Benefits of Custom Aluminum Profiles in Modern Manufacturing

Ever wondered how complex products achieve both strength and sleek design without breaking the bank? The secret often lies hidden in the materials chosen. Let’s explore a versatile champion in modern manufacturing.

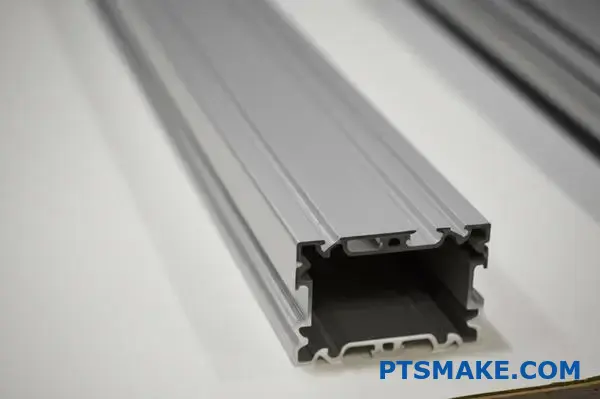

Custom aluminum profiles provide unmatched advantages like lightweight strength, natural corrosion resistance, excellent thermal conductivity, and overall cost-effectiveness, making them ideal for demanding precision engineering applications.

The choice of material is fundamental in manufacturing, significantly impacting performance, cost, and longevity. In precision engineering, where tolerances are tight and demands are high, custom aluminum profiles consistently stand out. They offer a unique combination of properties that standard materials often can’t match.

Lightweight Yet Strong

One of the most celebrated features of aluminum is its impressive strength-to-weight ratio. Compared to steel, aluminum alloys can provide comparable structural integrity at roughly one-third the weight. This is a game-changer in industries like aerospace and automotive, where reducing weight directly translates to improved fuel efficiency and performance. We’ve seen this firsthand at PTSMAKE when developing components for specialized robotics where minimizing mass is critical for speed and agility. Using custom aluminum profiles allows engineers to design complex, lightweight structures without compromising on durability.

Naturlig korrosionsbeständighet

Aluminum naturally forms a protective oxide layer when exposed to air. This thin, tough layer shields the metal from further oxidation and environmental corrosion. This inherent resistance makes aluminum profiles suitable for applications in various environments, from architectural elements exposed to weather to components used near liquids. For enhanced protection or specific aesthetic finishes, processes like anodizing[^1] can be applied, further extending the lifespan and appearance of the parts.

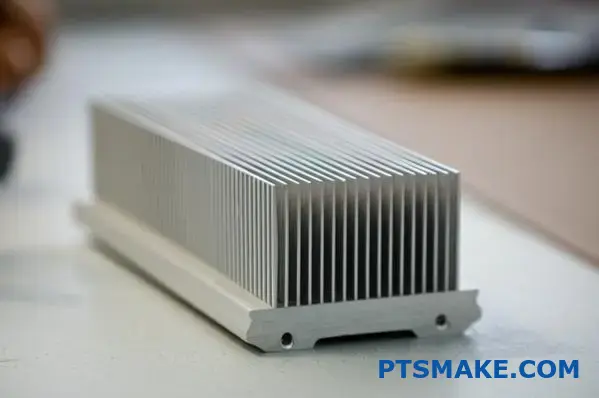

Efficient Thermal Conductivity

Aluminum is an excellent conductor of heat, making it ideal for applications requiring efficient thermal management. Think heat sinks for electronic components, LED lighting fixtures, or engine parts. Custom aluminum profiles can be extruded into intricate shapes with fins and channels designed specifically to maximize surface area and dissipate heat effectively. This property is crucial for maintaining the performance and reliability of sensitive electronic devices.

Understanding Cost-Effectiveness

While raw aluminum might sometimes have a higher initial cost per kilogram than steel, the overall cost-effectiveness often favors custom aluminum profiles. Here’s why:

- Extrusion Process: The extrusion process allows for complex cross-sections to be produced efficiently in long lengths, often reducing the need for subsequent machining operations.

- Bearbetbarhet: Aluminum is easier and faster to machine than steel, leading to lower machining costs and quicker turnaround times, something we optimize for in our CNC machining services at PTSMAKE.

- Lower Shipping Costs: The lighter weight reduces transportation expenses.

- Recyclability: Aluminum is highly recyclable without loss of quality, contributing to sustainability and potentially lower long-term material costs.

Here’s a simplified comparison of key properties:

| Funktion | Custom Aluminum Profiles | Steel (Typical Mild) |

|---|---|---|

| Density (approx.) | ~2.7 g/cm³ | ~7.85 g/cm³ |

| Motståndskraftig mot korrosion. | Utmärkt | Poor (requires coating) |

| Thermal Conduct. | Hög | Måttlig |

| Bearbetbarhet | Utmärkt | Medelgod till god |

Choosing custom aluminum profiles empowers engineers to create innovative, efficient, and durable products tailored precisely to their needs.

Design Considerations for Custom Aluminum Profile Applications

Ever think about what makes or breaks a custom aluminum profile design? It’s more than just the shape; key design choices are vital for performance and production feasibility. Let’s get into the critical factors.

Successful custom aluminum profiles depend heavily on smart design choices regarding wall thickness, achievable tolerances, and overall profile complexity. Getting these right ensures optimal performance and smooth manufacturing.

Designing for custom aluminum profiles involves balancing the desired form and function with the realities of the aluminum extrusion process. Overlooking key considerations early on can lead to manufacturing challenges, increased costs, or parts that don’t meet performance expectations. Based on our experience at PTSMAKE helping clients refine their designs, focusing on a few core areas makes a significant difference.

Wall Thickness: Finding the Balance

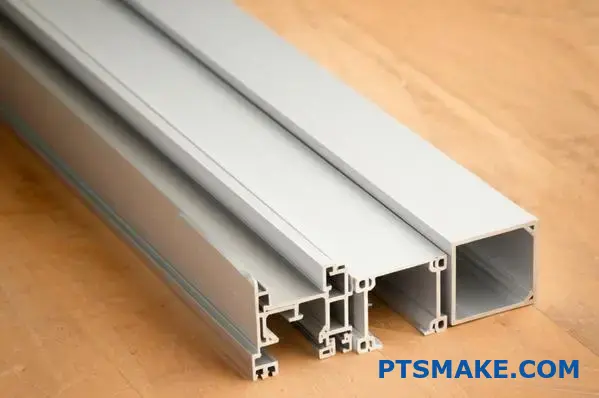

Wall thickness is a fundamental aspect of profile design. Extrusion dies have limitations on how thin or thick walls can be reliably produced.

Minimum and Maximum Thickness

Generally, very thin walls (often below 1mm, depending on the alloy and profile size) can be difficult to extrude consistently and may lack structural integrity. Conversely, excessively thick sections can lead to longer cooling times and potential internal stresses. It’s crucial to work within the practical limits advised by your manufacturing partner.

Uniformity Matters

Ideally, wall thicknesses should be as uniform as possible throughout the profile. Significant variations can cause uneven metal flow during extrusion and differential cooling rates, potentially leading to warping or dimensional inaccuracies. When variations are necessary, transitions should be gradual.

Tolerance Specifications: Precision vs. Practicality

Tolerances define the acceptable deviation from the specified dimensions. While aluminum extrusion can achieve relatively tight tolerances compared to other processes, demanding unnecessary precision significantly increases costs.

Standard vs. Precision Tolerances

Industry standards define typical achievable tolerances for various profile dimensions (e.g., wall thickness, angles, flatness). Requesting tolerances tighter than standard requires more precise tooling, slower extrusion speeds, and potentially additional quality control steps. Understanding the principles of Geometric Dimensioning and Tolerancing (GD&T)1 can be very helpful here.

Here’s a quick comparison:

| Toleransnivå | Kostnadspåverkan | Påverkan på ledtid | Typiskt användningsfall |

|---|---|---|---|

| Standard | Lägre | Kortare | General structural, architectural |

| Precision | Högre | Längre | Interlocking parts, high-tech equip. |

Always question if the tightest possible tolerance is truly necessary for the part’s function.

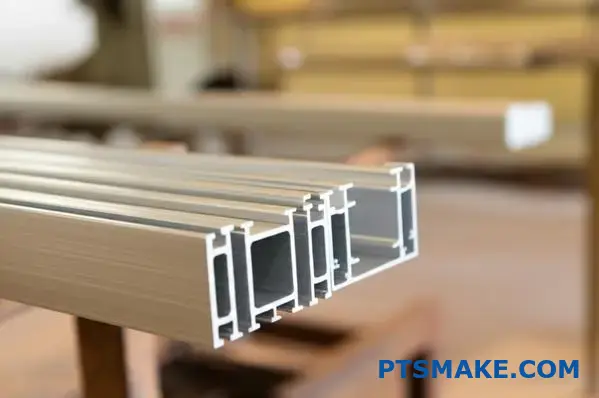

Profile Complexity: Designing for Manufacturability

The beauty of extrusion is its ability to create complex shapes, but complexity has limits and implications.

Intricate Features

Features like deep, narrow channels, sharp corners, or complex hollow sections increase tooling complexity and cost. They can also slow down the extrusion process as the metal flow becomes more challenging to manage. Sometimes, a slightly simplified design achieves the same functional goal with better manufacturability. At PTSMAKE, we often work with clients on design for manufacturability (DFM) reviews for their custom aluminum profiles to identify potential issues early.

Material Selection Guide for Aluminum Extrusion Profiles

Choosing the right metal is like picking the perfect tool for a job – get it wrong, and things get complicated. When it comes to custom aluminum profiles, selecting the correct alloy is the first step towards success.

Selecting the optimal aluminum alloy, such as 6061 for strength or 6063 for finish, is critical for custom aluminum profiles. This choice directly influences the profile’s strength, surface quality, and performance in its final application.

Aluminum isn’t just one material; it comes in various alloys, each with unique characteristics. The 6xxx series, containing magnesium and silicon, is incredibly popular for extrusion because it balances strength, extrudability, and corrosion resistance well. Think of alloys as different recipes, each tweaked for a specific outcome. Making the right selection early on prevents headaches during manufacturing and ensures your final product performs as expected. In our work at PTSMAKE, guiding clients through this selection for their custom aluminum profiles is a common and critical part of the process.

Common Alloys for Custom Profiles

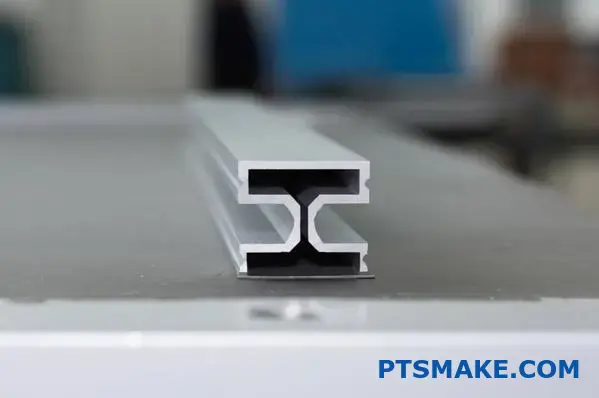

While many alloys exist, two dominate the custom aluminum profile landscape: 6061 and 6063.

6061 Alloy: The Workhorse

This is arguably the most versatile and widely used aluminum alloy. It offers excellent mechanical properties, good strength, and good weldability and machinability. We often see 6061 specified for structural components, machine parts, and applications where durability is paramount. If you need a profile that can handle significant stress or load, 6061 is usually the go-to choice. Its balance makes it suitable for many precision parts we manufacture.

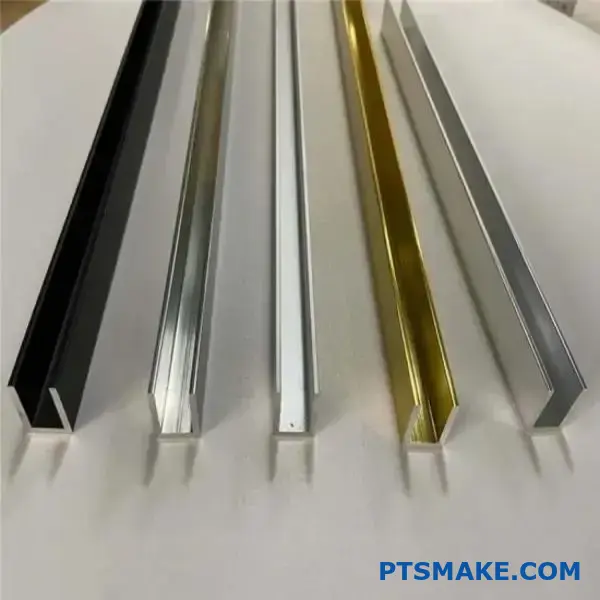

6063 Alloy: The Architect’s Choice

Known for its superb surface finish and excellent corrosion resistance, 6063 is often called the "architectural alloy." It extrudes easily into complex shapes, making it perfect for window frames, door frames, decorative trim, and intricate heat sinks. While not as strong as 6061, its aesthetic qualities and ability to be easily anodized make it ideal when appearance matters most.

Other Considerations

Beyond these two, other alloys like the 5xxx series (good for marine environments due to corrosion resistance) or the 7xxx series (very high strength, used in aerospace) exist but are typically chosen for more specialized custom aluminum profiles. The key is matching the alloy’s strengths to the application’s demands.

Impact on Key Properties

The choice between alloys like 6061 and 6063 directly impacts the final profile’s characteristics. The Temper designation2, which indicates the heat treatment process used, further refines these properties, affecting hardness and strength.

Here’s a simple comparison based on our experience:

| Funktion | 6061 Alloy | 6063 Alloy |

|---|---|---|

| Styrka | Högre | Måttlig |

| Ytfinish | Bra | Utmärkt |

| Extrudability | Good (for moderate complexity) | Excellent (for complex shapes) |

| Corrosion Res. | Bra | Utmärkt |

| Relativ kostnad | Slightly Higher | Standard |

Understanding these differences is crucial. Choosing 6061 for a highly complex, decorative profile might lead to extrusion difficulties, while using 6063 for a heavily loaded structural part could compromise safety. Consulting with your manufacturing partner ensures the selected alloy and temper truly fit your custom aluminum profile needs.

Value-Added Finishing Options for Custom Aluminum Profiles

Your custom aluminum profile is extruded, but is it truly finished? The raw metal is just the start; the right surface treatment unlocks its full potential for looks and longevity.

Enhance your custom aluminum profiles with finishing options like anodizing for durability, powder coating for vibrant color, or mechanical brushing for unique textures, boosting both aesthetics and performance.

Selecting the right finish for your custom aluminum profiles is as important as choosing the right alloy. It’s not just about appearance; finishes provide crucial protection against wear, corrosion, and environmental factors, while also adding specific functional benefits. At PTSMAKE, we guide clients through these options to ensure the final part meets every requirement. Let’s compare some popular choices.

Anodizing: Durable and Protective

Anodisering är en elektrokemisk process3 that thickens the natural oxide layer on the surface of aluminum. This creates a very hard, durable, and corrosion-resistant coating that’s integrated with the aluminum itself, not just layered on top.

Viktiga fördelar:

- Hållbarhet: Excellent resistance to abrasion and wear.

- Motståndskraft mot korrosion: Significantly enhances protection against weathering and chemicals.

- Color Options: Can be dyed during the process to achieve various colors, often with a metallic sheen. Clear anodizing maintains the aluminum look while adding protection.

- Non-Conductive: The anodic layer is typically an electrical insulator.

Powder Coating: Colorful and Tough

Powder coating involves applying a dry powder electrostatically and then curing it under heat. This creates a thick, durable finish that’s more resistant to chipping, scratching, and fading than traditional liquid paints.

Viktiga fördelar:

- Wide Color Range: Virtually unlimited color and texture options (gloss, matte, textured).

- Hållbarhet: Creates a tough, flexible finish resistant to impact and abrasion.

- Environmental: Generally produces fewer volatile organic compounds (VOCs) than liquid painting.

- Coverage: Good for covering minor surface imperfections on custom aluminum profiles.

Mechanical Finishes: Texture and Appearance

These finishes alter the surface texture through physical means before any coating is applied.

Borstning

Creates a distinctive look with fine, parallel lines, giving a satin or textured appearance. Often followed by clear anodizing or coating for protection.

Polering

Achieves a mirror-like, highly reflective surface. Primarily used for decorative applications and requires careful handling to maintain the finish.

Specialiserade ytbehandlingar

Other treatments exist for specific needs, such as chromate conversion coatings (used as a primer or for corrosion resistance, though environmental regulations are reducing its use) or specialized coatings for enhanced thermal dissipation or non-stick properties.

Here’s a quick comparison to help guide your choice:

| Alternativ för efterbehandling | Primär förmån | Estetik | Durability/Protection | Relativ kostnad |

|---|---|---|---|---|

| Anodisering | Motståndskraft mot korrosion | Metallic Sheen, Various Colors | Utmärkt | Måttlig |

| Pulverlackering | Color Variety/Toughness | Wide Color/Texture Range | Mycket bra | Måttlig |

| Borstning | Unique Texture | Satin, Linear Pattern | Low (needs topcoat) | Låg-Måttlig |

| Polering | Hög reflektionsförmåga | Mirror-like | Low (needs topcoat) | Hög |

Choosing the best finish depends on the end-use environment, desired look, performance requirements, and budget for your custom aluminum profiles. Considering these factors early in the design process ensures the final product is both functional and visually appealing.

Secondary Fabrication Capabilities for Custom Extrusions

Raw aluminum extrusions hold immense potential, but how do they transform into the precise components your project demands? It takes more than just the initial shape; specialized secondary operations are key.

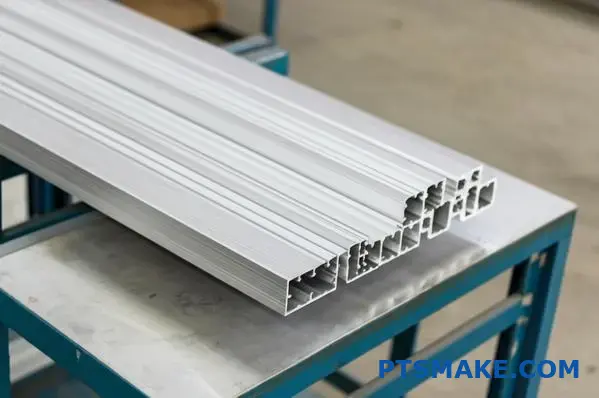

Secondary fabrication turns basic custom aluminum profiles into application-ready parts via precision cutting, CNC machining, punching, drilling, and assembly, providing comprehensive solutions tailored to specific needs.

Once a custom aluminum profile emerges from the extrusion die, it’s often just a starting point. To make it truly useful, it usually needs further refinement. These secondary fabrication steps add the necessary features and precision, transforming a length of shaped aluminum into a functional component ready for integration. Based on our experience at PTSMAKE helping clients achieve their design goals, understanding these capabilities is crucial.

Precision Cutting to Length

The first step is often cutting the long extruded lengths into specific part sizes. Accuracy here is vital, especially for parts that need to fit perfectly within an assembly. Common methods include high-speed saws for clean, straight cuts or laser cutting for more complex shapes or thinner materials. Ensuring cuts are burr-free and dimensionally accurate prevents issues down the line.

CNC Machining: Adding Complexity

Extrusion creates the cross-section, but CNC (Computer Numerical Control) machining adds features along the length or on the faces of the profile. This is essential for creating holes, slots, pockets, threads, chamfers, and complex contours not achievable through extrusion alone. At PTSMAKE, our precision CNC machining services are frequently employed to add these critical details to custom aluminum profiles, ensuring they meet tight tolerance requirements for demanding applications in sectors like electronics and robotics.

Punching and Drilling

For creating simpler holes or patterns, punching and drilling offer cost-effective alternatives to full CNC machining.

Punching uses a die to quickly create holes of specific shapes and sizes, ideal for repetitive patterns on flat surfaces of the profile.

Drilling is versatile for creating round holes of various diameters and depths. Both are effective for adding mounting points or passage ways to custom aluminum profiles.

Assembly Services: The Complete Package

Often, the final product requires more than just a single fabricated profile. Assembly services bring everything together. This can involve joining multiple extrusions using fasteners or specialized joining techniques, adding gaskets, installing hardware like brackets or end caps, or integrating the aluminum profile with components made from other materials. Managing tolerance stack-up4 becomes critical in assembly to ensure proper fit and function, something we meticulously manage in our projects. Offering assembly provides a streamlined, single-source solution for our clients.

Here’s a quick comparison of common secondary operations:

| Drift | Typisk användning | Precision Level | Relative Speed | Relativ kostnad |

|---|---|---|---|---|

| Skärande | Sizing parts | Good to High | Snabb | Låg |

| CNC-bearbetning | Complex features, tight tolerances | Mycket hög | Måttlig | Högre |

| Punching | Simple holes, patterns | Måttlig | Mycket snabb | Låg-Måttlig |

| Borrning | Round holes | Bra | Måttlig | Låg-Måttlig |

| Montering | Integrating multiple components | Varierande | Varierande | Varierande |

By leveraging these secondary fabrication capabilities, raw custom aluminum profiles are transformed into precise, functional components ready for their final application.

Industry-Specific Applications for Custom Aluminum Profiles

Have you ever stopped to consider how the lightweight frame of a high-speed train or the sleek housing of your laptop are made? Often, the answer lies in the remarkable versatility of custom aluminum profiles tailored for specific jobs.

Custom aluminum profiles are indispensable across diverse sectors, including automotive, aerospace, medical, electronics, and architecture, meeting unique demands for strength, weight reduction, precision, thermal management, and aesthetics.

The adaptability of custom aluminum profiles makes them a go-to solution for engineers and designers facing unique challenges in various fields. Their ability to be extruded into complex shapes, combined with aluminum’s inherent beneficial properties, allows for highly optimized components. At PTSMAKE, we’ve collaborated on projects across many of these sectors, seeing firsthand how tailored profiles solve specific problems. Let’s look at some key industries.

Automotive Advancements

In the automotive world, every gram counts. Lighter vehicles mean better fuel efficiency and performance. Custom aluminum profiles are extensively used for:

- Structural Components: Creating strong yet lightweight frames, chassis parts, and reinforcement structures.

- Crash Management Systems: Designing profiles that absorb impact energy effectively, enhancing safety.

- Battery Housings: For electric vehicles, aluminum profiles provide durable, lightweight, and thermally conductive enclosures for battery packs.

Our experience includes machining features onto profiles used in specialized vehicle sub-assemblies.

Aerospace Engineering

Weight reduction is even more critical in aerospace. Custom aluminum profiles, often made from high-strength alloys (like the 7xxx series mentioned earlier, though requiring specialized processing), are essential for:

- Aircraft Structures: Fuselage stringers, wing spars, and floor beams benefit from the high strength-to-weight ratio.

- Interior Components: Seat tracks, luggage racks, and galley structures utilize aluminum for durability without excessive weight penalties.

Tillverkning av medicintekniska produkter

Precision and cleanliness are paramount in the medical field. Custom aluminum profiles offer:

- Equipment Frames: Used for diagnostic machines, hospital beds, and mobility aids, providing stable, corrosion-resistant structures.

- Instrument Housings: Easily machinable profiles create precise enclosures for sensitive medical electronics. Anodized finishes provide a cleanable, durable surface.

Elektronik och teknik

Managing heat and providing sleek, durable enclosures are key in electronics. Custom aluminum profiles excel here:

- Heat Sinks5: Aluminum’s excellent thermal conductivity allows complex profile shapes to efficiently dissipate heat from CPUs, LEDs, and power supplies.

- Enclosures and Casings: Laptops, tablets, servers, and other devices use custom profiles for robust, lightweight, and aesthetically pleasing housings. PTSMAKE frequently machines features onto such profiles for clients in the consumer electronics sector.

Arkitektoniska tillämpningar

Architects value aluminum for its design flexibility, durability, and finish options.

- Window and Door Frames: 6063 alloy profiles provide excellent weather resistance and can be finished to match any design aesthetic.

- Curtain Walling and Facades: Large, complex profiles create modern building exteriors.

- Structural Framing Systems: Used for partitions, ceilings, and support structures.

Here’s a summary of how custom aluminum profiles meet industry needs:

| Industri | Viktiga krav | Vanliga tillämpningar |

|---|---|---|

| Fordon | Lightweight, Strength, Crashworthiness, Cost-Effective | Frames, Battery Housings, Trim, Heat Exchangers |

| Flyg- och rymdindustrin | Extreme Lightweight, High Strength, Durability | Structural Beams, Seat Tracks, Interior Fittings |

| Medicinsk | Precision, Cleanliness, Corrosion Resistance | Equipment Frames, Instrument Housings, Mobility Aids |

| Elektronik | Thermal Management, EMI Shielding, Aesthetics | Heat Sinks, Enclosures, Casings, Mounting Rails |

| Arkitektonisk | Aesthetics, Corrosion Resistance, Design Flexibility | Window/Door Frames, Facades, Curtain Walls, Railings |

The specific demands of each industry drive the innovation in custom aluminum profiles, making them a cornerstone material in modern manufacturing.

Cost Optimization Strategies for Custom Profile Projects

Looking to leverage custom aluminum profiles without straining your budget? Smart planning and strategic decisions are key. Discover how to achieve high-quality results cost-effectively for your next precision manufacturing project. Let’s dive in.

Optimize custom aluminum profile project costs through careful die design, selecting cost-effective materials like 6063 where feasible, simplifying profile complexity, and planning production volumes strategically to maximize economies of scale.

Getting the most value from custom aluminum profiles involves more than just the initial design; it requires a deliberate approach to cost management throughout the project lifecycle. In past projects at PTSMAKE, we’ve seen significant savings achieved by focusing on a few key areas without compromising the final part’s quality or function.

Optimizing the Extrusion Die

The extrusion die itself represents a significant initial investment. More complex profile shapes naturally require more intricate and costly dies.

Die Complexity vs. Cost

Simpler, more symmetrical designs generally lead to less expensive and more robust dies. Minimizing features like extremely sharp internal corners or very thin walls can reduce tooling costs.

Die Longevity and Reusability

Discussing expected project lifespan with your manufacturing partner helps. A well-maintained die can be used for multiple production runs, spreading the initial cost over more parts.

Strategiskt materialval

As discussed previously, aluminum alloys vary in price.

Balans mellan kostnad och prestanda

While 6061 offers higher strength, the more readily extrudable 6063 alloy is often sufficient and more cost-effective for applications where extreme strength isn’t the primary concern, like architectural trim or some electronic enclosures. Always evaluate if a standard alloy meets the needs before opting for more specialized, expensive options.

Simplifying Profile Design

Every feature adds cost, either in tooling or processing.

Tolerance Review

Are those ultra-tight tolerances absolutely necessary for function? Relaxing non-critical tolerances can significantly reduce manufacturing complexity and scrap rates.

Feature Reduction

Can multiple features be combined? Can a complex hollow be replaced with a simpler shape that achieves the same goal? Engaging in Design for Manufacturability (DFM) reviews early can identify simplification opportunities for custom aluminum profiles.

Volume Planning and Its Impact

Production volume heavily influences the per-part cost.

Stordriftsfördelar

Higher volumes generally mean lower unit costs due to efficiencies in setup, extrusion runs, and material purchasing.

Understanding Die Amortization

The initial die cost is often spread across the first production run. Understanding die amortization6 – how this cost is allocated per part – helps in planning optimal order quantities. Ordering too few parts results in a high per-part die cost.

Here’s how volume might affect relative unit cost (excluding material):

| Produktionsvolym | Die Cost / Part | Setup Cost / Part | Running Cost / Part | Relative Total Unit Cost |

|---|---|---|---|---|

| Low (e.g., 500m) | Hög | Hög | Standard | Mycket hög |

| Med (e.g., 2000m) | Måttlig | Måttlig | Standard | Måttlig |

| High (e.g., 10000m) | Låg | Låg | Standard | Låg |

Strategic planning across these areas ensures your custom aluminum profile project achieves its technical goals efficiently and economically.

Selecting the Right Custom Profile Manufacturing Partner

Choosing a manufacturing partner for your custom aluminum profiles can feel overwhelming, right? Get it wrong, and you risk delays and quality issues. Get it right, and your project flows smoothly from concept to completion.

Selecting the best custom aluminum profile manufacturer involves evaluating their technical capabilities, verifying quality certifications, assessing prototype support, and ensuring supply chain reliability and clear communication for project success.

Finding the right partner for your custom aluminum profiles goes far beyond just comparing quotes. It’s about finding a collaborator who truly understands your needs and has the proven ability to deliver consistently high-quality parts, on time. This decision directly impacts your product’s success and your peace of mind. In past projects at PTSMAKE, we’ve seen how a strong partnership built on trust and capability prevents costly errors and delays down the line. Let’s break down the critical factors to consider.

Assessing Technical Capabilities

First, ensure the potential partner has the necessary technical expertise and equipment. Do they specialize in the aluminum alloys you need? Can they handle the complexity and tolerances your design requires? Look beyond just extrusion. Do they offer the secondary fabrication services you need, such as precision CNC machining, cutting, punching, or finishing? A partner with comprehensive in-house capabilities, like we strive to provide at PTSMAKE, can streamline the process, reduce lead times, and ensure better quality control over the entire production cycle for your custom aluminum profiles. Ask about their specific machinery and process controls.

Quality Certifications and Systems

Quality shouldn’t be an afterthought. Look for manufacturers with recognized quality certifications, such as ISO 9001. This indicates they have established and adhere to standardized processes for quality control. However, don’t stop at the certificate. Inquire about their specific Quality Management System (QMS)7. How do they handle inspections? What are their defect rates? A reliable partner will be transparent about their quality processes and provide documentation if requested.

Prototyping and Support

Especially for new or complex custom aluminum profiles, the ability to create prototypes is invaluable. Does the manufacturer offer rapid prototyping services? This allows you to test and validate your design before committing to expensive production tooling. Equally important is their level of engineering support. A good partner acts as an extension of your team, offering Design for Manufacturability (DFM) feedback to optimize your design for efficient production and cost-effectiveness.

Supply Chain and Communication

Reliability is key. Investigate their track record for on-time delivery. What are their typical lead times for extrusion and secondary operations? Clear, consistent communication is also vital. How responsive are they to inquiries? Do you have a dedicated point of contact? A partner who communicates proactively, especially if issues arise, can save significant headaches. Also, consider their supply chain stability – where do they source their raw aluminum, and do they have contingency plans?

Here’s a summary table to guide your evaluation:

| Faktor | Betydelse | Vad ska man leta efter? |

|---|---|---|

| Technical Fit | Mycket hög | Expertise in your alloy/complexity, In-house secondary fabrication (CNC, finish) |

| Quality Systems | Mycket hög | ISO 9001 Certification, Transparent QMS procedures, Inspection reports |

| Prototyping/Support | Hög | Rapid prototyping capability, DFM feedback, Engineering assistance |

| Delivery/Reliability | Mycket hög | Proven on-time delivery record, Stated lead times, Stable material sourcing |

| Kommunikation | Hög | Responsiveness, Dedicated contact person, Proactive updates |

| Kostnad | Måttlig-Hög | Clear quoting, Value for services offered (not just lowest price) |

Choosing the right manufacturing partner is a strategic decision. Thoroughly evaluating these factors will help you build a successful long-term relationship for your custom aluminum profile needs.

Learn more about how GD&T ensures your part functions precisely as intended in assemblies. ↩

Understand how heat treatment affects aluminum’s final strength and hardness properties. ↩

Learn how this process modifies the aluminum surface itself for superior protection. ↩

Essential for ensuring assembled parts fit and function correctly. ↩

Explore how custom profiles optimize thermal performance in electronic devices. ↩

See how spreading the initial tooling investment impacts your per-part price. ↩

Understand how a structured QMS ensures consistent part quality and reliability. ↩