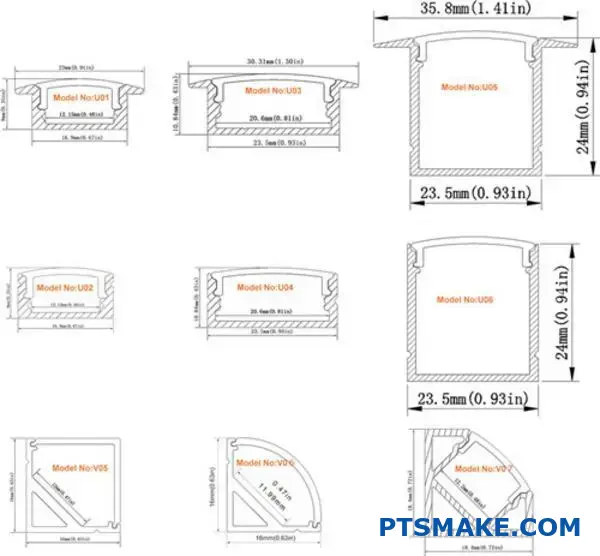

## What Size Are LED Profiles?

Choosing the right LED profile size can be confusing with so many options available. I’ve seen customers struggle with fitting profiles into their spaces only to discover they bought the wrong size, resulting in costly rework or project delays. Measurements matter more than most people realize.

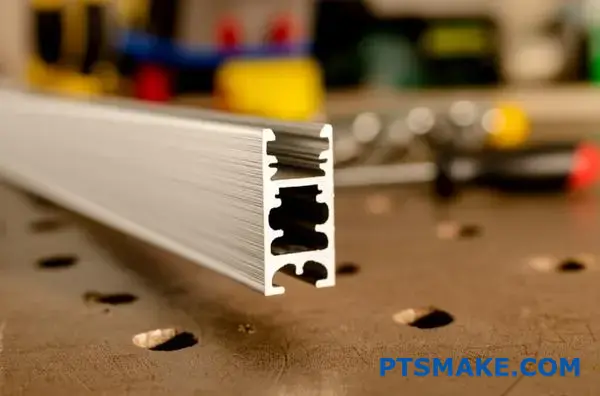

LED profiles typically range from 7mm to 25mm in width and 5mm to 30mm in height. The size you need depends on your LED strip width, desired light output, and installation space. Standard aluminum profiles often come in 1-2 meter lengths that can be cut to size.

When selecting LED profiles, you need to consider both the physical dimensions and the application requirements. The profile must accommodate your LED strip width while fitting into your installation space. At PTSMAKE, I help customers match their lighting needs with appropriate profile sizes daily. Let me guide you through the common sizes and what factors determine the right choice for your project.

What Is The Angle Of LED Profiles?

Have you ever set up LED strip lighting, expecting a smooth wash of light, only to get distracting hotspots or uneven beams? Misunderstanding the profile’s angle can easily lead to frustrating results and wasted effort.

The ‘angle’ of an LED profile primarily refers to the beam angle it helps create, typically ranging from a narrow 30° to a wide 120°. This angle determines the spread of light emitted from the LED strip within the profile.

When we talk about the angle of LED profiles, it’s not usually about a physical angle bent into the aluminum itself (though angled mounting profiles exist). Instead, it’s about how the profile’s design influences the direction and spread of light from the LED strip inside. Getting this right is crucial for achieving the desired lighting effect, whether it’s focused task lighting or broad ambient illumination. In past projects at PTSMAKE, we’ve seen how attention to this detail transforms a lighting installation.

Understanding Beam Angle in LED Profiles

The shape of the LED profile and the type of diffuser (cover) used are the main factors determining the final beam angle. The profile guides the light, and the diffuser spreads or focuses it.

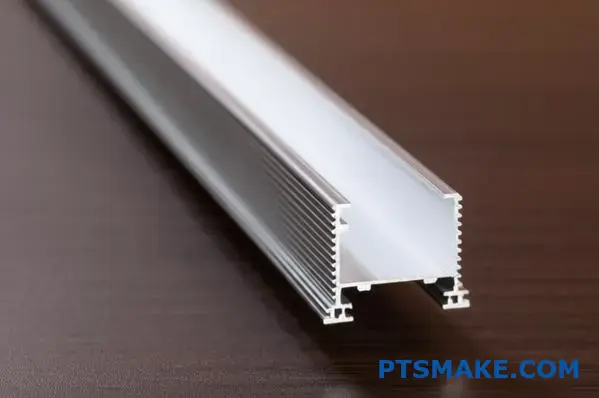

Profile Shape and Depth

Deeper profiles generally allow for better blending of light from individual LED diodes, especially when paired with an opal or frosted diffuser. This can result in a more uniform light output with less noticeable spotting. Shallow profiles might produce a wider, less controlled spread, potentially showing individual LED hot spots if the diffuser isn’t effective enough. The internal geometry, including any reflective surfaces or specific contours machined into the profile, also plays a role. Precise manufacturing, like the CNC machining we perform at PTSMAKE, ensures these internal shapes are consistent, leading to predictable light output.

Diffuser Type

The cover or diffuser fitted onto the LED aluminum profile significantly impacts the beam angle and light quality.

- Clear Diffusers: Offer maximum light output but do little to diffuse the light. The beam angle will be closest to that of the bare LED strip, often showing hot spots.

- Frosted Diffusers: Provide a balance between light output and diffusion. They soften the light and slightly widen the beam angle compared to a clear cover.

- Opal (Milky) Diffusers: Offer the best diffusion, creating a smooth, even line of light with minimal hot spots. However, they also reduce light output the most and typically create the widest, softest beam angle.

The choice of diffuser depends heavily on the application and the desired aesthetic.

Common Beam Angles and Their Applications

Different beam angles suit different purposes. Selecting the appropriate angle ensures the light performs its intended function effectively.

Narrow Angles (e.g., 30° – 45°)

Profiles designed to produce narrower beam angles are ideal for accent lighting, task lighting, or highlighting specific architectural features. They focus the light, minimizing spill and drawing attention to a particular area. This might be used for under-cabinet lighting directly over a workspace or illuminating artwork.

Medium Angles (e.g., 60° – 90°)

A medium beam angle provides a balance between focused light and broader coverage. This is versatile for general lighting tasks, such as cove lighting that washes a ceiling or wall, or illuminating display shelves where both focus and spread are needed. Many standard LED Aluminium Profiles combined with frosted diffusers fall into this category.

Wide Angles (e.g., 100° – 120°+)

Wide beam angles are used for general ambient illumination, aiming to light up a larger area softly and uniformly. Profiles achieving this, often using opal diffusers, are suitable for creating background light, filling spaces without harsh shadows, or backlighting translucent materials. The overall Photometric Distribution1 is much softer.

Factors Influencing Angle Choice

- Mounting Height: The higher the profile is mounted, the wider the beam angle might need to be to cover the desired area effectively. Conversely, lower mounting might require narrower beams for focus.

- Target Surface: Lighting a narrow shelf requires a different angle than illuminating a wide floor or ceiling.

- Desired Effect: Are you aiming for dramatic highlights (narrow angle) or soft, ambient light (wide angle)?

- LED Strip Properties: The native beam angle and brightness of the LED strip itself will also influence the final output, even with the profile and diffuser modifying it.

Here’s a simple comparison based on typical results we’ve observed in various applications:

| Beam Angle Range | Typical Diffuser | Common Use Cases | Light Effect |

|---|---|---|---|

| 30° – 45° | Clear / Focused | Task Lighting, Accent, Spotlights | Focused, Intense |

| 60° – 90° | Frosted | General Task, Cove, Shelving | Balanced Spread |

| 100° – 120°+ | Opal | Ambient, Wall Washing, Backlight | Wide, Soft, Uniform |

Understanding how the profile shape, diffuser, and even the LED strip interact is key. Sometimes standard profiles don’t provide the exact angle needed. In such cases, exploring custom profile designs, potentially involving precision machining to achieve specific internal optics, can be a solution we help clients explore at PTSMAKE.

Choosing the right angle isn’t just about technical specifications; it’s about achieving the desired mood and functionality for your space. Consider the interplay between the profile, the diffuser, and the LED strip to get the light spread you need.

Why Does The LED Strip Need An Aluminium Profile?

Ever installed LED strips hoping for that sleek, professional lighting effect, only to find them overheating, looking messy, or even starting to peel off after a while? It’s a common frustration when trying to use LED strips without the right support.

LED strips need an aluminium profile primarily for effective heat dissipation, which significantly extends the lifespan of the LEDs. Additionally, profiles provide crucial physical protection, offer a much cleaner aesthetic finish, simplify mounting, and can help diffuse the light for a smoother, more appealing look.

Using an LED strip seems simple enough – peel and stick. But to get the best performance, longevity, and visual appeal, pairing it with an LED Aluminium Profile is often essential. Based on our experience at PTSMAKE helping clients integrate lighting into various products and environments, skipping the profile can lead to preventable issues down the line. Let’s break down exactly why these profiles are so beneficial.

優れた熱管理

LEDs generate heat during operation. While much more efficient than traditional bulbs, this heat needs to go somewhere. If it builds up around the LED chips, it can drastically shorten their lifespan and affect their light output and color consistency.

How Aluminum Acts as a Heatsink

Aluminum is an excellent thermal conductor. When the LED strip is mounted inside an aluminum profile, the profile acts as a heatsink, drawing heat away from the delicate LED chips and dissipating it into the surrounding air. This process of 熱管理2 is critical for maintaining the LEDs’ optimal operating temperature. The larger surface area of the profile compared to the narrow strip itself greatly enhances this cooling effect.

Impact on LED Lifespan

Consistent overheating is the enemy of LED longevity. Our tests and industry data clearly show that LEDs run cooler in profiles, often leading to significantly longer operational life. Keeping the junction temperature low not only prevents premature failure but also ensures the light remains bright and true to its specified color over time. Investing in a profile is essentially investing in the durability of your lighting installation.

Enhanced Physical Protection

LED strips themselves are relatively fragile. The diodes, resistors, and circuit board are exposed and vulnerable.

Shielding from Dust and Moisture

An aluminum profile, especially when paired with a diffuser cover, creates a barrier against environmental factors. It helps protect the LED strip from dust accumulation, accidental splashes, and humidity (depending on the profile’s IP rating). This is particularly important in kitchens, bathrooms, workshops, or outdoor applications.

Preventing Physical Damage

The profile provides a rigid housing that guards the LED strip against bumps, impacts, and vibrations. Without this protection, the strip could easily be damaged during installation, cleaning, or just through everyday interaction with the surrounding environment. This structural support is something we emphasize at PTSMAKE, as robust design prevents field failures.

Achieving a Polished Look

Let’s face it, a bare LED strip stuck onto a surface can sometimes look unfinished or even cheap, especially when the individual light points (dots) are visible.

Concealment and Integration

LED Aluminium Profiles provide a clean, sophisticated housing that conceals the strip itself and often the wiring entry points. They allow the lighting to be integrated seamlessly into architecture, furniture, or displays, transforming it from a tacked-on element into a professional feature. Different profile shapes (surface-mounted, recessed, corner-mounted) offer design flexibility.

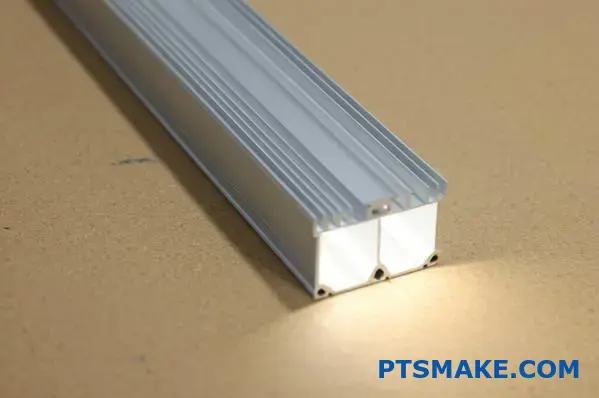

Light Diffusion

Many profiles come with diffuser covers (clear, frosted, or opal). These covers not only protect the strip but also shape the light output. Frosted and opal diffusers are particularly effective at smoothing out the light, reducing glare, and minimizing or eliminating the "dotted" look of individual LEDs. This creates a more uniform, aesthetically pleasing line of light.

Simplified and Secure Mounting

Getting an LED strip to stick reliably, especially on certain surfaces or upside down, can be tricky. The adhesive backing might fail over time due to heat, surface texture, or gravity.

Reliable Fixturing

Profiles offer secure and permanent mounting solutions. They typically come with mounting clips, can be screwed directly onto surfaces, or are designed for specific installation methods like recessing or suspension. This ensures the lighting stays exactly where you intended it to be.

Versatile Installation Options

The variety of profile shapes caters to different mounting needs. Surface profiles are easy to install, recessed profiles offer a flush finish, corner profiles fit neatly into angles, and specialized profiles exist for applications like stair treads or wardrobe rails. This versatility makes complex lighting designs much easier to execute reliably.

Improved Light Quality and Diffusion

Beyond just aesthetics, the profile and its diffuser play a role in controlling and improving the quality of the light emitted.

Reducing Glare and Hotspots

As mentioned, diffusers spread the light more evenly. This reduces harsh glare and minimizes the bright spots directly over each LED chip, leading to more comfortable and visually appealing illumination. The choice of diffuser allows for control over the trade-off between maximum brightness (clear diffuser) and maximum smoothness (opal diffuser).

Directing Light

While standard profiles primarily diffuse, some are specifically designed with internal angles or shapes, often achieved through precision manufacturing like CNC machining, to help direct the light in a particular way, enhancing focus or spread as needed for the application.

Here’s a quick summary of the core benefits:

| 特徴 | Benefit Without Profile | Benefit With Aluminium Profile |

|---|---|---|

| Heat | Builds up, reduces lifespan | Dissipated effectively, extends lifespan |

| 保護 | Exposed to dust, moisture, impact | Shielded, physically protected |

| 美学 | Can look unfinished, dotted | Clean, professional look, diffused light option |

| 取り付け | Adhesive may fail | Secure, reliable, versatile options |

| Light Quality | Potential for glare, hotspots | Smoother, more uniform, reduced glare |

In short, while you can use an LED strip without an aluminum profile, doing so sacrifices longevity, durability, safety, and the overall quality of the final result. For most applications, especially where the lighting is visible or intended to last, using an appropriate LED Aluminium Profile is the professional standard.

What Is The Use Of Aluminium Profile With LED Strip Lighting?

Have you ever installed LED strip lights only to see them fail prematurely or look unprofessional with visible dots and messy wiring? This often happens when they lack proper housing.

The primary use of an aluminium profile with LED strip lighting is to provide essential heat dissipation, physical protection, a clean aesthetic finish, easier mounting, and improved light diffusion for a smoother appearance.

Using LED strip lights seems straightforward, but achieving a durable, professional result often requires more than just the strip itself. An aluminium profile, often called an LED channel or extrusion, serves several critical functions that significantly enhance the performance, lifespan, and appearance of the LED strip. In past projects at PTSMAKE, we’ve consistently seen the difference a quality profile makes. Let’s explore why these profiles are so beneficial.

Essential Heat Dissipation

LEDs generate heat, and managing this heat is crucial for their longevity and consistent performance. Excess heat can cause the light output to decrease, the color to shift, and the LED chips to fail much sooner than expected.

How Aluminum Profiles Act as Heatsinks

Aluminum is chosen for these profiles due to its excellent 熱伝導率3. The profile acts as a heat sink, drawing thermal energy away from the LED strip’s circuit board and dissipating it into the surrounding air. The increased surface area provided by the profile allows for much more efficient cooling compared to a bare LED strip mounted directly onto a surface, especially thermally insulating ones like wood or plasterboard. The precision in manufacturing these profiles, which can involve CNC machining for specific shapes or features, ensures good contact with the LED strip for optimal heat transfer.

Impact on LED Longevity and Performance

By keeping the LEDs cooler, aluminium profiles directly contribute to a longer operational lifespan. Based on our observations working with clients on lighting integrations, LEDs housed in profiles maintain their initial brightness and color temperature for significantly longer periods compared to unprotected strips. Effective heat management is perhaps the single most important technical benefit of using LED Aluminium Profiles.

Providing Crucial Protection

LED strips are inherently quite delicate. The tiny diodes, resistors, and the flexible circuit board are vulnerable to damage.

Shielding from Environmental Factors

A profile, particularly when fitted with a diffuser cover, provides a physical barrier. It protects the LED strip from dust accumulation, accidental splashes, and even insects. In environments like kitchens, bathrooms, workshops, or outdoor settings (using appropriately IP-rated profiles), this protection is vital for preventing corrosion and short circuits.

Guarding Against Physical Damage

The rigid structure of the aluminium profile shields the LED strip from physical impacts, abrasion, and unwanted bending or flexing, especially during installation or cleaning. This structural integrity ensures the delicate circuitry remains intact.

Enhancing Aesthetics and Light Quality

A bare LED strip can sometimes look unfinished or create undesirable visual effects like distracting hotspots or glare.

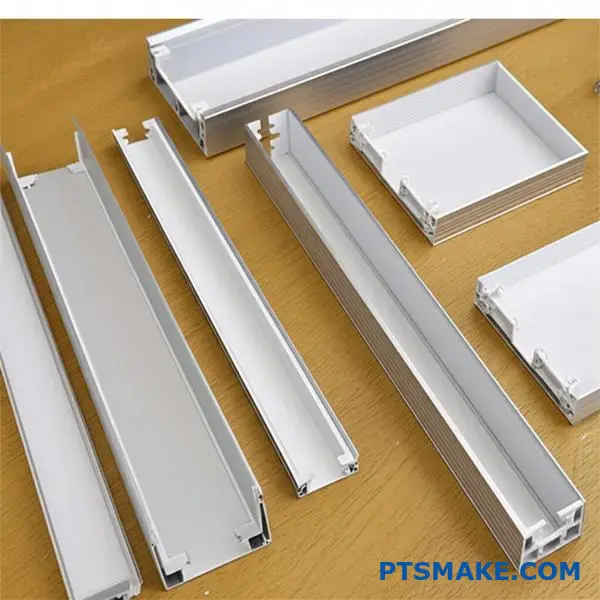

Achieving a Clean, Integrated Look

LED Aluminium Profiles provide a neat, professional housing that conceals the LED strip and associated wiring. This allows for seamless integration into architectural elements, furniture, display cases, or custom fixtures. Profiles come in various shapes – surface-mounted, recessed, corner-fit, suspended – offering tremendous design flexibility to match the application. This transforms the lighting from an add-on to an integral part of the design.

Diffusing Light for Smoothness

Most profiles are designed to be used with a diffuser cover (typically polycarbonate or PMMA), available in clear, frosted, or opal (milky) finishes. Frosted and opal diffusers scatter the light, blending the output from individual LED chips. This significantly reduces or eliminates the "dotted" effect, minimizes glare, and produces a more uniform, aesthetically pleasing line of light.

Simplifying Installation and Mounting

Relying solely on the adhesive backing of an LED strip can be problematic. It may fail over time due to heat, surface incompatibility, or simply gravity, especially in overhead applications.

Secure and Reliable Fixing

Aluminium profiles offer robust mounting methods. They can usually be secured using mounting clips, screwed directly to the surface, attached with strong adhesives or magnetic tape, or even suspended using wire kits. This ensures the lighting installation remains securely in place for the long term.

Versatile Mounting Options

The variety of available profile shapes makes installation easier in challenging locations. Corner profiles fit neatly into 90-degree angles, recessed profiles allow for a flush finish in drywall or furniture, and specialized profiles exist for applications like stair nosing or under-cabinet lighting. This adaptability simplifies the execution of creative lighting designs.

Here’s a quick comparison highlighting the advantages:

| 特徴 | Without Profile | With Aluminium Profile |

|---|---|---|

| 熱管理 | Poor; leads to shorter lifespan | Excellent; extends LED life & performance |

| 保護 | Exposed to damage, dust, moisture | Shielded & structurally supported |

| 外観 | Often looks unfinished, dotted | Professional, integrated, smooth light |

| 取り付け | Adhesive may fail over time | Secure, reliable, versatile methods |

| Light Control | Direct glare, potential hotspots | Diffused, reduced glare, uniform output |

While it’s technically possible to use LED strips without profiles in some temporary or hidden applications, the benefits of using LED Aluminium Profiles in terms of heat management, protection, aesthetics, and ease of installation make them an essential component for almost any permanent or high-quality LED strip lighting project. It’s an investment in the longevity and visual quality of your lighting.

How To Install LED Aluminium Profiles For Different Applications?

Ever find yourself puzzling over the best way to install LED strip lights for different surfaces or effects? Getting that sleek, integrated look often depends heavily on choosing and correctly installing the right profile for the job.

Installing LED Aluminium Profiles varies by application: surface mounting typically uses clips or screws, recessed mounting requires cutting a groove, corner mounting uses angled profiles, and suspended options need specific kits. Proper measuring, cutting, securing the profile, installing the strip, and adding the diffuser are key steps.

Installing LED Aluminium Profiles isn’t a one-size-fits-all process. The method you choose depends heavily on where you’re putting the lights and the final look you want to achieve. Whether it’s under cabinets, inside furniture, along walls, or suspended from a ceiling, each application has its own set of considerations. At PTSMAKE, we often guide clients not just on profile selection but also on best practices for installation to ensure a professional and long-lasting result. Let’s break down the common installation methods.

Preparing for Installation

Before you start cutting or drilling, preparation is key. Regardless of the application, some initial steps are universal:

- Measure Carefully: Measure the exact length required for your LED Aluminium Profile. Double-check your measurements to avoid cutting errors.

- Gather Tools: You’ll typically need a measuring tape, a pencil or marker, a fine-toothed hacksaw or a mitre saw with an appropriate blade for cutting aluminum, safety glasses, a drill (if screwing), mounting clips or screws, and possibly a level.

- Plan Wiring: Determine where your power supply will be located and how you will run the low-voltage wiring to the LED strip within the profile. Plan for entry and exit points.

Surface Mounting Installation

This is often the simplest method, ideal for under cabinets, along walls, or on ceilings where you don’t need a flush finish.

Cutting the Profile and Diffuser

Cut the aluminum profile and the plastic diffuser cover to your measured length. A clean, straight cut is important for a professional look, especially if joining sections. Use a fine-toothed blade to minimize burrs.

Fixing the Profile

- Mounting Clips: Most surface-mount profiles come with small metal or plastic clips. Screw these clips onto the surface at regular intervals (e.g., every 30-50cm). Then, simply snap the aluminum profile into the clips. This allows for easy removal if needed.

- Direct Screwing: Some profiles have a thicker base allowing you to drill pilot holes and screw directly through the profile base into the mounting surface. Ensure screw heads are countersunk or low-profile so they don’t interfere with the LED strip.

- Adhesive Tape: For lighter profiles in non-critical applications, high-bond double-sided tape can sometimes be used, but test the surface and consider heat and longevity. Mechanical fixing is generally more reliable.

Installing the LED Strip and Diffuser

Clean the inside of the profile. Peel the backing off your LED strip and carefully press it into the channel. Connect the wiring. Finally, snap or slide the diffuser cover into place.

Recessed Mounting Installation

Recessed mounting offers a sleek, integrated look where the profile sits flush with the surface (e.g., drywall, wood panels, furniture).

Creating the Groove

This is the most critical step. You need to cut a channel or groove into the mounting surface that matches the width and depth of the specific recessed LED Aluminium Profile you are using. This often requires tools like a router or a circular saw with a guide. Precision is key here – the groove must be straight and sized correctly for a snug fit. Consider the substrate compatibility4 when planning the cut.

Fixing the Profile

Some recessed profiles are designed for a friction fit, possibly aided by a bead of adhesive/sealant within the groove. Others may have small flanges that allow for screwing into the sides of the groove before the final surface finishing (e.g., plastering). Winged recessed profiles (plaster-in) are designed to be plastered over for a completely trimless look.

Strip and Diffuser Installation

Once the profile is securely in place and any surrounding finish is complete, install the LED strip and diffuser cover as described for surface mounting. Ensure the diffuser sits flush with the surrounding surface.

Corner Mounting Installation

Corner profiles are specifically designed to fit into 90-degree angles, perfect for room corners, display cases, or where walls meet ceilings or floors.

Profile Types

Corner profiles are typically triangular or quarter-round in shape. Some mount flat against both surfaces, while others are designed to project light at a 45-degree angle out from the corner.

Fixing Methods

Similar to surface mounting, corner profiles are usually installed using mounting clips screwed into the corner or by screwing directly through the profile base into the wall surfaces. Ensure the profile sits snugly in the corner along its entire length.

Strip and Diffuser

Install the LED strip, manage wiring (often running it out one end of the profile), and attach the diffuser. The angled nature often helps direct light effectively.

Other Applications

- Suspended Profiles: Require specific suspension kits (wires and ceiling mounts). Careful planning is needed for level installation and managing the power feed wire.

- Stair Nosing Profiles: Designed to be integrated into stair edges, often requiring routing and robust fixing for safety and durability.

- Wardrobe Rails: Profiles designed to double as clothes rails with integrated lighting.

Installation Method Comparison

Here’s a quick comparison of the common methods:

| 特徴 | Surface Mount | Recessed Mount | Corner Mount |

|---|---|---|---|

| Difficulty | Easiest | Moderate to Difficult | Easy to Moderate |

| Tools Needed | Basic hand tools, drill | Router/Saw needed for groove | Basic hand tools, drill |

| 美学 | Visible profile | Flush, integrated | Fits neatly into corners |

| Prep Work | 最小限 | Significant (cutting groove) | 最小限 |

| 一般的な使用 | Under cabinets, ceilings, walls | Drywall, furniture, shelves | Room corners, display cases |

No matter the application, taking your time with measurements, ensuring clean cuts, and using the appropriate fixing method for your chosen LED Aluminium Profile are crucial. In our work at PTSMAKE, providing precisely manufactured profiles helps ensure these installations go smoothly, leading to a better final product for our clients. Always follow safety precautions, especially when working with tools and electricity.

How To Choose The Right LED Aluminium Profile Size For Your Project?

Ever picked out LED aluminium profiles only to find your LED strip is too wide to fit inside, or the profile itself is too bulky for your sleek design? Getting the size wrong can derail your project timeline and budget.

To choose the right LED aluminium profile size, primarily consider the internal width to match your LED strip, the external dimensions (width and height/depth) to fit your installation space, and the profile’s overall size for adequate heat dissipation and the desired aesthetic.

Selecting the correct LED aluminium profile size goes beyond just aesthetics; it’s crucial for functionality, longevity, and ease of installation. A profile that’s too small won’t accommodate your LED strip or might not dissipate heat effectively. One that’s too large might not fit the designated space or could look out of place. In my experience at PTSMAKE, guiding clients through size selection is a common step, ensuring the final lighting solution is both effective and seamlessly integrated. Let’s dive into the details you need to consider.

Key Factors Determining Profile Size

Choosing the right size involves balancing several technical and design requirements. Missing any one of these can lead to complications.

LED Strip Width Compatibility

This is often the first check. The internal width of the aluminium profile must be slightly larger than the width of your LED strip’s PCB (Printed Circuit Board). Common LED strip widths are 8mm, 10mm, and 12mm, but wider strips exist. Always check the manufacturer’s specifications for both the strip and the profile. Trying to force a wide strip into a narrow profile just won’t work and can damage the strip. The Internal Width5 is a non-negotiable starting point.

Installation Space Constraints

Where will the profile be installed? Measure the available width, height (or depth, depending on orientation), and length for the profile.

- Width: Consider surface profiles mounted on narrow beams or recessed profiles fitting into tight grooves. The external width must fit.

- Height/Depth: This is critical for recessed applications or installations with limited clearance, like under shallow shelves or in slim furniture panels. A profile that’s too tall won’t sit flush or might obstruct other components.

Heat Dissipation Requirements

While all aluminium profiles help dissipate heat, larger profiles with more surface area generally offer better thermal management. High-power LED strips generate more heat and benefit significantly from more substantial profiles. For demanding applications or where the LEDs will be on for extended periods, choosing a profile with a decent amount of aluminium mass helps ensure longevity and stable performance. Inadequate heat sinking is a common cause of premature LED failure we sometimes see in improperly specified projects.

Aesthetic Considerations and Light Diffusion

The profile’s size also impacts the final look.

- Slim Profiles: Offer a minimalist appearance, ideal for discreet lighting where the fixture itself shouldn’t draw attention. However, they might offer less diffusion and heat sinking.

- Wider/Deeper Profiles: Can make more of a statement but crucially, deeper profiles often allow for better light diffusion when used with an opal or frosted cover. The increased distance between the LED strip and the diffuser helps blend the light from individual diodes, reducing hotspots and creating a smoother, more uniform line of light. Our testing at PTSMAKE confirms that deeper profiles paired with opal diffusers provide the most dot-free results.

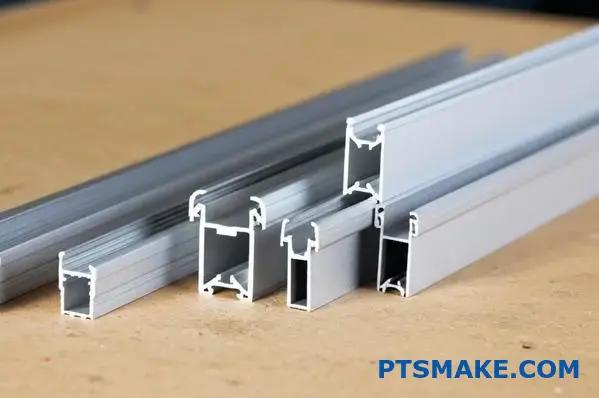

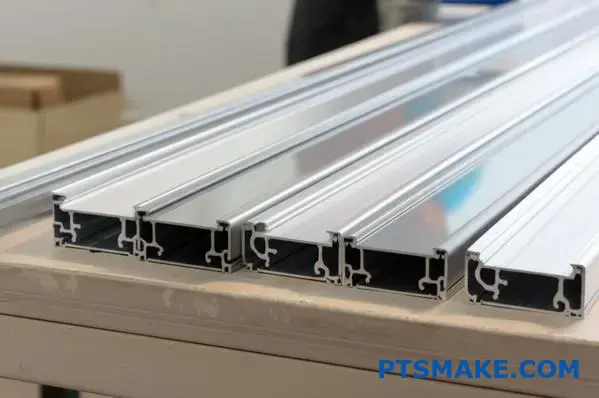

Understanding Profile Dimensions

Manufacturers typically list several key dimensions. It’s important to know what they refer to.

Internal Width vs. External Width

- Internal Width: The space inside the channel where the LED strip sits. This MUST be wider than your LED strip.

- External Width: The overall width of the profile itself. This determines how much space it occupies visually and physically.

Profile Height/Depth

This is the measurement from the base of the profile to the top (either the top of the aluminium or the top of the diffuser when installed). This dictates how much vertical space it needs and is crucial for recessing or fitting into tight spots.

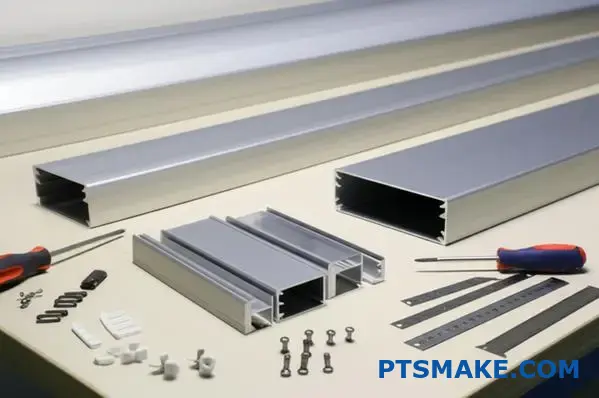

Standard Lengths and Customization

LED Aluminium Profiles are commonly sold in standard lengths, often 1 meter, 2 meters, or sometimes 3 meters. These can usually be easily cut to the exact length required for your project using a hacksaw or power saw with an appropriate blade. At PTSMAKE, we also handle precision cutting as part of our manufacturing services when clients require specific lengths for production runs.

Common Profile Sizes and Applications

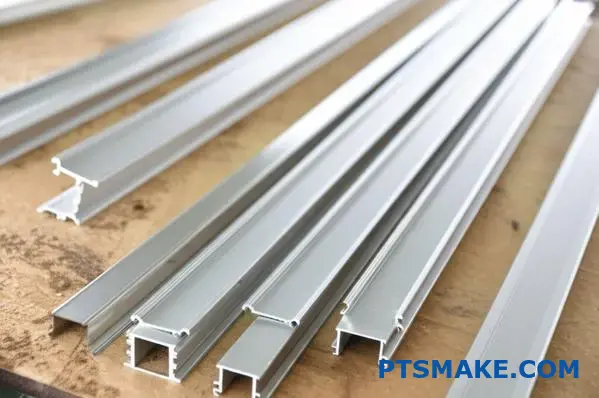

While there’s a vast range, here are some typical size categories and their uses:

| プロフィール・タイプ | Typical Internal Width | Typical External Dimensions (W x H) | 一般的なアプリケーション | 備考 |

|---|---|---|---|---|

| Slim Surface | 8-12mm | 15-18mm x 6-8mm | Under cabinets, accent lighting, tight spaces | Minimalist look, basic heat sinking, may show dots with clear cover |

| Standard Surface/Recessed | 10-15mm | 17-25mm x 8-15mm | General purpose, cove lighting, furniture integration | Good balance of size, diffusion potential, and heat management |

| Deep Recessed/Surface | 10-20mm | 17-30mm x 15-30mm+ | Architectural lighting, dotless linear fixtures | Excellent diffusion, better heat sinking, requires more space |

| Wide Profiles | 20mm+ | 30mm+ x 10mm+ | Housing multiple LED strips, creating broader fixtures | Higher light output potential, significant visual presence |

Note: Dimensions are approximate examples and vary widely between manufacturers.

Tips for Measuring and Selection

- Measure Twice, Cut Once: Applies to both your installation space and the profiles themselves.

- Check LED Strip Specs: Know your LED strip’s exact width before shopping for profiles.

- Consider the Diffuser: Remember the diffuser adds to the overall height and affects the light output/appearance.

- Get Samples: If unsure, especially for larger projects, obtaining samples can help verify fit and appearance before committing.

- Factor in End Caps and Clips: These add slightly to the overall length or require minor clearance. Account for them in your measurements.

Choosing the right LED Aluminium Profile size is a critical step that impacts compatibility, performance, and aesthetics. By carefully considering your LED strip width, installation space, heat dissipation needs, and desired look, you can select a profile that ensures a successful and professional lighting installation. Don’t hesitate to consult specifications or ask suppliers if you’re unsure – getting it right upfront saves time and hassle later.

Can LED Aluminium Profiles Be Customized For Unique Lighting Designs?

Struggling to find an off-the-shelf LED profile that perfectly matches your unique architectural feature or product design? Are standard shapes and sizes limiting your creative lighting concepts?

Absolutely! LED aluminium profiles offer extensive customization possibilities. Beyond standard options, you can tailor lengths, shapes, finishes, and even incorporate specific machined features to create truly unique and integrated lighting solutions for almost any design vision.

Standard LED aluminium profiles cover many common applications, but innovative designs often demand something more specific. Whether you need a profile bent to follow a curve, finished in a unique color, or precisely machined for seamless integration, customization opens up a world of possibilities. In my experience at PTSMAKE, we frequently collaborate with designers and engineers to develop bespoke profile solutions that bring ambitious lighting ideas to life. Let’s explore what aspects you can customize and how the process typically works.

What Can Be Customized in LED Aluminium Profiles?

The flexibility of aluminium and modern manufacturing techniques allow for significant tailoring. Here are the key areas where customization is common:

Custom Lengths

While profiles often come in standard 1, 2, or 3-meter lengths, suppliers can usually cut them to precise custom lengths required for your project. This minimizes waste and ensures a perfect fit without needing on-site cutting. For larger projects, ordering pre-cut lengths can save significant installation time.

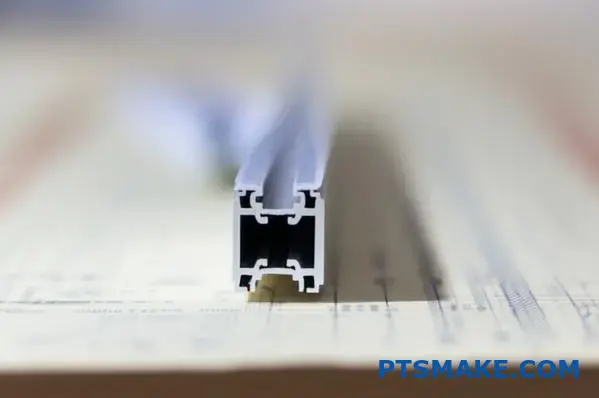

Unique Profile Shapes and Designs

This is where true design freedom comes in. Using the Die Extrusion6 process, manufacturers can create entirely new profile shapes.

- Specific Dimensions: Need a profile slightly wider, deeper, or shallower than standard? A custom extrusion die can achieve this.

- Unique Geometries: Require a profile with internal ridges for specific optics, asymmetrical shapes to fit unusual spaces, or integrated channels for wiring? Custom extrusion makes this possible.

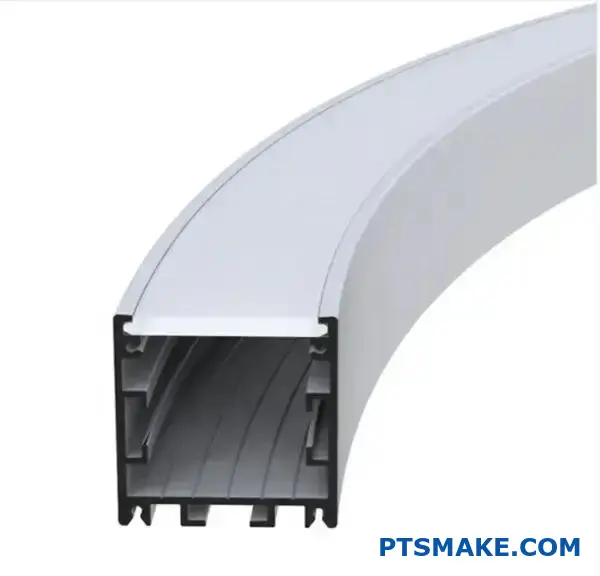

- Curved or Bent Profiles: While extrusions are initially straight, some profiles can be bent or curved post-extrusion (within certain limits depending on the alloy and profile complexity) to follow architectural curves.

Creating a custom extrusion die involves initial tooling costs and development time, making it most suitable for projects with sufficient volume or where a standard profile simply won’t work.

Custom Finishes and Colors

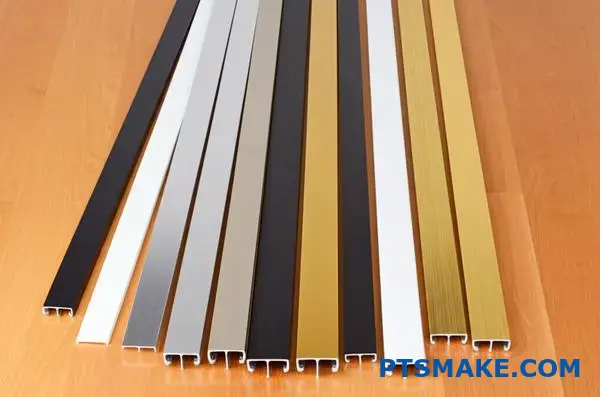

Standard profiles are often available in silver anodized, black anodized, or sometimes white powder-coated finishes. Customization greatly expands these options:

- 陽極酸化処理: Different anodizing processes can achieve various shades (e.g., bronze, gold) and finishes (e.g., brushed). Anodizing enhances durability and corrosion resistance.

- パウダーコーティング: Offers a vast range of RAL colors to perfectly match branding or interior design schemes. Powder coating provides a durable and decorative finish.

- Mill Finish: You can also order profiles in their raw, untreated state (mill finish) if you plan to apply a custom finish locally or if the raw look suits the design.

Machining for Special Features

Beyond the basic profile shape, CNC machining can add precise features. This is an area where PTSMAKE excels, leveraging our precision machining capabilities.

- Drilled Holes: For mounting screws, cable entry/exit points, or integrating sensors.

- Milled Slots: For specific mounting hardware, ventilation, or unique aesthetic patterns.

- Mitred Corners: For creating clean, seamless joins in custom frames or shapes.

- Tapped Holes: For threaded fixings.

- Cutouts: For switches, connectors, or integrating other components directly into the profile.

The Customization Process Explained

Embarking on a custom LED aluminium profile project involves several steps:

- Concept and Design: Define your requirements – shape, dimensions, finish, special features, tolerances. Detailed drawings (e.g., CAD files) are essential.

- Manufacturer Consultation: Discuss feasibility with a manufacturer like PTSMAKE. We can advise on design for manufacturability, material selection, and potential costs.

- Tooling (for Custom Extrusions): If a new shape is needed, an extrusion die must be designed and manufactured. This involves tooling costs and lead time (often several weeks).

- Prototyping: Producing sample pieces to verify the design, fit, and finish before committing to full production is highly recommended.

- Production Run: Once the prototype is approved, the full batch of custom profiles is manufactured, finished, and machined as specified.

- 品質管理: Ensuring all custom profiles meet the agreed specifications and tolerances.

When Does Customization Make Sense?

Custom profiles aren’t always necessary, but they become invaluable in certain situations:

- Unique Aesthetic Integration: When standard profiles disrupt the desired look or cannot blend seamlessly with architectural elements or product designs.

- Specific Functional Requirements: Needing integrated heat sinks beyond standard capacity, specific mounting solutions, or profiles designed for harsh environments.

- Brand Consistency: Requiring specific brand colors or finishes across a lighting installation.

- High-Volume Projects: While there’s an initial tooling cost for custom extrusions, the per-unit cost can become competitive with standard profiles at large quantities, especially if it simplifies installation or improves performance.

Here’s a general comparison:

| 特徴 | Standard Profiles | カスタムプロファイル |

|---|---|---|

| 柔軟性 | Limited to available shapes/sizes | High design freedom (shape, size, finish) |

| リードタイム | Typically short (stock items) | Longer (tooling, custom production) |

| 初期費用 | Low (no tooling) | Higher (tooling costs for new extrusions) |

| ユニット単価 | Generally lower for small quantities | Can be competitive at high volumes |

| Minimum Order | Often low or none | Usually requires a minimum order quantity |

| Suitability | Common applications, budget projects | Unique designs, specific needs, branding |

Ultimately, the ability to customize LED aluminium profiles empowers designers and engineers to overcome the limitations of standard components. It allows lighting to become a truly integrated and tailored element within a space or product. While it involves more planning and potentially higher initial costs, the payoff in achieving a unique, high-performance, and perfectly suited lighting solution is often well worth the investment, especially for signature projects or specialized products. Consulting with an experienced manufacturing partner early in the design process can help determine if customization is the right path for your needs.

What Are The Thermal Management Benefits Of LED Aluminium Profiles?

Ever wonder why some LED strip installations fail way too soon or lose their brightness quickly? Often, the hidden culprit is excessive heat building up within the strip itself.

LED aluminium profiles provide crucial thermal management by acting as heatsinks. They draw heat away from the LED chips using aluminum’s high thermal conductivity and dissipate it over a larger surface area. This significantly lowers operating temperatures, extending LED lifespan and ensuring stable performance.

Using LED strips without proper thermal management is like running an engine without coolant – it might work for a while, but problems are almost inevitable. LEDs are sensitive electronic components, and heat is their primary adversary. Understanding how aluminium profiles help manage this heat is key to designing reliable and long-lasting lighting solutions.

Why Heat is the Enemy of LEDs

While LEDs are far more energy-efficient than older lighting technologies, they still convert some electrical energy into heat. This heat is generated within the tiny semiconductor chip (the heart of the LED). If this heat isn’t effectively removed, it leads to several negative consequences:

- Reduced Lifespan: This is the most significant impact. Every degree increase in the operating temperature of the LED chip (junction temperature) can shorten its operational life considerably. Consistent overheating accelerates material degradation within the LED package.

- Lumen Depreciation: LEDs gradually lose brightness over time. Excessive heat dramatically speeds up this process, meaning your lights get dimmer much faster than they should.

- Color Shift: High temperatures can also cause the color output of the LED to change over its lifetime. A warm white might drift towards a cooler or different hue, compromising the intended lighting design.

- Sudden Failure: In extreme cases, overheating can lead to complete failure of the LED or the associated components on the strip.

How Aluminium Profiles Combat Heat

This is where LED Aluminium Profiles become essential. They are not just cosmetic housings; they are functional components designed specifically for thermal management.

The Power of Aluminium’s Thermal Conductivity

Aluminium is the material of choice for these profiles because it has excellent thermal conductivity. It’s significantly better at conducting heat than materials like wood, plasterboard, or most plastics, which LED strips might otherwise be mounted directly onto. These materials act more like insulators, trapping heat around the LED strip. An aluminium profile provides an efficient pathway for the heat to escape. At PTSMAKE, we ensure the aluminium alloys used in profiles we might provide or recommend offer optimal thermal properties.

Acting as a Heatsink

The aluminium profile essentially functions as a heatsink. It makes direct contact (or near-direct contact via thermal tape) with the back of the LED strip’s PCB. Heat flows from the small LED chips, through the PCB, and into the much larger mass of the aluminium profile. This draws the heat away from the sensitive chips, preventing excessive temperature buildup at the source.

Increasing Surface Area for Convection

Once the heat is drawn into the aluminium profile, it needs to be dissipated into the surrounding environment. Heat transfers from the profile’s surface to the ambient air primarily through convection7. Aluminium profiles vastly increase the surface area available for this heat exchange compared to the narrow LED strip alone. Some profiles even feature fins or ridges specifically designed to maximize this surface area, further enhancing cooling efficiency.

Creating a Thermal Pathway

For the profile to work effectively, good thermal contact between the LED strip and the profile’s inner surface is crucial. Any air gaps or poor contact points will impede heat flow. This is why using thermally conductive adhesive tape is often recommended when installing the strip. Moreover, the precision manufacturing of the profile itself ensures a flat, consistent surface for mounting. In past projects at PTSMAKE requiring custom profiles, ensuring a design that facilitates good thermal contact has always been a key consideration.

Tangible Benefits of Effective Thermal Management

Using an LED aluminium profile translates directly into measurable improvements in your lighting installation’s performance and reliability.

Extended LED Lifespan

This is the primary benefit. By significantly lowering the operating temperature of the LEDs, aluminium profiles can dramatically extend their useful life, often by thousands of hours compared to improperly mounted strips. In our experience assisting clients, proper thermal management is the single biggest factor in achieving the long lifespans LEDs promise. This means fewer replacements, lower maintenance costs, and greater long-term value.

Consistent Brightness and Color

Keeping LEDs cool helps maintain their initial brightness levels for longer. Lumen depreciation is slowed down considerably. Similarly, the color stability of the LEDs is preserved, ensuring the lighting quality remains consistent throughout the installation’s life. You get the light you specified, for longer.

Improved Reliability and Performance

Cooler operating temperatures mean LEDs are less stressed, leading to more reliable operation and fewer unexpected failures. This is especially critical in commercial settings, hard-to-reach locations, or applications where consistent lighting is essential. The profile adds a layer of robustness to the entire system.

単純化して比較するとこうなる:

| 特徴 | LED Strip Only (on Wood/Plastic) | LED Strip in Aluminium Profile |

|---|---|---|

| Operating Temp | 高い | より低い |

| 寿命 | より短い | Significantly Longer |

| Brightness Stability | Drops Faster | More Stable |

| 色の一貫性 | Prone to Shift | More Consistent |

| Failure Risk | より高い | より低い |

In essence, the thermal management provided by an LED aluminium profile is not just a minor improvement; it’s fundamental to achieving the full potential of LED technology in terms of lifespan, performance consistency, and reliability. It turns a simple strip of lights into a durable and professional lighting fixture.

What Are The Cost Benefits Of Using LED Aluminium Profiles In Large-Scale Projects?

Planning a massive lighting installation and getting sticker shock looking at the cost of LED aluminium profiles? Does that initial expense make you wonder if they’re truly worth it for a large-scale deployment?

In large-scale projects, LED aluminium profiles deliver significant cost benefits primarily through reduced energy consumption due to better heat management, lower maintenance/replacement expenses from extended LED lifespan, faster installation possibilities, and improved project aesthetics that enhance overall property value, leading to a strong long-term ROI.

When tackling extensive lighting projects, scrutinizing every line item on the budget is essential. The added cost of LED aluminium profiles might seem like an easy place to cut corners, especially when multiplied across hundreds or thousands of feet. However, based on project experience, focusing solely on the upfront cost is shortsighted. The true cost benefits emerge when you consider the entire lifecycle of the installation. Let’s break down how these profiles actually save money in the long run for large-scale applications.

Lowering Energy Consumption Through Efficiency

LEDs are known for their energy efficiency, but heat is their enemy. As LEDs operate, they generate heat, and excessive heat reduces their efficiency, meaning more electricity is wasted as thermal energy instead of producing light. Aluminium profiles act as effective heatsinks, drawing heat away from the LED chips.

By maintaining lower operating temperatures, LEDs housed in profiles operate closer to their peak efficiency for longer. While a bare strip might overheat and draw slightly more power for the same light output (or produce less light for the same power), a profiled strip maintains better performance. In large projects with thousands of fixtures running for many hours, even a small percentage increase in efficiency translates to noticeable energy savings on utility bills over the years. Our internal tests often show a measurable difference in sustained efficacy when comparing profiled LEDs to bare strips under continuous operation.

Slashing Maintenance and Replacement Costs

This is often the most significant long-term saving. Heat dramatically shortens the lifespan of LEDs. By providing superior thermal management, aluminium profiles significantly extend the operational life of the LED strips installed within them.

Consider a large commercial building, warehouse, or public space. Replacing failed LED strips isn’t just about the cost of the new strip. The major expense is often the labor involved – accessing high ceilings, removing old fixtures, installing new ones, and potentially disrupting operations. If profiles help extend LED life by, say, 30-50% (a realistic expectation in many scenarios), you’re effectively reducing the frequency of these costly replacement cycles by a similar margin. Over a 10 or 15-year lifespan of an installation, this adds up to substantial savings in both materials and, more importantly, labor and associated logistical costs. The physical protection offered by the profile also reduces failures due to accidental damage during cleaning or routine building maintenance.

Optimizing Installation Time and Labor

While adding a component might seem like it increases installation time, LED aluminium profiles can actually streamline the process in large-scale projects, reducing labor costs.

- Simplified Mounting: Profiles often come with mounting clips or standardized channels that allow for quick and secure fixing, which can be faster than meticulously applying adhesive strips directly, especially on challenging surfaces or overhead.

- Consistent Alignment: Achieving perfectly straight lines with bare LED strips over long distances can be fussy and time-consuming. Rigid profiles ensure straight, professional-looking runs with less adjustment needed.

- Wiring Management: Profiles provide a channel to neatly conceal wiring, speeding up the final finishing stages.

- Pre-Cut Lengths & Customization: For large orders, profiles can often be supplied cut to specific lengths. At PTSMAKE, we sometimes provide custom-machined profiles or precisely cut standard lengths, which drastically reduces on-site cutting time and material waste compared to trimming every single piece individually.

Here’s how installation aspects can compare:

| 特徴 | Bare LED Strips | LED Strips with Profiles | Cost Implication (Large Scale) |

|---|---|---|---|

| 取り付け方法 | Adhesive backing (surface prep) | Clips, Screws, Recessing | Profile methods can be faster overall |

| アライメント | Requires careful positioning | Naturally straight | Less time spent on adjustments |

| Wiring | Often exposed, needs managing | Concealed within profile | Faster final installation, cleaner look |

| Length Adjustment | Cut on-site (time, waste) | Pre-cut options available | Reduced site labor & material waste |

While there’s an extra step of fitting the strip into the profile, the overall time saved in mounting, alignment, and finishing can lead to net labor savings on large installations.

Enhancing Value Through Quality and Aesthetics

The finished look matters, especially in commercial, retail, or high-end residential projects. Bare LED strips can look unfinished, display distracting hotspots, and collect dust easily. Aluminium profiles provide a sleek, professional housing.

Using profiles with diffusers creates smooth, uniform lines of light, reducing glare and enhancing visual comfort. This superior aesthetic quality contributes directly to the perceived value of the property or space. In retail, better lighting can improve product presentation; in offices, it can enhance the working environment. While harder to quantify directly than energy savings, this improved quality and professional finish delivered by profiles are definite cost benefits in terms of property value and user satisfaction.

Calculating the Long-Term Return on Investment (ROI)

When evaluating the cost-effectiveness of LED aluminium profiles for large projects, it’s crucial to look beyond the initial purchase price and consider the 総所有コスト8. This includes:

- Initial cost of profiles + LED strips.

- Installation labor costs.

- Energy consumption costs over the project’s lifespan.

- Maintenance and replacement costs (materials + labor) over the lifespan.

- Potential impact on property value or user experience.

While the initial investment is higher with profiles, the significant savings in energy, maintenance, potential labor savings during installation, and the extended lifespan of the LEDs frequently result in a lower TCO and a much better ROI compared to using bare strips, especially in large-scale, long-term installations. Collaborating with partners like PTSMAKE, who understand manufacturing precision and material properties, can help ensure you select profiles that maximize these long-term benefits.

Learn more about how light intensity is distributed in different directions from a source. ↩

Explore the science behind managing heat in electronic components like LEDs for optimal performance. ↩

Discover how different materials transfer heat, crucial for LED cooling efficiency. ↩

Learn about how different mounting surfaces affect installation choices and profile adhesion. ↩

Understand the critical dimension inside the profile that dictates LED strip compatibility. ↩

Discover the manufacturing process used to create custom aluminum profile shapes. ↩

Learn about heat transfer through fluid movement, like air cooling the profile. ↩

Learn how TCO considers all costs over an asset’s life, not just the purchase price. ↩