I often hear engineers debating about material choices for their projects. When it comes to durability, the titanium versus stainless steel comparison is a common source of confusion. Many professionals waste time and money making the wrong choice between these metals.

Titanium generally lasts longer than stainless steel due to its superior corrosion resistance and higher strength-to-weight ratio. While both metals are durable, titanium’s natural oxide layer provides better protection against environmental damage and chemical exposure.

I help companies make smart material choices every day at PTSMAKE. Let me share what matters most when choosing between titanium and stainless steel. We’ll look at their key properties, ideal applications, and how to select the right one for your project.

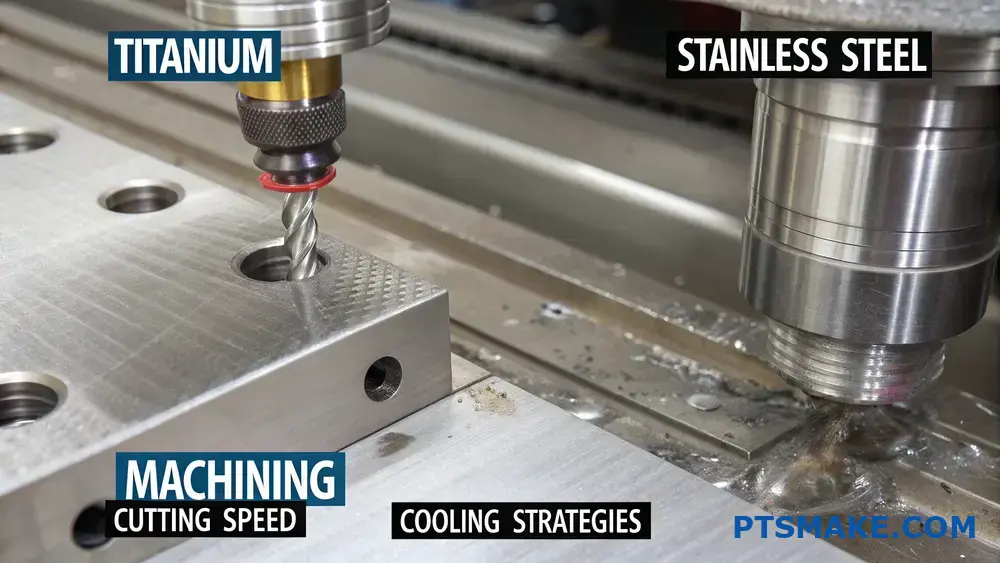

Is Titanium Harder To Machine Than Stainless Steel?

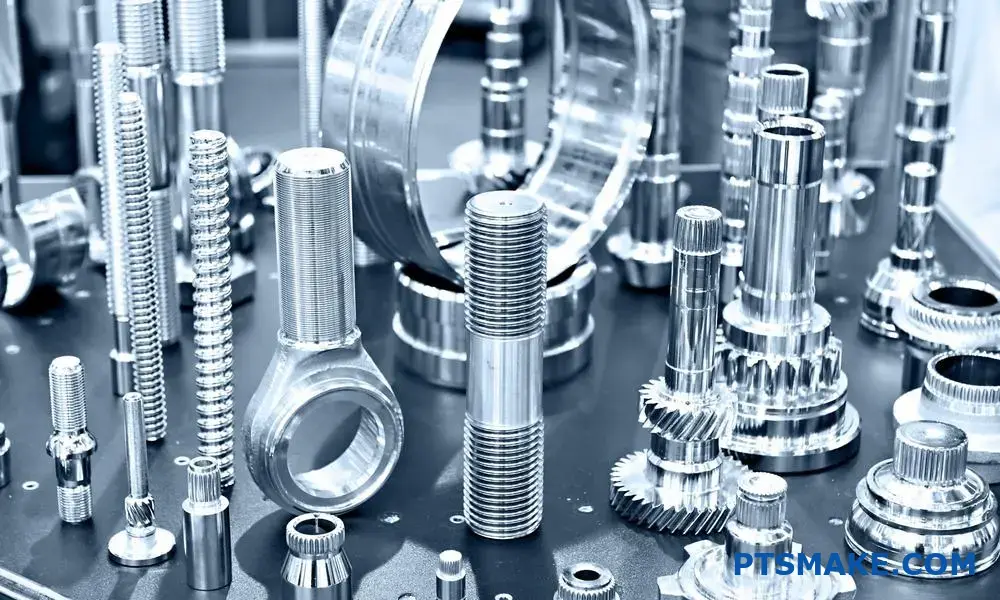

When it comes to machining metals, many engineers and manufacturers often struggle with titanium and stainless steel. I frequently receive questions about which material is more challenging to machine, as choosing the wrong approach can lead to costly tool wear, extended production times, and quality issues.

While both materials present unique challenges, titanium is generally harder to machine than stainless steel due to its lower thermal conductivity, higher chemical reactivity, and tendency to work harden. These properties make titanium approximately 30% more difficult to machine compared to common stainless steel grades.

Understanding Material Properties

The key to successful machining lies in understanding the fundamental properties of both materials. During my experience at PTSMAKE, I’ve observed how these properties directly impact machining operations.

Thermal Conductivity

Titanium’s low thermal conductivity poses a significant challenge. When machining titanium, about 80% of the generated heat remains concentrated at the cutting edge, while stainless steel better dissipates heat throughout the workpiece. This characteristic of titanium leads to:

- Accelerated tool wear

- Increased risk of thermal damage

- Need for specialized cooling strategies

Work Hardening Characteristics

The strain hardening rate1 varies significantly between these materials. Here’s a detailed comparison:

| Property | Titanium | Stainless Steel |

|---|---|---|

| Initial Hardness | Lower | Higher |

| Work Hardening Speed | Very Rapid | Moderate |

| Depth of Hardened Layer | Deep | Shallow |

| Impact on Tool Life | Severe | Moderate |

Cutting Parameters and Tool Selection

Speed and Feed Rates

At PTSMAKE, we’ve developed specific parameters for both materials:

Titanium:

- Cutting speeds: 30-60 surface feet per minute (SFM)

- Feed rates: 0.002-0.005 inches per revolution (IPR)

Stainless Steel:

- Cutting speeds: 70-100 SFM

- Feed rates: 0.004-0.008 IPR

Tool Material Requirements

The choice of cutting tools significantly impacts machining success:

| Tool Material | Titanium Compatibility | Stainless Steel Compatibility |

|---|---|---|

| Carbide | Excellent | Good |

| HSS | Poor | Moderate |

| Ceramic | Not Recommended | Good |

| CBN | Limited Use | Excellent |

Process Control Considerations

Coolant Strategy

Proper coolant application is crucial for both materials but especially critical for titanium:

High-Pressure Cooling

- Titanium requires 1000+ PSI

- Stainless steel operates well at 300-500 PSI

Coolant Type

- Titanium: Oil-based coolants preferred

- Stainless Steel: Water-soluble coolants effective

Machine Rigidity Requirements

Machine setup plays a vital role in successful machining:

Titanium demands:

- Higher machine rigidity

- More robust workholding

- Enhanced vibration control

- Premium tool holders

Stainless Steel allows:

- Standard machine setups

- Conventional workholding

- Normal vibration control measures

Cost Implications

The challenges of machining titanium translate directly to costs:

| Cost Factor | Titanium | Stainless Steel |

|---|---|---|

| Tool Wear Rate | High | Moderate |

| Machine Time | 30-40% More | Baseline |

| Coolant Usage | Higher | Standard |

| Setup Requirements | Complex | Standard |

Quality Control Methods

Quality assurance requires different approaches for each material:

Surface Finish

Titanium often requires:

- Multiple finishing passes

- Special surface treatment

- Careful tool path planning

Stainless Steel typically needs:

- Standard finishing passes

- Normal surface treatment

- Regular tool paths

Dimensional Accuracy

Both materials require careful monitoring, but titanium’s thermal properties make it more prone to dimensional changes during machining.

Best Practices for Success

Based on our experience at PTSMAKE, here are key recommendations:

For Titanium:

- Use rigid setups

- Maintain sharp tools

- Apply high-pressure coolant

- Monitor tool wear closely

- Implement specialized cutting strategies

For Stainless Steel:

- Use appropriate speeds and feeds

- Select correct tool geometries

- Apply adequate cooling

- Monitor work hardening

- Maintain consistent cutting parameters

Is Titanium Difficult To Machine?

When customers approach me about titanium machining, I often sense their hesitation. They’ve heard stories about melted tools, scrapped parts, and costly production delays. The challenges of machining titanium keep many manufacturers awake at night, wondering if their projects are doomed before they begin.

Yes, titanium is generally more difficult to machine compared to common metals like aluminum or mild steel. This is due to its high strength-to-weight ratio, low thermal conductivity, and strong chemical reactivity with cutting tools. However, with proper techniques and parameters, titanium can be machined successfully.

Understanding Titanium’s Unique Properties

Titanium’s distinctive characteristics make it both valuable and challenging to machine. The metal’s work hardening2 behavior means that as we cut it, the material becomes increasingly harder. At PTSMAKE, we’ve developed specialized approaches to handle these unique properties:

Chemical and Physical Properties

- Low thermal conductivity (7.2 W/m·K)

- High strength-to-weight ratio

- Strong chemical reactivity

- High elastic modulus

Impact on Machining Operations

The following table shows how titanium’s properties affect different machining aspects:

| Property | Impact on Machining | Solution Strategy |

|---|---|---|

| Low Thermal Conductivity | Heat concentration at cutting edge | Use proper cooling methods |

| High Strength | Increased cutting forces | Reduce cutting speed |

| Chemical Reactivity | Tool wear acceleration | Select appropriate tool coating |

| Work Hardening | Surface hardening during cuts | Maintain constant chip load |

Critical Factors in Titanium Machining

Cutting Speed Considerations

When machining titanium, cutting speed is crucial. I recommend:

- Using speeds 50-60% lower than those used for steel

- Maintaining consistent feed rates

- Avoiding stops during cutting operations

Tool Selection and Management

Tool selection significantly impacts success rates:

- Carbide tools with specialized coatings

- Sharp cutting edges

- Regular tool wear monitoring

- Proper tool holder selection

Cooling Strategies

Effective cooling is essential for titanium machining:

- High-pressure coolant delivery

- Through-tool cooling when possible

- Abundant coolant flow

- Proper coolant concentration

Best Practices for Successful Titanium Machining

Machine Setup Requirements

For optimal results:

- Use rigid machine tools

- Ensure proper workpiece clamping

- Minimize tool overhang

- Check machine alignment regularly

Process Parameters

I’ve found these parameters crucial for success:

| Operation Type | Speed (SFM) | Feed Rate (IPR) | Depth of Cut (inches) |

|---|---|---|---|

| Roughing | 150-250 | 0.008-0.015 | 0.040-0.150 |

| Finishing | 250-400 | 0.004-0.008 | 0.010-0.030 |

| Drilling | 100-150 | 0.004-0.006 | N/A |

Quality Control Measures

Maintaining quality requires:

- Regular dimensional checks

- Surface finish monitoring

- Tool wear inspection

- Temperature monitoring

Industry-Specific Applications

Aerospace Applications

In aerospace, titanium machining demands:

- Strict tolerance adherence

- Certified material traceability

- Specialized finishing techniques

- Complex geometry capabilities

Medical Device Manufacturing

Medical applications require:

- Biocompatible surface finish

- Ultra-precise tolerances

- Clean room conditions

- Validated processes

Cost Considerations and ROI

Investment Requirements

Successfully machining titanium requires:

- High-end machine tools

- Quality cutting tools

- Advanced cooling systems

- Skilled operators

Long-term Benefits

Despite higher initial costs, titanium machining offers:

- Higher part value

- Market differentiation

- Expanded capabilities

- Enhanced reputation

At PTSMAKE, we’ve invested heavily in titanium machining capabilities, allowing us to serve demanding industries like aerospace and medical devices. Our experience shows that while titanium is challenging to machine, the right approach makes it manageable and profitable.

The key to successful titanium machining lies in understanding its unique properties and adapting your processes accordingly. With proper planning, equipment, and expertise, manufacturers can overcome the challenges and successfully produce high-quality titanium components.

Why Use Titanium Instead Of Stainless Steel?

Selecting between titanium and stainless steel isn’t as straightforward as many engineers think. I’ve seen many projects fail because of incorrect material selection. The wrong choice can lead to component failure, increased maintenance costs, and project delays.

Titanium outperforms stainless steel in specific applications due to its superior strength-to-weight ratio, excellent corrosion resistance, and biocompatibility. While it’s more expensive, titanium’s unique properties make it the preferred choice for aerospace, medical, and marine applications.

Material Properties Comparison

When comparing titanium and stainless steel, we need to examine several key properties. The most significant difference lies in their crystalline structure3, which affects their performance characteristics. Let me break down the main differences:

| Property | Titanium | Stainless Steel |

|---|---|---|

| Density | 4.5 g/cm³ | 8.0 g/cm³ |

| Tensile Strength | 350-1200 MPa | 515-827 MPa |

| Corrosion Resistance | Excellent | Good |

| Cost per kg | $35-50 | $4-6 |

| Thermal Conductivity | Low | Moderate |

Strength-to-Weight Advantages

Superior Weight Efficiency

At PTSMAKE, I’ve worked with numerous aerospace clients who choose titanium specifically for its exceptional strength-to-weight ratio. Titanium offers nearly the same strength as steel but at 45% less weight. This weight reduction translates into:

- Improved fuel efficiency in aerospace applications

- Reduced energy consumption in moving parts

- Better performance in high-speed applications

Fatigue Resistance

The fatigue properties of titanium are remarkable, especially in applications involving cyclic loading:

- Higher endurance limit compared to stainless steel

- Better performance under repeated stress

- Longer component lifespan in dynamic applications

Corrosion Resistance Benefits

Chemical Stability

Titanium’s exceptional corrosion resistance comes from its ability to form a stable oxide layer. This makes it particularly valuable in:

- Marine environments

- Chemical processing

- Medical implants

Environmental Performance

In harsh environments, titanium demonstrates superior resistance to:

- Salt water corrosion

- Chemical attack

- High-temperature oxidation

Application-Specific Considerations

Aerospace Applications

In aerospace manufacturing, titanium is often the preferred choice due to:

- High strength at elevated temperatures

- Excellent fatigue resistance

- Compatible with composite materials

Medical Applications

The biocompatibility of titanium makes it ideal for:

- Surgical implants

- Medical devices

- Dental applications

Cost Analysis and ROI

When evaluating the cost-effectiveness of titanium versus stainless steel, consider:

| Factor | Titanium Impact | Stainless Steel Impact |

|---|---|---|

| Initial Cost | Higher | Lower |

| Maintenance | Minimal | Moderate |

| Lifespan | Extended | Standard |

| Replacement Frequency | Low | Higher |

Manufacturing Challenges

Machining Considerations

At PTSMAKE, we’ve developed specialized processes for machining titanium effectively:

- Requires specific cutting tools and speeds

- Needs proper cooling strategies

- Demands expertise in handling the material

Quality Control

Working with titanium requires:

- Stringent quality control measures

- Advanced inspection techniques

- Specialized handling procedures

Environmental Impact

Sustainability Factors

While titanium has a higher initial environmental impact during production, its benefits include:

- Longer service life

- Reduced maintenance requirements

- Complete recyclability

- Lower operational environmental impact

Industry-Specific Applications

Different industries require different material properties:

| Industry | Titanium Advantage | Stainless Steel Advantage |

|---|---|---|

| Aerospace | Weight savings | Cost-effectiveness |

| Medical | Biocompatibility | Ease of sterilization |

| Marine | Corrosion resistance | Initial cost |

| Chemical | Chemical resistance | Availability |

Through my experience at PTSMAKE, I’ve observed that the choice between titanium and stainless steel often depends on a careful analysis of these factors. While titanium’s higher cost can be a deterrent, its superior properties often justify the investment in critical applications where performance and reliability are paramount.

What Is The Best Material For Cutting Titanium?

Cutting titanium effectively has become a significant challenge in modern manufacturing. Many machinists struggle with tool wear, heat generation, and poor surface finish when machining titanium, leading to increased production costs and reduced efficiency.

The best material for cutting titanium is Carbide with PVD or CVD coating, particularly TiAlN or AlTiN coated tools. These materials provide optimal heat resistance, hardness, and wear resistance necessary for effectively machining titanium and its alloys.

Understanding Tool Materials for Titanium Machining

When it comes to machining titanium, selecting the right cutting tool material is crucial for success. Based on my experience at PTSMAKE, where we regularly machine titanium components for aerospace and medical applications, I’ve found that different tool materials offer varying advantages and limitations.

High-Speed Steel (HSS)

HSS tools are the most basic option, but they’re generally not recommended for titanium machining due to their relatively low heat resistance. The thermal conductivity4 of titanium causes excessive heat buildup at the cutting edge, which quickly degrades HSS tools.

Carbide Tools

Carbide tools represent the most practical and widely used option for titanium machining. They offer:

- Superior hardness at high temperatures

- Better wear resistance

- Longer tool life

- Improved surface finish quality

At PTSMAKE, we primarily use carbide tools with specialized coatings for our titanium machining operations.

Ceramic Tools

While ceramic tools excel in machining other materials, they’re generally not suitable for titanium due to:

- Poor thermal shock resistance

- Tendency to crack under the interrupted cuts

- Chemical reactivity with titanium

Coating Technologies That Enhance Performance

The effectiveness of cutting tools largely depends on their coating. Here are the most effective coatings for titanium machining:

| Coating Type | Benefits | Best Applications |

|---|---|---|

| TiAlN | High heat resistance, excellent wear protection | High-speed machining |

| AlTiN | Superior oxidation resistance, high hardness | Heavy cutting operations |

| TiCN | Good toughness, reduced friction | Medium-duty machining |

| Diamond | Exceptional hardness, low friction | Specific titanium composites |

Optimizing Tool Geometry for Titanium

The geometry of the cutting tool plays a crucial role in successful titanium machining:

Rake Angle Considerations

- Positive rake angles reduce cutting forces

- Typically between 6° to 12° for optimal performance

- Helps prevent work hardening of the titanium

Relief Angle Requirements

- Higher relief angles prevent rubbing

- Recommended range: 10° to 15°

- Reduces heat generation during cutting

Advanced Tool Strategies

To maximize tool life and cutting efficiency when machining titanium, consider these strategies:

Tool Path Optimization

- Maintain consistent chip load

- Avoid sharp directional changes

- Use trochoidal milling techniques

Cutting Parameters

- Lower cutting speeds (30-60 m/min)

- Higher feed rates to maintain productivity

- Adequate depth of cut to prevent work hardening

Special Considerations for Different Titanium Alloys

Different titanium alloys require specific approaches:

Ti-6Al-4V (Grade 5)

- Most common aerospace alloy

- Requires moderate cutting speeds

- Benefits from high-pressure coolant

Ti-6Al-2Sn-4Zr-2Mo

- Higher strength variant

- Needs reduced cutting speeds

- Demands premium grade carbide tools

Industrial Applications and Real-World Examples

At PTSMAKE, we’ve successfully implemented these tool material selections in various applications:

- Aerospace components requiring precise tolerances

- Medical implants with complex geometries

- Racing car parts subject to high stress

- Military equipment components

Cost Considerations and ROI Analysis

While premium cutting tools may have higher initial costs, they often provide better value:

Cost Factors

- Tool life duration

- Machining time efficiency

- Surface finish quality

- Scrap rate reduction

Investment Benefits

- Reduced tool changes

- Increased productivity

- Better part quality

- Lower overall production costs

Environmental and Safety Considerations

Proper tool selection also impacts environmental and safety aspects:

- Reduced coolant consumption

- Lower energy usage

- Improved chip control

- Safer operation conditions

Future Trends in Titanium Machining Tools

The field of titanium machining continues to evolve with:

- Development of new coating technologies

- Advanced tool geometries

- Hybrid tool materials

- Smart tool monitoring systems

Through implementing these material choices and strategies at PTSMAKE, we’ve achieved consistent success in titanium machining operations, delivering high-quality components to our clients in aerospace, medical, and other demanding industries.

How Does Machining Cost Compare Between Titanium And Stainless Steel?

Comparing machining costs between titanium and stainless steel can be a challenging task for many manufacturers. With rising material costs and complex manufacturing requirements, making the wrong choice can significantly impact your project’s budget and timeline.

Based on my manufacturing experience, machining titanium typically costs 2-3 times more than stainless steel due to its higher material price, slower cutting speeds, and specialized tooling requirements. However, the exact cost difference depends on factors like part complexity, volume, and specific grade.

Material Cost Considerations

The base material cost significantly impacts the overall machining expenses. Titanium alloys generally cost 3-5 times more than stainless steel grades. For example, Grade 5 titanium (Ti-6Al-4V) typically ranges from $25-35 per pound, while 316L stainless steel usually costs $5-8 per pound.

Material pricing can fluctuate based on:

- Market demand and availability

- Grade specifications

- Purchase quantity

- Global supply chain conditions

Tooling Requirements and Costs

Cutting Tool Selection

Machining titanium requires specialized cutting tools with specific carbide grades5. At PTSMAKE, we’ve found that these tools often cost 40-60% more than those used for stainless steel. The tool selection impacts:

- Cutting performance

- Tool life

- Surface finish quality

- Overall productivity

Tool Life Comparison

| Material | Average Tool Life | Replacement Frequency | Relative Tool Cost |

|---|---|---|---|

| Titanium | 20-30 parts | Every 2-3 hours | High |

| Stainless Steel | 50-70 parts | Every 6-8 hours | Medium |

Machining Parameters and Productivity

Cutting Speed Differences

Titanium’s poor thermal conductivity and high strength require slower cutting speeds:

- Titanium: 50-150 surface feet per minute (SFM)

- Stainless Steel: 200-400 SFM

This speed difference directly affects production time and costs.

Coolant Requirements

Proper cooling is crucial for both materials but differs in application:

- Titanium needs high-pressure coolant systems

- Stainless steel works with conventional cooling methods

Labor and Machine Time Costs

Hourly Rate Comparison

| Cost Factor | Titanium | Stainless Steel |

|---|---|---|

| Machine Hour Rate | $150-200 | $100-150 |

| Setup Time | 2-3 hours | 1-2 hours |

| Operator Skill Level | Expert | Intermediate |

Production Time Analysis

The slower cutting speeds for titanium result in:

- Longer cycle times

- Increased labor costs

- Higher machine utilization

- Extended project timelines

Quality Control and Inspection Costs

Titanium parts often require:

- More frequent inspections

- Advanced measurement techniques

- Stricter tolerance verification

- Additional surface finish checks

These quality control measures add approximately 15-20% to the overall cost compared to stainless steel parts.

Volume Considerations

The cost difference between titanium and stainless steel machining varies with production volume:

Low Volume Production (1-10 pieces)

- Titanium: $300-500 per piece

- Stainless Steel: $100-200 per piece

Medium Volume Production (11-100 pieces)

- Titanium: $200-400 per piece

- Stainless Steel: $80-150 per piece

High Volume Production (100+ pieces)

- Titanium: $150-300 per piece

- Stainless Steel: $60-120 per piece

Application-Specific Cost Factors

Different industries have varying requirements that affect machining costs:

Aerospace Applications

- Higher material certification costs

- Stricter quality control

- More documentation requirements

Medical Applications

- Special surface finish requirements

- Additional cleaning processes

- Biocompatibility testing

Industrial Applications

- Standard tolerances

- Basic surface finish requirements

- Regular quality control

Cost Optimization Strategies

To help our clients at PTSMAKE optimize machining costs, we recommend:

- Design optimization for manufacturability

- Appropriate material grade selection

- Efficient tooling strategies

- Batch size optimization

- Process parameter optimization

Long-Term Cost Considerations

When evaluating total cost of ownership, consider:

- Material durability

- Maintenance requirements

- Replacement frequency

- Performance benefits

The initial higher cost of titanium machining might be justified by:

- Extended product life

- Reduced maintenance needs

- Better performance characteristics

- Weight savings benefits

What Tool Wear Differences Exist When Machining Titanium VS Stainless Steel?

Machinists often struggle with tool wear when working with titanium and stainless steel. The rapid degradation of cutting tools not only impacts part quality but also leads to frequent tool replacements, causing production delays and increased costs. These challenges can make even experienced manufacturers hesitate.

The primary difference in tool wear between machining titanium and stainless steel lies in their unique material properties. Titanium causes more severe tool wear due to its low thermal conductivity and high chemical reactivity, while stainless steel mainly causes abrasive wear through work hardening and built-up edge formation.

Understanding Material Properties and Their Impact

The way cutting tools wear during machining is directly influenced by the properties of the workpiece material. At PTSMAKE, we’ve observed that the work hardening rate6 of these materials plays a crucial role in tool deterioration. Let me break down the key differences:

Thermal Conductivity Effects

Titanium:

- Extremely low thermal conductivity (7 W/m·K)

- Heat concentrates at the cutting edge

- Causes rapid tool deterioration

- Requires enhanced cooling strategies

Stainless Steel:

- Moderate thermal conductivity (16 W/m·K)

- Better heat distribution

- More predictable tool wear patterns

- Standard cooling methods usually sufficient

Types of Tool Wear Mechanisms

For Titanium Machining

Chemical Wear

- Rapid diffusion between tool and workpiece

- Formation of titanium carbide layer

- Accelerated crater wear on tool face

Thermal Wear

- High cutting temperatures (up to 1000°C)

- Softening of tool material

- Plastic deformation of cutting edge

Mechanical Wear

- Chipping due to interrupted cutting

- Notch wear at depth-of-cut line

- Edge breakdown from thermal shock

| Wear Type | Primary Cause | Prevention Strategy |

|---|---|---|

| Chemical | Material reactivity | Use coated tools |

| Thermal | Heat concentration | Implement proper cooling |

| Mechanical | Impact forces | Reduce cutting speed |

For Stainless Steel Machining

Abrasive Wear

- Gradual removal of tool material

- Uniform flank wear

- Predictable tool life

Built-up Edge Formation

- Material adhesion to cutting edge

- Irregular surface finish

- Tool geometry alteration

Work Hardening Effects

- Increased cutting forces

- Progressive tool strain

- Reduced material removal rate

| Wear Pattern | Characteristics | Mitigation Method |

|---|---|---|

| Abrasive | Progressive flank wear | Select appropriate coating |

| Adhesive | Material build-up | Optimize cutting parameters |

| Strain-induced | Increased cutting forces | Use rigid tool holders |

Optimizing Tool Life

Cutting Parameters Selection

For Titanium:

- Lower cutting speeds (30-60 m/min)

- Moderate feed rates

- Smaller depth of cuts

- High-pressure coolant application

For Stainless Steel:

- Medium cutting speeds (80-120 m/min)

- Higher feed rates possible

- Larger depth of cuts acceptable

- Regular coolant flow sufficient

Tool Material Considerations

Titanium Machining Tools:

- Carbide grades with cobalt content

- PVD coated tools

- Ceramic tools for high-speed applications

- Enhanced edge preparation

Stainless Steel Machining Tools:

- Standard carbide grades

- CVD coated tools

- High-speed steel for simple operations

- Standard edge preparation

Economic Implications

At PTSMAKE, we’ve developed specific strategies to manage tool wear costs:

Cost Comparison Table

| Aspect | Titanium | Stainless Steel |

|---|---|---|

| Tool Life | 20-30 minutes | 45-60 minutes |

| Tool Cost | Higher | Moderate |

| Productivity | Lower | Higher |

| Setup Time | More Critical | Standard |

Productivity Enhancement Strategies

Tool Life Management

- Regular tool condition monitoring

- Predictive wear analysis

- Optimal replacement scheduling

Process Optimization

- Cutting parameter adjustment

- Cooling system enhancement

- Tool path optimization

Cost Reduction Methods

- Bulk tool purchasing

- Regrinding services

- Tool inventory management

Advanced Solutions

Modern Tool Technologies

Smart Tools

- Built-in wear sensors

- Real-time monitoring

- Automatic parameter adjustment

Specialized Coatings

- Multi-layer designs

- Nano-structured materials

- Application-specific solutions

Hybrid Processing

- Combined machining methods

- Reduced tool stress

- Enhanced material removal

Through these comprehensive approaches, we at PTSMAKE have successfully managed tool wear challenges in both titanium and stainless steel machining. The key lies in understanding the distinct wear mechanisms and implementing appropriate countermeasures for each material.

Which Surface Finish Achievements Differ In Titanium VS Stainless Steel Machining?

When manufacturers need to achieve specific surface finishes in metal machining, they often struggle with the distinct challenges posed by titanium and stainless steel. The varying material properties and machining behaviors can lead to inconsistent results, causing production delays and quality issues.

The key difference in surface finish achievements between titanium and stainless steel machining lies in their material characteristics. Titanium typically achieves a rougher surface finish (32-125 μin) under standard machining conditions, while stainless steel can achieve smoother finishes (16-63 μin) with similar parameters.

Understanding Material Properties and Their Impact

The distinct surface finish outcomes in machining titanium versus stainless steel stem from their fundamental material properties. Titanium’s high work hardening rate7 creates additional challenges during the machining process. I’ve observed that titanium’s thermal conductivity is significantly lower than stainless steel, which affects how heat dissipates during machining operations.

Thermal Conductivity Comparison

| Material | Thermal Conductivity (W/m·K) | Heat Distribution | Impact on Surface Finish |

|---|---|---|---|

| Titanium | 6.7 | Concentrated heat at cutting zone | More prone to tool wear and rougher finish |

| Stainless Steel | 16.2 | Better heat dissipation | More consistent surface finish |

Surface Finish Capabilities

Titanium Surface Finish Characteristics

At PTSMAKE, we’ve developed specific protocols for titanium machining to achieve optimal surface finishes. The material’s properties require:

- Lower cutting speeds (150-400 SFM)

- Higher feed rates

- Specialized cutting tools with specific geometries

- Enhanced cooling strategies

Stainless Steel Surface Finish Characteristics

Working with stainless steel allows for:

- Higher cutting speeds (400-600 SFM)

- More conventional machining approaches

- Greater flexibility in tool selection

- More predictable surface finish outcomes

Tool Selection and Impact

The choice of cutting tools significantly influences surface finish quality. Here’s a detailed breakdown:

| Tool Type | Performance on Titanium | Performance on Stainless Steel |

|---|---|---|

| Carbide Tools | Good wear resistance, moderate finish | Excellent finish, long tool life |

| Ceramic Tools | Poor performance, rapid wear | Good performance, consistent finish |

| CBN Tools | Excellent for finishing, expensive | Limited applications |

Cooling Strategies and Their Effects

Titanium Cooling Requirements

The cooling approach for titanium machining demands:

- High-pressure coolant delivery

- Precise coolant targeting

- Often requires specialized coolant formulations

- More frequent tool changes

Stainless Steel Cooling Requirements

Stainless steel machining typically needs:

- Standard coolant pressure

- Conventional flood cooling

- Regular coolant maintenance

- Standard tool life management

Process Parameters for Optimal Surface Finish

Speed and Feed Considerations

| Parameter | Titanium | Stainless Steel |

|---|---|---|

| Cutting Speed (SFM) | 150-400 | 400-600 |

| Feed Rate (IPR) | 0.005-0.015 | 0.004-0.012 |

| Depth of Cut (inches) | 0.040-0.080 | 0.050-0.100 |

Quality Control Measures

To ensure consistent surface finish quality, we implement:

- Regular surface roughness measurements

- Tool wear monitoring

- Temperature control systems

- Real-time process adjustment capabilities

Industry Applications and Requirements

Different industries require varying surface finish standards:

Aerospace Requirements

- Titanium components: Ra 32-63 μin

- Stainless steel parts: Ra 16-32 μin

- Strict documentation requirements

- 100% inspection protocols

Medical Device Standards

- Titanium implants: Ra 16-32 μin

- Stainless surgical tools: Ra 8-16 μin

- Biocompatibility considerations

- Validated processes

Future Trends and Developments

The industry is moving toward:

- Advanced cutting tool materials

- Improved cooling technologies

- Smart machining systems

- Enhanced surface finish monitoring

At PTSMAKE, we continuously invest in these emerging technologies to provide our clients with the best possible surface finish outcomes for both titanium and stainless steel components. Our experience in precision machining allows us to optimize processes for each material’s unique characteristics, ensuring consistent quality across all projects.

How Does Production Time Vary For Titanium VS Stainless Steel Components?

Manufacturing timelines can be a major headache when dealing with metal components. Many engineers and procurement managers struggle to accurately predict production schedules, especially when choosing between titanium and stainless steel. The uncertainty often leads to project delays and budget overruns.

The production time for titanium components typically takes 30-50% longer than stainless steel due to its higher hardness, lower thermal conductivity, and special tooling requirements. However, exact timelines depend on part complexity, quantity, and specific material grades.

Material Properties Impact on Production Time

The fundamental differences between titanium and stainless steel significantly affect their machining characteristics. Titanium’s work hardening8 behavior requires slower cutting speeds and more frequent tool changes. At PTSMAKE, we’ve optimized our processes to handle these challenges efficiently.

Cutting Speed Comparison

| Material | Maximum Cutting Speed (SFM) | Tool Life Expectancy |

|---|---|---|

| Titanium Grade 5 | 150-250 | 30-45 minutes |

| 316L Stainless Steel | 300-400 | 60-90 minutes |

Tool Wear and Replacement Factors

Tool wear occurs more rapidly when machining titanium compared to stainless steel. This reality necessitates:

- More frequent tool changes

- Higher tooling costs

- Additional setup time

- Extended production schedules

Production Planning Considerations

I find that successful production planning must account for:

- Material removal rates

- Tool change frequency

- Coolant requirements

- Surface finish specifications

Heat Management Challenges

Titanium’s low thermal conductivity creates unique challenges:

Temperature Control Methods

| Cooling Method | Titanium | Stainless Steel |

|---|---|---|

| Flood Coolant | Required | Optional |

| High-Pressure Coolant | Recommended | Not Required |

| Minimum Quantity Lubrication | Not Suitable | Suitable |

Production Time Breakdown

Setup Time Variations

The initial setup time varies significantly:

Titanium Components:

- Tool preparation: 2-3 hours

- Machine calibration: 1-2 hours

- Test runs: 1-2 hours

Stainless Steel Components:

- Tool preparation: 1-2 hours

- Machine calibration: 0.5-1 hour

- Test runs: 0.5-1 hour

Material-Specific Production Strategies

Based on my experience overseeing countless projects at PTSMAKE, I’ve developed specific strategies for each material:

Titanium Production Optimization

Pre-production Planning

- Detailed tool path simulation

- Comprehensive cooling strategy

- Regular tool wear monitoring

During Production

- Constant feed rate maintenance

- Regular quality checks

- Preventive tool replacement

Stainless Steel Production Efficiency

Standard Operating Procedures

- Optimized cutting parameters

- Regular coolant maintenance

- Tool life monitoring

Quality Control Measures

- In-process inspection

- Surface finish verification

- Dimensional accuracy checks

Batch Size Impact

Production time variations become more pronounced with larger batch sizes:

| Batch Size | Titanium Time Premium | Contributing Factors |

|---|---|---|

| 1-10 units | 30-40% longer | Setup dominates |

| 11-50 units | 40-45% longer | Tool changes impact |

| 50+ units | 45-50% longer | Cumulative wear effects |

Industry-Specific Considerations

Different industries have varying requirements that affect production time:

Aerospace

- Stringent quality requirements

- Additional inspection points

- Certified material traceability

Medical

- Surface finish requirements

- Biocompatibility validation

- Cleanliness standards

Industrial

- Cost optimization focus

- Production efficiency

- Competitive lead times

Cost vs. Time Trade-offs

Understanding the relationship between production time and costs helps in making informed decisions:

| Factor | Titanium Impact | Stainless Steel Impact |

|---|---|---|

| Tool Costs | High | Moderate |

| Machine Time | Extended | Standard |

| Labor Hours | Increased | Normal |

| Quality Control | Intensive | Standard |

Recommendations for Optimal Production Planning

To minimize production time while maintaining quality:

Design Optimization

- Simplify geometries where possible

- Consider material-specific features

- Incorporate manufacturing feedback early

Production Strategy

- Plan for appropriate tool inventory

- Schedule maintenance windows

- Implement robust quality control

Resource Allocation

- Skilled operator assignment

- Machine availability planning

- Quality control staffing

At PTSMAKE, we’ve refined these processes through years of experience, enabling us to deliver consistent results while managing production timelines effectively. Our advanced CNC machinery and experienced team help minimize the time differential between titanium and stainless steel production while maintaining the highest quality standards.

What Material Selection Criteria Matter Most For Precision Machining Projects?

Selecting the right material for precision machining projects can be overwhelming. With countless options available and multiple factors to consider, engineers and project managers often struggle to make the optimal choice that balances performance requirements, cost constraints, and manufacturability.

The most critical material selection criteria for precision machining projects include mechanical properties, machinability, cost-effectiveness, and environmental resistance. These factors must be carefully weighed against specific application requirements, production volume, and budget constraints to ensure project success.

Understanding Material Properties

Mechanical Properties

The foundation of material selection starts with understanding mechanical properties. I always emphasize to my clients at PTSMAKE that these properties directly impact the part’s performance in its intended application:

- Tensile Strength

- Yield Strength

- Hardness

- Fatigue Resistance

- Impact Resistance

One crucial aspect often overlooked is the material’s anisotropic behavior9 during machining, which can significantly affect the final part’s performance.

Chemical and Environmental Resistance

Environmental factors play a vital role in material selection:

- Corrosion Resistance

- Temperature Stability

- UV Resistance

- Chemical Compatibility

- Moisture Resistance

Machinability Considerations

Surface Finish Requirements

Different materials respond differently to machining processes. Here’s a comparison table I’ve developed based on common materials we work with:

| Material Type | Surface Finish Potential (Ra) | Tool Life Impact | Cost Factor |

|---|---|---|---|

| Aluminum | 0.2-0.8 μm | Low | Low |

| Stainless Steel | 0.4-1.6 μm | High | Medium |

| Titanium | 0.8-3.2 μm | Very High | High |

| Brass | 0.2-0.4 μm | Low | Medium |

Tool Life and Processing Speed

The impact of material choice on tooling costs cannot be understated:

- Tool Wear Rates

- Cutting Speed Limitations

- Required Cooling Methods

- Special Tooling Requirements

Cost Considerations

Material Cost Analysis

When evaluating material costs, consider:

- Raw Material Price

- Material Availability

- Minimum Order Quantities

- Scrap Rate

- Processing Time

Production Volume Impact

The relationship between material choice and production volume:

| Production Volume | Recommended Material Considerations |

|---|---|

| Prototypes | Focus on machinability and availability |

| Low Volume | Balance between cost and performance |

| High Volume | Optimize for processing efficiency |

Industry-Specific Requirements

Aerospace and Defense

For aerospace applications, I typically recommend materials that offer:

- High Strength-to-Weight Ratio

- Excellent Fatigue Resistance

- Superior Corrosion Resistance

- Thermal Stability

Medical Industry

Medical applications require materials with:

- Biocompatibility

- Sterilization Capability

- Chemical Resistance

- Traceability

Practical Selection Process

Step-by-Step Approach

- Define Performance Requirements

- Identify Environmental Conditions

- Establish Budget Constraints

- Assess Manufacturing Capabilities

- Consider Regulatory Requirements

Common Material Comparisons

Here’s a comparative analysis of frequently used materials:

| Property | Titanium | Stainless Steel | Aluminum |

|---|---|---|---|

| Strength | Very High | High | Medium |

| Weight | Low | High | Very Low |

| Cost | High | Medium | Low |

| Machinability | Poor | Good | Excellent |

Future Considerations

Sustainability Impact

Modern material selection must consider:

- Recyclability

- Carbon Footprint

- Energy Consumption

- Waste Reduction

Quality Assurance

At PTSMAKE, we implement rigorous quality control measures for all materials:

- Material Certification Verification

- Incoming Material Inspection

- In-Process Testing

- Final Quality Validation

Optimization Strategies

To optimize material selection, consider:

- Design for Manufacturability

- Alternative Material Options

- Hybrid Material Solutions

- Processing Method Variations

The importance of proper material selection cannot be overstated. Through careful consideration of these criteria and thorough analysis of project requirements, you can make informed decisions that lead to successful precision machining outcomes. At PTSMAKE, we guide our clients through this process, ensuring optimal material selection for each unique application.

How Do Industry Applications Differ For Machined Titanium VS Stainless Steel Parts?

Engineers often struggle with selecting between titanium and stainless steel for their machined parts. The challenge becomes more complex when considering factors like cost, performance requirements, and specific industry standards. Making the wrong choice can lead to project delays, budget overruns, or even component failure.

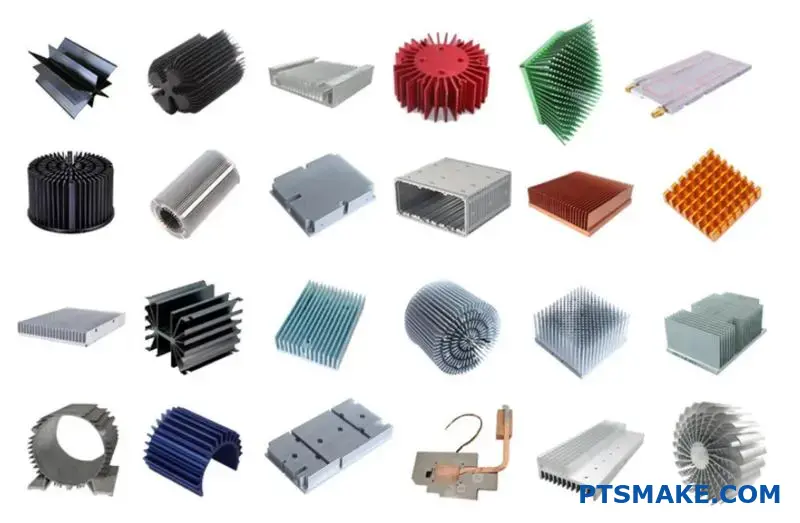

Both titanium and stainless steel serve distinct industrial applications based on their unique properties. Titanium excels in aerospace and medical applications due to its strength-to-weight ratio and biocompatibility, while stainless steel dominates in food processing and chemical industries for its corrosion resistance and cost-effectiveness.

Material Properties and Their Impact on Applications

At PTSMAKE, we’ve observed that understanding the fundamental properties of these materials is crucial for making informed decisions. The key difference lies in their metallurgical structure10, which directly influences their industrial applications.

Titanium Characteristics

- Exceptional strength-to-weight ratio

- Superior corrosion resistance

- Biocompatibility

- High heat resistance

- Lower thermal conductivity

Stainless Steel Characteristics

- High durability

- Good corrosion resistance

- Magnetic properties (depending on grade)

- Better thermal conductivity

- Cost-effective

Industry-Specific Applications

Aerospace Industry

Titanium components dominate aerospace applications due to their lightweight nature and high strength. Common applications include:

- Engine components

- Landing gear parts

- Structural elements

- Fasteners

Stainless steel finds its place in:

- Interior components

- Non-critical structural parts

- Ground support equipment

Medical Industry

The medical sector heavily relies on both materials:

| Material | Applications | Key Benefits |

|---|---|---|

| Titanium | Implants, Surgical instruments, Dental implements | Biocompatibility, Osseointegration |

| Stainless Steel | Surgical tools, External fixation devices | Cost-effectiveness, Durability |

Marine and Chemical Industries

Marine Applications

Stainless steel dominates marine applications due to:

- Excellent saltwater resistance

- Cost-effective maintenance

- Wide availability

Titanium usage is limited to:

- High-performance components

- Specialty applications

- Premium vessel components

Chemical Processing Industry

Here’s how these materials serve different purposes:

| Application Type | Preferred Material | Reasoning |

|---|---|---|

| Storage tanks | Stainless Steel | Cost-effective, Good chemical resistance |

| Heat exchangers | Titanium | Superior corrosion resistance in aggressive environments |

| Pumps and valves | Both materials | Depends on specific chemical exposure |

Cost Considerations and Manufacturing Challenges

Material Costs

- Titanium typically costs 5-10 times more than stainless steel

- Raw material availability affects pricing

- Processing costs vary significantly

Manufacturing Considerations

At PTSMAKE, we’ve developed specialized techniques for both materials:

Titanium Machining Challenges

- Requires specialized cutting tools

- Lower cutting speeds

- More frequent tool changes

- Higher machining costs

Stainless Steel Machining Benefits

- Standard tooling options

- Higher cutting speeds possible

- More predictable machining process

- Lower overall production costs

Environmental Factors and Sustainability

Environmental Impact

| Factor | Titanium | Stainless Steel |

|---|---|---|

| Energy consumption in production | Higher | Lower |

| Recyclability | Excellent | Excellent |

| Life cycle cost | Higher initial, lower long-term | Lower initial, variable long-term |

Sustainability Considerations

- Both materials are 100% recyclable

- Titanium’s longer service life often justifies higher initial costs

- Stainless steel’s lower production energy requirements benefit carbon footprint

Future Trends and Industry Evolution

The manufacturing landscape continues to evolve, and at PTSMAKE, we’re seeing:

- Increased demand for lightweight solutions favoring titanium

- Advanced machining technologies reducing production costs

- Growing importance of sustainable manufacturing practices

- Hybrid material solutions emerging

Emerging Applications

- Electric vehicles

- Renewable energy systems

- Advanced medical devices

- Aerospace innovations

Through years of experience at PTSMAKE, I’ve learned that the choice between machined titanium and stainless steel parts isn’t always straightforward. Each material has its unique advantages and optimal applications. Understanding these differences helps ensure the right material selection for specific industry needs.

Our expertise in machining both materials allows us to guide clients toward the most appropriate choice for their specific applications, considering factors like performance requirements, budget constraints, and industry standards. This comprehensive understanding of material properties and applications ensures optimal outcomes for every project.

What Machining Techniques Optimize Results For Titanium VS Stainless Steel?

Machinists often struggle with the complexities of working with titanium and stainless steel. These materials’ unique properties can lead to rapid tool wear, poor surface finishes, and increased production costs. The wrong machining approach can result in scrapped parts and missed deadlines, causing significant financial losses.

To optimize machining results for titanium versus stainless steel, you need specific cutting parameters and tooling strategies for each material. Titanium requires slower speeds, higher feed rates, and rigid tooling, while stainless steel demands higher cutting speeds with moderate feed rates and proper cooling techniques.

Understanding Material Properties

Before diving into specific machining techniques, it’s crucial to understand the fundamental differences between these materials. Titanium exhibits high work hardening11 characteristics and low thermal conductivity, making it more challenging to machine than stainless steel. At PTSMAKE, we’ve developed specialized approaches for both materials to ensure optimal results.

Material Characteristics Comparison

| Property | Titanium | Stainless Steel |

|---|---|---|

| Thermal Conductivity | Low | Moderate |

| Hardness | Moderate to High | Moderate |

| Work Hardening | Severe | Moderate |

| Tool Wear Rate | High | Moderate |

| Cost | Higher | Lower |

Cutting Speed and Feed Rate Optimization

Titanium Machining Parameters

For titanium, I always recommend using lower cutting speeds but higher feed rates. This approach helps maintain tool life and prevents heat buildup in the cutting zone. Based on our experience at PTSMAKE, the following parameters work well:

- Cutting speed: 150-250 SFM (Surface Feet per Minute)

- Feed rate: 0.004-0.008 inches per revolution

- Depth of cut: 0.040-0.080 inches

Stainless Steel Parameters

Stainless steel allows for higher cutting speeds but requires moderate feed rates:

- Cutting speed: 300-400 SFM

- Feed rate: 0.003-0.006 inches per revolution

- Depth of cut: 0.030-0.060 inches

Tooling Selection and Strategy

Tools for Titanium

When machining titanium, tool selection is critical. I recommend:

- Carbide tools with multi-layer coatings

- Larger tool diameter when possible

- Rigid tool holders to minimize vibration

- Tools with positive rake angles

Tools for Stainless Steel

For stainless steel, different tooling considerations apply:

- High-speed steel or carbide tools

- Standard tool holders

- Tools with chip breakers

- Neutral to slightly positive rake angles

Cooling and Lubrication Techniques

Titanium Cooling Methods

Proper cooling is essential for titanium machining:

- High-pressure coolant delivery

- Through-tool cooling when possible

- Abundant coolant flow

- Regular coolant concentration monitoring

Stainless Steel Cooling Approaches

Stainless steel requires different cooling strategies:

- Standard flood coolant

- Medium pressure delivery

- Regular coolant replacement

- Proper concentration maintenance

Surface Finish Optimization

To achieve optimal surface finishes, we’ve developed specific techniques for each material:

Titanium Surface Finishing

- Light finishing passes

- Sharp, fresh cutting tools

- Consistent cutting parameters

- Rigid workpiece holding

Stainless Steel Finishing

- Higher speeds for finishing

- Regular tool changes

- Proper chip evacuation

- Stable workpiece fixturing

Tool Life Management

The key to cost-effective machining lies in proper tool life management:

Titanium Tool Management

- Regular tool wear monitoring

- Predetermined tool change intervals

- Backup tooling readily available

- Tool path optimization

Stainless Steel Tool Considerations

- Standard tool life tracking

- Normal wear patterns

- Regular maintenance schedules

- Cost-effective tool selection

Process Monitoring and Quality Control

At PTSMAKE, we implement rigorous monitoring procedures:

Titanium Process Controls

- In-process temperature monitoring

- Regular dimensional checks

- Surface finish verification

- Tool wear tracking

Stainless Steel Controls

- Standard quality checks

- Regular dimensional inspection

- Surface finish monitoring

- Tool condition assessment

Cost Considerations

Understanding the economic aspects of machining these materials is crucial:

| Cost Factor | Titanium | Stainless Steel |

|---|---|---|

| Material Cost | Very High | Moderate |

| Tool Cost | High | Moderate |

| Machine Time | Longer | Standard |

| Labor Cost | Higher | Standard |

Through implementing these optimized techniques at PTSMAKE, we’ve achieved consistent, high-quality results for both materials. The key is understanding each material’s unique characteristics and adjusting machining parameters accordingly. This comprehensive approach ensures optimal outcomes while maintaining cost-effectiveness and meeting tight tolerances.

Learn how strain hardening affects machining efficiency and tool life for better production outcomes. ↩

Learn how work hardening affects titanium machining and improve your cutting strategies. ↩

Understanding crystalline structures aids in selecting the right material for performance and reliability. ↩

Understand how titanium’s thermal properties affect tool performance and machining efficiency. ↩

Learn about cost differences to make informed material choices for your manufacturing projects. ↩

Learn how work hardening affects tool wear for improved machining strategies. ↩

Learn how work hardening affects machining efficiency and surface quality in titanium. ↩

Learn about work hardening in titanium to improve machining efficiency and reduce production delays. ↩

Learn about the impact of anisotropic behavior on machining performance and project outcomes. ↩

Learn how metallurgical structure influences material performance and application suitability. ↩

Learn about work hardening effects to enhance machining efficiency and tool longevity. ↩