Ever tried joining metal to glass or ceramic? Traditional metals expand at different rates when heated, causing cracks and failures. This leaves engineers frustrated with broken components, failed seals, and wasted time and money on projects requiring precise material matching.

Kovar machining is the process of cutting, shaping, and forming Kovar—a specialized iron-nickel-cobalt alloy designed to match the thermal expansion rate of glass and ceramics—using CNC milling, turning, and other precision techniques to create electronic components and glass-to-metal seals.

At PTSMAKE, I’ve worked with Kovar for various electronic applications. This unique alloy solves critical problems in industries where metal must bond reliably with glass or ceramic materials. If you’re considering Kovar for your project, understanding its machining properties and applications will help you determine if it’s the right choice for your specific needs.

What Material Is Kovar Equivalent To?

Have you ever been stuck trying to find an alternative to Kovar for your critical engineering project? The frustration of needing a material with specific thermal expansion properties but not knowing what else might work can delay projects and increase costs. When deadlines loom, this uncertainty becomes even more stressful.

Kovar is equivalent to ASTM F15 alloy, NILO K, and is similar to Alloy 42 and Invar 36. These nickel-iron-cobalt alloys share Kovar’s low thermal expansion properties and glass-sealing compatibility, though with slight compositional differences that affect their specific performance characteristics.

Understanding Kovar and Its Composition

Kovar is a controlled-expansion alloy comprised primarily of iron (approximately 54%), nickel (29%), and cobalt (17%), with trace amounts of manganese, silicon, and carbon. This specific composition gives Kovar its most valuable property – a low coefficient of thermal expansion (CTE) that closely matches that of certain glasses and ceramics.

In my experience working with precision components at PTSMAKE, Kovar stands out for its ability to form reliable hermetic seals with glass and ceramic materials. This makes it invaluable in applications where maintaining a perfect seal across temperature variations is critical.

Chemical Composition Comparison

When looking for Kovar equivalents, understanding the compositional similarities and differences is crucial:

| Material | Ni (%) | Co (%) | Fe (%) | Other Elements | Standard Designation |

|---|---|---|---|---|---|

| Kovar | 29 | 17 | 53-54 | Mn, Si, C | ASTM F15 |

| NILO K | 29 | 17 | 53-54 | Similar to Kovar | British Standard |

| Alloy 42 | 42 | 0.5 | 57.5 | Mn, Si, C | UNS K94100 |

| Invar 36 | 36 | 0 | 64 | Mn, Si, C | UNS K93600 |

Primary Kovar Equivalents

ASTM F15 Alloy

ASTM F15 is essentially the standardized designation for Kovar. When customers ask for an "equivalent" to Kovar, often they’re actually referring to material that meets the ASTM F15 specification. In our CNC machining operations, we treat ASTM F15 and Kovar as interchangeable for most applications.

NILO K

NILO K is the British equivalent to Kovar with virtually identical composition and properties. The primary difference lies in naming convention rather than performance characteristics. When sourcing materials for international projects, understanding these naming differences prevents unnecessary confusion.

Similar Alternatives to Kovar

Alloy 42 (42% Nickel Iron)

Alloy 42 represents one of the closest alternatives to Kovar but contains a higher percentage of nickel (42%) and lacks the cobalt content of Kovar. This compositional difference results in:

- Slightly different thermal expansion characteristics

- Good glass-sealing properties, though not identical to Kovar

- Often lower cost due to the absence of cobalt

When thermal expansion coefficient1 matching isn’t absolutely critical, Alloy 42 can be a cost-effective substitute in many applications.

Invar 36

Invar 36 contains 36% nickel with the balance primarily being iron. While its thermal expansion coefficient is extremely low (even lower than Kovar in certain temperature ranges), it lacks cobalt, which affects its glass-sealing properties.

In precision machining applications where glass-to-metal sealing isn’t required but dimensional stability across temperature ranges is paramount, Invar 36 sometimes outperforms Kovar.

Application-Based Selection Criteria

The "best" Kovar equivalent depends entirely on your specific application requirements:

- For hermetic glass-to-metal seals: True Kovar or ASTM F15 is often irreplaceable

- For dimensional stability: Invar 36 might be preferable

- For cost-sensitive applications: Alloy 42 offers a reasonable compromise

- For international standards compliance: Understanding regional equivalents like NILO K is essential

At PTSMAKE, we’ve machined components from all these materials, and I’ve found that sometimes the application’s specific thermal cycling requirements dictate which material will perform optimally.

Machining Considerations for Kovar and Its Equivalents

When CNC machining Kovar or its equivalents, several considerations affect the final component quality:

- These alloys work-harden rapidly, requiring sharp tools and appropriate cutting speeds

- Their gumminess can create challenges during fine detail machining

- Heat treatment may be necessary to achieve optimal properties

- Surface finish requirements often dictate machining strategy

For precision components, our approach at PTSMAKE involves specialized tooling and optimized cutting parameters developed specifically for these challenging materials.

Key Properties Comparison

Understanding the slight property differences helps in selecting the most appropriate material:

| Property | Kovar | Alloy 42 | Invar 36 |

|---|---|---|---|

| CTE (0-300°C) | 5.5 × 10^-6/°C | 5.3 × 10^-6/°C | 1.3 × 10^-6/°C |

| Glass Sealing | Excellent | Good | Limited |

| Magnetic Properties | Ferromagnetic | Ferromagnetic | Ferromagnetic |

| Relative Cost | Higher | Medium | Medium |

| Machinability | Moderate | Moderate | Moderate |

What Is the Difference Between Kovar and Invar?

Have you ever found yourself staring at material specs for a critical engineering project, confused about whether to choose Kovar or Invar? The subtle differences between these two alloys can make or break your design, yet understanding when to use each remains a challenge for many engineers.

Kovar and Invar are both nickel-iron alloys designed for controlled thermal expansion, but they serve different purposes. Kovar excels in glass-to-metal seals due to its thermal expansion match with glass, while Invar offers superior dimensional stability with near-zero expansion, making it ideal for precision instruments.

Key Composition Differences Between Kovar and Invar

When comparing Kovar and Invar, understanding their chemical composition provides crucial insights into their performance characteristics. Both are nickel-iron alloys, but their exact compositions create distinct properties that make each suitable for specific applications.

Kovar (also known as NILO K) typically consists of 29% nickel, 17% cobalt, and 54% iron, along with trace elements. This specific ratio gives Kovar its signature property – a thermal expansion coefficient that closely matches certain types of glass and ceramics. In my experience working with electronic component manufacturers, this composition makes Kovar particularly valuable for applications requiring hermetic seals.

Invar, on the other hand, contains approximately 36% nickel and 64% iron. The significantly higher nickel content is what gives Invar its remarkable dimensional stability. This composition creates an alloy with a thermal expansion anomaly2 that results in almost zero expansion when exposed to temperature changes within a specific range.

Thermal Expansion Properties Comparison

The primary difference between these two alloys lies in their thermal expansion behavior:

| Property | Kovar | Invar |

|---|---|---|

| Thermal Expansion Coefficient | 5.5 × 10^-6/°C (20-400°C) | 1.3 × 10^-6/°C (20-100°C) |

| Temperature Range for Controlled Expansion | 20-400°C | 20-100°C |

| Primary Application Advantage | Matched expansion with glass | Ultra-stable dimensions |

Kovar’s thermal expansion coefficient is specifically engineered to match borosilicate glasses and certain ceramic materials. This makes it ideal for creating reliable glass-to-metal seals in electronic packages, vacuum tubes, and power tubes.

Invar, with its remarkably low expansion coefficient (about 1/10th that of steel), maintains nearly constant dimensions even with significant temperature fluctuations. For precision measuring devices, optical systems, and scientific instruments, this property is invaluable.

Mechanical and Physical Properties

Beyond thermal expansion, these alloys differ in several other important aspects:

Machinability and Fabrication Considerations

In my years overseeing CNC machining projects at PTSMAKE, I’ve found that Kovar and Invar present different challenges during manufacturing. Kovar tends to work-harden rapidly during machining, requiring frequent tool changes and controlled cutting speeds. When performing Kovar machining, we typically use sharp carbide tools and maintain moderate cutting speeds to prevent excessive tool wear.

Invar can be even more challenging to machine properly. Its work hardening tendency is significant, and it’s notably tougher than Kovar. At our facilities, we’ve developed specialized CNC machining parameters for Invar components to ensure dimensional accuracy while maintaining reasonable tool life.

Electrical and Magnetic Properties

| Property | Kovar | Invar |

|---|---|---|

| Electrical Resistivity | 49 μΩ·cm | 82 μΩ·cm |

| Magnetic Permeability | Ferromagnetic | Ferromagnetic |

| Curie Temperature | ~435°C | ~230°C |

Kovar’s lower electrical resistivity makes it slightly more conductive than Invar, though both are relatively poor conductors compared to copper or aluminum. Both materials are ferromagnetic, but Kovar retains its magnetic properties at higher temperatures due to its higher Curie point.

Application-Specific Advantages

The unique properties of each alloy make them suited for distinct applications:

Kovar’s Primary Applications

- Electronic packaging requiring glass-to-metal seals

- Microelectronic housings and headers

- Power tube components

- Integrated circuit packages

- Semiconductor lead frames

Kovar’s ability to create reliable seals with glass makes it invaluable in electronics where hermetic packaging is required. We’ve manufactured numerous Kovar components for aerospace clients who need absolute reliability in their sealed electronic systems.

Invar’s Primary Applications

- Precision measuring instruments

- Laser systems and optical benches

- Shadow masks in color CRT displays

- Clock pendulums requiring temperature compensation

- Scientific instruments requiring dimensional stability

The exceptional dimensional stability of Invar makes it essential in applications where even microscopic changes in dimension could cause significant problems. One particularly interesting project we worked on at PTSMAKE involved Invar components for a satellite-based optical system where thermal fluctuations in space would have rendered other materials unsuitable.

Cost and Availability Considerations

An often overlooked factor when choosing between these alloys is the economic aspect:

Kovar is generally more expensive than Invar due to its cobalt content, which is a relatively costly element. Additionally, the complex manufacturing process required to ensure its precise thermal expansion properties adds to its cost.

Invar, while still more expensive than common steels, tends to be more economical than Kovar when comparing raw material costs. However, the machining challenges it presents can sometimes offset this advantage in finished component pricing.

Both materials are specialty alloys with limited suppliers, making availability and lead times important considerations for project planning. At PTSMAKE, we maintain relationships with reliable suppliers of both materials to ensure consistent quality and timely delivery for our clients’ projects.

What Is Kovar Used For?

Have you ever wondered why some electronic components remain functional despite extreme temperature changes? Or why certain glass-to-metal seals in aerospace applications don’t crack under stress? The struggle to find materials that maintain their integrity under harsh conditions is real—and costly when you get it wrong.

Kovar is used primarily for glass-to-metal seals in electronic components due to its thermal expansion properties that match glass. It serves critical applications in aerospace, telecommunications, medical devices, and semiconductor industries where hermetic sealing and thermal stability are essential for component reliability.

Key Applications of Kovar in Modern Industries

Kovar’s unique combination of properties makes it indispensable across several high-tech industries. Having worked with numerous clients at PTSMAKE, I’ve seen firsthand how this specialty alloy solves critical engineering challenges that few other materials can address.

Electronics and Semiconductor Applications

In the electronics industry, Kovar plays a crucial role in manufacturing components that require hermetic sealing. The material’s ability to maintain a reliable seal with glass makes it perfect for:

- Transistor housings

- Power semiconductor packages

- Vacuum tube components

- Microelectronic package frames

One of the most common applications I see is in producing hermetic feedthroughs3 for electronic packages. These components allow electrical connections to pass through a sealed barrier while maintaining complete isolation from the external environment.

Aerospace and Defense Applications

The aerospace sector demands materials that perform reliably under extreme conditions. Kovar meets these requirements through:

- Sensor housings for high-altitude aircraft

- Satellite components

- Guidance system parts

- Connectors for space vehicle electronics

At PTSMAKE, we’ve machined Kovar components for aerospace clients who need parts that can withstand the thermal cycling between the extreme cold of space and the heat generated during operation.

Telecommunications Industry Uses

Modern telecommunications infrastructure relies heavily on Kovar for:

- Microwave package housings

- RF connectors

- Waveguide components

- Optical fiber feedthrough assemblies

The material’s electromagnetic properties also make it suitable for applications where signal integrity is paramount.

Medical Device Applications

In the medical field, Kovar finds applications in:

- Implantable device housings

- Medical imaging equipment

- Diagnostic instruments

- Hermetically sealed medical electronics

Comparing Kovar with Alternative Materials

When evaluating material options, engineers often need to weigh the benefits of Kovar against alternatives. Here’s how it compares to other common materials:

| Material | Thermal Expansion Coefficient | Machinability | Cost Factor | Best Applications |

|---|---|---|---|---|

| Kovar | Very Low (5.5 × 10⁻⁶/°C) | Moderate | High | Glass-to-metal seals, electronic packages |

| Invar | Very Low (1.2 × 10⁻⁶/°C) | Difficult | Very High | Precision instruments, measuring devices |

| Stainless Steel | Moderate (16-18 × 10⁻⁶/°C) | Good | Moderate | General purpose, less critical seals |

| Titanium | Moderate (8.6 × 10⁻⁶/°C) | Difficult | High | Lightweight applications, corrosive environments |

| Aluminum | High (23 × 10⁻⁶/°C) | Excellent | Low | Non-hermetic applications, weight-sensitive designs |

Machining Considerations for Kovar Components

From my experience at PTSMAKE, machining Kovar presents unique challenges. The material work-hardens quickly during cutting operations, requiring specific machining strategies:

- Tooling Selection: Carbide tools with positive rake angles perform best

- Cutting Speed: Lower speeds (30-50% of those used for stainless steel)

- Cooling: Abundant cooling is essential to prevent work hardening

- Tool Wear: More frequent tool changes compared to other materials

For clients requiring precision Kovar components, we typically recommend CNC machining rather than conventional methods, as it provides the tight tolerances these applications demand.

Future Trends in Kovar Applications

As technology evolves, I’m seeing emerging trends in how Kovar is being utilized:

- Miniaturization: As electronic devices shrink, the precision of Kovar seals becomes even more critical

- Advanced Packaging: New semiconductor packaging technologies are finding innovative uses for Kovar’s properties

- Hydrogen Applications: Potential use in hydrogen storage and transport systems due to excellent hermeticity

- Additive Manufacturing: Exploration of 3D printing techniques for complex Kovar geometries

While the material has been around for decades, its unique properties ensure it will remain relevant for cutting-edge applications well into the future.

Does Kovar Work Harden?

Have you ever machined Kovar and noticed it becoming increasingly difficult to cut as you progress? Or perhaps you’ve designed components that unexpectedly failed due to material property changes during manufacturing? This frustrating phenomenon has derailed many precision projects when least expected.

Yes, Kovar does work harden significantly during machining processes. This nickel-iron-cobalt alloy can experience up to 50% increase in hardness when subjected to mechanical deformation, requiring specialized cutting techniques, proper tool selection, and carefully controlled machining parameters to achieve precise results.

Understanding Work Hardening in Kovar

Work hardening, also known as strain hardening, occurs when a metal experiences plastic deformation, causing its microstructure to change. In Kovar, this process is particularly pronounced due to its unique composition of approximately 29% nickel, 17% cobalt, and 53% iron, along with trace elements. When subjected to mechanical forces during machining, Kovar’s crystalline structure deforms, creating dislocations that impede further movement within the metal’s grain structure.

From my experience working with aerospace and electronics clients at PTSMAKE, I’ve observed that Kovar’s work hardening tendency creates both challenges and opportunities. The material starts with a moderate hardness of about 80-90 HRB (Rockwell B scale) in the annealed condition but can rapidly increase to 25-30 HRC (Rockwell C scale) when worked.

Factors Affecting Work Hardening Rate in Kovar

Several variables influence how quickly and significantly Kovar work hardens:

- Deformation Speed: Higher cutting speeds typically accelerate work hardening

- Temperature: Elevated temperatures can reduce work hardening effects

- Prior Processing: Material that has been previously cold worked may exhibit different hardening behavior

- Alloy Composition: Minor variations in the Kovar composition can affect work hardening characteristics

When machining Kovar components for precision applications, we must carefully consider these factors. For example, a hermetic seal housing for semiconductor equipment requires maintaining tight tolerances while preventing excessive material hardening that might lead to cracking or dimensional issues.

Measuring Work Hardening in Kovar

To quantify work hardening in Kovar, several testing methods can be employed:

Hardness Testing Comparison

| Test Method | Before Machining | After 30% Deformation | Percentage Increase |

|---|---|---|---|

| Rockwell B | 85-90 HRB | Not applicable* | N/A |

| Rockwell C | ~10 HRC | 25-30 HRC | ~150-200% |

| Vickers | 180-200 HV | 280-320 HV | ~60% |

*Rockwell B scale is not suitable for measuring harder materials after significant work hardening

Through tensile testing, we can also observe that Kovar’s yield strength typically increases from approximately 345 MPa in the annealed condition to over 690 MPa after severe cold working. This significant change illustrates why machining strategies must account for work hardening phenomena4 as cutting progresses.

Practical Implications for Machining Kovar

Based on my experience with precision machining at PTSMAKE, I’ve developed several strategies to address Kovar’s work hardening tendency:

Tool Selection and Cutting Parameters

When machining Kovar, tool selection becomes critical. Carbide tools with positive rake angles typically perform better than high-speed steel options. For optimal results, I recommend:

- Using sharp carbide cutting tools with appropriate coatings (TiAlN works particularly well)

- Maintaining moderate cutting speeds (30-60 m/min)

- Employing generous coolant flow to manage heat

- Taking consistent, moderate depth cuts rather than light, superficial passes

The latter point is especially important – light cuts can actually increase work hardening by repeatedly working the surface without removing sufficient material.

Machining Sequence Considerations

The order of operations becomes particularly important when working with Kovar. I typically recommend:

- Rough machining in the annealed condition

- Stress relieving heat treatment at 595-705°C if significant material removal occurred

- Finish machining with appropriate tools and parameters

- Final dimensional verification accounting for potential springback

For complex components, such as precision housings for space-grade electronics that we manufacture at PTSMAKE, we sometimes introduce intermediate stress-relieving steps to maintain dimensional stability throughout the manufacturing process.

Leveraging Work Hardening to Your Advantage

While work hardening presents challenges, it can also be advantageous in certain applications. The increased surface hardness resulting from machining can improve:

- Wear resistance

- Fatigue strength

- Surface finish durability

For components like valve seats or bearing surfaces, controlled work hardening can be deliberately introduced to enhance performance. This requires precise control of machining parameters and thorough understanding of the material’s behavior.

By understanding and properly managing Kovar’s work hardening tendencies, we can transform what might initially seem like a manufacturing challenge into a competitive advantage for specialized applications requiring both thermal expansion matching and enhanced surface properties.

How Strong Is Kovar?

Have you ever selected a material for your project, only to discover later it couldn’t withstand the operating conditions? Or struggled to find that perfect balance between thermal expansion properties and mechanical strength for your glass-to-metal seals? The wrong material choice can lead to catastrophic failures when least expected.

Kovar’s ultimate tensile strength ranges from 70,000 to 80,000 psi (483-552 MPa), with yield strength around 45,000-55,000 psi (310-379 MPa). This medium strength, combined with exceptional thermal expansion properties, makes it ideal for glass-to-metal seals in electronic packages and hermetic applications.

Understanding Kovar’s Mechanical Strength Properties

Kovar (also known as ASTM F15 alloy) is an iron-nickel-cobalt alloy specifically designed for applications requiring matched thermal expansion characteristics with certain glasses and ceramics. While Kovar is primarily chosen for its unique thermal properties, its mechanical strength characteristics are equally important to consider for many applications.

When evaluating Kovar’s strength, we need to examine several key mechanical properties:

Tensile Strength and Yield Point

Kovar demonstrates moderate to good strength properties compared to other specialty alloys. Here’s a breakdown of its key strength parameters:

| Property | Typical Value (Imperial) | Typical Value (Metric) |

|---|---|---|

| Ultimate Tensile Strength | 70,000-80,000 psi | 483-552 MPa |

| Yield Strength | 45,000-55,000 psi | 310-379 MPa |

| Elongation | 30-40% | 30-40% |

| Hardness | 80-85 Rockwell B | 150-170 Brinell |

The yield strength indicates the stress at which Kovar begins to deform plastically. This is particularly important in applications where dimensional stability is critical, such as in precise electronic packages or hermetic seals.

Hardness and Wear Resistance

Kovar’s hardness falls in the moderate range, with a typical Rockwell B hardness of 80-85 (equivalent to approximately 150-170 Brinell). This makes it reasonably resistant to deformation while still being machinable. At PTSMAKE, we’ve found that Kovar provides adequate wear resistance for most electronic applications, though it isn’t typically chosen for components where abrasion resistance is the primary requirement.

Temperature Effects on Strength

One of Kovar’s most valuable attributes is how it maintains its strength properties across a wide temperature range. The material retains useful strength up to approximately 400°C (752°F), making it suitable for electronic components that may experience elevated temperatures during operation.

| Temperature | Relative Strength Retention |

|---|---|

| Room Temperature | 100% |

| 200°C (392°F) | ~90% |

| 400°C (752°F) | ~75% |

| 600°C (1112°F) | ~50% |

Comparing Kovar to Similar Alloys

To better understand Kovar’s strength profile, it’s helpful to compare it with similar alloys used in related applications:

Kovar vs. Invar

Invar (Fe-36Ni) shares Kovar’s low thermal expansion characteristics but differs in strength profile:

| Property | Kovar | Invar |

|---|---|---|

| Ultimate Tensile Strength | 483-552 MPa | 450-500 MPa |

| Yield Strength | 310-379 MPa | 280-350 MPa |

| Primary Advantage | Better glass sealing properties | Lower thermal expansion |

Kovar vs. Stainless Steel (304)

While stainless steel offers higher strength, it lacks Kovar’s specialized thermal properties:

| Property | Kovar | Stainless Steel (304) |

|---|---|---|

| Ultimate Tensile Strength | 483-552 MPa | 505-750 MPa |

| Yield Strength | 310-379 MPa | 215-505 MPa |

| CTE (20-100°C) | ~5.1 x 10⁻⁶/°C | ~17.3 x 10⁻⁶/°C |

From my experience working with various alloys at PTSMAKE, I’ve observed that while stainless steel might be stronger, Kovar is irreplaceable in applications requiring controlled thermal expansion5 with glass or ceramic components.

Practical Applications Based on Kovar’s Strength

Kovar’s balanced strength properties make it suitable for specific application types:

Electronic Packaging and Hermetic Seals

Kovar’s moderate strength combined with its thermal expansion characteristics makes it ideal for hermetic packages in microelectronics. The material provides sufficient strength to maintain package integrity while ensuring reliable glass-to-metal seals remain intact during thermal cycling.

Semiconductor Industry Applications

In semiconductor manufacturing, Kovar components must maintain precise dimensions while withstanding moderate mechanical stresses. The yield strength is sufficient to prevent deformation in these precision applications, where even microscopic changes can affect device performance.

Aerospace and Defense Electronics

For aerospace applications, Kovar’s ability to maintain strength across temperature ranges while providing reliable hermetic sealing capabilities makes it valuable for mission-critical components. The material’s strength characteristics help ensure these components survive the vibration and shock environments experienced in aerospace applications.

Machining Considerations Based on Strength Properties

When machining Kovar at PTSMAKE, we consider several strength-related factors:

- Work hardening tendency – Kovar work hardens moderately during machining

- Tool wear – Carbide tooling is recommended due to Kovar’s moderate hardness

- Cutting speeds – Moderate speeds are optimal to prevent excessive work hardening

- Heat treatment effects – Stress relief annealing may be necessary after machining

For precision electronic components, we typically implement a machining strategy that minimizes internal stresses during the cutting process, ensuring the final parts maintain dimensional stability during subsequent thermal cycling.

What Are the Key Challenges in Kovar Machining?

Have you ever tried machining Kovar only to end up with unpredictable results? Those special projects requiring glass-to-metal seals where nothing else will work, but the material fights you every step of the way? The frustration of dealing with tool wear, dimensional changes, and surface finish issues can make even experienced machinists question their skills.

Kovar machining presents unique challenges due to its work-hardening properties, thermal sensitivity, and tough composition. Key difficulties include rapid tool wear, maintaining tight tolerances, controlling heat generation, achieving proper surface finishes, and managing the material’s tendency to work-harden during machining operations.

Understanding Material Properties That Complicate Machining

Kovar, a nickel-cobalt-iron alloy, has become indispensable in electronics and aerospace applications due to its unique thermal expansion properties. When I work with clients needing glass-to-metal or ceramic-to-metal seals, Kovar is often the only viable option. However, its material properties present significant machining challenges.

The composition of Kovar (typically 29% nickel, 17% cobalt, and 54% iron) creates a material with excellent electrical properties but also contributes to its machinability issues. Its work-hardening tendency6 means that as you cut the material, the remaining surface becomes progressively harder. This creates a compounding problem where each pass makes subsequent operations more difficult.

Thermal Sensitivity Considerations

Kovar’s thermal expansion coefficient (5.5 × 10^-6/°C) is one of its most valuable properties but also creates machining complications. During machining operations, temperature fluctuations can cause dimensional changes that complicate achieving tight tolerances. I’ve found that even slight variations in cutting temperature can lead to measurable differences in the final part dimensions.

Temperature control becomes especially critical when machining Kovar components for electronics applications, where dimensional stability is paramount. Some specifications I’ve worked with require tolerances as tight as ±0.0005 inches (0.0127 mm), making thermal management essential throughout the machining process.

Tool Wear and Selection Challenges

Tool wear represents one of the most persistent challenges in Kovar machining. The material’s abrasive nature causes cutting tools to deteriorate rapidly, affecting both productivity and part quality. In my experience at PTSMAKE, we’ve found that tool life when machining Kovar can be 40-60% shorter compared to machining similar stainless steels.

Optimal Cutting Tool Materials

Selecting the right tool material dramatically impacts machining success. Here’s a comparison of common tool materials for Kovar machining:

| Tool Material | Advantages | Disadvantages | Best Applications |

|---|---|---|---|

| Carbide | Good wear resistance, reasonable cost | Brittle, can chip with interruptions | General Kovar machining, higher speeds |

| Ceramic | Excellent heat resistance, high hardness | Expensive, brittle | High-speed finishing operations |

| CBN/PCD | Superior wear resistance, long tool life | Very expensive, limited geometries | High-volume production, specific geometries |

| HSS | Toughness, shock resistance | Rapid wear with Kovar | Only for simple operations, low production |

When working with precision components, I typically recommend carbide tools with specialized coatings like TiAlN or AlCrN. These coatings extend tool life and allow for more stable machining parameters, particularly important for the tight tolerances many Kovar applications demand.

Surface Finish Requirements and Challenges

Achieving consistent surface finishes on Kovar components presents another significant challenge. The material’s work-hardening properties can lead to built-up edge formation during machining, which creates unpredictable surface quality issues.

For applications requiring smooth surfaces (like hermetic seals), I recommend:

- Using sharp, coated cutting tools

- Implementing rigid workholding to minimize vibration

- Applying appropriate cutting fluids specifically formulated for nickel alloys

- Employing light finishing passes with optimized speed/feed combinations

Reaching Ra values below 0.8μm often requires additional finishing operations like grinding or polishing, which adds complexity to the manufacturing process.

Dimensional Stability and Tolerance Control

Maintaining dimensional stability during Kovar machining requires specialized approaches. The material’s response to both mechanical and thermal stress means that traditional machining approaches often fall short when tight tolerances are required.

Strategies for Improving Dimensional Accuracy

Through numerous projects, I’ve developed these approaches for enhancing dimensional control:

- Incorporate stress-relief heat treatments between roughing and finishing operations

- Employ balanced machining sequences to distribute internal stresses evenly

- Use consistent workholding pressure to avoid distortion

- Allow parts to thermally stabilize between critical operations

- Consider cryogenic treatment for complex geometries requiring ultimate stability

For medical and aerospace clients with particularly demanding requirements, we sometimes implement in-process measurement systems that monitor dimensional changes during machining, allowing for real-time adjustments.

Economic Considerations in Kovar Machining

The technical challenges of machining Kovar translate directly into economic ones. The combination of slower cutting speeds, increased tool consumption, and the need for specialized equipment impacts production costs significantly.

When quoting Kovar projects, I typically calculate machining costs at 1.5-2.5 times that of comparable stainless steel components. This cost differential stems from:

- Reduced cutting speeds (typically 30-50% slower than stainless steel)

- Increased tool consumption and related change-over time

- Additional in-process quality control requirements

- Specialized coolant systems and filtration needs

- Higher likelihood of rework due to dimensional or surface finish issues

Despite these challenges, Kovar remains irreplaceable for many specialized applications, making economical machining strategies essential rather than optional.

How to Make a Decision After Supplier Assessment for Kovar Machining?

Have you ever found yourself drowning in supplier assessment data, unsure how to weigh different factors when selecting a Kovar machining partner? Do you struggle with making the final call even after gathering all the information, second-guessing whether you’re prioritizing the right criteria?

Making a decision after supplier assessment requires balancing technical capabilities, price competitiveness, quality certifications, and relationship potential. The best approach is to use a weighted scoring system that reflects your specific project priorities, then validate your top choices with sample orders before committing to a long-term partnership.

Implement a Structured Decision-Making Process

After completing comprehensive supplier assessments for your Kovar machining needs, you now face the crucial task of making the final decision. This step transforms all your research into actionable business relationships. Having personally guided many companies through this process, I’ve found that implementing a structured approach yields the most consistent results.

Create a Weighted Scoring Matrix

The first step in making your decision is to organize all assessment data into a weighted scoring matrix. This approach ensures that factors most important to your specific application receive appropriate consideration.

Here’s a sample scoring matrix I often recommend:

| Evaluation Criteria | Weight (%) | Supplier A | Supplier B | Supplier C |

|---|---|---|---|---|

| Technical Capability | 25 | 9 (2.25) | 8 (2.00) | 7 (1.75) |

| Quality System | 20 | 8 (1.60) | 9 (1.80) | 7 (1.40) |

| Cost | 20 | 7 (1.40) | 9 (1.80) | 8 (1.60) |

| Lead Time | 15 | 9 (1.35) | 7 (1.05) | 8 (1.20) |

| Communication | 10 | 8 (0.80) | 7 (0.70) | 9 (0.90) |

| Financial Stability | 10 | 9 (0.90) | 8 (0.80) | 7 (0.70) |

| Total Score | 100 | 8.30 | 8.15 | 7.55 |

The numbers in parentheses represent the weighted scores (criteria score × weight percentage). This approach prevents emotional or biased decision-making by keeping the process objective and data-driven.

Analyze the Risk-Reward Profile

Beyond scoring, analyze each supplier’s risk-reward profile. This step is especially important for Kovar machining, where material properties must be preserved throughout the manufacturing process.

Consider these risk factors:

- Geographic risk (supply chain disruptions)

- Financial stability concerns

- Capacity limitations

- Intellectual property protection measures

- Metallurgical compatibility7 with your specific Kovar alloy requirements

At PTSMAKE, we maintain robust metallurgical testing capabilities to ensure Kovar’s critical properties remain intact throughout machining, which significantly reduces one of the major risk factors in supplier selection.

Validate Your Decision with Sample Orders

Before finalizing your decision, I strongly recommend placing sample orders with your top two or three candidates. This real-world test often reveals aspects of the supplier relationship that paperwork cannot.

What to Evaluate in Sample Orders

When ordering Kovar machined samples, pay particular attention to these areas:

- Dimensional accuracy – Kovar’s thermal expansion properties make precision machining challenging

- Surface finish quality – Especially important for components requiring hermetic sealing

- Material certification verification – Confirm the Kovar composition matches specifications

- Response to engineering queries – Test their technical knowledge and communication

- On-time delivery performance – Even with small orders, timeliness matters

I’ve seen numerous clients discover critical insights during the sample order phase that completely changed their supplier ranking. For instance, one aerospace client found that a mid-ranked supplier actually delivered the best Kovar components because of their specialized experience with glass-to-metal sealing applications.

Consider Long-Term Partnership Potential

While immediate needs drive many supplier decisions, evaluating long-term partnership potential often yields better results over time. This is particularly relevant for Kovar machining, where specialized knowledge accumulates with experience.

Partnership Indicators to Consider

Look for these qualities that indicate strong partnership potential:

- Willingness to invest in relationship-specific assets or training

- Transparent communication about capabilities and limitations

- Proactive problem-solving approach rather than reactive responses

- Compatible business cultures and values

- Evidence of continuous improvement initiatives

At PTSMAKE, we’ve maintained many of our Kovar machining partnerships for over a decade because we focus on being a true manufacturing partner, not just a vendor.

Make the Final Decision

With all data collected and analyzed, it’s time to make your final decision. I recommend following these steps:

- Review your weighted scoring matrix results

- Incorporate insights from sample orders

- Consider partnership potential factors

- Consult key stakeholders for final input

- Document your decision rationale for future reference

The final selection should balance objective data with your organization’s priorities and risk tolerance. Remember that the lowest-cost supplier isn’t always the best value when considering the total cost of ownership, especially for critical Kovar components.

Negotiating Terms with Your Selected Supplier

Once you’ve selected your Kovar machining supplier, focus on negotiating terms that protect both parties and set clear expectations.

Key areas to address in your negotiations include:

- Pricing structures and volume discounts

- Quality acceptance criteria specific to Kovar machining

- Lead time expectations and rush order provisions

- Intellectual property protections

- Regular performance review schedules

- Escalation procedures for quality or delivery issues

Establishing these terms upfront prevents misunderstandings and creates a foundation for a successful partnership. At PTSMAKE, we prefer transparent negotiations that result in fair terms for both parties rather than one-sided agreements that often lead to problems later.

What Surface Finishes Are Compatible With Kovar Machining?

Have you ever received Kovar parts that looked perfect but failed during application due to improper surface finishing? Or spent valuable time and resources on rework because the surface treatment wasn’t compatible with your Kovar components? These finishing decisions can make or break your precision projects.

Kovar machining is compatible with various surface finishes including electroplating (gold, silver, nickel), electroless nickel plating, anodizing, passivation, and physical vapor deposition coatings. The optimal finish depends on your application’s specific requirements for corrosion resistance, solderability, or electrical conductivity.

Understanding Kovar Surface Finish Compatibility

Working with Kovar requires careful consideration of surface treatments due to its unique composition. As an iron-nickel-cobalt alloy, Kovar demonstrates excellent thermal expansion properties but can be particular about which surface finishes adhere properly and enhance its performance characteristics.

In my experience at PTSMAKE, I’ve found that selecting the appropriate surface finish for Kovar components involves evaluating several factors: the application environment, required electrical properties, hermeticity needs, and aesthetic considerations. Let’s explore the most common and effective surface finishes compatible with Kovar machining.

Electroplating Options for Kovar

Electroplating remains one of the most versatile surface treatments for Kovar components. This process deposits a thin layer of metal onto the Kovar substrate using an electrical current.

Gold Plating

Gold plating offers excellent corrosion resistance and electrical conductivity. For Kovar parts used in aerospace and electronics, I typically recommend gold plating between 50-100 microinches thick. This provides ideal protection while maintaining dimensional precision. This finish is particularly beneficial for components requiring galvanic compatibility8 with other gold-plated parts in assemblies.

Nickel Plating

Nickel electroplating creates a hard, wear-resistant surface on Kovar components. The typical thickness ranges from 100-300 microinches, providing good corrosion protection while maintaining dimensional stability. I’ve found nickel plating especially useful for Kovar components that require both corrosion resistance and moderate wear protection.

Silver Plating

Silver plating provides superior electrical conductivity and solderability. For RF/microwave applications, silver-plated Kovar offers excellent performance. However, be mindful that silver is susceptible to tarnishing and may require additional protective measures in certain environments.

Electroless Nickel Plating

Electroless nickel plating deposits a uniform layer of nickel-phosphorus alloy without using electrical current. This process creates an exceptionally uniform coating even on complex geometries—a significant advantage when working with intricate Kovar components.

The coating thickness typically ranges from 100-500 microinches, with various phosphorus content options:

| Phosphorus Content | Characteristics | Recommended Applications |

|---|---|---|

| Low (2-5%) | Magnetic, hardest deposit | Wear resistance applications |

| Medium (6-9%) | Semi-magnetic, good corrosion resistance | General purpose protection |

| High (10-13%) | Non-magnetic, best corrosion resistance | Harsh environment components |

When machining medical device components at PTSMAKE, I often specify high-phosphorus electroless nickel for Kovar parts that require both precise dimensions and excellent corrosion resistance.

Passivation Treatments

Passivation creates a thin oxide layer on Kovar surfaces, enhancing corrosion resistance without adding measurable thickness. This chemical process removes free iron from the surface and promotes the formation of a protective oxide layer.

Two common passivation processes for Kovar include:

- Citric acid passivation – A more environmentally friendly option

- Nitric acid passivation – Traditional method with excellent results

Passivation works well as a standalone treatment for mild environments or as a preparation step before applying other finishes.

Physical Vapor Deposition (PVD) Coatings

For specialized applications requiring extreme hardness or unique properties, PVD coatings offer excellent adhesion to Kovar substrates. These thin-film coatings (typically 1-5 microns) provide:

- Exceptional hardness (up to 2500 HV)

- Low friction coefficients

- High temperature resistance

- Excellent wear protection

Common PVD coatings compatible with Kovar include titanium nitride (TiN), chromium nitride (CrN), and diamond-like carbon (DLC).

Selecting the Right Surface Finish for Your Application

When helping clients choose the optimal surface finish for their Kovar components, I consider these key factors:

- Environmental exposure: Will the part face moisture, chemicals, or extreme temperatures?

- Electrical requirements: Is conductivity or insulation needed?

- Mechanical considerations: Will the component experience wear or friction?

- Assembly requirements: Will the part be soldered, welded, or bonded?

- Cost constraints: What is the budget for secondary operations?

For instance, in aerospace applications where reliability is paramount, I typically recommend gold plating over nickel for critical Kovar components. For high-volume electronic applications where cost sensitivity exists alongside performance requirements, electroless nickel often provides the best balance.

Surface Finish Comparison for Kovar Machining

To simplify your decision-making process, here’s a comparative overview of surface finishes compatible with Kovar:

| Surface Finish | Corrosion Resistance | Wear Resistance | Electrical Conductivity | Relative Cost | Typical Applications |

|---|---|---|---|---|---|

| Gold Plating | Excellent | Poor | Excellent | High | Electronics, RF connectors |

| Nickel Plating | Good | Good | Fair | Moderate | General purpose protection |

| Silver Plating | Good | Poor | Excellent | Moderate-High | RF/microwave components |

| Electroless Nickel | Very Good | Very Good | Fair | Moderate | Precision components, medical devices |

| Passivation | Fair | Poor | Poor | Low | Pre-treatment, mild environments |

| PVD Coatings | Excellent | Excellent | Varies | High | Specialized applications |

Testing Surface Finish Compatibility

At PTSMAKE, I always recommend testing surface finishes on sample Kovar components before full production. This approach has saved many projects from costly errors. A comprehensive testing program typically includes:

- Adhesion testing (ASTM D3359)

- Corrosion resistance testing (ASTM B117)

- Solderability testing (if applicable)

- Environmental stress testing

- Electrical property verification (if required)

These tests ensure that the selected surface finish not only adheres properly to the Kovar substrate but also delivers the performance characteristics required by your application.

How Does Kovar Machining Impact Lead Times in Production?

Have you ever waited anxiously for critical components only to face repeated delays? Or perhaps you’ve struggled with suppliers who promise quick turnarounds on Kovar parts but consistently miss deadlines? This common frustration can derail project timelines and create cascading problems throughout your production cycle.

Kovar machining significantly impacts production lead times due to its challenging material properties. While difficult to machine due to its hardness, high nickel content, and work-hardening characteristics, specialized techniques and proper equipment can reduce lead times by 30-50% compared to conventional approaches. The right manufacturing partner is crucial for optimizing these timelines.

Understanding Kovar’s Unique Machining Challenges

Kovar’s composition (29% nickel, 17% cobalt, and 53% iron) creates specific machining challenges that directly affect production lead times. Its unique glass-to-metal sealing properties9 make it essential for many high-tech applications, but these same properties create manufacturing hurdles.

When working with Kovar, I’ve observed that standard machining approaches often lead to excessive tool wear, poor surface finishes, and dimensional inconsistencies – all of which extend lead times considerably. The material’s high tensile strength (around 50,000 psi) and low thermal conductivity create a perfect storm for manufacturing delays.

Material Preparation Impact on Lead Times

The initial preparation of Kovar significantly impacts overall project timelines. Unlike more common metals, Kovar requires specific conditioning before machining can begin:

| Preparation Stage | Standard Lead Time | Optimized Lead Time | Impact Factors |

|---|---|---|---|

| Material Sourcing | 2-4 weeks | 1-2 weeks | Supplier relationships, stock availability |

| Stress Relief | 3-5 days | 1-2 days | Heat treatment equipment, process knowledge |

| Initial Cutting | 2-3 days | 1 day | Cutting technology, fixture availability |

At PTSMAKE, we’ve developed specialized material sourcing channels that reduce the typical 2-4 week lead time for Kovar acquisition to just 1-2 weeks in most cases. This initial time savings cascades throughout the entire production process.

CNC Machining Parameters and Their Effect on Timelines

The specific machining parameters used for Kovar directly impact production schedules. From my experience managing complex Kovar projects, I’ve found these critical settings significantly influence lead times:

Cutting Speed Considerations

Kovar requires slower cutting speeds compared to many other metals – typically 30-60% slower than stainless steel. While this naturally extends machining time, using improper speeds leads to even longer delays due to:

- Excessive tool wear requiring frequent replacements

- Work hardening that damages both tools and workpieces

- Surface quality issues requiring additional finishing operations

Using proper cutting speeds with high-quality carbide tooling can reduce overall machining time by up to 35% compared to using standard parameters. This approach might seem counterintuitive (slower is faster?), but the reduced need for rework and tool changes creates substantial time savings.

Thermal Management Strategies

Kovar’s thermal properties create unique challenges that affect project timelines. Without proper thermal management during machining, components can warp, leading to rejection rates as high as 15-20%. Each rejected part extends overall lead time dramatically.

Effective thermal management strategies include:

- Specialized coolant formulations designed for nickel alloys

- Intermittent machining approaches that prevent heat buildup

- Multi-stage machining processes with cooling intervals

By implementing comprehensive thermal management, we’ve reduced rejection rates to under 3% on complex Kovar components, significantly improving overall lead times.

Finishing Operations and Quality Control Implications

The finishing requirements for Kovar parts have substantial timeline implications. Many high-precision applications require specialized surface treatments that add complexity to the production schedule:

| Finishing Operation | Typical Timeline | Quality Impact | Lead Time Reduction Strategy |

|---|---|---|---|

| Precision Grinding | 2-5 days | Critical for flatness | Combine with main machining when possible |

| Surface Passivation | 1-2 days | Prevents oxidation | Batch processing multiple parts |

| Final Inspection | 1-3 days | Ensures specifications | Automated inspection systems |

The most effective approach I’ve implemented for reducing lead times is parallel processing whenever possible. By conducting certain finishing operations while the next batch of parts begins machining, we’ve compressed overall timelines by up to 40% on complex Kovar projects.

Supplier Expertise and Its Critical Role

Perhaps the most significant factor affecting Kovar machining lead times is supplier expertise. Working with a partner experienced in this specific alloy can dramatically reduce production timelines.

At PTSMAKE, our 15+ years specializing in challenging materials like Kovar has allowed us to develop proprietary machining protocols that consistently outperform industry standards for lead times. When evaluating potential manufacturing partners for Kovar projects, consider:

- Demonstrated experience with Kovar specifically (not just general metals)

- Investment in specialized tooling and fixtures for nickel alloys

- Quality control processes tailored to Kovar’s unique characteristics

- Ability to source material rapidly through established supply channels

The right partner can often reduce overall lead times by 30-50% compared to working with a general machine shop without specific Kovar expertise.

Optimizing Design for Kovar Manufacturability

One area frequently overlooked when considering lead times is design optimization specifically for Kovar’s properties. I’ve seen countless projects where design modifications could have dramatically reduced production times:

- Minimizing thin walls and features prone to warping

- Designing for specific tool paths that leverage Kovar’s machinability characteristics

- Including stress-relief features that maintain dimensional stability

- Specifying proper tolerances that consider Kovar’s unique properties

Working closely with manufacturing engineers early in the design process can identify opportunities to reduce machining complexity while maintaining functional requirements – often reducing overall lead times by 20-30%.

What Quality Control Measures Ensure Reliable Kovar Machining?

Have you ever received Kovar components that failed unexpectedly during assembly? Or struggled with inconsistent dimensional accuracy across batches? These quality issues don’t just delay your project—they can completely derail it, especially when working with a specialized material like Kovar.

Quality control in Kovar machining requires a comprehensive approach combining material verification, precise measurement protocols, environmental controls, and specialized testing methods. Effective QC systems monitor the entire process from material receipt to final inspection, ensuring components meet exact specifications and maintain the critical properties that make Kovar valuable.

Understanding the Critical Nature of Kovar Quality Control

Quality control for Kovar machining demands exceptional attention to detail due to the material’s specialized applications in electronics, aerospace, and medical devices. As a glass-to-metal sealing alloy with carefully controlled thermal expansion characteristics10, even minor deviations can compromise functionality.

At PTSMAKE, I’ve implemented comprehensive quality control protocols specifically designed for Kovar components. These measures ensure that each part not only meets dimensional specifications but also maintains the essential material properties that make Kovar valuable for its intended applications.

Material Verification and Traceability

Certificate of Analysis Verification

Each batch of Kovar material that enters our facility undergoes rigorous verification against its Certificate of Analysis (CoA). This document provides critical information about:

- Chemical composition percentages (nickel, cobalt, iron)

- Mechanical properties

- Lot number and manufacturing information

- Compliance with industry standards

We maintain complete material traceability from raw material to finished component, allowing us to trace any potential issue back to its source.

XRF Testing for Material Confirmation

X-ray fluorescence (XRF) testing provides an additional verification layer. This non-destructive method confirms the material composition matches what’s specified on the CoA and design requirements.

Dimensional Inspection Protocols

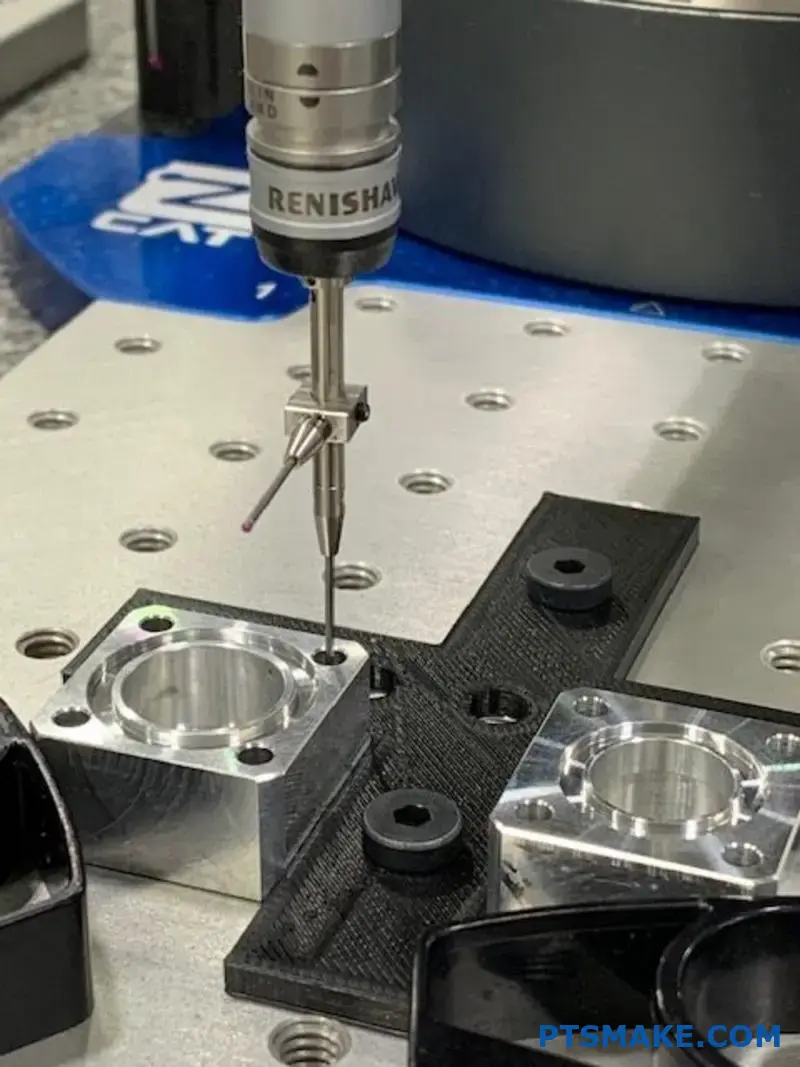

Coordinate Measuring Machine (CMM) Inspection

For high-precision Kovar components, we employ CMM inspection with temperature-controlled environments to ensure accurate measurements. Our protocol includes:

- First article inspection for new products

- In-process verification at critical manufacturing stages

- Final dimensional verification before shipping

Statistical Process Control Implementation

Statistical Process Control (SPC) helps us maintain consistency across production runs by:

| SPC Parameter | Application in Kovar Machining | Benefit |

|---|---|---|

| Cp/Cpk analysis | Measures process capability | Ensures consistent tolerance adherence |

| X-bar and R charts | Monitors process variations | Identifies trends before they cause issues |

| First article inspection | Validates initial setup | Prevents batch-wide errors |

| Sampling plans | Determines inspection frequency | Balances quality assurance with efficiency |

Surface Finish and Cleanliness Controls

Surface finish quality directly impacts Kovar’s ability to form hermetic seals and bond with other materials. Our quality measures include:

Surface Roughness Testing

We measure surface roughness using calibrated profilometers, ensuring components meet the specified Ra values. This is particularly critical for components requiring subsequent plating or glass-to-metal sealing.

Contamination Prevention Protocols

Kovar is susceptible to contamination that can compromise its properties. Our clean manufacturing environment includes:

- Dedicated machining areas for Kovar

- Specialized cleaning protocols using appropriate solvents

- Particulate-free packaging for finished components

- Regular monitoring of environmental conditions

Specialized Testing for Kovar Properties

Magnetic Permeability Testing

For applications requiring specific magnetic properties, we conduct permeability testing to verify the material behaves as expected after machining processes.

Oxidation and Plating Adhesion Tests

When Kovar components require plating (commonly gold or nickel), we perform adhesion tests to ensure proper bonding and coating integrity, preventing issues in subsequent assembly operations.

Final Quality Assurance Procedures

Leak Testing for Sealed Components

For Kovar components designed for hermetic sealing applications, we perform helium leak testing to verify seal integrity down to extremely low leak rates (often measured in 10^-9 std cc/sec).

Thermal Cycling Validation

When required by critical applications, we can perform thermal cycling tests to verify the Kovar component maintains its integrity through temperature fluctuations, confirming its coefficient of thermal expansion performs as expected.

Documentation and Certification

Each Kovar machining project is accompanied by comprehensive documentation, including:

- Material certifications

- Dimensional inspection reports

- Process control data

- Test results for specialized requirements

- Lot traceability information

This documentation package provides assurance that components meet all specified requirements and helps troubleshoot any issues that might arise.

Real-World Application of Quality Controls

In a recent aerospace project at PTSMAKE, we implemented these rigorous quality control measures for Kovar housings used in satellite communication systems. The enhanced inspection protocols allowed us to achieve a 99.8% first-pass yield rate, compared to the industry average of around 95% for similar components. This level of quality assurance is particularly crucial for components that cannot be easily replaced once deployed.

By implementing these comprehensive quality control measures, we’ve been able to deliver Kovar components that consistently meet our customers’ demanding specifications, even for the most critical applications in aerospace, defense, and medical devices.

Learn about this critical property for preventing component failure in extreme environments. ↩

Learn how this property can transform your precision engineering projects. ↩

Learn more about these critical electronic components and how they’re manufactured. ↩

Click to learn advanced techniques for managing work hardening during precision machining. ↩

Click to learn how controlled thermal expansion affects material selection for critical components. ↩

Click for detailed explanation of work-hardening effects on tool selection. ↩

Understanding this concept ensures optimal material performance in your final components. ↩

Understanding this concept helps prevent unexpected material interactions in your projects. ↩

Learn how these properties affect your specific application’s timeline requirements. ↩

Learn why controlled thermal expansion makes Kovar essential for critical applications. ↩