Understanding Two-Shot Injection Molding Fundamentals

Ever wondered how your smartphone case has that perfect soft-touch grip while maintaining a rigid structure? Or how automotive dashboards combine different textures and colors so seamlessly? The manufacturing magic behind these everyday marvels is more fascinating than you might think.

Two-shot injection molding revolutionizes product manufacturing by injecting two different materials into a single mold sequentially, creating components that bond at the molecular level without additional assembly steps. This innovative process delivers complex, multi-material parts in a single efficient operation.

The Evolution of Two-Shot Injection Molding

Two-shot injection molding (also called dual-shot or multi-material molding) has transformed manufacturing across numerous industries. As someone deeply involved in precision manufacturing at PTSMAKE, I’ve witnessed this technology evolve from a specialized technique to an essential manufacturing process for companies seeking competitive advantages in product design and production efficiency.

The history of this technology traces back to the 1970s when manufacturers began experimenting with ways to combine multiple materials in a single molding cycle. Today, it has matured into a sophisticated process that allows for intricate designs previously impossible or economically unfeasible with traditional manufacturing methods.

How Two-Shot Injection Molding Works

The Basic Process

The two-shot injection molding process occurs in two distinct phases:

- First Shot: The primary material (usually the harder substrate) is injected into the mold cavity to form the base component.

- Second Shot: The mold either rotates or slides to reveal new cavity space, where a second material is injected to bond with the first component.

What makes this process truly remarkable is the molecular bonding1 that occurs between the two materials. Unlike mechanical assembly or adhesive bonding, the materials join at a molecular level when properly selected, creating exceptionally strong connections.

Equipment Requirements

The specialized equipment needed for two-shot injection molding includes:

| Equipment Component | Function | Importance |

|---|---|---|

| Dual Injection Units | Allows injection of two different materials | Essential |

| Rotating or Sliding Mold | Repositions the first shot for the second material | Critical for alignment |

| Advanced Control Systems | Coordinates timing between shots | Ensures quality results |

| Material Handling Systems | Manages different plastics efficiently | Prevents contamination |

At PTSMAKE, we’ve invested in state-of-the-art two-shot equipment that ensures precise material delivery and exceptional part consistency.

Material Compatibility Considerations

One of the most critical aspects of two-shot injection molding is material selection. Not all materials bond well together, and understanding compatibility is essential for successful production.

Common Material Combinations

In my experience working with clients across various industries, these material combinations consistently perform well:

- Rigid/Flexible Combinations: Polycarbonate (PC) with thermoplastic elastomer (TPE)

- Transparent/Opaque Pairs: Clear polycarbonate with colored ABS

- Chemical Resistant Pairings: Nylon with specially formulated TPEs

- High/Low Modulus Materials: Polypropylene with softer polyethylene

The key factor determining compatibility is the chemical affinity between materials. Materials with similar chemical structures typically form stronger bonds than those with vastly different compositions.

Material Selection Factors

When helping clients select materials for two-shot applications, I consider several factors:

- End-use requirements: Will the part need to withstand specific environmental conditions?

- Mechanical properties: What strength, flexibility, or hardness is required?

- Processing temperatures: Can both materials process within a compatible temperature range?

- Shrinkage rates: Will differential shrinkage create stress or warping?

At PTSMAKE, our materials engineers work closely with design teams to ensure optimal material selection for each application.

Key Advantages of Two-Shot Injection Molding

Design Flexibility

Two-shot molding opens up remarkable design possibilities that simply aren’t achievable with conventional methods:

- Multi-color components without painting or decorating

- Varying textures within a single part (soft-touch grips on hard handles)

- Embedded seals and gaskets without secondary assembly

- Selective rigidity where some sections remain firm while others flex

Production Efficiency

Beyond design advantages, the process delivers substantial manufacturing benefits:

- Reduced assembly costs by eliminating secondary operations

- Lower labor requirements without manual assembly steps

- Improved quality with fewer potential failure points

- Faster overall production cycles compared to multi-step manufacturing

- Reduced inventory of component parts

Enhanced Product Performance

The molecular bonding between materials results in products with superior characteristics:

- Higher durability with seamless material transitions

- Better environmental resistance without seams where moisture can penetrate

- Improved ergonomics through strategic material placement

- Enhanced aesthetic appeal with premium look and feel

In my years guiding manufacturers through material selection and process optimization, I’ve consistently seen two-shot molding deliver products that outperform traditionally assembled alternatives.

Common Applications Across Industries

The versatility of two-shot injection molding makes it valuable across numerous sectors:

Consumer Electronics

- Smartphone cases with rubberized grips

- Remote controls with soft-touch buttons

- Wearable devices with multiple material components

Automotive Components

- Dashboard controls with illuminated indicators

- Door handles with integrated seals

- Shifter knobs with ergonomic grips

Medical Devices

- Surgical instruments with customized grip surfaces

- Diagnostic equipment with sealed interfaces

- Drug delivery devices with precise material transitions

I’ve personally helped develop two-shot solutions for clients in each of these industries at PTSMAKE, and the results consistently exceed expectations in terms of both functionality and aesthetics.

Two-Shot Molding vs. Overmolding: Key Differences

Have you ever picked up a power tool with that perfect rubber grip over a hard plastic body and wondered how they created such a seamless combination? The manufacturing magic behind this isn’t just clever assembly—it’s a sophisticated molding technology that’s revolutionizing product design.

Two-shot injection molding and overmolding represent two distinct approaches to creating multi-material plastic parts. Though they achieve similar end results, their processing methods, equipment requirements, and production efficiencies differ significantly, impacting everything from design possibilities to manufacturing costs.

Technical Process Distinctions

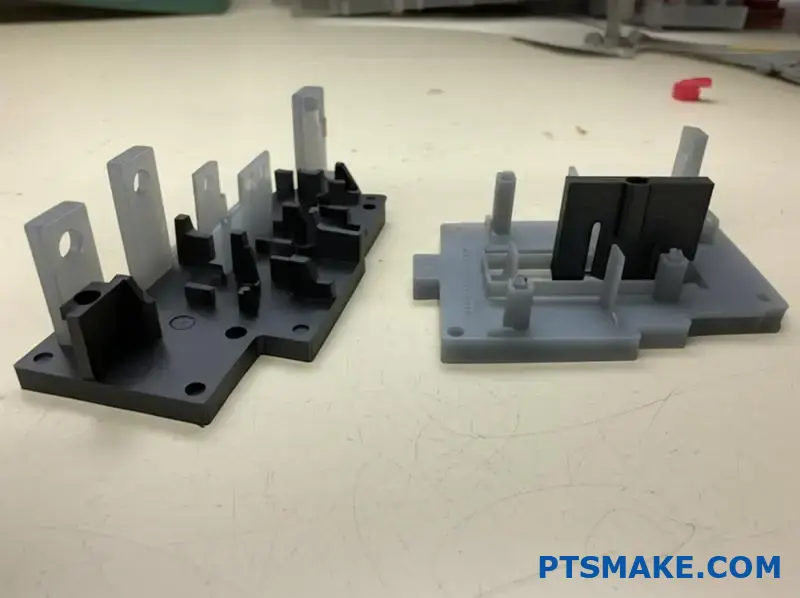

Two-Shot Molding: Single Machine, Dual Injection

Two-shot injection molding represents a more integrated approach to multi-material production. The process unfolds within a single machine cycle, making it distinct from other multi-material techniques.

In a typical two-shot process:

- The first material (often a rigid substrate) is injected into the mold cavity

- The mold then rotates or indexes to a second position

- The second material is injected into or around the first component

- Both materials cool together, forming molecular bonds at their interface

The key innovation here is the specialized rotating or indexing mold technology. These sophisticated tools allow the first shot to be repositioned precisely for the second material injection without removing the part from the machine.

At PTSMAKE, we’ve refined this process to achieve exceptionally precise material transitions, which is particularly valuable for clients in medical and consumer electronics industries where component quality is non-negotiable.

Overmolding: Two-Step Process

Overmolding, while achieving similar multi-material results, typically follows a different production path:

- The base component (substrate) is molded in a conventional injection molding process

- This completed first-shot part is either:

- Transferred to a second machine

- Kept in the same machine but with the mold opened and the second shot injected in a new cycle

- The second material is injected over the first component

- The finished multi-material part is ejected

This sequential approach creates a distinct workflow compared to two-shot molding. The interval between first and second shots can range from seconds to days, depending on the production setup.

Equipment Requirements and Complexity

The machinery differences between these processes represent significant considerations for manufacturers:

| Aspect | Two-Shot Molding | Overmolding |

|---|---|---|

| Machine Requirements | Specialized dual-injection machines | Can use standard injection molding equipment |

| Mold Complexity | Complex rotating or indexing molds | Simpler mold designs possible |

| Initial Investment | Higher | Lower |

| Automation Level | Highly automated | Can be partially manual |

| Floor Space | Compact (single machine) | May require more space (two machines) |

The equipment investment represents one of the most significant differentiators between these processes. Two-shot molding requires specialized machinery with multiple injection units and rotating mold systems. This specialized equipment comes with higher initial costs but delivers greater efficiency for suitable applications.

Material Bonding Considerations

The intermolecular adhesion2 between materials represents a critical factor in both processes, but the timing differences create distinct considerations:

Two-Shot Bonding Dynamics

In two-shot molding, the second material is injected while the first shot is still warm. This creates ideal conditions for molecular bonding as the polymer chains can more readily interact at elevated temperatures. The result is often a stronger material interface without requiring specialized adhesion promoters.

This thermal advantage means two-shot molding can sometimes bond materials that would be challenging to join using overmolding. At PTSMAKE, we’ve successfully paired rigid polycarbonates with TPEs (thermoplastic elastomers) using two-shot processes where traditional overmolding would require special surface treatments.

Overmolding Bonding Challenges

Since overmolding often involves a completely cooled first component, the bonding dynamics differ significantly:

- The interface temperature is lower, potentially reducing molecular entanglement

- Surface treatments or primers may be necessary for optimal adhesion

- Material compatibility becomes even more critical

- Chemical bonding agents might be required for certain material combinations

This doesn’t mean overmolding creates inferior bonds—just that the material selection and preparation considerations differ from two-shot processes.

Production Efficiency Comparison

The efficiency differences between these processes impact overall production economics:

Cycle Time Analysis

Two-shot molding typically delivers faster overall cycle times for complete parts since:

- No part transfer between machines is required

- The first shot doesn’t need to completely cool before the second shot

- Both materials cool simultaneously during the final phase

In high-volume production scenarios, these time savings can translate to significant cost advantages. For several automotive clients, we’ve reduced production time by up to 30% by converting traditional overmolding processes to two-shot technology.

Labor and Handling Considerations

The handling requirements also differ substantially:

- Two-Shot Process: Minimal handling between shots, reducing labor costs and contamination risks

- Overmolding: May require manual or automated transfer systems between molding stages

For medical device manufacturers particularly concerned with cleanliness and part integrity, the reduced handling of two-shot processes often justifies the higher equipment investment.

Application Suitability Factors

Despite their differences, both processes have optimal applications where their particular characteristics shine:

Ideal Two-Shot Applications

Two-shot molding excels for:

- High-volume production runs where efficiency justifies equipment costs

- Parts requiring precise alignment between materials

- Designs with complex geometry at material transitions

- Products needing high-strength material interfaces

- Components with thin-wall sections in the second material

Optimal Overmolding Scenarios

Overmolding often works best for:

- Lower volume production runs

- Simpler geometries with less complex material transitions

- Applications where the substrate needs to fully cure before second shot

- Situations where existing standard equipment must be utilized

- Products where the second material completely encapsulates the first

Understanding these application suitabilities helps manufacturers choose the most cost-effective process for specific product requirements.

Making the Right Manufacturing Choice

The decision between two-shot molding and overmolding ultimately depends on multiple factors including production volume, part design complexity, material requirements, and available manufacturing infrastructure.

At PTSMAKE, we conduct thorough process feasibility analyses for clients weighing these options, considering factors like:

- Annual production volumes

- Product lifetime expectations

- Available capital for tooling investment

- Material combination requirements

- Quality and cosmetic specifications

- Long-term manufacturing strategy

By thoroughly evaluating these factors, manufacturers can select the multi-material process that delivers the optimal balance of quality, efficiency, and cost-effectiveness for their specific application.

Advantages of Two-Shot Injection Molding Technology

Ever picked up a game controller with that perfect grippy texture, or admired how your toothbrush combines firm handle and soft bristle holder in one seamless piece? These everyday marvels showcase manufacturing innovation that’s changing how products are made, felt, and experienced.

Two-shot injection molding technology delivers extraordinary advantages that traditional manufacturing simply can’t match. By fusing different materials at the molecular level during a single production cycle, this process creates products with enhanced durability, superior aesthetics, and innovative functionality while dramatically streamlining manufacturing.

Enhanced Product Durability

Molecular Bonding Advantage

Unlike mechanically fastened or glued components that can separate under stress, two-shot injection molded parts feature true molecular bonding between materials. This creates an exceptionally strong connection that significantly enhances product durability.

When we select compatible materials for two-shot molding at PTSMAKE, we’re creating parts where different polymers actually intertwine at the molecular level during formation. This interaction occurs because the second material is injected while the first material is still warm and reactive, allowing polymer chains to entangle and form a powerful bond.

The strength of this molecular connection offers several key durability advantages:

- Elimination of failure points: Traditional assembly methods create seams and joints that become natural failure points. Two-shot molding removes these vulnerabilities entirely.

- Superior stress distribution: Forces applied to multi-material parts are distributed more evenly across material boundaries.

- Enhanced chemical resistance: Without seams or gaps, corrosive substances can’t penetrate between material layers.

- Improved impact resistance: The transition zone between materials can actually absorb and distribute impact forces more effectively than single-material parts.

Environmental Resistance

Two-shot molded products demonstrate remarkable resistance to environmental challenges that would quickly damage conventionally assembled parts:

- Water and moisture resistance: The seamless transition between materials prevents moisture ingress, making two-shot parts ideal for outdoor, marine, and high-humidity applications.

- Temperature cycling tolerance: With properly selected materials, two-shot parts can withstand repeated temperature changes without delamination or cracking at material boundaries.

- UV stability: Specialized material combinations can provide both structural integrity and UV protection in a single component.

In automotive applications, we’ve developed two-shot molded exterior components that maintain their appearance and functionality after years of exposure to extreme conditions – something that would be nearly impossible with conventional assembly methods.

Reduced Manufacturing Time

Elimination of Secondary Operations

One of the most significant efficiency advantages of two-shot injection molding is the dramatic reduction in secondary operations:

| Traditional Assembly | Two-Shot Molding |

|---|---|

| Separate molding of components | Single molding operation |

| Parts cooling and storage | Continuous process flow |

| Material handling between operations | No intermediate handling |

| Assembly line setup | Not required |

| Quality inspection at multiple stages | Single quality checkpoint |

This streamlined process creates a manufacturing timeline that’s often 40-60% shorter than traditional methods. At PTSMAKE, we’ve helped manufacturers convert multi-step assembly processes to two-shot molding and achieve production time reductions that transformed their business economics.

Cycle Time Optimization

The two-shot process naturally optimizes cycle times in several ways:

- Parallel cooling: While the second shot is being injected, the first shot is still cooling, creating time efficiency.

- Reduced handling: Without parts transfer between machines or assembly stations, overall cycle time decreases.

- Automation compatibility: The entire two-shot process is easily automated, eliminating variable human handling times.

- Continuous production flow: The single-machine approach creates a smoother production cadence with fewer interruptions.

For high-volume products where every second of cycle time impacts profitability, two-shot molding provides a competitive advantage that’s difficult to achieve through other manufacturing methods.

Elimination of Assembly Steps

Labor Reduction Impact

The automation of what would traditionally be assembly steps creates significant labor savings:

- Reduced direct labor hours: Manual assembly of multi-material components is eliminated entirely.

- Decreased training requirements: With fewer manual operations, workforce training is simplified.

- Lower quality control staffing: Fewer inspection points means more efficient quality assurance.

- Minimized rework labor: The consistent nature of two-shot molding reduces defects that would require labor-intensive correction.

These labor advantages extend beyond just cost savings – they also make production more predictable and less vulnerable to workforce availability challenges.

Quality Improvements Through Process Integration

When assembly steps are eliminated, quality improves almost automatically:

- Consistent material alignment: The precision of the mold ensures perfect alignment between materials every time.

- Elimination of assembly errors: Human assembly errors are completely removed from the equation.

- Reduced contamination risk: Fewer handling steps means less opportunity for contamination of sensitive components.

- Documented process control: The integrated two-shot process is more easily monitored and controlled than multi-step assembly.

In my experience working with medical device manufacturers, this quality improvement aspect of two-shot molding is often even more valuable than the efficiency gains, particularly for Class II medical devices3 that face rigorous regulatory scrutiny.

Design Flexibility Advantages

Complex Geometry Capabilities

Two-shot injection molding opens up design possibilities that simply aren’t achievable through traditional manufacturing:

- Intricate internal features: Geometries that would be impossible to assemble conventionally can be created through the two-shot process.

- Undercuts and complex curves: Challenging features become achievable when created in sequence rather than assembled.

- Variable wall thickness: Different materials can be used to create sections with varying thickness and properties.

- Integrated channels and pathways: Fluid or air channels can be created between material layers with perfect sealing.

At PTSMAKE, we’ve helped product designers transform concepts that were previously deemed "unmanufacturable" into production realities using two-shot technology.

Material Combination Innovation

The ability to combine different materials creates exciting design opportunities:

- Rigid/flexible combinations: Hard structural components with soft-touch surfaces or flexible sections.

- Opaque/transparent pairings: Clear viewing windows within solid housings without seams or fasteners.

- Conductive/insulating materials: Electrical products with integrated conductive pathways and insulating housings.

- Material-specific performance zones: Different performance characteristics in specific areas of a single part.

This material flexibility allows designers to optimize each section of a product for its specific requirements rather than compromising with a single material.

Improved Aesthetics and User Experience

Seamless Material Transitions

The visual appeal of two-shot molded parts comes largely from their seamless material transitions:

- No visible parting lines: Materials flow together without the visible lines that assembly creates.

- Perfect alignment: Material boundaries align with absolute precision every time.

- Preserved surface finish: Each material maintains its intended surface texture and appearance.

- Crisp color demarcation: Color boundaries are sharp and consistent without bleeding or misalignment.

These aesthetic advantages create products with a premium look and feel that’s immediately apparent to consumers.

Multi-Color and Multi-Texture Possibilities

The creative options available through two-shot molding enhance both visual appeal and user experience:

- Color contrast without painting: Different colored materials can be combined without secondary decorating processes.

- Tactile differentiation: Varying surface textures can guide users’ hands to proper grip areas or controls.

- Visual hierarchy through materials: Important features can be highlighted through material and color contrast.

- Ergonomic customization: Soft materials can be placed precisely where user comfort is most important.

Many of our clients at PTSMAKE have discovered that these aesthetic and experiential advantages translate directly to market differentiation and premium positioning for their products.

When properly implemented, two-shot injection molding transforms not just how products are made, but what’s possible in product design. The technology delivers a rare combination of manufacturing efficiency, enhanced durability, design freedom, and improved user experience that continues to find new applications across industries.

Design Principles for Optimal Two-Shot Molded Parts

Ever wondered why some multi-material products feel seamlessly integrated while others seem obviously assembled? The secret lies not just in the manufacturing technology, but in the intricate design considerations that make two-shot injection molding truly shine. Getting these design elements right can mean the difference between mediocre parts and exceptional ones.

Two-shot injection molding demands thoughtful design that respects how materials flow, interact, and solidify together. By carefully engineering wall transitions, draft angles, and gate locations, manufacturers can consistently produce parts with precise dimensions, strong material bonds, and flawless aesthetics – turning design challenges into competitive advantages.

Material Flow Pattern Considerations

Understanding how plastic flows during the two-shot molding process is fundamental to successful part design. As someone who has overseen hundreds of two-shot molding projects, I’ve learned that material flow patterns significantly impact final part quality and production efficiency.

Visualizing Flow Paths

When designing for two-shot molding, we must visualize how each material will travel through the mold cavity. The flow pattern determines:

- Areas where weld lines might form

- Potential thin spots where materials might not completely fill

- Regions where air might be trapped

- How the first material interfaces with the second shot

Using advanced simulation software at PTSMAKE, we can predict these flow patterns before cutting steel, allowing us to optimize designs early in the development process.

Balancing Flow Length and Pressure

Each material has an optimal flow length-to-pressure ratio. Exceeding this ratio can lead to:

- Incomplete filling (short shots)

- Excessive internal stress

- Dimensional inconsistencies

- Poor bonding at material interfaces

For complex geometries, we often incorporate flow leaders—subtle channels that guide the material through difficult passages without compromising the part’s structural integrity.

Avoiding Flow Hesitation

When plastic hesitates during injection, it can create visible defects or weak spots. This is especially problematic in two-shot applications where the second material needs to bond properly with the first. Strategic design features that help maintain consistent flow include:

- Graduated thickness transitions

- Radiused corners instead of sharp angles

- Uniform wall sections where possible

- Strategic rib placement to guide material flow

These seemingly minor design elements make a tremendous difference in part consistency and appearance.

Wall Thickness Transition Design

The transition between varying wall thicknesses represents one of the most challenging aspects of two-shot design. Poorly executed transitions lead to sink marks, warping, and weak points.

Gradual Thickness Changes

A fundamental rule we follow at PTSMAKE is to limit thickness transitions to no more than 25% change per 3mm of flow length. This gradual approach:

- Reduces internal stresses

- Minimizes visible sink marks

- Ensures consistent cooling

- Prevents warping during ejection

The diagram below illustrates proper versus improper wall thickness transitions:

| Transition Type | Description | Effect on Quality |

|---|---|---|

| Abrupt Change | Wall thickness changes suddenly | Creates sink marks and stress concentration |

| Stepped Transition | Multiple small steps between thicknesses | Better than abrupt but still creates stress |

| Gradual Taper | Smooth, continuous thickness change | Optimal flow and minimal visible defects |

| Variable Transition | Uses ribs or other features to manage flow | Complex but effective for difficult geometries |

When designing the second shot components, maintaining appropriate wall thickness relative to the first shot is equally critical. The second material typically should be between 40-100% of the first shot’s thickness for optimal bonding and dimensional stability.

Material-Specific Considerations

Different materials behave differently during flow and cooling, requiring specific thickness guidelines:

- Amorphous materials (like polycarbonate) can generally handle more thickness variation

- Semi-crystalline materials (like nylon) require more controlled transitions

- Filled materials need special attention due to fiber orientation effects

- Elastomers used in second shots often need more generous thickness allowances

At PTSMAKE, we’ve developed material-specific design guidelines based on years of manufacturing experience across dozens of polymer combinations.

Draft Angle Implementation

Proper draft angles are essential for all injection molding, but they take on special significance in two-shot applications where part removal must happen twice without damage.

First Shot Draft Requirements

The first shot component must include draft angles that facilitate:

- Easy removal from the first position mold cavity

- Proper positioning for the second shot

- Minimal stress during ejection

- Consistent dimensions for interface with the second material

We typically recommend a minimum of 1.5° draft for the first shot—slightly more generous than single-shot applications to account for the additional processing.

Second Shot Considerations

The second shot introduces additional draft angle requirements:

- Draft must be designed to prevent the second material from locking onto the mold

- Undercuts relative to the first shot must be carefully planned

- Areas where the second material encapsulates the first need special draft consideration

- Ejection systems must account for the composite part behavior

For elastomeric second shots, we often increase draft angles to 3-5° to compensate for the material’s tendency to grip the mold surface.

Draft in Textured Areas

When texture is applied to either the first or second shot surfaces, draft angles must increase proportionally:

- Fine textures (SPI A-1, A-2) typically require an additional 1° of draft

- Medium textures (SPI B-1, B-2) need approximately 1.5° additional draft

- Deep textures (SPI C-1, C-2) may require 2-3° extra draft

Failing to account for texture in draft calculations is one of the most common design oversights we encounter in two-shot molding.

Strategic Gate Location Design

The location of injection gates dramatically influences how materials flow, bond, and ultimately perform in two-shot molded parts.

First Shot Gating Strategies

When positioning gates for the first shot, we consider:

- The eventual interface with the second material

- Flow patterns that promote uniform cooling

- Minimizing visible gate marks on exposed surfaces

- Creating an optimal substrate for the second shot

Gates should generally be placed away from areas where the second material will bond, as gate areas often have higher internal stress that can compromise bond strength.

Second Shot Gate Positioning

The second shot gate location requires even more careful planning:

- Gates should direct material flow parallel to the interface when possible

- Positioning should avoid disturbing the first shot component

- Gates must ensure complete filling of sometimes complex second shot geometries

- Location should minimize visible marks on the final part

One effective strategy we employ at PTSMAKE is using sequential valve gates for the second shot, which allows us to control the flow progression and ensure proper filling without disrupting the first shot component.

Venting Considerations

Proper venting becomes especially critical in two-shot designs because:

- Trapped air between the first and second shots can prevent proper bonding

- The first shot component may block traditional vent paths

- The second shot often needs to fill difficult geometries

We incorporate venting features not just at traditional end-of-flow locations but also strategically along the interface between materials to ensure air can escape as the second material advances.

Material Interface Optimization

The interface between materials represents the most critical area in any two-shot molded part. This is where the molecular entanglement4 between materials occurs, determining the long-term durability of the component.

Surface Preparation

The surface condition of the first shot significantly impacts bond strength. Key considerations include:

- Surface energy compatibility between materials

- Micro-texture that increases bonding surface area

- Cleanliness from mold release or contamination

- Temperature at the time of second shot injection

At PTSMAKE, we sometimes intentionally texture interface areas (invisible in the final part) to enhance mechanical bonding between materials with limited chemical compatibility.

Timing Parameters

The timing between first and second shots critically affects bond strength:

- Injecting the second shot while the first is still warm promotes stronger bonding

- Consistent cycle timing ensures repeatable bond strength

- Temperature control of both the first shot component and the incoming second material is essential

This timing optimization is why dedicated two-shot equipment often produces better results than transferring parts between separate machines for overmolding.

Through careful attention to these design principles, manufacturers can create two-shot molded parts that not only look seamless but perform exceptionally well under real-world conditions. At PTSMAKE, we’ve refined these design approaches through years of manufacturing experience, helping our clients transform good designs into exceptional products.

Common Applications Across Industries

Ever wonder what makes your power tool comfortable to grip yet durable enough to withstand constant use? Or how medical devices combine rigid structures with soft-touch surfaces so seamlessly? Behind these everyday innovations lies a manufacturing marvel that’s transforming products across virtually every industry.

Two-shot injection molding has revolutionized product design by enabling manufacturers to combine different materials in a single component without assembly. This technology creates automotive parts with integrated seals, medical devices with ergonomic grips, electronics with tactile interfaces, and power tools with comfortable handles – all while improving durability and reducing production costs.

Automotive Components: Combining Functionality with Aesthetics

The automotive industry has enthusiastically embraced two-shot injection molding to solve complex design challenges while improving vehicle quality and reducing assembly costs.

Integrated Seals and Gaskets

One of the most valuable applications of two-shot molding in automotive manufacturing is the creation of components with integrated seals. Consider these common applications:

- Door handles with built-in weather seals

- Fluid reservoir caps with integrated gaskets

- Electrical connectors with waterproof seals

- HVAC control modules with environmental protection

By molding rigid structural components with elastomeric seals in a single operation, manufacturers eliminate assembly steps while improving reliability. Having worked with several automotive suppliers at PTSMAKE, I’ve seen firsthand how these integrated seal components significantly reduce warranty claims related to water ingress and environmental contamination.

Interior Components with Enhanced Ergonomics

The passenger cabin presents another ideal application for two-shot molding:

- Dashboard controls with soft-touch surfaces

- Steering wheel components with tactile grips

- Shift knobs with multi-material construction

- Door panels with integrated soft-touch zones

These components not only look and feel premium but also withstand years of daily use without degradation. The molecular bond between the rigid substrate and the overmolded material creates a connection that’s far more durable than adhesives or mechanical fastening.

Under-Hood Applications

Perhaps most impressively, two-shot molding has found applications in the harsh under-hood environment:

| Component | Primary Material | Secondary Material | Key Benefit |

|---|---|---|---|

| Fluid Reservoirs | Glass-filled Nylon | TPV Seals | Chemical resistance with perfect sealing |

| Wire Harness Connectors | PBT | Silicone Gaskets | Temperature resistance with waterproofing |

| Air Intake Components | Polypropylene | TPE Vibration Dampeners | Noise reduction with structural stability |

| Sensor Housings | PPS | Fluorosilicone Seals | High-temp stability with fluid resistance |

These applications showcase how two-shot molding can create components that withstand extreme temperature variations, chemical exposure, and constant vibration – conditions that would quickly destroy conventionally assembled parts.

Medical Devices: Where Ergonomics Meets Precision

The medical industry presents unique challenges that make two-shot injection molding particularly valuable. The combination of regulatory requirements, ergonomic needs, and sterilization demands creates perfect opportunities for this technology.

Surgical Instruments with Ergonomic Grips

Surgical instruments benefit tremendously from two-shot molding:

- Scalpel handles with precision grip zones

- Surgical staplers with ergonomic finger positions

- Endoscopic tools with non-slip handles

- Orthopedic instruments with shock-absorbing grips

The ability to create instruments with perfectly positioned soft-touch zones improves surgeon comfort during lengthy procedures while maintaining the structural integrity needed for precise operation. At PTSMAKE, we’ve helped medical device manufacturers reduce surgeon hand fatigue through strategic placement of overmolded materials in high-contact areas.

Diagnostic Equipment with Sealed Interfaces

Diagnostic devices present another excellent application:

- Blood glucose meters with waterproof button interfaces

- Handheld ultrasound devices with impact-resistant edges

- Patient monitoring equipment with antimicrobial surfaces

- Portable testing devices with chemical-resistant housings

The seamless integration of different materials allows for creating devices that withstand rigorous cleaning protocols without compromising functionality or ergonomics.

Drug Delivery Systems

Perhaps the most critical medical applications involve drug delivery systems:

- Auto-injectors with non-slip surfaces

- Inhalers with precise triggering mechanisms

- Insulin pens with clear viewing windows and comfortable grips

- Infusion pump components with waterproof interfaces

For these applications, the material selection becomes particularly critical. The primary material must provide dimensional stability and chemical resistance, while the secondary material often needs to combine comfort with bio-compatibility. The molecular bonding between materials ensures that no bacteria-harboring gaps exist between components – a critical consideration for medical devices.

Consumer Electronics: Merging Function with Form

The electronics industry has perhaps the most visible applications of two-shot molding technology, as consumers interact directly with these products daily.

Smartphones and Tablets

Modern mobile devices utilize two-shot molding for:

- Cases with integrated shock-absorbing corners

- Button arrays with precise tactile feedback

- Speaker grilles with waterproof membranes

- Camera bezels with protective lens surrounds

The technology allows designers to create devices that are both aesthetically pleasing and durable enough for everyday use. The elimination of assembly steps also reduces the thickness of components – a critical consideration in the ever-shrinking world of portable electronics.

Remote Controls and Input Devices

Input devices showcase the ergonomic benefits of two-shot molding:

- Remote controls with illuminated, soft-touch buttons

- Game controllers with non-slip grip surfaces

- Computer mice with precisely positioned finger rests

- Keyboard keycaps with dual-material construction

These applications highlight how two-shot molding can create intuitive user interfaces that combine visual, tactile, and functional elements in a single component. The precision of the process ensures that buttons have consistent feel and response – critical for user satisfaction.

Wearable Technology

The booming wearable technology sector relies heavily on two-shot molding:

- Fitness trackers with comfortable skin-contact surfaces

- Smartwatch bands with rigid attachment points and flexible wearing sections

- AR/VR headsets with face-contact cushioning

- Hearable devices with precisely fitted ear contact points

These applications must balance durability with comfort, often requiring complex geometries that would be impossible to create through traditional assembly methods.

Power Tools: Where Durability Meets Comfort

Professional power tools represent perhaps the most demanding application for two-shot molding, requiring components that withstand extreme use while providing ergonomic benefits.

Ergonomic Handles with Vibration Dampening

Tool handles showcase advanced two-shot applications:

- Drill handles with strategically placed vibration-dampening zones

- Saw grips with moisture-wicking textures

- Impact driver handles with shock-absorbing materials

- Grinder bodies with heat-resistant grip areas

These handles must remain comfortable during extended use while withstanding significant mechanical stress, environmental exposure, and chemical contact from various building materials. The molecular bond between rigid and flexible materials creates handles that remain intact despite years of professional use.

Functional Housings with Sealed Interfaces

Beyond handles, power tool housings benefit from two-shot technology:

- Battery interfaces with environmental seals

- Motor housings with integrated vibration isolation

- Control panels with waterproof button arrays

- Accessory attachment points with wear-resistant surfaces

These components showcase how two-shot molding can incorporate multiple functions into a single part, reducing assembly complexity while improving reliability.

Through my work at PTSMAKE, I’ve seen firsthand how two-shot injection molding has transformed product design across these industries. The ability to combine materials at the molecular level, eliminate assembly steps, and create components with zone-specific properties continues to open new possibilities for innovative products. As material science advances and processing techniques improve, we can expect to see even more creative applications of this versatile manufacturing technology.

Cost Considerations and Production Volume Analysis

When it comes to manufacturing decisions, the bottom line often speaks louder than technical specifications. Two-shot injection molding presents a fascinating economic paradox that many product developers initially struggle to understand: higher upfront investment for dramatically reduced long-term costs.

While initial tooling costs exceed traditional injection molding, two-shot processes deliver significant long-term savings for high-volume production by eliminating assembly, reducing labor, and minimizing quality issues. This economic equation transforms what appears to be an expensive technology into a powerful cost-reduction strategy for the right applications.

Initial Investment vs. Long-Term Economics

Understanding the Investment Curve

Two-shot injection molding requires a higher initial capital investment than conventional molding or assembly processes. This investment primarily comes from:

- More complex mold designs with rotating or indexing systems

- Specialized dual-injection molding equipment

- Additional engineering time for process development

- More elaborate material handling systems

For companies accustomed to traditional manufacturing approaches, this upfront cost can initially seem prohibitive. However, manufacturing economics must be evaluated across the entire product lifecycle, not just at the tooling stage.

The investment curve for two-shot molding follows a distinctive pattern:

| Production Phase | Traditional Assembly | Two-Shot Molding |

|---|---|---|

| Initial Tooling | Lower cost | 30-50% higher cost |

| Production Setup | Multiple stations needed | Single machine setup |

| Per-Part Production | Higher ongoing costs | Lower ongoing costs |

| Break-Even Point | N/A | Typically 10,000-50,000 parts |

| High-Volume Production | Increasingly expensive | Increasingly economical |

At PTSMAKE, we’ve guided numerous clients through this economic analysis, helping them understand where their particular product falls on this curve. For products with expected lifespans of several years and volumes exceeding 100,000 units, the economic advantage of two-shot molding becomes increasingly compelling.

The Break-Even Analysis

The break-even point—where the higher tooling costs are offset by production savings—varies significantly depending on:

- Part complexity

- Assembly steps eliminated

- Labor costs in the manufacturing region

- Production volume projections

- Product lifespan expectations

For simpler components with few assembly steps, the break-even point might occur at higher volumes. However, for complex parts with multiple assembly operations, the economics can become favorable at surprisingly low volumes—sometimes as few as 10,000 units.

Labor Cost Reduction Analysis

Assembly Labor Elimination

One of the most substantial economic benefits of two-shot molding is the elimination of assembly labor. This advantage manifests in several ways:

- Direct Labor Reduction: Manual assembly operations are completely eliminated

- Indirect Labor Savings: Fewer quality inspections, material handling, and supervision requirements

- Training Cost Elimination: No need to train assembly personnel

- Workspace Reduction: Assembly stations and related infrastructure become unnecessary

I’ve worked with manufacturers who initially focused only on direct labor savings but later discovered that indirect labor and related costs represented an even larger economic benefit. One automotive component manufacturer reduced total labor costs by 73% after converting a multi-part assembly to a two-shot molded design.

Quality Control Cost Impact

The quality control economics of two-shot molding create additional savings:

- Inspection Reduction: Fewer quality checkpoints throughout the process

- Decreased Rejection Rates: Elimination of assembly errors

- Rework Elimination: No repairs of poorly assembled components

- Documentation Simplification: Streamlined quality procedures for a single-step process

For regulated industries like medical devices or automotive safety components, these quality-related cost savings can be particularly significant. The simplified regulatory documentation and validation requirements for a single molding process versus multiple assembly operations can save hundreds of hours of engineering time.

Volume Scaling Economics

High-Volume Production Advantages

The economic advantages of two-shot molding become increasingly pronounced as production volumes increase:

- Cycle Time Efficiency: The elimination of assembly steps creates cumulative time savings

- Material Handling Reduction: Less inventory, fewer components to track and manage

- Floor Space Optimization: Compact production cells versus expansive assembly lines

- Energy Consumption: Lower overall energy usage per finished part

These scaling factors explain why two-shot molding has become particularly prevalent in high-volume industries like automotive components, consumer electronics, and medical disposables. As volumes increase, the economic advantages compound.

Automation Integration Benefits

Modern two-shot molding cells integrate seamlessly with automation technologies:

- Robotic Part Handling: Automated removal and packaging

- In-Line Quality Verification: Vision systems and testing integrated with molding

- Digital Process Monitoring: Real-time production data for predictive maintenance

- Consistent Cycle Times: Elimination of human variability

This automation compatibility further enhances the economics at scale. At PTSMAKE, we’ve implemented fully automated two-shot production cells that operate with minimal supervision, dramatically reducing the per-part cost for high-volume applications.

Material Cost Implications

Material Efficiency Considerations

Two-shot molding can impact material costs in several ways:

- Targeted Material Placement: Higher-cost materials used only where needed

- Reduced Waste: Lower overall material consumption without assembly scrap

- Simplified Material Handling: Fewer material types to manage in production

- Optimized Properties: Each section of the part uses only what’s needed for its function

One of the most interesting economic aspects I’ve observed is the ability to use premium materials more strategically. Rather than making an entire part from an expensive engineering plastic, two-shot molding allows us to use that material only where its properties are required, with standard materials elsewhere.

Case Study: Material Cost Optimization

To illustrate this concept, consider a medical device handle we helped redesign:

| Design Approach | Material Usage | Material Cost |

|---|---|---|

| Single Material | 100% glass-filled nylon | Higher overall cost |

| Two-Shot Design | 70% standard nylon, 30% glass-filled | 22% material cost reduction |

| Additional Benefit | Improved ergonomics with selective material properties | Enhanced product value |

This strategic approach to material placement delivers both cost savings and performance improvements simultaneously—a rare combination in manufacturing economics.

Secondary Operations and Finishing Costs

Eliminated Post-Molding Processes

Beyond assembly, two-shot molding eliminates many secondary operations that add cost to traditional manufacturing:

- Pad Printing/Labeling: Multi-color components without decoration

- Painting/Coating: Different colors and textures integrated during molding

- Mechanical Surface Treatments: Textures molded directly into specific areas

- Adhesive Application: No bonding operations required

Each eliminated operation represents not just direct cost savings but also the removal of a potential quality issue and production bottleneck. This streamlining effect creates both economic and scheduling advantages.

Reduced Inventory and Logistics

The consolidated component approach of two-shot molding creates supply chain efficiencies:

- Fewer SKUs to Manage: Single components rather than multiple parts

- Reduced Inventory Value: Lower overall stock requirements

- Simplified Logistics: Fewer components to transport and track

- Decreased Warehousing Needs: Less space required for parts storage

These supply chain optimization5 benefits can be substantial for manufacturers operating in just-in-time environments or those with complex international supply chains.

Quality-Related Cost Factors

Warranty and Field Failure Economics

Perhaps the most difficult economic factor to quantify, but often the most significant, involves long-term quality benefits:

- Reduced Warranty Claims: Fewer failures from components separating or interfaces leaking

- Extended Product Lifespan: More durable construction extends usable life

- Decreased Field Service: Fewer repairs required during product use

- Enhanced Brand Reputation: Improved customer satisfaction from higher quality products

For products where failure carries significant consequences—like medical devices, automotive safety components, or industrial equipment—these quality-related economic benefits can dwarf the direct manufacturing savings.

A power tool manufacturer I worked with calculated that their warranty claim reduction after switching to two-shot molded handles saved approximately three times what they saved in direct manufacturing costs. The enhanced durability and reliability created economic benefits that rippled throughout their business model.

Regulatory Compliance Economics

For regulated industries, two-shot molding can significantly impact compliance costs:

- Simplified Validation: Single manufacturing process versus multiple operations

- Reduced Documentation: Fewer manufacturing steps to document and control

- More Consistent Results: Less variation means easier regulatory approval

- Decreased Risk Management: Fewer failure modes to analyze and mitigate

These regulatory benefits translate directly to economic advantages through faster product approvals, reduced compliance overhead, and lower ongoing quality management costs.

Making the Economic Decision

When evaluating whether two-shot injection molding makes economic sense for a specific product, manufacturers should consider several key questions:

- What is the anticipated production volume over the product’s entire lifecycle?

- How many assembly steps would be eliminated by converting to a two-shot design?

- What secondary operations (printing, labeling, etc.) could be integrated into the molding process?

- Are there quality, warranty, or regulatory concerns with the current manufacturing approach?

- How would inventory and logistics be impacted by component consolidation?

At PTSMAKE, we work through these questions systematically with clients, often developing comparative cost models that project economics across different volume scenarios and timeframes. This analytical approach ensures that decisions are based on comprehensive economic understanding rather than simply comparing initial tooling quotes.

While two-shot injection molding isn’t economically justified for every application, particularly for low-volume or short-lifecycle products, its long-term cost advantages make it increasingly the manufacturing method of choice for high-volume, quality-critical components across industries.

Click for expert insights on material bonding techniques and optimization strategies. ↩

Learn how molecular bonds affect strength in multi-material parts. ↩

Discover the regulatory requirements for medical devices manufactured using multi-material molding techniques. ↩

Learn how polymers bond at the microscopic level to create strong interfaces. ↩

Learn about advanced strategies for optimizing manufacturing supply chains through component consolidation. ↩