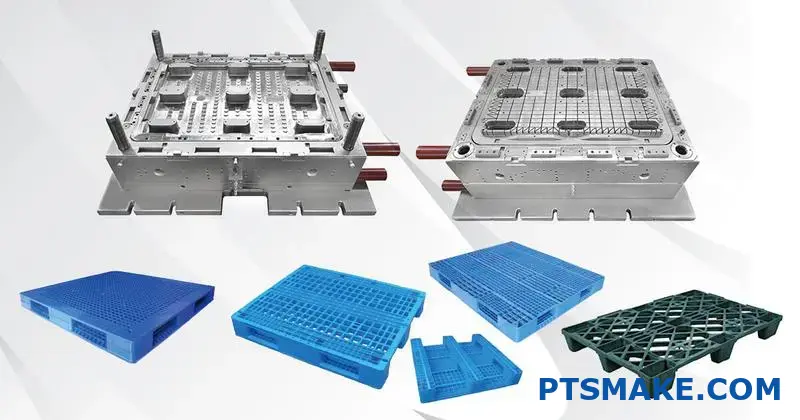

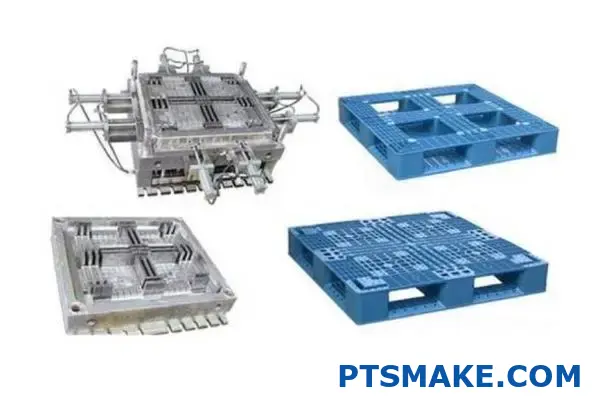

Fundamentals of Plastic Pallet Mould Design

Ever wondered why some plastic pallets last for years while others crack under minimal pressure? The secret lies not in the plastic itself, but in the invisible engineering marvel: the mould that shapes it.

Creating effective plastic pallet moulds requires mastering a delicate balance of scientific principles and practical engineering. From load distribution analysis to material flow optimization, each design decision directly impacts the pallet’s performance, durability, and manufacturing efficiency.

Understanding the Core Elements of Pallet Mould Design

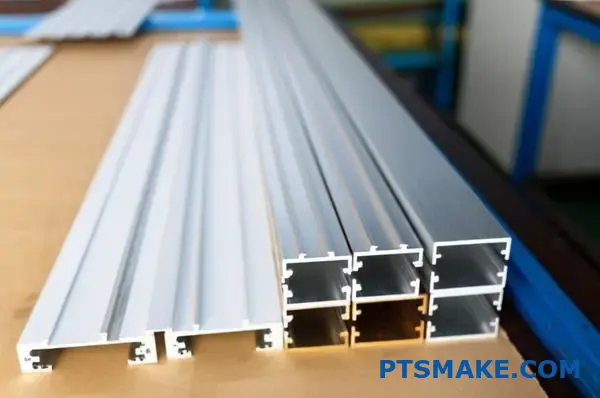

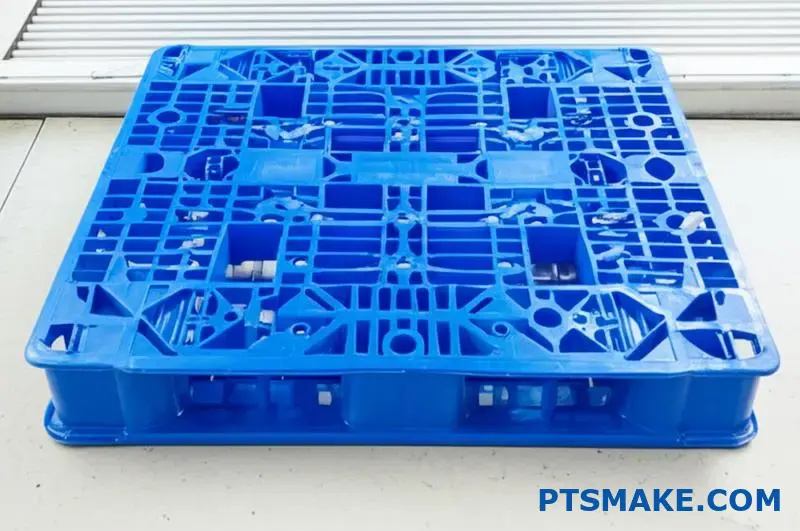

When diving into plastic pallet mould design, we must first recognize that these seemingly simple products are actually complex engineering projects. At PTSMAKE, I’ve learned that successful mould design always begins with a thorough understanding of the end-use requirements. This includes weight capacity, stacking strength, environmental conditions, and handling methods.

The melt flow index1 of the chosen plastic material significantly influences how we approach the mould design. Different polymers behave uniquely during injection, requiring specific gate placements and wall thickness calculations.

Load-Bearing Analysis: The Foundation of Durable Pallets

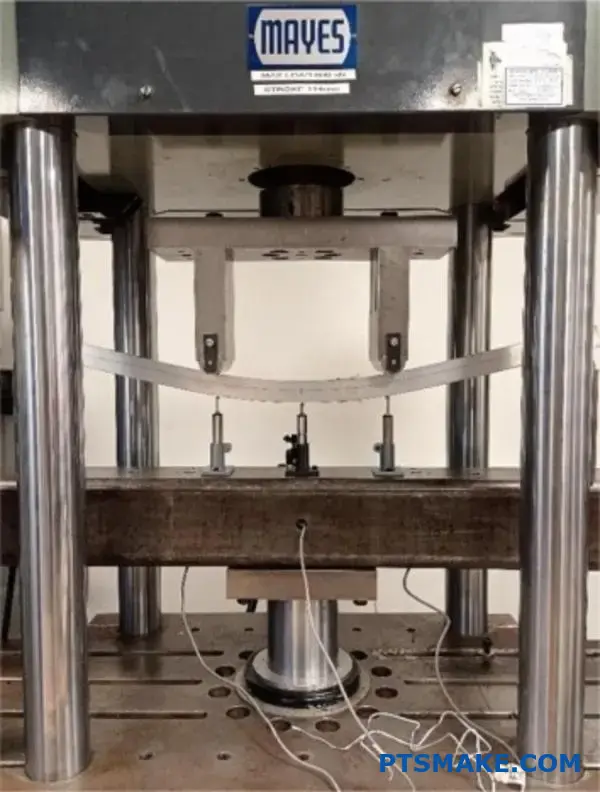

A critical aspect of pallet mould design involves comprehensive load analysis. We must consider:

- Static Load Capacity – The maximum weight the pallet can hold while stationary

- Dynamic Load Capacity – Weight capacity during movement (typically 75-80% of static capacity)

- Racking Load Capacity – Support strength when pallet is supported only at the edges

The mould design must incorporate these requirements through strategic ribbing patterns, material distribution, and structural support features.

Stress Distribution Optimization

Proper stress distribution is achieved through:

- Uniform wall thickness to prevent warping and sink marks

- Strategic rib placement for maximum strength with minimal material

- Radiused corners to prevent stress concentration

- Balanced material flow paths to ensure consistent density

Molding Process Considerations

When designing plastic pallet moulds, we must account for the entire manufacturing process. This includes:

| Design Feature | Manufacturing Implication | Design Solution |

|---|---|---|

| Deep draws | Can cause material thinning | Incorporate progressive draft angles |

| Thick sections | Potential for sink marks | Design hollow cores and gas-assist options |

| Complex geometries | Difficult material flow | Strategic gate placement and flow analysis |

| Cooling requirements | Cycle time impact | Optimized cooling channel layout |

Material Selection Impact on Mould Design

The plastic material selection directly influences the mould design requirements. At PTSMAKE, we typically work with:

- High-Density Polyethylene (HDPE) – Requires moulds with excellent venting due to its high shrinkage rate

- Polypropylene (PP) – Needs precise temperature control zones in the mould

- Recycled Plastics – Often demand more robust mould construction to handle inconsistencies

Each material exhibits different flow characteristics, shrinkage rates, and cooling behaviors, all of which must be accounted for in the mould design.

Preventing Common Defects Through Design

Effective pallet mould design anticipates and prevents common manufacturing defects:

- Warping – Controlled through balanced cooling and uniform wall thickness

- Short shots – Addressed through proper gate location and size

- Weld lines – Minimized by strategic flow path design

- Sink marks – Prevented by proper support structure design and cooling

Industry Standards and Compliance

Pallet mould design must ensure the final product meets relevant industry standards, including:

- ISO 8611 for pallet testing protocols

- Regional load-bearing requirements

- Material safety compliance for specific industries (food, pharmaceuticals, etc.)

The mould design directly influences the pallet’s ability to meet these standards, making compliance considerations essential from the earliest design phases.

Cost-Efficiency Balancing Act

Finding the perfect balance between durability and production cost is perhaps the most challenging aspect of pallet mould design. Through careful material distribution, strategic reinforcement, and innovative cooling solutions, we can create moulds that produce pallets meeting performance requirements while maintaining competitive pricing.

At PTSMAKE, our approach involves simulation-driven design iterations that identify the optimal balance point for each client’s specific needs, allowing us to create plastic pallet moulds that deliver exceptional value.

Gate Design & CAE Analysis for Optimal Flow

Ever stared at a flawless plastic pallet and wondered how it’s possible to create something so large without visible flow marks or weak points? The secret lies in the invisible architecture of gates and runners that feed molten plastic into the mould.

Multi-point gate design is the unsung hero of large-scale plastic pallet production, working like a carefully orchestrated irrigation system to ensure every corner of your pallet receives the perfect amount of material at the ideal temperature and pressure.

The Critical Role of Multi-Point Gate Systems

When dealing with large plastic pallet moulds, conventional single-gate designs simply don’t cut it. The sheer size of pallets (typically 40×48 inches or larger) creates significant challenges for material flow. At PTSMAKE, we’ve found that multi-point gate systems are absolutely essential for successful pallet mould design.

Multi-point gates provide several critical advantages:

- Balanced material flow across the entire mould cavity

- Reduced pressure requirements compared to single-gate designs

- More consistent cooling leading to more uniform shrinkage

- Lower risk of warpage in the finished product

- Minimized flow length for each material path

The strategic positioning of gates is perhaps the most crucial design decision in the entire mould development process. Too few gates, and you’ll face incomplete fills; too many, and you’ll create excessive weld lines and increased production costs.

Gate Placement Strategy for Optimal Flow

Gate placement isn’t simply about ensuring the mould fills completely – it’s about controlling how it fills. For plastic pallets, we generally follow these principles:

- Gates should be placed at points of maximum thickness

- Maintain equal flow distances from each gate when possible

- Position gates to direct material flow toward areas with complex geometry

- Avoid placing gates in highly visible or structural areas where gate vestiges might compromise performance

- Consider the flow orientation2 effects on material properties in critical structural areas

I’ve found that most plastic pallets benefit from 4-8 gate points, depending on their size and complexity. The exact number and position must be determined through careful analysis and simulation.

Leveraging CAE Software for Flow Optimization

Computer-Aided Engineering (CAE) simulation has revolutionized mould design, particularly for complex products like plastic pallets. At PTSMAKE, we utilize advanced flow simulation software to predict and prevent potential issues before cutting any steel.

Benefits of Flow Simulation in Pallet Mould Design

Our CAE analysis provides crucial insights that would be impossible to determine through experience alone:

| Analysis Type | What It Reveals | Why It Matters |

|---|---|---|

| Fill Time Analysis | How quickly and evenly the mould fills | Prevents short shots and overheated material |

| Pressure Distribution | Areas of high and low pressure during filling | Identifies potential structural weaknesses and flash |

| Temperature Mapping | Material temperature throughout the flow path | Prevents degradation and ensures proper fusion |

| Air Trap Prediction | Where air pockets might form | Prevents burn marks and incomplete fills |

| Weld Line Locations | Where material flow fronts meet | Highlights potential structural weak points |

These simulations allow us to test different gate configurations virtually, saving significant time and resources compared to traditional trial-and-error approaches.

Preventing Defects Through Simulation

Weld lines are a particular concern in multi-gated designs because they represent potential weak points in the finished product. Our CAE analysis allows us to:

- Predict the exact location of all weld lines

- Optimize gate placement to move weld lines away from high-stress areas

- Adjust processing parameters to improve weld line strength

- Implement design features that compensate for weld line weakness

For example, in a recent pallet design, our simulation revealed that the original 6-gate configuration would create a weld line directly through a critical forklift entry point. By adjusting to an 8-gate system with modified positioning, we were able to shift the weld line to a reinforced area, increasing load capacity by approximately 15%.

Hot Runner Systems for Large Pallet Moulds

While cold runner systems are simpler, large plastic pallet moulds almost always benefit from hot runner technology. Integral hot runner systems offer several crucial advantages:

Benefits of Hot Runner Systems in Pallet Production

- Material Efficiency: Eliminates runner scrap, which can be substantial in large pallets

- Cycle Time Reduction: No need to cool and eject runners

- Consistent Processing: Maintains material temperature throughout the entire fill cycle

- Reduced Pressure Requirements: Lower injection pressures due to maintained material temperature

- Precise Control: Ability to balance flow between multiple gates through individual temperature control zones

The initial investment in hot runner technology is quickly offset by material savings and production efficiency, especially for high-volume pallet production.

Balancing Material Flow Through Manifold Design

The hot runner manifold design is critical to ensuring balanced flow through all gates. At PTSMAKE, we design custom manifold systems that account for:

- Symmetrical flow paths when possible

- Balanced pressure drops across different flow path lengths

- Optimized melt channel diameters to maintain consistent material properties

- Strategic thermal isolation to prevent heat transfer to cooling pallet sections

Our approach to manifold design focuses not just on filling the mould, but on maintaining consistent material properties throughout the pallet. This results in more uniform shrinkage, reduced warpage, and ultimately a more durable product.

The combination of multi-point gate design, comprehensive CAE analysis, and integrated hot runner systems allows us to create plastic pallet moulds that produce consistent, high-quality parts with minimal defects and maximum efficiency. When properly implemented, these technologies can significantly reduce cycle times while improving overall pallet performance.

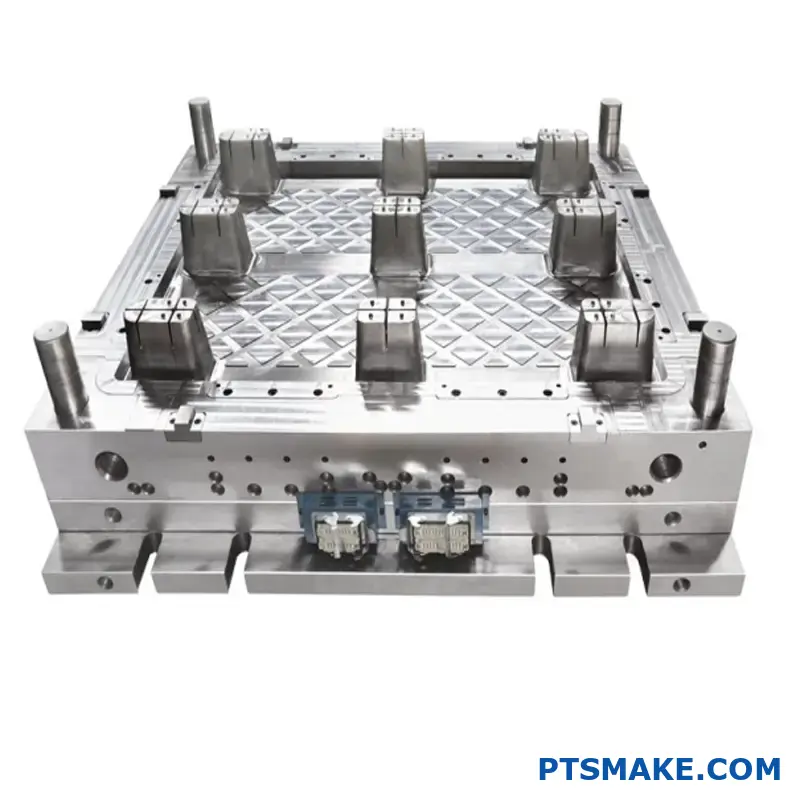

Mould Insert Engineering & Cooling Systems

Ever wondered what makes a plastic pallet mould operate with such precision despite extreme temperature fluctuations? The secret lies in the engineering marvel of inserts and cooling systems that work in harmony to create flawless products time after time.

Mould insert engineering and cooling systems represent the critical foundation of plastic pallet mould performance. These components ensure dimensional stability, prevent deformation during thermal cycling, and ultimately determine both the quality and production efficiency of your pallets.

The Critical Role of Precision Inserts in Pallet Moulds

The success of a plastic pallet mould largely depends on the precision and durability of its inserts. At PTSMAKE, I’ve seen firsthand how properly engineered inserts can dramatically extend mould life while maintaining product consistency.

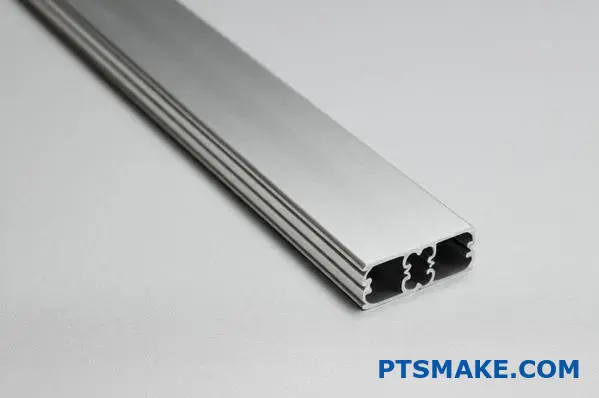

Mould inserts are specialized components that form critical features in the pallet design. For plastic pallets, these typically include:

- Corner formations that must withstand repeated impacts

- Load-bearing rib structures that provide strength

- Entry points for forks and pallet jacks

- Stacking features that ensure secure nesting

The challenge with inserts in moving and fixed portions of the mould is preventing shifting during heat cycles. When a mould heats during injection and cools afterward, thermal expansion and contraction create forces that can gradually displace inserts.

Material Selection for Insert Longevity

The choice of insert materials significantly impacts performance and longevity. For plastic pallet moulds, we typically recommend:

| Insert Material | Key Properties | Best Applications |

|---|---|---|

| P20 Tool Steel | Good toughness, fair wear resistance | General pallet features |

| H13 Tool Steel | Excellent hot hardness, good wear resistance | High-stress areas, corners |

| S7 Tool Steel | Superior impact resistance | Areas subject to mechanical shock |

| Beryllium Copper | Superior thermal conductivity | Areas requiring rapid cooling |

Each material offers specific advantages, but must be matched to the particular demands of the insert location. For example, in high-wear areas like fork entry points, we often use hardened H13 steel inserts to maximize longevity.

Securing Inserts Against Thermal Movement

To prevent shifting during heat cycles, proper insert engineering incorporates several key strategies:

Mechanical Anchoring Systems

The most reliable approach to insert security involves mechanical anchoring through:

- Dovetail designs – These create an interlocking joint that physically prevents movement in key directions

- Shoulder locks – Stepped features that resist lateral movement

- Retention pins – Additional fastening elements that secure the insert from multiple directions

Precise Fitting Tolerances

The interference fit3 between inserts and the mould base plays a critical role in preventing movement. We typically maintain tolerances of ±0.005mm for insert placements, ensuring a secure fit while allowing for thermal expansion.

Strategic Material Combinations

By selectively using materials with complementary thermal expansion coefficients, we can create insert systems that maintain position throughout the heating and cooling cycle.

Advanced Cooling Arrangements for Dimensional Stability

Even with perfectly secured inserts, inconsistent cooling creates other problems. Hot spots lead to differential shrinkage, warping, and extended cycle times. For plastic pallet moulds, cooling system design is particularly challenging due to:

- Large surface areas requiring even cooling

- Varying wall thicknesses throughout the design

- Deep ribs and structural elements that trap heat

- The need for rapid cycle times in production

Balanced Cooling Circuit Design

Effective cooling arrangements for pallet moulds feature:

- Independent cooling zones – Different areas of the mould require varying cooling intensities

- Conformal cooling channels – These follow the contours of the pallet’s geometry

- Turbulent flow promotion – Special channel designs that enhance heat transfer

- Balanced water flow – Equal cooling across all circuits

At PTSMAKE, our thermal analysis uses computational fluid dynamics to simulate cooling performance before mould construction begins. This allows us to identify and eliminate potential hot spots.

Cooling Challenges in Ribbed Structures

Plastic pallets rely on internal ribbing for structural integrity, but these ribs present significant cooling challenges. The deep sections trap heat, while thin walls cool quickly, creating uneven shrinkage.

To address this, we implement:

- Cascading cooling circuits – Providing higher cooling capacity to thick sections

- Thermal pins – Specialized cooling elements that reach deep into rib sections

- Differential cooling timing – Staged cooling that maintains even temperature distribution

Thermal Management for Material Flow Optimization

Beyond dimensional stability, cooling arrangements directly impact material flow. Strategic cooling helps:

- Control solidification sequence to prevent voids

- Manage material viscosity during filling

- Reduce internal stresses in the finished product

- Ensure complete packing of all features

Preventive Engineering Against Common Failure Modes

When designing insert and cooling systems for plastic pallet moulds, we proactively address common failure modes:

Thermal Fatigue Prevention

Repeated heating and cooling cycles eventually lead to thermal fatigue in mould components. To mitigate this:

- Stress-relieved insert mounting – Designs that accommodate thermal expansion

- Gradual heating/cooling cycles – When possible, avoiding extreme thermal shock

- Thermal barrier coatings – Protective layers that reduce thermal transfer to sensitive components

Wear Resistance Strategies

High-volume pallet production means thousands of injection cycles, creating significant wear on insert surfaces. Our approach includes:

- Surface treatments – Nitriding and other hardening processes

- PVD coatings – Physical vapor deposition of wear-resistant layers

- Replaceable wear inserts – Design that allows easy replacement of high-wear components

By combining precision insert engineering with optimized cooling arrangements, we create plastic pallet moulds that maintain dimensional stability throughout production runs. This integration ensures even material flow, eliminates hot spots, and delivers consistent part quality with optimized cycle times.

The careful coordination between insert design and cooling systems ultimately determines not just the quality of the finished pallet, but also the mould’s production efficiency and overall lifespan. At PTSMAKE, this holistic approach to mould engineering has proven essential for creating durable, high-performance plastic pallet moulds.

Ejection System Requirements for Pallet Moulds

Ever struggled with plastic pallets that show unsightly ejector pin marks or, worse, crack during production? The hidden culprit is often an improperly designed ejection system – the unsung hero of successful pallet moulding.

A well-engineered ejection system is critical for plastic pallet mould performance, requiring precise pin placement, balanced force distribution, and robust structural support. When designed correctly, it ensures smooth release without compromising the pallet’s structural integrity or aesthetic quality.

Strategic Ejector Pin Placement for Optimal Release

When designing ejection systems for plastic pallet moulds, pin placement is absolutely crucial. The large surface area and complex geometry of pallets create unique challenges that demand thoughtful engineering solutions.

Unlike smaller plastic parts that might require just a few ejector pins, plastic pallets typically need dozens of strategically positioned pins to ensure even force distribution during ejection. At PTSMAKE, we’ve found that proper pin placement follows several key principles:

- Uniform force distribution across the entire pallet surface

- Strategic positioning at points of maximum structural rigidity

- Avoidance of thin-walled sections that could deform under ejection pressure

- Placement at natural angles to minimize resistance during release

Each pin location must be carefully considered based on the pallet’s specific design features, including rib structures, load-bearing areas, and mounting points.

Calculating Required Ejection Force

Determining the appropriate ejection force begins with understanding the factors that create resistance during part removal:

| Factor | Impact on Ejection | Mitigation Strategy |

|---|---|---|

| Surface Area | Larger contact area increases resistance | Optimize draft angles and texture |

| Material Shrinkage | Higher shrinkage creates tighter grip | Adjust material selection and cooling system |

| Surface Texture | Textured surfaces increase friction | Balance texture requirements with release needs |

| Draft Angles | Insufficient draft increases resistance | Implement minimum 1.5° draft on all vertical surfaces |

| Undercuts | Create mechanical locking | Use side-actions or sacrificial features where possible |

For large pallet moulds, we typically calculate a minimum ejection force of 2-3 tons per square meter of projected surface area, depending on the specific material properties and design features.

Preventing Pin-Related Defects

Poorly designed ejection systems often create visible defects in the finished pallet. Common issues include:

- Push marks – Visible indentations where ejector pins contact the part

- Stress whitening – Localized discoloration due to excessive ejection pressure

- Cracking – Structural failure caused by uneven ejection forces

- Sticking – Incomplete release causing production delays and damage

To prevent these issues, we implement several specialized design features:

Advanced Pin Head Designs

Standard flat-head ejector pins often leave visible marks on plastic pallets. Instead, we utilize:

- Custom-profiled heads that match the pallet’s surface contour

- Larger diameter heads that distribute force over a wider area

- Polished pin surfaces that minimize friction and marking

- Multi-stage ejection pins that provide progressive release

Structural Support Requirements for Ejection Systems

The ejection system for plastic pallet moulds must be robustly supported to withstand thousands of production cycles without failure. Key structural components include:

Ejector Plate Assembly Design

The ejector plate assembly must be engineered to:

- Distribute force evenly across all pins

- Maintain alignment throughout the ejection stroke

- Resist deflection under load

- Provide smooth, controlled movement during operation

For large pallet moulds, we typically implement dual ejector plates with additional support columns to prevent plate bending and ensure consistent pin movement. The primary ejector plate houses the pins, while the secondary plate provides structural support and connects to the ejection cylinders.

Guide System Precision

Precise guidance of the ejection system is essential for trouble-free operation. Our designs incorporate:

- Hardened and ground guide pillars to ensure smooth movement

- Precision bushings4 with minimal clearance to prevent misalignment

- Self-lubricating components to reduce wear and maintenance requirements

- Anti-rotation features that prevent twisting during ejection

This precision guidance ensures that all ejector pins maintain proper alignment with their corresponding holes, preventing binding and premature wear.

Quality Requirements for Ejector Pins and Accessories

The individual components of the ejection system must meet stringent quality standards to ensure reliable performance:

Material Specifications for Ejector Components

We select materials based on specific operational requirements:

| Component | Recommended Material | Key Properties |

|---|---|---|

| Ejector Pins | H13 Tool Steel (HRC 48-52) | Excellent wear resistance, dimensional stability |

| Return Pins | W1 Tool Steel (HRC 58-62) | Superior impact resistance, good wear properties |

| Ejector Plates | P20 Pre-hardened Steel | Good machinability, adequate strength, stability |

| Guide Pillars | M2 High-Speed Steel (HRC 60-63) | Exceptional hardness, wear resistance, rigidity |

For applications involving corrosive materials or extended production runs, we may specify additional treatments such as gas nitriding or PVD coatings to enhance durability.

Surface Finish and Tolerance Requirements

Quality ejection components require precise manufacturing tolerances:

- Ejector pins require h7 tolerance on diameter (typically ±0.008mm)

- Pin holes in cavity plates should be H7 tolerance (typically ±0.010mm)

- Surface finish on ejector pins should be Ra 0.2 μm or better

- Perpendicularity of pins must be within 0.01mm over 100mm length

These tight tolerances ensure smooth operation and prevent premature wear or binding during production.

Advanced Ejection Features for Complex Pallet Designs

Modern plastic pallets often incorporate complex features that require specialized ejection solutions:

Two-Stage Ejection Systems

For pallets with varying wall thicknesses or deep draws, we often implement two-stage ejection:

- Primary ejection – Releases the main pallet structure from the mould cavity

- Secondary ejection – Targets specific features that require additional force or movement

This staged approach prevents distortion by ensuring that stronger sections are released first, followed by more delicate features.

Pneumatic Assistance Systems

For particularly challenging areas, pneumatic assistance provides additional benefits:

- Air blast ejection – Strategically positioned air channels that help break vacuum and initiate release

- Sequenced pneumatic cylinders – Provide precisely timed auxiliary ejection force

- Controlled venting – Prevents vacuum formation in deep draw areas

These pneumatic systems work in conjunction with the mechanical ejection to ensure complete and controlled part release.

Maintenance Considerations in Ejection System Design

A well-designed ejection system must also account for long-term maintenance requirements:

- Easy access to ejector pins and return mechanisms

- Standardized components where possible to simplify replacement

- Wear monitoring features that indicate when maintenance is needed

- Lubrication systems that ensure consistent performance

At PTSMAKE, we design our pallet mould ejection systems with maintenance intervals that align with overall mould maintenance schedules, minimizing production downtime.

By implementing these comprehensive ejection system requirements, we ensure that our plastic pallet moulds deliver consistent, high-quality parts with minimal production issues. The careful integration of strategic pin placement, robust structural support, and high-quality components results in ejection systems that perform reliably throughout the mould’s operational life.

Strategic Steel Selection for Pallet Moulds

In the competitive world of plastic pallet manufacturing, the difference between profit and loss often comes down to one critical decision – the steel you choose for your mould. This seemingly small detail can dramatically impact your production efficiency and product longevity.

Steel selection for plastic pallet moulds involves a careful balancing act between durability, performance, and cost-effectiveness. The right steel choice not only determines your mould’s lifespan but also influences cycle times, maintenance requirements, and ultimately your production economics.

The Critical Balance of Hardness and Toughness

When selecting steel for plastic pallet moulds, I’ve learned that achieving the right balance between hardness and toughness is absolutely essential. This isn’t merely a theoretical consideration – it directly impacts your daily production and long-term profitability.

Hardness provides wear resistance, helping your mould maintain critical dimensions through thousands of production cycles. However, excessive hardness often comes at the expense of toughness, potentially leading to premature cracking or chipping. For pallet moulds that often undergo significant mechanical stress during operation, this balance becomes particularly critical.

Understanding Steel Properties for Mould Applications

The ideal steel for pallet moulds must possess several key properties:

- Wear Resistance – Ability to withstand abrasion from glass-filled polymers

- Corrosion Resistance – Protection against rust and chemical attack

- Machinability – Ease of manufacturing complex geometric features

- Polishability – Capacity to achieve required surface finish

- Thermal Conductivity – Efficient heat transfer for optimal cycling

- Dimensional Stability – Minimal distortion during heat treatment

- Toughness – Resistance to cracking under mechanical stress

Each steel grade offers a different combination of these properties, making selection a matter of prioritizing what matters most for your specific application.

Popular Steel Grades for Pallet Moulds

Based on my experience working with numerous plastic pallet manufacturers, several steel grades have emerged as industry standards, each with distinct advantages for specific applications.

P20 Pre-Hardened Steel: The Versatile Workhorse

P20 (also known as 1.2311 or 3Cr2Mo) remains the most commonly used steel for plastic pallet moulds, and for good reason. This chrome-moly tool steel offers:

- Pre-hardened condition (28-32 HRC) requiring no additional heat treatment

- Good machinability and weldability

- Adequate wear resistance for most thermoplastics

- Excellent polishability for surface-critical applications

- Reasonable corrosion resistance

- Good dimensional stability

For standard pallet applications where extreme wear is not expected, P20 provides an excellent balance of performance and cost-effectiveness. Its pre-hardened nature significantly reduces lead time and eliminates the risk of distortion during heat treatment.

H13 Hot Work Tool Steel: The Durability Champion

When producing pallets from abrasive materials like glass-filled polymers or requiring extremely high production volumes, H13 (1.2344) offers superior performance:

- Excellent hot hardness (can be hardened to 48-52 HRC)

- Superior wear resistance compared to P20

- Better resistance to thermal fatigue

- Good toughness to resist impact loading

- Excellent thermal crack resistance

H13 requires additional heat treatment, increasing both cost and lead time. However, this investment pays dividends through extended mould life and reduced maintenance costs for high-volume production.

718 Modified Mould Steel: The Premium Alternative

For manufacturers seeking an optimal balance between P20’s ease of use and H13’s durability, 718 modified steel (1.2738) offers compelling advantages:

- Pre-hardened to 35-40 HRC with through-hardening capability

- Improved wear resistance compared to standard P20

- Better nitriding response5 for surface enhancement

- Excellent polishability for aesthetic applications

- Improved through-thickness hardness uniformity

- Enhanced weldability for repairs and modifications

Though approximately 20-30% more expensive than standard P20, 718 modified steel often provides better overall value through extended service life and reduced maintenance requirements.

Stainless Steel Options: Corrosion Protection Priority

When producing pallets for food, pharmaceutical, or outdoor applications where corrosion resistance is paramount, stainless options become necessary:

| Steel Grade | Hardness (HRC) | Corrosion Resistance | Relative Cost | Best Applications |

|---|---|---|---|---|

| 420 Stainless | 48-52 | Good | Medium-High | Food-grade pallets |

| 440C Stainless | 56-58 | Moderate | High | High-wear corrosive environments |

| S136 (AISI 420) | 48-52 | Excellent | Very High | Medical/pharmaceutical pallets |

These stainless options command a significant price premium but are essential when regulatory compliance or extreme environmental conditions are concerns.

Strategic Material Allocation for Cost Optimization

A sophisticated approach to pallet mould construction involves strategic material allocation – using different steels for different mould components based on their specific requirements.

Hybrid Construction Approaches

Rather than building the entire mould from a single steel grade, consider these hybrid approaches:

Core/Cavity Differentiation – Using more durable steel for the cavity (which typically experiences more wear) and economical steel for the core

Insert-Based Strategy – Constructing the main mould body from P20 while using H13 inserts for high-wear areas like:

- Gate locations experiencing material flow erosion

- Thin ribs subject to mechanical stress

- Corner features prone to impact damage

- Sliding components with metal-to-metal contact

Surface Treatment Optimization – Applying targeted surface treatments to standard steels:

- Nitriding for improved surface hardness

- PVD coatings for reduced friction and wear

- Chrome plating for corrosion protection

This strategic approach can reduce overall material costs by 15-25% while maintaining or even improving performance in critical areas.

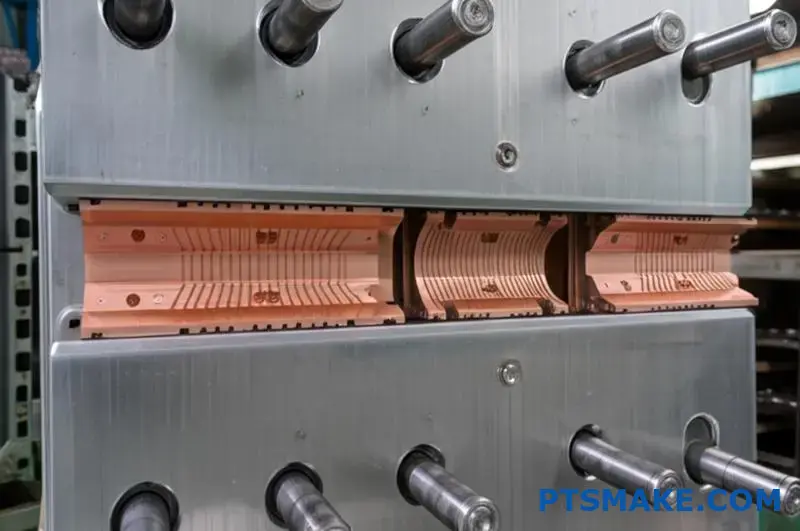

Copper Alloy Components for Thermal Management

While steel forms the structural foundation of pallet moulds, strategic use of copper alloys significantly improves thermal performance. Beryllium copper (BeCu) offers thermal conductivity approximately 5 times higher than tool steel, making it ideal for:

- Cores in thick sections – Removing heat from areas prone to sink marks

- Areas requiring rapid cooling – Reducing cycle time in critical sections

- Hot spots identified in thermal analysis – Balancing overall cooling

Despite its higher material cost, BeCu often delivers compelling ROI through cycle time reduction and quality improvements in challenging pallet designs.

Processing Implications of Steel Selection

Your steel choice directly impacts several aspects of mould manufacturing and maintenance:

Machining Considerations

Harder steels generally require:

- Reduced cutting speeds

- More frequent tool changes

- Specialized cutting strategies

- Longer machining time

These factors increase initial mould cost but may be offset by improved longevity.

Heat Treatment Requirements

Non-pre-hardened steels require careful heat treatment planning:

- Proper stress relief before final machining

- Controlled heating and cooling to minimize distortion

- Multiple tempering cycles for optimal performance

- Additional machining allowance to compensate for dimensional changes

When selecting through-hardened steels, factor an additional 2-3 weeks of lead time for proper heat treatment.

Maintenance and Serviceability

Different steels offer varying degrees of repairability:

- P20 offers excellent weldability for repairs

- H13 requires pre-heating and specialized welding procedures

- Stainless grades often require specialized electrodes

Consider your maintenance capabilities when selecting mould materials, especially for high-volume production where downtime is costly.

By carefully evaluating the specific requirements of your plastic pallet application, production volume, and lifetime cost considerations, you can select the optimal steel that balances performance and economics. Remember that the cheapest steel is rarely the most economical in the long run – the true measure is cost-per-part over the mould’s entire production life.

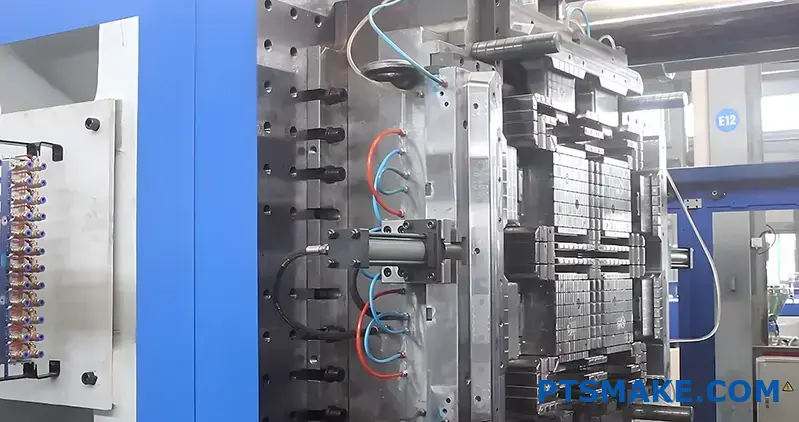

Manufacturing Equipment & Processing Technologies

Ever wondered what powers the precision behind those flawlessly engineered plastic pallets? The magic lies behind factory doors where specialized machinery transforms raw designs into durable industrial workhorses.

Manufacturing high-quality plastic pallet moulds requires a sophisticated ecosystem of cutting-edge equipment and refined processing technologies. From precision machining centers to advanced inspection systems, each piece of equipment plays a crucial role in delivering moulds that perform flawlessly for millions of cycles.

The Essential Machinery for Precision Pallet Mould Manufacturing

Creating plastic pallet moulds that deliver consistent, high-quality products requires specialized manufacturing equipment that offers exceptional precision and reliability. At PTSMAKE, our production floor houses a comprehensive array of machinery specifically designed for mould manufacturing excellence.

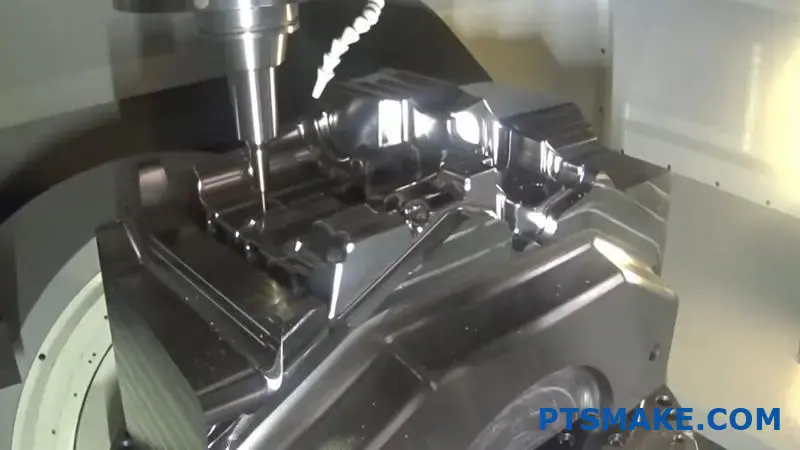

High-Precision CNC Machining Centers

At the heart of our pallet mould manufacturing process are advanced CNC machining centers. These sophisticated systems perform the critical cutting operations that transform raw steel blocks into precision mould components.

For large pallet moulds, we utilize 5-axis machining centers with the following specifications:

| Machine Type | Key Capabilities | Best Applications |

|---|---|---|

| 5-Axis CNC Mills | Complex 3D surfaces, undercuts | Cavity and core machining |

| High-Speed CNC | Fine details, excellent surface finish | Finishing operations |

| Heavy-Duty CNC | Large workpieces, deep cavity work | Base plate and large component machining |

These machines offer positioning accuracy within ±0.005mm, essential for creating the perfect mating surfaces between mould components. For plastic pallet moulds with complex rib structures and textured surfaces, this precision ensures proper material flow and part formation.

The latest high-speed machining centers also provide exceptional surface finishes directly from machining, reducing the need for manual polishing and ensuring more consistent cooling performance through the finished mould surfaces.

Specialized EDM Equipment for Complex Features

Electrical Discharge Machining (EDM) plays a crucial role in creating features that would be impossible with conventional machining. For plastic pallet moulds, we employ both wire and sinker EDM systems:

- Wire EDM – Creates precise cutting paths for complex insert shapes and ejector pin holes

- Sinker EDM – Forms textured surfaces and deep cavities with sharp corners

Our EDM equipment can achieve surface finishes as fine as Ra 0.1 μm, essential for creating texture patterns that both enhance pallet appearance and improve release during molding.

Precision Grinding Equipment

Surface grinding and cylindrical grinding machines ensure perfect flatness and dimensional accuracy for mating surfaces. These machines deliver:

- Surface flatness within 0.01mm over 1000mm length

- Parallelism within 0.005mm

- Surface finishes of Ra 0.4 μm or better

For plastic pallet moulds, where proper sealing between mould halves is essential to prevent flash, precision grinding creates the perfect mating surfaces that ensure dimensional stability throughout the mould’s operational life.

Advanced Heat Treatment Facilities

Heat treatment plays a critical role in determining the performance and longevity of plastic pallet moulds. Our heat treatment capabilities include:

- Vacuum heat treatment – Minimizes distortion and prevents surface oxidation

- Controlled atmosphere furnaces – Ensures consistent hardening throughout large components

- Cryogenic processing – Enhances wear resistance for high-production moulds

- Stress relief processing – Prevents warpage during machining and operation

For high-volume plastic pallet production, properly heat-treated moulds offer dramatically extended service life, often running millions of cycles before requiring maintenance.

Advanced Metrology Systems for Quality Assurance

Quality control is paramount in plastic pallet mould manufacturing. Our inspection systems verify that every dimension meets exacting specifications before assembly begins.

Coordinate Measuring Machines (CMM)

Our CMM systems provide comprehensive verification of complex 3D geometries, measuring:

- Dimensional accuracy to within ±0.003mm

- Form tolerances including flatness, roundness, and cylindricity

- Positional relationships between critical features

For plastic pallet moulds with dozens of ejector pins, cooling channels, and mating surfaces, this precision ensures proper alignment and function of all components.

Optical Measurement Systems

For surface textures and fine details, optical scanning provides:

- Non-contact measurement of delicate features

- Rapid scanning of complex geometries

- Comparison against CAD models with color-coded deviation maps

This technology is particularly valuable for textured surfaces on plastic pallets, ensuring consistent appearance across multiple moulds when production scaling requires multiple tools.

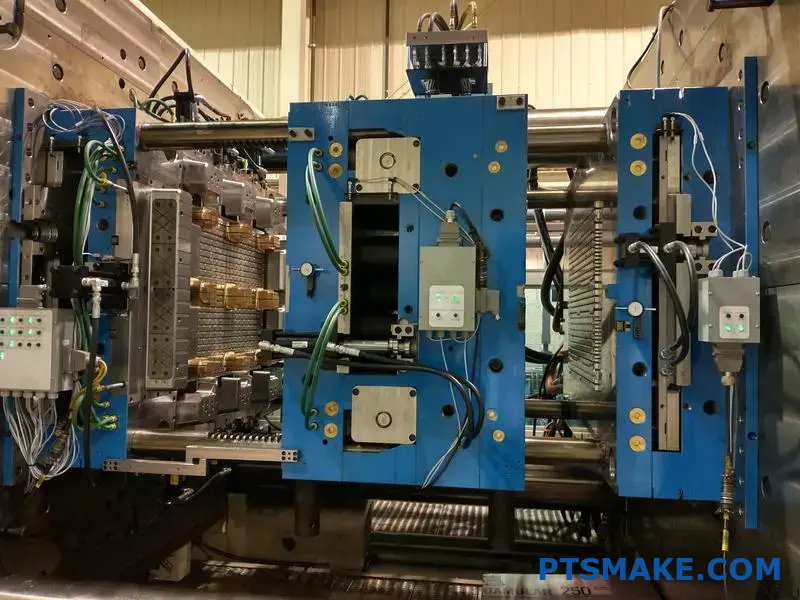

Digital Moulding Systems for Process Control

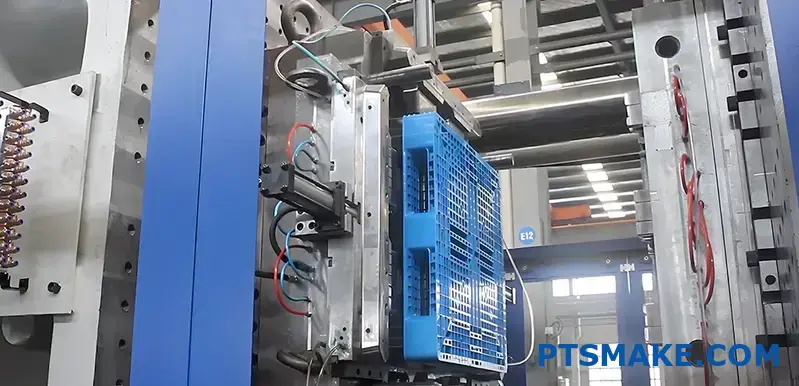

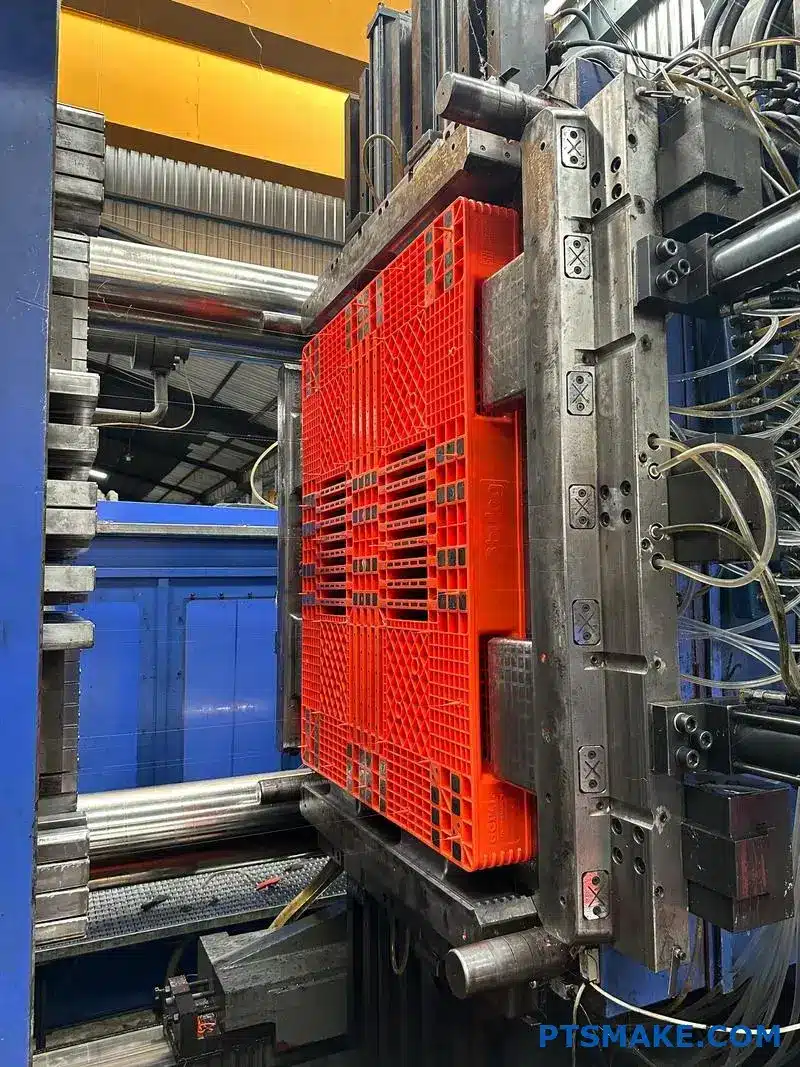

Modern plastic pallet production relies on sophisticated injection molding machines6 with advanced control systems. These digital systems provide:

Precision Parameter Control

Today’s injection molding systems offer unprecedented control over:

- Injection pressure profiles – Programmable in multiple stages for optimal filling

- Temperature zoning – Independent control of different mould areas

- Clamp force distribution – Ensuring proper sealing despite large mould sizes

- Cooling time optimization – Balancing cycle time against part quality

For large plastic pallets, these controls prevent common defects like warping, sink marks, and incomplete filling that would otherwise compromise performance.

Integrated Monitoring Systems

Real-time monitoring ensures consistent quality throughout production runs:

- Cavity pressure sensors that detect filling abnormalities

- Temperature monitoring throughout the mould

- Clamp force verification to prevent flash

- Cycle time analysis for continuous optimization

These monitoring systems allow operators to catch potential issues before they result in defective parts, maintaining consistent quality throughout production runs.

Adaptive Processing Technology

The latest molding systems incorporate machine learning algorithms that:

- Detect process drift before it affects part quality

- Automatically adjust parameters to compensate for material variations

- Optimize cycle times based on historical performance data

- Predict maintenance needs before failures occur

For plastic pallet production, where consistency is essential for stackability and load-bearing capacity, these adaptive systems ensure uniform quality across millions of parts.

Human Expertise: The Critical Factor

Despite all the advanced equipment, the most valuable asset in plastic pallet mould manufacturing remains skilled personnel. At PTSMAKE, our team includes:

Master Toolmakers

With decades of experience, our toolmakers possess:

- Deep understanding of material behavior during machining

- Ability to achieve perfect fits between components

- Expertise in hand finishing and polishing

- Troubleshooting skills for complex mould issues

Their craftsmanship ensures that every plastic pallet mould not only meets specifications but also offers optimal performance in production.

Process Engineers

Our process engineers bridge the gap between design and production by:

- Optimizing machining strategies for efficiency and quality

- Developing specialized fixtures for complex components

- Creating standardized procedures for consistent results

- Implementing continuous improvement initiatives

Their expertise translates into moulds that not only perform well initially but maintain that performance throughout their operational life.

Quality Control Specialists

Dedicated QC personnel ensure that every component meets our exacting standards:

- Comprehensive inspection of all critical dimensions

- Documentation of all measurements for traceability

- Final assembly verification prior to testing

- Performance validation under production conditions

Their meticulous attention to detail prevents costly issues during production, ensuring that plastic pallet moulds deliver consistent performance from the first shot.

By combining cutting-edge equipment with experienced personnel, PTSMAKE creates plastic pallet moulds that deliver exceptional performance, longevity, and value. Our comprehensive manufacturing capabilities ensure that every mould component meets the highest standards of precision and quality, resulting in plastic pallets that consistently exceed our customers’ expectations.

Block Production Methods for Large Pallet Moulds

Have you ever wondered how those massive plastic pallets that handle tons of goods are made with such precision? The secret lies not in making one giant mould, but in a clever production technique that breaks down the seemingly impossible into manageable pieces.

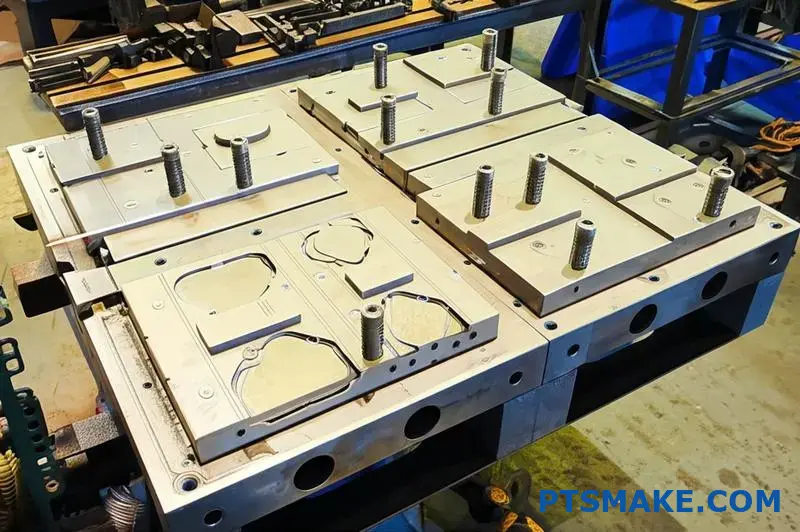

Block-type splicing production represents a revolutionary approach to manufacturing large pallet moulds, dividing complex structures into smaller, manageable pieces that can be produced simultaneously. This method dramatically shortens production cycles while enabling precise manufacturing that would be challenging or impossible with traditional single-piece approaches.

The Fundamentals of Block-Type Splicing Production

When tackling the challenge of producing large plastic pallet moulds, traditional single-piece manufacturing approaches often hit significant limitations. The sheer size of pallet moulds (typically 1200×1000mm or larger) creates challenges for machining, heat treatment, and quality control. Block-type splicing production offers an elegant solution by breaking these massive moulds into manageable sections.

The concept is surprisingly straightforward yet powerful: instead of creating one enormous mould, we divide it into multiple blocks that can be manufactured independently and then assembled with precision. This approach transforms what would be an unwieldy, time-consuming project into parallel workflows that can be optimized individually.

At PTSMAKE, I’ve implemented this methodology for numerous clients, consistently achieving reductions in lead time of 30-40% compared to traditional approaches. The benefits extend beyond just speed—this method enables superior precision and quality control throughout the production process.

Strategic Block Division Planning

The success of block-type splicing begins with intelligent division of the mould into appropriate sections. This planning phase considers several critical factors:

- Structural Integrity – Block divisions must maintain the overall structural strength

- Functional Boundaries – Dividing along natural functional boundaries of the pallet design

- Manufacturing Accessibility – Creating blocks that can be effectively machined on available equipment

- Assembly Precision – Planning for high-precision joining of blocks during assembly

- Thermal Management – Ensuring cooling channels can be properly integrated across block boundaries

The division planning typically begins with 3D model analysis, identifying logical separation points that minimize interference with critical features like cooling channels, ejector pin locations, and structural elements.

Parallel Processing Advantages

The most significant advantage of block-type splicing is the ability to process multiple components simultaneously. This parallel workflow offers numerous benefits:

| Advantage | Traditional Method | Block Splicing Method |

|---|---|---|

| Machine Utilization | Single large machine required | Multiple smaller machines can be used concurrently |

| Processing Time | Sequential operations on one large piece | Parallel operations on multiple blocks |

| Heat Treatment | Challenging for large pieces with risk of distortion | More uniform and controlled for smaller blocks |

| Quality Control | Difficult for large dimensions | Precise inspection possible for each block |

| Risk Management | One error affects entire mould | Issues isolated to individual blocks |

This parallel approach dramatically reduces the critical path in project timelines. For example, while one block undergoes heat treatment, another can be in the machining phase, and a third in the finishing process.

Precision Joining Techniques for Block Assembly

The effectiveness of block splicing production hinges on precision joining of the individual components. Several advanced techniques ensure seamless integration:

High-Precision Mechanical Interlocking

Modern block splicing relies on sophisticated interlocking mechanisms:

- Dovetail Joints – Provide mechanical strength across joining surfaces

- Keying Systems – Ensure perfect alignment between adjacent blocks

- Stepped Interfaces – Create self-aligning surfaces that prevent misalignment

These mechanical connections work in conjunction with fastening systems to create a unified structure that functions as if it were manufactured from a single piece.

Precision Fastening Systems

Beyond interlocking geometries, specialized fastening systems secure the blocks:

- High-tensile Steel Bolts – Provide clamping force to maintain position during thermal cycling

- Tapered Pins – Ensure precise positioning between adjacent blocks

- Expansion Dowels – Compensate for thermal expansion during operation

The fastening system design must account for the thermal cycling that the mould will experience during production, ensuring that joints remain tight despite repeated heating and cooling.

Surface Finishing Considerations

The joining surfaces between blocks require exceptional surface finish to:

- Create leak-proof seals that prevent plastic intrusion

- Provide maximum contact area for thermal transfer

- Ensure structural rigidity across the entire assembly

We typically machine these surfaces to Ra 0.4μm or better, often with additional hand lapping to achieve perfect mating surfaces.

Thermal Management Across Block Boundaries

One of the most challenging aspects of block splicing is maintaining effective cooling across block boundaries. Plastic pallets require uniform cooling to prevent warping and ensure consistent shrinkage.

Cross-Block Cooling Channel Design

To maintain effective cooling, we implement several specialized techniques:

- O-ring Sealed Connections – Allow cooling channels to cross block boundaries without leakage

- Modular Cooling Manifolds – Distribute coolant evenly across all blocks

- Thermal Interface Materials – Enhance heat transfer between block surfaces

- Redundant Cooling Paths – Provide backup cooling if one channel becomes restricted

The cooling system design must consider both the thermal requirements of the pallet design and the physical constraints introduced by the block divisions.

Thermal Simulation Validation

Before manufacturing begins, we conduct comprehensive thermal simulation of the entire assembly:

- Finite Element Analysis confirms uniform cooling across the entire mould

- Flow simulation verifies balanced coolant distribution through all channels

- Thermal cycling analysis predicts expansion and contraction at block interfaces

These simulations allow us to refine the design before cutting any steel, ensuring that the finished mould will provide consistent cooling despite its modular construction.

Practical Advantages in Manufacturing Operations

Block-type splicing production offers several practical advantages beyond just faster lead times:

Enhanced Maintenance and Repairability

When damage or wear occurs in a traditional single-piece mould, repairs can be extremely complex and time-consuming. With block construction:

- Individual blocks can be removed and repaired without dismantling the entire mould

- Damaged sections can be replaced rather than repairing the entire mould

- Specialized surfaces can be updated or modified independently

This modular approach significantly reduces downtime and repair costs throughout the mould’s operational life.

Facilitating Design Modifications

Market requirements for plastic pallets evolve over time, and designs often need modification. Block construction allows:

- Targeted updates to specific pallet features by replacing only relevant blocks

- A/B testing of design variations by swapping alternative blocks

- Gradual upgrading of mould components without complete replacement

This flexibility extends the useful life of the mould investment and allows manufacturers to adapt to changing market needs more efficiently.

Transportation and Logistics Benefits

Large single-piece moulds present significant logistical challenges:

- May exceed weight limits for standard handling equipment

- Require specialized transportation arrangements

- Create safety concerns during installation and movement

Block construction addresses these issues by allowing the mould to be transported in manageable sections and assembled on-site, simplifying logistics and reducing associated costs.

The block-type splicing production method represents a significant advancement in large pallet mould manufacturing. By dividing complex moulds into manageable pieces, this approach enables faster production, enhanced precision, and greater flexibility throughout the entire mould lifecycle. For manufacturers seeking to optimize their plastic pallet production capabilities, this methodology offers compelling advantages in both initial manufacturing and long-term operations.

Advantages of Modern Plastic Pallet Moulding

Ever wondered why leading logistics companies worldwide are rapidly switching from wooden to plastic pallets? The transformation isn’t just about following trends—it’s driven by remarkable technological advancements in plastic pallet moulding that deliver game-changing benefits across supply chains.

Modern plastic pallet moulding combines advanced engineering, sustainable materials, and precision manufacturing to create products that outperform traditional alternatives in virtually every metric. From environmental impact to operational efficiency, these innovations are revolutionizing how goods move through global supply chains.

The Environmental Revolution in Plastic Pallet Production

The misconception that plastic pallets are environmentally unfriendly couldn’t be further from today’s reality. Modern plastic pallet moulding has transformed into one of the most sustainable options in materials handling through several key innovations.

Closed-Loop Recycling Systems

One of the most significant advantages of modern plastic pallet moulding is the implementation of closed-loop recycling systems. Unlike wooden pallets that eventually splinter and become waste, plastic pallets can be:

- Completely recycled at end-of-life

- Reprocessed into new pallets with minimal quality loss

- Kept out of landfills indefinitely

- Tracked through their lifecycle using embedded RFID technology

At PTSMAKE, we’ve helped clients implement systems where damaged pallets are collected, ground down, and directly reincorporated into new production—creating a truly circular economy for materials handling.

Innovative Use of Post-Consumer Plastics

Modern pallet moulding technologies have advanced significantly in their ability to utilize post-consumer recycled (PCR) materials:

| Material Type | Recycled Content Capability | Applications |

|---|---|---|

| HDPE | Up to 100% recycled content | General-purpose pallets |

| PP | 30-70% recycled content | Chemical-resistant applications |

| Mixed Plastics | 80-100% recycled content | Economy pallets |

This capability transforms what would otherwise be waste plastic into valuable, functional products with multi-year lifespans. The environmental advantage is clear—each recycled plastic pallet can prevent approximately 3-4kg of plastic from entering landfills or oceans.

Lower Carbon Footprint Through Design Optimization

Advanced moulding techniques allow us to create plastic pallets that:

- Weigh 30-40% less than comparable wooden pallets

- Require fewer trucks for transportation

- Reduce fuel consumption during distribution

- Minimize carbon emissions throughout their lifecycle

Through finite element analysis and structural optimization, modern moulding technology creates pallets that maximize strength while minimizing material usage—a win-win for both economics and environmental sustainability.

Customization Capabilities for Specialized Applications

Unlike wooden pallets with limited design flexibility, modern plastic pallet moulding offers unprecedented customization options that address specific industry challenges.

Industry-Specific Design Features

Modern moulding technology enables the inclusion of specialized features tailored to particular industries:

Pharmaceutical and Medical Applications

For pharmaceutical transport, we can create pallets with:

- Completely sealed surfaces that prevent contamination

- Built-in RFID tracking for regulatory compliance

- Temperature-monitoring integration

- Sterilization compatibility

Food Processing Requirements

Food-grade pallets benefit from:

- Antimicrobial additives that inhibit bacterial growth

- Smooth, non-porous surfaces that prevent food trap points

- High-pressure washdown capability

- Metal detectability for food safety protocols

Electronics and Sensitive Components

For delicate electronics, plastic pallet moulding offers:

- Static dissipative properties to protect sensitive components

- Precision dimensional consistency for automated handling

- Smooth surfaces that won’t generate particles or dust

- Flame-retardant additives for safety compliance

Modular Construction Possibilities

Advanced moulding techniques enable modular pallet designs that were previously impossible:

- Interlocking components that can be assembled in various configurations

- Field-replaceable parts for extended service life

- Compatibility between different pallet types within a system

- Customizable dimensions beyond standard sizes

This modularity provides logistics managers with unprecedented flexibility to adapt their material handling systems to changing requirements without complete fleet replacement.

Color-Coding and Branding Opportunities

Modern plastic pallet moulding allows for integral coloring and branding:

- Color-coding for inventory management and routing

- Embedded logos and text that won’t wear off

- High-visibility safety colors for specific applications

- Custom aesthetics for retail or display applications

These features enhance operational efficiency and brand visibility throughout the supply chain.

Hygienic Advantages Through Non-Porous Construction

The non-porous nature of plastic pallets created through modern moulding techniques provides significant advantages in hygiene-critical applications.

Elimination of Bacterial Harboring Spaces

Unlike wooden pallets that absorb liquids and harbor bacteria in cracks and grain, plastic pallets:

- Resist moisture absorption completely

- Provide no crevices for bacterial growth

- Maintain cleanliness through repeated usage

- Prevent cross-contamination between loads

This makes them ideal for food, pharmaceutical, and healthcare applications where hygiene is paramount.

Enhanced Cleaning and Sanitization Options

Modern plastic pallet moulding enables designs that are compatible with advanced cleaning processes:

- High-temperature steam cleaning (up to 121°C)

- Chemical sanitization without material degradation

- Automated washing systems compatibility

- Pressure washing without damage to structural integrity

These cleaning capabilities ensure that plastic pallets maintain hygienic conditions throughout their service life, something impossible with wooden alternatives.

Significant Cost Advantages Over Traditional Materials

Perhaps the most compelling advantage of modern plastic pallet moulding is the substantial cost savings it delivers across multiple dimensions.

Extended Service Life

While wooden pallets typically last for 15-30 trips before requiring repair or replacement, plastic pallets routinely deliver:

- 100+ trips in closed-loop systems

- 5-10 year service life under normal conditions

- Consistent performance throughout their lifespan

- Predictable maintenance requirements

This extended service life dramatically reduces the total cost of ownership, even when the initial purchase price may be higher than wood alternatives.

Reduced Handling Damage and Product Loss

The precision engineering possible with modern plastic pallet moulding creates products that:

- Maintain dimensional stability throughout their life

- Eliminate nail protrusions that damage goods

- Provide consistent load distribution to protect products

- Prevent splinters and contamination of merchandise

By reducing product damage rates by as much as 40%, plastic pallets deliver significant savings that often go unmeasured in traditional ROI calculations.

Elimination of Regulatory Treatment Costs

International shipping regulations like ISPM-15 require wooden pallets to undergo heat treatment or fumigation to prevent pest transmission. Plastic pallets:

- Are exempt from these phytosanitary regulations

- Eliminate treatment costs

- Avoid shipment delays due to inspection

- Prevent chemical contamination from fumigation

For companies engaged in global trade, these advantages alone can justify the transition to plastic pallets.

Modern plastic pallet moulding technology has transformed what was once a simple material handling tool into a sophisticated logistics solution that delivers compelling advantages across environmental sustainability, customization, hygiene, and cost-effectiveness. As supply chains continue to optimize for efficiency and sustainability, the adoption of these advanced moulding technologies will accelerate, further expanding the gap between plastic and traditional wooden pallets.

Learn how this critical material property affects your pallet design and performance. ↩

Learn how polymer chains align during injection and impact the structural integrity of your finished pallet. ↩

Learn about this critical engineering principle that ensures component stability during thermal cycling. ↩

Learn how proper bushing selection affects long-term ejection system performance and maintenance requirements. ↩

Discover how this surface hardening process can extend your mould life while maintaining core toughness. ↩

Learn about the latest advancements in injection molding machine technology and how they improve plastic pallet production. ↩