuts in each profile.

- Straight Plates: Flat plates used to reinforce joints or attach profiles parallel to each other.

Specialized Connectors for Versatility

Beyond basic brackets, a range of specialized connectors offers different aesthetic or functional advantages.

Internal Connectors (Hidden Fasteners)

These provide a cleaner look by concealing the connection hardware within the profile slots.

- Anchor Fasteners: Small, expanding anchors placed inside the slot, tightened via a screw accessed through a hole drilled in the mating profile. Good aesthetics, moderate strength.

- Bolt Connectors (Universal Fasteners): Typically involve a specially shaped bolt head or barrel nut that engages the slot internally, tightened via a screw through an access hole. Often require machining (an access hole) on one profile. Can provide very strong connections.

- Inserti filettati: Some systems allow tapping the central core hole of the profile and using a standard bolt directly, but this requires precise end-machining.

Cube Connectors and Multi-Axis Joints

For connecting three or more profiles intersecting at a single point (e.g., the corner of a cube frame), specialized cube connectors or multi-axis brackets are available. These simplify complex intersections while maintaining strength.

Achieving Rigidity Without Welding

A common question is whether these bolted connections can be as strong or rigid as a welded joint. While welding creates a monolithic structure, t-slot systems achieve rigidity through different means:

- Component Choice: Using appropriately sized profiles (e.g., 40 series vs. 20 series) and heavy-duty connectors is fundamental.

- Proper Torque: Tightening fasteners to the manufacturer’s recommended torque specification is crucial. This creates the necessary clamping force and preload4 in the joint, maximizing friction and preventing slippage. Under-tightening leads to weak joints, while over-tightening can damage the profile or fastener.

- Connector Selection: Gusseted corner brackets inherently provide more rigidity against twisting forces than simple T-nut connections alone. Internal connectors can also offer high rigidity if chosen and installed correctly.

- Bracing: For very large frames or high loads, diagonal braces (additional profiles connected with brackets) can be added to significantly increase overall stiffness, similar to how trusses work.

The key advantage remains: these rigid structures can still be easily disassembled, modified, or reconfigured. Need to move a cross-member? Just loosen the bolts, slide it, and retighten. Compare that to cutting and re-welding a steel frame! For applications requiring a more permanent assembly, thread-locking compounds can be applied to the bolts.

Choosing the Right Connection Method

The best method depends on the specific requirements of the joint:

| Connection Method | Uso tipico | La forza | Ease of Assembly | Estetica | Reconfigurability | Costo relativo |

|---|---|---|---|---|---|---|

| T-Nut + Bolt (Direct Connect) | Attaching panels, accessories | Medio | Alto | Medio | Alto | Basso |

| T-Nut + Corner Bracket | 90-degree frame joints | Alto | Alto | Medium / Low | Alto | Medio |

| T-Nut + Joining Plate | End-to-end connections | Alto | Alto | Medio | Alto | Medio |

| Internal Anchor Fastener | Clean look 90-degree joints | Medio | Medio | Alto | Medio | Medium / High |

| Internal Bolt Connector | Strong, clean look joints | Alto | Medium (needs access hole) | Alto | Medio | Medium / High |

| Cube Connector | Multi-axis intersections | Alto | Medio | Basso | Alto | Alto |

(Note: Strength and cost are relative comparisons within the t-slot system itself.)

By understanding these various assembly methods and hardware options for t slot aluminum profile systems, you can design and build structures that are not only strong and precise but also adaptable to future needs – a core principle we value when helping clients integrate our precision parts at PTSMAKE.

Comparing Standard Sizes & Profile Configurations

Choosing the wrong t slot aluminum profile can turn your brilliant design into a wobbly mess or an overbuilt expense. How do you navigate the maze of sizes and styles to find the perfect fit for your project’s needs and budget?

Standard t slot aluminum profile sizes like 15×15, 20×20, 30×30, and 40x40mm offer varying strength, while configurations like single-slot, multi-slot, or heavy-duty walls impact rigidity and connection options. Matching the profile to load requirements and application is crucial for success.

Selecting the right t slot aluminum profile is more than just picking a size; it’s about understanding the interplay between dimensions, wall thickness, and the specific demands of your application. Over my 15+ years in precision manufacturing, including countless projects at PTSMAKE where our machined or molded parts integrate into these frameworks, I’ve seen how critical this choice is. Let’s break down the common options to help you make an informed decision.

Standard Profile Sizes: The Foundation

T-slot profiles are typically categorized by their primary cross-sectional dimension, often in millimeters. This dimension usually refers to the width and height for square profiles.

15mm Series (e.g., 15x15mm)

- Characteristics: The smallest standard size. Very lightweight and compact.

- Best Suited For: Extremely light-duty applications, small sensor mounts, desktop enclosures, model building, framing for very small guards where space is minimal and loads are negligible.

- Considerations: Limited load capacity and rigidity. Fewer connector options compared to larger series. Uses smaller, less robust M3 or M4 fasteners.

20mm Series (e.g., 20x20mm)

- Characteristics: A popular choice for light-duty framing. Offers a good balance between size, weight, and moderate strength. Widely available with many accessory options.

- Best Suited For: Light machine guards, small workstations, test fixtures, display stands, enclosures for electronics, 3D printer frames.

- Considerations: Suitable for spans up to around 1 meter with light loads. Deflection can become noticeable on longer unsupported lengths. Typically uses M4 or M5 fasteners.

30mm Series (e.g., 30x30mm)

- Characteristics: A significant step up in strength and rigidity compared to the 20mm series. Offers a good compromise between the lighter 20mm and heavier 40mm series.

- Best Suited For: Medium-duty machine frames, workbenches, sturdy guarding, conveyor supports, ergonomic workstations, structures requiring moderate load capacity.

- Considerations: Noticeably heavier and bulkier than 20mm profiles. Provides better performance over longer spans. Typically uses M6 fasteners, offering stronger connections.

40mm Series (e.g., 40x40mm, 40x80mm)

- Characteristics: The workhorse for many industrial applications. Offers substantial strength, rigidity, and load-bearing capacity. Available in various configurations, including heavy-duty options.

- Best Suited For: Robust machine bases, heavy-duty safety enclosures, automation framework, material handling carts, structural supports, gantry systems.

- Considerations: Significantly heavier and requires more robust connection hardware. Ideal for applications where stiffness and load capacity are primary concerns. Often uses M8 fasteners for maximum joint strength. Experience from past PTSMAKE client projects shows that the 40mm series is frequently chosen for frames supporting CNC-machined components or heavy automation equipment.

There are also larger series (45mm, 50mm, 60mm, etc.) for extremely demanding structural tasks, but the 20, 30, and 40 series cover the vast majority of common applications.

Profile Configurations: Beyond the Basic Square

Within each size series, you’ll find variations in the profile’s design or configuration:

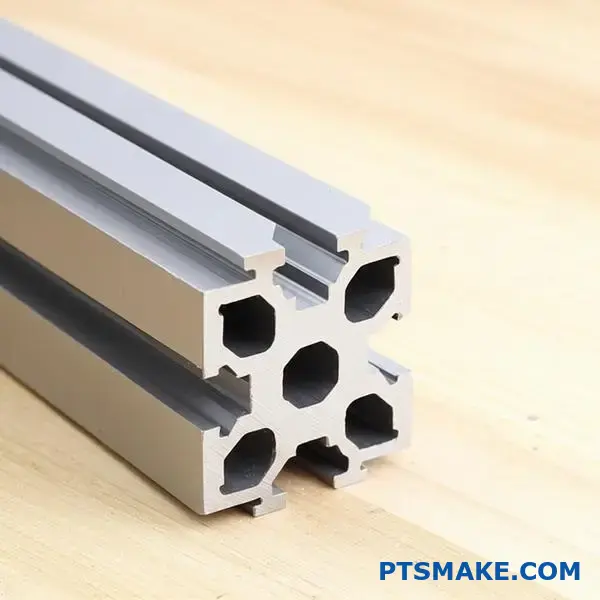

Number of Slots

- Single Slot: Profiles with a T-slot on only one face. Less common, used for specific edge or finishing applications.

- Two Slots (Adjacent): Slots on two adjacent faces (like an L-shape). Useful for corners or specific mounting needs.

- Two Slots (Opposite): Slots on two opposite faces.

- Three Slots: Slots on three faces.

- Four Slots: The most common configuration for square profiles (e.g., 20×20, 40×40), offering maximum connection flexibility on all sides. Rectangular profiles (e.g., 40×80) might have slots on all four faces or just the wider/narrower faces depending on the design.

Wall Thickness (Light vs. Heavy-Duty)

- Standard/Light: Features thinner walls to save weight and cost. Suitable for applications where maximum load capacity isn’t the primary driver.

- Heavy-Duty: Incorporates thicker walls and sometimes internal webbing. This significantly increases the profile’s weight, strength, stiffness (resistance to bending and twisting), and overall load capacity. These are crucial for machine bases, long spans, or applications subject to vibration or dynamic loads. Selecting a heavy-duty profile can often prevent issues related to structural buckling5 under compressive loads.

Smooth vs. Slotted Faces

- Fully Slotted: T-slots on all available faces provide maximum connection points.

- Partially Smooth: Some profiles have one or more faces intentionally left smooth (without a T-slot). This can be for aesthetic reasons, ease of cleaning (fewer crevices), or for specific mounting requirements where a flat surface is preferred.

Making the Right Choice: Load, Application, and Cost

Selecting the optimal t slot aluminum profile involves balancing several factors:

- Load Requirements: This is paramount. Estimate the maximum static and dynamic loads the structure will bear. Consult manufacturer load tables for the specific profiles you’re considering, paying attention to span lengths and load types (point vs. distributed). Always apply a safety factor. For critical applications, performing basic beam calculations or Finite Element Analysis (FEA) is recommended.

- Rigidity Needs: How much deflection (bending) is acceptable? Machine bases and precision fixtures require high rigidity (minimal deflection), often demanding larger series or heavy-duty profiles. Simple guards might tolerate more deflection.

- Application Environment: Will it be in a cleanroom (smooth profiles might be better)? Exposed to vibration (heavy-duty recommended)? Space constraints (smaller series)?

- Connection Needs: How many connection points are required? Do you need slots on all faces? Will you use internal or external fasteners?

- Bilancio: Larger series and heavy-duty profiles are more expensive and heavier (increasing shipping costs). Balance performance needs with cost-effectiveness. Sometimes, clever design with a smaller series profile (e.g., adding bracing) can achieve the required strength more economically than simply jumping to a larger size.

- Estetica: Does the final appearance matter? Smooth faces or hidden connectors might be preferred for customer-facing equipment or displays.

Here’s a simplified selection guide:

| Fattore | Raccomandazione | Example Scenario |

|---|---|---|

| Very Light Load | 15mm or 20mm Series, Standard Wall | Small sensor bracket, display frame |

| Moderate Load/Span | 30mm Series, Standard Wall or 40mm Light | Workbench, medium machine guard |

| Heavy Load/Long Span | 40mm Series (Standard or Heavy-Duty), potentially larger series (45mm+) | Machine base, automation cell frame |

| High Rigidity Needed | Heavy-Duty Profile, Larger Series (e.g., 40mm+), consider bracing | Precision measurement fixture |

| Cost Sensitive | Smallest series that meets load/rigidity needs, Standard Wall | Simple enclosure, non-critical frame |

| Maximum Flexibility | Profile with slots on all four faces | Prototyping, adaptable workstation |

| Clean Environment | Profiles with smooth faces where possible, minimize crevices | Lab equipment frame |

In practice, many projects utilize a mix of profile sizes and types. For instance, a machine frame might use heavy-duty 40×80 profiles for the main base supports and lighter 40×40 or even 30×30 for secondary bracing or guarding components. Understanding the strengths and limitations of each standard size and configuration empowers you to design and build t slot aluminum profile structures that are both functional and efficient. At PTSMAKE, helping clients match the right structural components with the precision parts we manufacture ensures the success of the final assembly.

Custom Solutions & Compatibility Between Brands

Standard t slot aluminum profile parts get you far, but what if your project needs a specific length, a unique look, or must integrate parts from different suppliers? Navigating custom options and brand compatibility can feel tricky, but it’s key to unlocking truly optimized solutions.

T slot aluminum profile systems offer extensive customization, from precise cuts and unique finishes to specialized machining. While many metric profiles share similarities, understanding brand compatibility and potential interchangeability issues is crucial for successful procurement and assembly.

While the modularity of t slot aluminum profile systems is a major draw, relying solely on off-the-shelf components doesn’t always cut it. Sometimes, the standard sizes, finishes, or even the profiles themselves need tweaking to meet specific design requirements. Furthermore, in the real world of procurement, you might face situations where using components from different manufacturers seems necessary or cost-effective. Let’s explore the landscape of customization and the critical topic of cross-brand compatibility.

Tailoring Profiles to Your Exact Needs

Getting the perfect fit often goes beyond just selecting the right profile series. Customization services allow you to adapt standard extrusions precisely for your application.

Precision Cutting Services

The most basic customization is cutting profiles to specific lengths. While you can cut profiles yourself, dedicated suppliers offer precision cutting services that ensure clean, square ends vital for strong, accurate joints. Beyond simple straight cuts, many also provide:

- Miter Cuts: Cutting profiles at angles (typically 45 degrees) allows for creating angled frame joints without needing specialized brackets, sometimes offering a cleaner look or fitting into tight spaces.

- Tolerance Control: Professional cutting ensures lengths are within tight tolerances (e.g., +/- 0.5mm or better), which is critical for complex assemblies where cumulative errors can cause misalignment. At PTSMAKE, we appreciate precision – the machined parts we deliver often need to align perfectly with frame elements, making accurate profile lengths essential.

Beyond Silver and Black: Special Finishes

Standard clear (silver) and black anodized finishes suit most industrial needs. However, specific applications might demand different aesthetics or enhanced properties:

- Color Anodizing: Various colors (blue, red, gold, etc.) can be achieved through anodizing for branding, safety coding (e.g., identifying specific lines or functions), or pure aesthetics.

- Rivestimento in polvere: Applying a powder-coated finish offers a vast range of colors and textures. It provides a durable, often thicker coating than standard anodizing, which can be beneficial for scratch resistance or specific environmental challenges. It’s a common request for consumer-facing equipment or architectural elements made with t slot aluminum profile sections.

- Special Treatments: Depending on the environment, treatments like chemical-resistant coatings or specific pre-treatments before finishing might be necessary.

Machining for Functionality

Sometimes, the profile itself needs modification beyond simple cutting:

- Drilling & Tapping: Creating threaded holes directly in the profile end (often in the central core) or on its faces allows for direct bolt connections without T-nuts, useful for mounting plates or specific components.

- Access Holes: Many internal or hidden connectors require precisely positioned access holes drilled into the mating profile to tighten the fastener. Accurate machining is key here.

- Milling: More complex modifications like milling slots, pockets, or specific contours can be done for integrating unique hardware, sensors, or other custom elements directly into the profile structure.

Navigating the Compatibility Maze

A frequent question arises: Can I mix t slot aluminum profile components from different manufacturers? The answer is complex: sometimes yes, but with significant caveats.

Metric vs. Fractional Systems

First and foremost, metric profiles (based on millimeter dimensions like 20mm, 40mm series) and fractional profiles (based on inch dimensions, common in North America) are fundamentally incompatible. Their dimensions, slot sizes, and fastener standards are entirely different. Attempting to mix these system types will lead to frustration and poorly fitting assemblies. Stick to one system throughout your project.

Within Metric Systems: Are They All the Same?

This is where it gets subtle. Many manufacturers produce metric profiles based on similar nominal dimensions (e.g., 40x40mm with an 8mm slot). Superficially, they look interchangeable. However, slight variations can exist in:

- Slot Width Tolerance: Is the 8mm slot exactly 8.0mm, or is it 8.1mm? This affects how snugly T-nuts fit.

- Slot Depth & Lip Shape: The internal geometry of the slot, including the depth and the shape of the "lips" that retain the T-nut, can differ slightly. This is critical for connector engagement. Accurate metrologia6 is required to confirm these subtle differences if mixing is considered.

- Overall Profile Tolerances: While extrusion standards exist, minor variations in overall profile dimensions or straightness could occur between manufacturers.

The Connector Conundrum

Accessories, especially T-nuts and specialized connectors (like internal bolt connectors), are often designed very specifically for the manufacturer’s own profile slot geometry. Using Brand A’s T-nuts in Brand B’s profile might result in:

- Loose Fit: T-nuts may wobble or not seat firmly, leading to weak joints or movement under load.

- Tight Fit/No Fit: Connectors might be difficult or impossible to insert or properly tighten.

- Reduced Holding Force: The clamping action might be compromised if the T-nut doesn’t engage the slot shoulders correctly.

While simple brackets might seem more forgiving, their hole spacing is designed for specific profile centerlines and slot positions. Even minor discrepancies can make assembly difficult or introduce stress.

Smart Procurement: Ensuring Interchangeability Works

Given the potential pitfalls, how should procurement managers and engineers approach compatibility?

The Risks and Rewards of Mixing Brands

The primary driver for mixing brands is often cost savings or availability. One supplier might have better pricing on profiles, while another has specific connectors needed. The potential rewards are lower upfront costs. The risks, however, include:

- Increased assembly time due to fitting issues.

- Compromised structural integrity or performance.

- Difficulty troubleshooting problems.

- Need for custom adaptation or shimming.

- Inconsistent appearance.

Specification is Key

If mixing brands is unavoidable, meticulous specification is crucial.

- Obtain detailed technical drawings and tolerance specifications for profiles and connectors from all potential suppliers.

- Compare critical dimensions, especially slot width, depth, and overall profile tolerances.

- Consider ordering samples for fit testing before committing to large quantities. Ensure T-nuts seat properly and connectors align as expected.

Supplier Collaboration

Discuss your needs openly with suppliers. A knowledgeable supplier can often advise on known compatibility issues or suggest alternatives. When clients approach PTSMAKE needing precision components that will integrate into a t slot aluminum profile frame, understanding the specific profile system they are using helps us ensure our parts interface correctly. We can sometimes anticipate potential integration challenges based on the chosen framing system.

Here’s a quick summary of compatibility considerations:

| Aspetto | Key Consideration | Raccomandazione |

|---|---|---|

| Tipo di sistema | Metric vs. Fractional | NEVER mix metric and fractional components. |

| Metric Series | Nominal size (e.g., 40mm) usually consistent | Generally safe to mix profiles of same series. |

| Slot Dimensions | Width, Depth, Lip Shape can vary subtly | High Risk: Verify dimensions before mixing. |

| T-Nuts | Designed for specific slot geometry | High Risk: Test fit; ideally use matched brand. |

| Connectors/Brackets | Hole spacing & design specific to profile geometry | Medium/High Risk: Test fit; check alignment. |

| Fasteners (Bolts) | Thread size (M6, M8 etc.) usually standard | Generally interchangeable if thread matches T-Nut. |

While standard t slot aluminum profile systems offer immense flexibility, customization unlocks tailored solutions. And while mixing brands might seem tempting, approach it with caution and thorough verification. Often, sticking with a single, reliable supplier for both profiles and connectors ensures the smoothest assembly and most dependable results, even if it requires leveraging their customization services for specific project needs.

Cost-Effectiveness vs. Traditional Fabrication Methods

Struggling to keep project budgets and timelines under control when building custom frames or structures? Traditional methods often come with hidden costs and delays. Let’s explore a modern alternative that could drastically change your approach and your bottom line.

When comparing t slot aluminum profile systems to traditional welded steel, the true cost-effectiveness emerges not just from initial material prices, but significantly from reduced labor, unparalleled modification flexibility, and superior long-term value, offering a compelling ROI for manufacturers.

When decision-makers look at structural fabrication, the conversation often starts—and sometimes unfortunately ends—with the upfront cost of materials. Comparing a pile of steel beams to a pallet of t slot aluminum profile extrusions might suggest steel is cheaper initially. However, this misses the bigger picture entirely. In my experience working on diverse manufacturing projects at PTSMAKE, focusing solely on the raw material cost is a common pitfall that overlooks substantial savings elsewhere in the project lifecycle.

Initial Costs: Beyond the Material Price Tag

Let’s be upfront: on a per-kilogram basis, aluminum extrusion generally costs more than raw steel. However, this is just one piece of the puzzle.

Considerazioni sui materiali

While steel stock might seem cheaper, remember that aluminum profiles are significantly lighter (about one-third the density of steel). You often need less weight of aluminum to achieve the required structural integrity for many applications, especially when considering the optimized shapes of extrusions. Furthermore, t slot aluminum profile parts usually come with a durable, corrosion-resistant anodized finish included. Steel, on the other hand, requires surface preparation (cleaning, grinding) and protective coatings (painting, galvanizing) to prevent rust, adding material and labor costs not immediately apparent in the raw steel price.

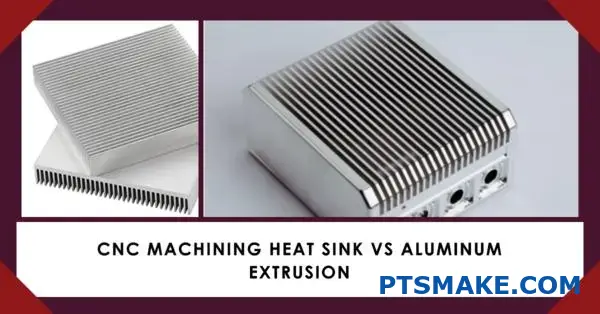

Equipment and Setup

Traditional steel fabrication demands a significant investment in equipment and space: welders, grinders, cutting saws suitable for steel, paint booths, and potentially specialized jigs. Crucially, it requires skilled labor – certified welders aren’t cheap, and their availability can impact project timelines.

Contrast this with t slot aluminum profile assembly. The required tools are basic hand tools: wrenches, Allen keys, a saw for cutting profiles (if not ordered pre-cut), and a measuring tape. There’s no need for welding fumes extraction, extensive grinding stations, or paint facilities. The skillset required for assembly is much lower and easier to train, reducing dependency on specialized trades.

Labor Savings: The Game Changer

This is where t slot aluminum profile systems truly shine. The time—and therefore labor cost—saved during assembly is substantial compared to welding steel.

Assembly Speed

Building with T-slots is fundamentally faster. There’s no need for complex jigging to hold parts while welding, no waiting for welds to cool, no time spent grinding welds smooth, and no painting process. Components are simply bolted together. Feedback from various projects and industry observations consistently suggest that assembly using t slot aluminum profile framing can cut labor time by 30-50%, sometimes even more, compared to building an equivalent welded steel structure. This faster build time translates directly into lower labor costs and quicker project completion.

Reduced Rework

Welding can introduce heat distortion, potentially requiring parts to be straightened or adjusted post-fabrication. Bolted t-slot connections eliminate this risk, ensuring higher dimensional accuracy from the start and reducing time spent on rework or troubleshooting alignment issues.

Modification Flexibility: Adapting to Change

Manufacturing needs evolve. Processes change, equipment gets upgraded, and layouts are reconfigured. This is where the rigidity of welded structures becomes a major drawback.

Ease of Modification

Need to move a support beam, add a sensor bracket, or adjust the height of a work surface on a t slot aluminum profile frame? It’s usually a simple matter of loosening some bolts, repositioning the components, and retightening. Modifications that might take hours or days with a welded structure (involving cutting, re-welding, grinding, repainting) can often be done in minutes with T-slots.

Riutilizzabilità

When a welded steel frame reaches the end of its specific purpose, it’s often destined for the scrap heap. T-slot aluminum profiles, however, can be easily disassembled. The profiles and connectors retain their value and can be repurposed for entirely new structures. This inherent reusability significantly reduces waste and the need to purchase new materials for future projects, contributing positively to sustainability efforts. This is a factor many procurement managers we work with at PTSMAKE find increasingly valuable.

Long-Term Value and ROI

Considering the entire lifecycle of a structure reveals the compelling long-term value proposition of t slot aluminum profile systems. Instead of just initial cost, decision-makers should focus on the Costo totale di proprietà (TCO)7.

Manutenzione ridotta

Anodized aluminum doesn’t rust. Steel structures, even when painted, often require periodic inspection and touch-ups to manage corrosion, especially in demanding industrial environments. This ongoing maintenance adds to the long-term cost of steel.

Adaptability = Lower Future Costs

The cost of modifying or replacing a welded structure when needs change can be substantial. The flexibility of T-slots means future adaptations are significantly less expensive and disruptive. This adaptability translates directly into savings over the structure’s lifespan.

Calculating the Return on Investment (ROI)

For decision-makers, presenting a clear ROI analysis is key. While the initial outlay for t slot aluminum profile materials might be slightly higher in some cases, the calculation must include:

- Lower initial labor costs (faster assembly, less skill needed).

- Eliminated costs for welding equipment, consumables, and specialized labor.

- Eliminated costs for grinding, painting, and finishing.

- Significantly lower costs for future modifications or reconfigurations.

- Value recovered through component reusability.

- Reduced maintenance costs (no rust).

When all these factors are considered, the ROI for choosing t slot aluminum profile systems over welded steel often becomes overwhelmingly positive, especially for applications requiring customization, precision, or potential future changes.

Here’s a comparative summary:

| Caratteristica | T-Slot Aluminum Profile | Welded Steel Structure |

|---|---|---|

| Costo iniziale del materiale | Moderate to High (per kg), Finish often included | Low to Moderate (per kg), Finishing extra |

| Initial Labor Cost | Low (Fast assembly, basic skills) | High (Slow assembly, welding, grinding, paint) |

| Attrezzatura necessaria | Basic hand tools, saw | Welders, grinders, paint gear, specialized jigs |

| Modification Cost | Very Low (Loosen bolts, reposition) | Very High (Cut, weld, grind, repaint) |

| Manutenzione | Minimal (Corrosion resistant) | Moderate (Rust prevention, paint touch-ups) |

| Riutilizzabilità | High (Easily disassembled and repurposed) | Low (Difficult to repurpose components) |

| Long-Term Value (TCO) | Excellent (Savings from labor, mods, reuse) | Fair (High modification & potential maint. costs) |

While welded steel certainly has its place for very heavy-duty, static structures where cost per kilogram is the absolute dominant factor and modifications are unlikely, t slot aluminum profile systems offer a far more cost-effective, flexible, and ultimately valuable solution for a vast range of industrial framing, guarding, workstation, and automation applications. Considering the total picture is essential for making the smartest investment.

Design Tips & Software Tools for Project Planning

Ready to transform your t slot aluminum profile concept into a robust reality? Good planning and the right tools are essential. Skipping this stage can lead to costly rework or structures that don’t meet requirements. Let’s explore how to design effectively from the start.

Maximize your t slot aluminum profile projects with smart design tips focusing on strength, accessibility, and future expansion. Utilize CAD software and specialized configurators to streamline planning, ensure structural integrity, and visualize the final assembly before cutting a single piece.

Designing with t slot aluminum profile systems offers incredible flexibility, but great results depend on thoughtful planning. It’s not just about connecting beams; it’s about creating a structure that is strong, functional, easy to work with, and adaptable for the future. Based on experience integrating precision components from PTSMAKE into client frameworks, thorough upfront design is key.

Foundational Design Principles

Before diving into specific software, grounding your project in solid design principles is crucial. These apply regardless of the tools you use.

Understand Load Paths and Forces

Think about how forces will travel through your structure. Where are the main loads applied? Are they static (constant weight) or dynamic (moving parts, vibration)? Understanding these forces helps determine where you need stronger profiles, reinforced connections, or bracing. Neglecting load paths is a common cause of under-designed frames.

Prioritize Stability and Rigidity

Strength isn’t just about not breaking; it’s also about resisting bending (deflection) and twisting (torsion). For applications like machine bases or measurement fixtures, rigidity is paramount. Consider:

- Profile Selection: Use larger series (e.g., 40mm vs. 20mm) or heavy-duty profiles for critical load-bearing members or long spans.

- Bracing: Adding diagonal braces dramatically increases stiffness against racking forces.

- Connection Choice: Gusseted corner brackets provide significantly more rigidity than simple direct connections.

Design for Assembly

Think about the person who has to build your design. Can connectors be easily accessed with standard tools? Are T-nuts accessible, or will they need to be pre-loaded? Designing for ease of assembly saves significant time and frustration during the build phase.

Leveraging Software Tools

Modern software significantly simplifies the design and planning process for t slot aluminum profile projects.

Standard CAD Software (SolidWorks, AutoCAD, Fusion 360, etc.)

Most engineers and designers already use standard CAD packages. These tools are excellent for:

- 3D Modeling: Creating detailed models of your frame, allowing you to visualize the final structure, check clearances, and integrate other components (like the CNC machined parts we might supply from PTSMAKE).

- Parametric Modeling8: Defining relationships between components. If you change the length of one profile, connected parts can automatically adjust, saving significant redesign time.

- Basic Stress Analysis (FEA): Many CAD packages include basic Finite Element Analysis tools. These can simulate loads and show potential stress points or areas of high deflection, helping you optimize the design for strength before building.

- Bill of Materials (BOM): Automatically generating a list of required profiles (with cut lengths) and connectors.

Specialized T-Slot Configurators

Many t slot aluminum profile manufacturers offer free online or downloadable configurators specifically for their systems. These tools offer advantages:

- Pre-loaded Libraries: Contain the manufacturer’s entire catalog of profiles, connectors, and accessories, ensuring compatibility.

- Guided Assembly: Often provide intelligent connection options, suggesting appropriate brackets or fasteners for specific joints.

- Automated BOM Generation: Create accurate parts lists specific to that manufacturer’s part numbers, simplifying procurement.

- Ease of Use: Often have a gentler learning curve than full CAD packages for users focused solely on frame design.

Software Comparison Snapshot

| Caratteristica | Standard CAD Software | T-Slot Configurator |

|---|---|---|

| Flessibilità | Very High (Model anything) | High (Within system limits) |

| Curva di apprendimento | Da moderato a elevato | Da basso a moderato |

| Component Library | Manual Creation / Download | Built-in (Manufacturer specific) |

| Strumenti di analisi | Basic to Advanced FEA | Often Limited / Basic |

| BOM Generation | Yes (Setup required) | Yes (Automated, specific) |

| Costo | License Fee (Often high) | Usually Free |

| Compatibilità | Universal | Manufacturer Specific |

Note: Feature availability varies between specific software packages.

Optimization Tips

Designing isn’t just about making it work; it’s about making it work well.

Optimizing for Strength

- Use Triangles: Incorporate diagonal bracing to create triangles within your frame sections. This is the most effective way to increase rigidity against racking.

- Orient Profiles Correctly: Rectangular profiles (like 40×80) are much stiffer when loaded against their taller side. Orient them to maximize their moment of inertia against the primary load direction.

- Connector Placement: Ensure connectors are placed effectively. For cantilevered loads, place support brackets as close to the load as feasible. Use multiple connectors for high-stress joints.

Designing for Accessibility

Consider future maintenance or adjustments.

- Component Access: Ensure key components mounted on the frame can be reached for inspection, adjustment, or replacement without major disassembly.

- Wiring and Plumbing: Plan pathways for cables and pneumatic lines. Use profile slots with cover strips for a clean and protected installation. Avoid blocking access routes with poorly planned wiring.

Planning for Future Expansion

The modularity of t slot aluminum profile systems shines here.

- Standardize: Stick to a common profile series and connection methods within a project where possible. This makes future additions simpler.

- Leave Space: If future expansion is likely, consider leaving physical space or accessible connection points (unused T-slots) in the initial design.

- Modular Sections: Design the structure in logical modules that can be potentially added to or replicated later.

By combining sound design principles with the power of CAD software or configurators, and keeping strength, accessibility, and future needs in mind, you can create t slot aluminum profile structures that are efficient, robust, and adaptable. This careful planning ensures seamless integration with other components, like the high-precision parts manufactured at PTSMAKE, leading to successful project outcomes.

Learn more about the metal extrusion process and its capabilities for creating complex shapes. ↩

Discover why material emissions matter in sensitive manufacturing settings. ↩

Understand how this property impacts structural stiffness and prevents bending under load. ↩

Learn how proper bolt tension ensures a strong and lasting connection. ↩

Learn about buckling, a failure mode where structures suddenly bend under compression. ↩

Explore metrology to understand how precise measurements ensure component compatibility. ↩

Explore Total Cost of Ownership (TCO) to understand the full financial impact of an asset beyond its purchase price. ↩

Learn how parametric modeling allows designs to adapt automatically to changes. ↩