Designing plastic parts can be a daunting challenge for many engineers. I’ve seen numerous projects fail due to overlooked design principles, resulting in manufacturing defects, increased costs, and project delays. These issues often surface late in the development cycle, causing significant setbacks and budget overruns.

Successful plastic part design requires a systematic approach focusing on four key elements: functional requirements, material selection, manufacturability, and assembly optimization. By following these principles, engineers can create designs that are both cost-effective and reliable.

Understanding Functional Requirements

Before diving into the design process, we must clearly define what the part needs to do. This includes:

- Operating environment conditions

- Load-bearing requirements

- Chemical resistance needs

- Temperature exposure ranges

- Expected product lifetime

Material Selection Criteria

The choice of material significantly impacts the success of your design. Consider these factors:

- Mechanical properties

- Chemical resistance

- Thermal characteristics

- Cost considerations

- Environmental impact

One critical aspect often overlooked is the material’s crystallinity1, which affects both processing parameters and final part properties.

Design for Manufacturability (DFM)

Wall Thickness Considerations

| Wall Thickness Aspect | Recommended Range | Impact on Production |

|---|---|---|

| Nominal thickness | 2.0-3.0mm | Optimal material flow |

| Maximum variation | ±10% | Prevents warpage |

| Rib thickness | 50-70% of wall | Reduces sink marks |

Draft Angles and Undercuts

Draft angles are essential for proper part ejection. I recommend:

- Minimum 1° draft for textured surfaces

- 0.5° draft for smooth surfaces

- Avoiding undercuts where possible

- Using side-actions only when necessary

Radius and Fillet Design

Sharp corners are stress concentrators and should be avoided:

- Outer corners: minimum radius of 0.5mm

- Inner corners: minimum radius of 1.0mm

- Uniform radius transitions

- Gradual thickness changes

Assembly Optimization

Snap Fit Design

Proper snap fit design ensures:

- Easy assembly

- Reliable retention

- Damage-free disassembly

- Cost-effective production

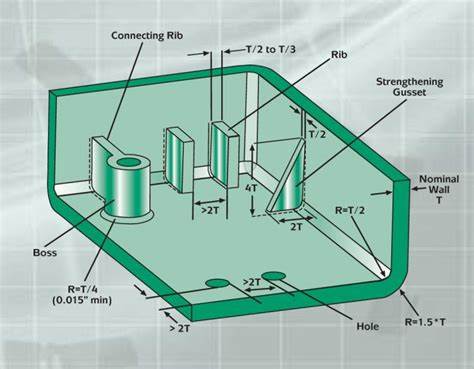

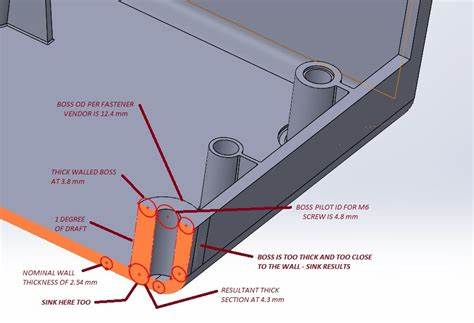

Bosses and Ribs

Design guidelines for structural features:

- Boss diameter: 2x wall thickness

- Rib height: 3x wall thickness

- Support gussets for tall features

- Proper spacing for material flow

Surface Finish and Aesthetics

Consider these aspects for appearance:

- Texture requirements

- Parting line location

- Gate location

- Ejector pin placement

Design Validation

Before finalizing the design:

- Conduct FEA analysis

- Create rapid prototypes

- Perform mold flow analysis

- Test assembly procedures

Through implementing these design principles, I’ve helped numerous clients at PTSMAKE achieve successful plastic part designs. The key is to consider all aspects early in the design phase, preventing costly modifications later. Remember that good design isn’t just about creating a part that works – it’s about creating one that can be manufactured efficiently and economically.

I always emphasize to our clients that successful plastic part design is iterative. Start with the basics, validate your assumptions, and refine based on feedback. This approach has consistently led to successful outcomes in our projects.

What is the minimum radius for plastic parts?

Designing plastic parts with incorrect corner radii can lead to devastating manufacturing failures. I’ve seen parts crack under minimal stress, warp during molding, and fail quality inspections – all because of poorly designed radii that created stress concentration points.

The minimum radius for plastic parts typically follows the 0.5x wall thickness rule for internal corners, while external radii should equal the internal radius plus wall thickness. This guideline ensures proper material flow and reduces stress concentration, preventing part failures.

Understanding the Importance of Corner Radii

When designing plastic parts, the stress concentration factor2 at corners significantly impacts part performance. I always emphasize to our clients that proper radius design is not just about aesthetics – it’s fundamental to part functionality. Here’s why radii matter:

Material Flow

- Improves mold filling patterns

- Reduces hesitation marks

- Prevents short shots during injection

- Ensures uniform cooling

Structural Integrity

- Distributes stress more evenly

- Reduces risk of part failure

- Enhances overall durability

- Improves impact resistance

Recommended Minimum Radius Guidelines

Based on extensive testing and real-world applications, I’ve developed this comprehensive guide for minimum radius recommendations:

| Wall Thickness (mm) | Minimum Internal Radius (mm) | Recommended External Radius (mm) |

|---|---|---|

| 0.5 | 0.25 | 0.75 |

| 1.0 | 0.50 | 1.50 |

| 1.5 | 0.75 | 2.25 |

| 2.0 | 1.00 | 3.00 |

| 2.5 | 1.25 | 3.75 |

| 3.0 | 1.50 | 4.50 |

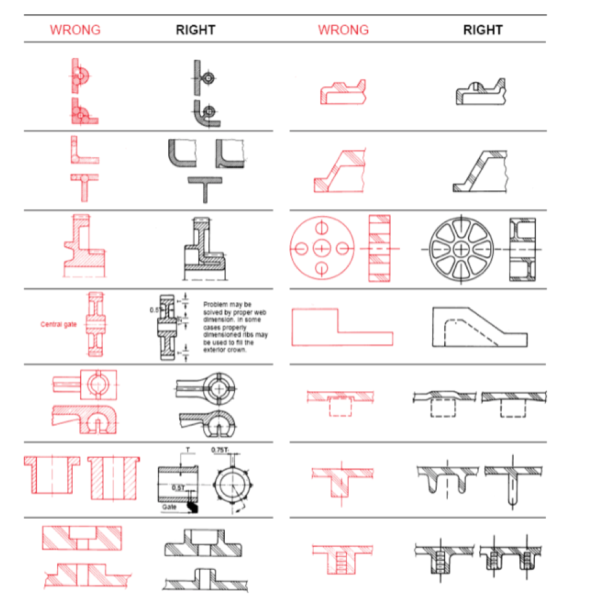

Common Design Mistakes to Avoid

I regularly encounter these radius-related issues in plastic part designs:

Inconsistent Radii

- Creates uneven material flow

- Leads to unpredictable shrinkage

- Causes appearance defects

- Results in varying cooling rates

Sharp Corners

- Act as stress concentrators

- Increase risk of part failure

- Complicate mold release

- Create weak points in the design

Special Considerations for Different Materials

Different plastic materials require specific radius considerations:

Glass-Filled Materials

- Require larger radii due to reduced flow

- Minimum internal radius: 0.75x wall thickness

- Need gradual transitions

- More susceptible to stress concentration

Flexible Materials

- Can accommodate smaller radii

- Minimum internal radius: 0.3x wall thickness

- Less prone to stress cracking

- Better flow characteristics

Impact on Manufacturing Process

Proper radius design affects several manufacturing aspects:

Molding Cycle Time

- Optimized radii reduce cycle time

- Improve material flow speed

- Enable faster cooling

- Increase production efficiency

Tool Maintenance

- Reduces wear on mold corners

- Extends tool life

- Minimizes maintenance requirements

- Lowers production costs

Quality Control Considerations

I implement these quality control measures for radius verification:

Measurement Methods

- Digital inspection systems

- Profile projectors

- 3D scanning technology

- Coordinate measuring machines

Common Quality Issues

- Sink marks at thick sections

- Warpage from uneven cooling

- Flash at parting lines

- Surface finish inconsistencies

Cost Implications

Proper radius design impacts manufacturing costs:

Initial Design Phase

- Reduced design iterations

- Faster design approval

- Lower prototype costs

- Improved manufacturability

Production Phase

- Decreased scrap rate

- Improved yield

- Lower maintenance costs

- Increased tool longevity

Future Trends in Radius Design

The industry is evolving with new approaches to radius design:

Digital Solutions

- AI-powered design optimization

- Automated radius checking

- Simulation-driven design

- Real-time analysis tools

Advanced Materials

- New material-specific guidelines

- Innovative corner treatments

- Enhanced flow properties

- Improved stress resistance

This comprehensive approach to radius design helps ensure successful plastic part manufacturing while minimizing potential issues and optimizing production efficiency.

What are design considerations when designing a part?

Designing parts without proper consideration of manufacturing constraints often leads to costly revisions and production delays. Many engineers struggle with balancing design intent against manufacturability, resulting in parts that either can’t be produced efficiently or fail to meet performance requirements.

Successful part design requires careful attention to five key elements: material selection, wall thickness uniformity, draft angles, structural support features, and shrinkage compensation. These factors directly impact both manufacturability and part performance.

Material Selection Fundamentals

The choice of material forms the foundation of any successful part design. At PTSMAKE, I always emphasize how material properties influence both manufacturing processes and end-use performance. When selecting materials, we consider:

Mechanical Properties

- Tensile strength

- Impact resistance

- Flexural modulus

- Heat deflection temperature

Chemical Properties

- Resistance to UV exposure

- Chemical compatibility

- Moisture absorption

- Hygroscopic behavior3

Processing Requirements

- Melt flow characteristics

- Processing temperature range

- Mold temperature requirements

- Drying specifications

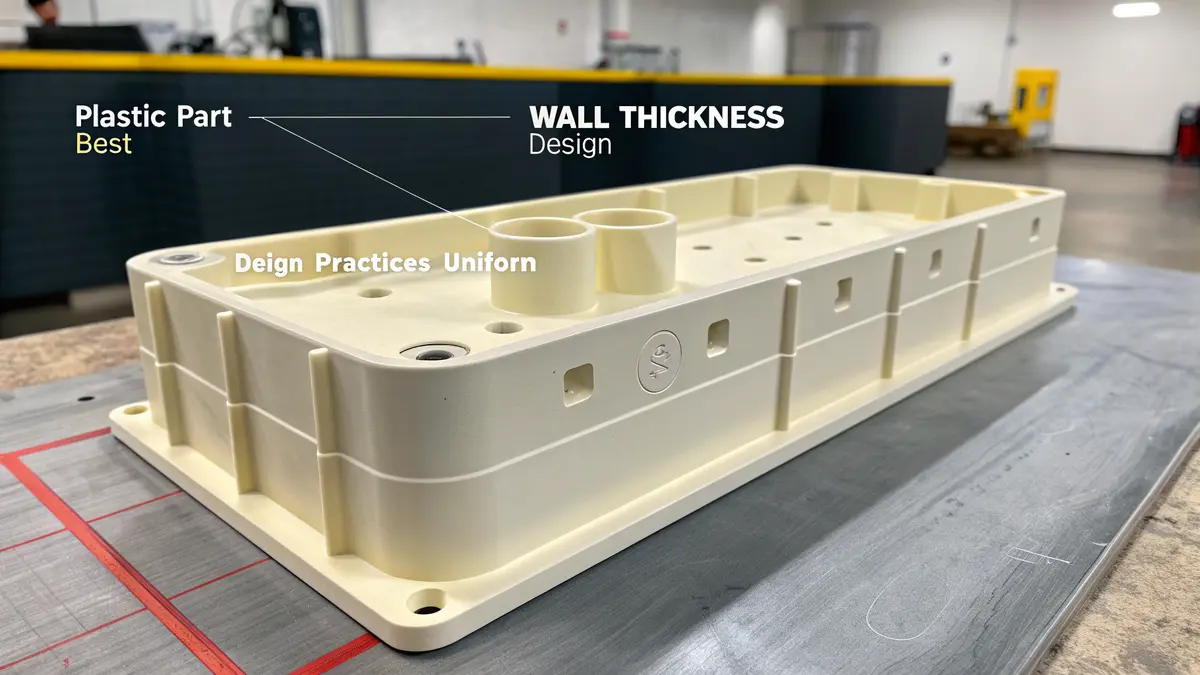

Wall Thickness Optimization

Maintaining uniform wall thickness is crucial for preventing manufacturing defects. Based on my experience at PTSMAKE, I recommend:

| Wall Thickness Range | Typical Applications | Key Benefits |

|---|---|---|

| 0.5mm – 1.0mm | Small electronic enclosures | Faster cooling, material savings |

| 1.0mm – 2.5mm | Consumer products | Good balance of strength and moldability |

| 2.5mm – 3.5mm | Structural components | Enhanced rigidity and stability |

| 3.5mm – 4.0mm | Heavy-duty applications | Maximum strength requirements |

Draft Angle Implementation

Draft angles are essential for proper part ejection from the mold. The general guidelines we follow include:

- Minimum 1° draft for textured surfaces

- 0.5° to 2° draft for smooth surfaces

- Additional draft for deep ribs and bosses

- Increased draft for grained or textured surfaces

Rib and Boss Design Principles

Structural features require careful consideration to prevent cosmetic defects while maintaining strength:

Rib Design Guidelines

- Maximum rib thickness: 60% of adjacent wall

- Height-to-thickness ratio: 2.5:1 to 3:1

- Minimum spacing between ribs: 2x wall thickness

- Gradual transitions at rib bases

Boss Configuration

- Boss diameter: 2x hole diameter

- Wall thickness: 60% of adjacent wall

- Support ribs for tall bosses

- Coring for thick sections

Shrinkage Compensation Strategies

Different materials exhibit varying shrinkage rates. Our approach includes:

Material-Specific Compensation

- Amorphous materials: 0.3-0.7%

- Semi-crystalline materials: 0.8-2.5%

- Glass-filled materials: 0.1-0.5%

Geometric Considerations

- Wall thickness variations

- Flow direction effects

- Gate location impact

- Cooling time optimization

Design for Assembly Integration

While focusing on individual design elements, we must consider assembly requirements:

Snap Fit Features

- Proper engagement angles

- Sufficient flexibility

- Stress concentration prevention

- Assembly clearances

Living Hinges

- Material selection for cyclic loading

- Thickness requirements

- Flex radius optimization

- Gate location considerations

Thread Design

- Thread pitch selection

- Core and cavity considerations

- Wear compensation

- Assembly torque requirements

At PTSMAKE, we ensure these design considerations are implemented early in the development process. This proactive approach helps our customers avoid costly modifications and achieve optimal part performance. I’ve found that successful part design requires balancing these various elements while maintaining focus on the end-use requirements and manufacturing constraints.

The key to successful part design lies in understanding how these various elements interact with each other. A change in material selection, for example, might require adjustments to wall thickness and draft angles. Similarly, the addition of structural features like ribs and bosses must be balanced against the potential for sink marks and other cosmetic defects.

What are design guidelines for injection molding plastic parts?

Designing plastic parts for injection molding can be overwhelming. Many engineers struggle with part failures, quality issues, and costly design revisions because they overlook critical design principles. I’ve seen projects delayed by months due to these preventable mistakes.

The key design guidelines for injection molding focus on proper wall thickness, draft angles, rib design, and gate location selection. These principles ensure part quality, reduce production costs, and minimize defects while maintaining dimensional accuracy and structural integrity.

Wall Thickness Considerations

Wall thickness is crucial for successful injection molding. Maintaining uniform wall thickness helps prevent warping, sink marks, and internal stresses. The optimal wall thickness depends on the material and part requirements:

| Material Type | Recommended Wall Thickness (mm) |

|---|---|

| ABS | 1.2 – 3.5 |

| Polycarbonate | 1.0 – 3.8 |

| Nylon | 0.8 – 3.0 |

| HDPE | 0.8 – 3.0 |

| POM | 0.8 – 3.0 |

Draft Angle Implementation

Draft angles are essential for easy part ejection. When designing plastic parts, incorporate adequate draft angles on all walls parallel to the mold opening direction. The parting line4 location affects draft angle requirements:

- Textured surfaces: 3° minimum draft

- Smooth surfaces: 1° minimum draft

- Deep ribs or posts: 2-3° draft

- External walls: 1-2° draft

Rib and Boss Design

Ribs provide structural support while minimizing material usage. Follow these guidelines:

- Rib thickness: 50-60% of adjoining wall thickness

- Rib height: Maximum 3 times the wall thickness

- Spacing between ribs: Minimum 2 times wall thickness

- Base radius: 25-50% of wall thickness

Gate Location Selection

Proper gate location affects part quality and appearance:

- Place gates in thick sections

- Avoid gates on visible surfaces

- Consider multiple gates for large parts

- Allow adequate flow length

- Account for weld line formation

Corner and Radius Design

Sharp corners create stress concentrations and molding difficulties:

- Inside radius: Minimum 0.5mm

- Outside radius: Minimum 1.5 times wall thickness

- Maintain consistent wall thickness around corners

- Avoid thick sections at corners

Material Selection Considerations

Different materials have unique processing requirements:

Amorphous materials

- Lower shrinkage rates

- Better dimensional stability

- Examples: ABS, PC, PMMA

Semi-crystalline materials

- Higher shrinkage rates

- Better chemical resistance

- Examples: PP, PE, POM

Cooling Channel Design

Proper cooling channel design ensures uniform part cooling:

- Channel diameter: 8-12mm typical

- Channel spacing: 3-4 times diameter

- Distance from part surface: 1.5-2 times diameter

- Maintain consistent cooling circuit length

- Consider conformal cooling for complex geometries

Surface Finish Requirements

Surface finish affects both aesthetics and functionality:

| Finish Type | SPI Number | Application |

|---|---|---|

| High Polish | A1 | Optical parts |

| Semi-Polish | A2 | Visible surfaces |

| Matte | B1 | Non-visible parts |

| Textured | C1 | Grip surfaces |

Undercut Management

Minimize undercuts where possible:

- Use side actions for necessary undercuts

- Consider sliding cores for complex features

- Design snap fits with appropriate relief

- Calculate side action travel requirements

Assembly Considerations

Design for efficient assembly:

- Include alignment features

- Standardize snap fit dimensions

- Consider ultrasonic welding requirements

- Plan for insert molding when needed

- Design self-locating features

Remember, successful injection molding design requires careful consideration of all these elements. Each component affects the others, creating an interconnected system where changes in one area can impact the entire part’s manufacturability and quality.

How does wall thickness affect plastic part design?

Designing plastic parts with inconsistent wall thickness is like building a house with varying foundation depths – it’s a recipe for disaster. Many engineers struggle with this fundamental aspect, leading to costly production issues, quality defects, and project delays.

Wall thickness is a critical factor in plastic part design that directly impacts structural integrity and manufacturability. The ideal thickness typically ranges from 0.5mm to 5mm, with uniform distribution being key to preventing common defects like sink marks and internal stresses.

Understanding the Impact of Wall Thickness

Wall thickness affects every aspect of plastic part production. In my experience working with various projects at PTSMAKE, I’ve observed that proper wall thickness design can make the difference between a successful product and a failed one. The crystallization rate5 of the plastic material during cooling is directly influenced by wall thickness variations.

Optimal Wall Thickness Guidelines

Here’s a comprehensive guide for different plastic materials:

| Material Type | Recommended Thickness (mm) | Maximum Thickness (mm) |

|---|---|---|

| ABS | 1.2 – 3.5 | 4.0 |

| Polycarbonate | 0.8 – 4.0 | 4.5 |

| Nylon | 0.8 – 3.0 | 3.5 |

| HDPE | 0.8 – 2.5 | 3.0 |

| POM | 0.8 – 3.0 | 3.5 |

Common Design Challenges

Sink Marks and Voids

Thick sections in plastic parts cool slower than thin sections, creating sink marks on the surface. To prevent this:

- Keep wall thickness uniform whenever possible

- Design gradual transitions between different thicknesses

- Implement proper cooling channels in the mold

Warpage Control

Uneven cooling caused by varying wall thickness can lead to warpage. Our solution includes:

- Using ribs and gussets instead of thick walls

- Maintaining thickness ratios below 3:1

- Strategic placement of cooling lines in the mold

Material-Specific Considerations

Different materials behave uniquely during the injection molding process:

Amorphous Materials

- More forgiving with thickness variations

- Better flow characteristics

- Lower shrinkage rates

Semi-crystalline Materials

- More sensitive to thickness changes

- Higher shrinkage rates

- Require more precise temperature control

Design Optimization Techniques

Structural Requirements

When designing for strength:

- Use ribs instead of increasing wall thickness

- Maintain rib thickness at 60% of adjacent wall

- Place ribs in high-stress areas

Cost Efficiency

To optimize material usage:

- Eliminate unnecessary thick sections

- Design hollow features where possible

- Consider core-outs in thick areas

Quality Control Measures

At PTSMAKE, we implement several quality control measures:

- Digital simulation before production

- First article inspection

- Regular process monitoring

- Dimensional stability checks

Production Efficiency

Proper wall thickness design impacts:

- Cycle time optimization

- Material usage efficiency

- Tool longevity

- Production costs

Future Considerations

As manufacturing technology evolves, we’re seeing:

- Advanced simulation capabilities

- New materials with different requirements

- Improved cooling solutions

- Better process control methods

By understanding and implementing these wall thickness principles, designers can create more efficient, cost-effective, and high-quality plastic parts. Our experience shows that careful attention to wall thickness during the design phase prevents costly modifications later in production.

This comprehensive approach to wall thickness design has helped us deliver superior products to our clients across various industries, from automotive components to consumer electronics. The key is maintaining a balance between design requirements and manufacturing constraints while considering material properties and end-use applications.

Why is draft important in plastic part design?

Imagine designing a plastic part only to discover it’s stuck in the mold like a stubborn puzzle piece. This nightmare scenario happens more often than you’d think, causing production delays and costly damage. Without proper draft angles, even the simplest plastic parts can become manufacturing disasters.

Draft angles are essential design elements in plastic injection molding that allow parts to be easily removed from the mold. By incorporating a slight taper (typically 1-2 degrees) on vertical walls, manufacturers can ensure smooth part ejection and maintain surface quality.

Understanding Draft Angles

The concept of draft angles might seem simple, but it’s a crucial aspect of plastic part design that requires careful consideration. Draft angles create a slight taper on vertical surfaces, allowing the part to release from the mold without resistance. The parting line serves as the reference point from which draft angles are measured.

Factors Affecting Draft Angle Selection

Surface Texture and Finish

Different surface textures require varying draft angles:

| Surface Type | Recommended Draft Angle |

|---|---|

| Smooth Finish | 1° – 2° |

| Light Texture | 2° – 3° |

| Medium Texture | 3° – 5° |

| Deep Texture | 5° – 7° |

Material Properties

The material chosen for your part plays a significant role in determining the appropriate draft angle:

- Rigid materials like glass-filled nylon may require larger draft angles

- Flexible materials like TPE can sometimes work with smaller draft angles

- Crystalline materials often need more draft due to their shrinkage characteristics

Common Draft-Related Challenges

Depth Considerations

Deeper parts generally require more draft than shallow ones. For every inch of depth, consider adding an extra 0.5° to 1° of draft to ensure proper release. This is especially important for parts with significant vertical walls.

Internal Features

Internal features often require more draft than external ones because:

- They shrink onto the core

- Access for polishing is limited

- Ejection forces are more concentrated

Best Practices for Draft Implementation

Early Design Integration

- Include draft considerations during the initial design phase

- Use CAD software to analyze draft requirements

- Consider draft impact on part functionality

Strategic Draft Placement

- Apply more draft where ejection forces are highest

- Maintain uniform wall thickness when applying draft

- Consider the impact on assembly requirements

Quality Control Measures

- Use mold flow analysis to validate draft angles

- Implement proper cooling strategies

- Monitor part quality during initial production runs

Economic Impact of Proper Draft Design

The implementation of appropriate draft angles affects various aspects of production:

Production Efficiency

- Reduced cycle times

- Lower rejection rates

- Improved part quality

- Decreased maintenance requirements

Cost Considerations

- Initial mold design costs

- Long-term production savings

- Reduced scrap rates

- Extended mold life

Advanced Draft Considerations

Complex Geometries

When dealing with complex part geometries:

- Use variable draft angles where necessary

- Consider split-line locations carefully

- Account for undercuts and side actions

Material-Specific Requirements

Different materials require specific draft considerations:

| Material Type | Minimum Draft Angle |

|---|---|

| ABS | 1.5° |

| Polycarbonate | 1° |

| Polypropylene | 0.5° |

| Glass-Filled Materials | 2° – 3° |

Surface Finish Impact

The relationship between surface finish and draft:

- Polished surfaces may work with minimal draft

- Textured surfaces require additional draft

- EDM surfaces need intermediate draft angles

Benefits of Modern Draft Analysis Tools

Modern design tools offer significant advantages:

Digital Validation

- Real-time draft analysis

- Interference checking

- Flow pattern visualization

Optimization Capabilities

- Automatic draft angle suggestions

- Performance simulations

- Material behavior predictions

Through proper draft angle implementation, manufacturers can achieve:

- Consistent part quality

- Reduced production costs

- Improved cycle times

- Extended mold longevity

These benefits make draft angle consideration a crucial aspect of successful plastic part design and manufacturing.

What role do ribs and bosses play in plastic parts?

Designing plastic parts with optimal structural integrity while maintaining cost-effectiveness is a constant challenge. Many engineers struggle with parts that either use too much material or suffer from structural weaknesses, leading to failures and costly redesigns.

Ribs and bosses are critical design elements in plastic parts that provide structural support and mounting capabilities. These features enhance part strength and functionality while minimizing material usage, making them essential components in efficient plastic part design.

Understanding Rib Design Principles

The effectiveness of ribs in plastic parts depends heavily on proper design implementation. I’ve found that successful rib design requires careful consideration of several key factors:

- Height-to-thickness ratio: Ribs should maintain a height that’s no more than 3 times the wall thickness to prevent warping

- Spacing: The distance between ribs should be at least 2-3 times the wall thickness

- Draft angles: A minimum of 0.5° draft angle per side ensures proper part ejection

- Corner transitions: Proper radiusing6 at the base helps prevent stress concentration

Boss Design Fundamentals

Bosses serve as crucial mounting points in plastic parts. When designing bosses, I always consider these essential elements:

Core Dimensions

- Inner diameter: Based on specific fastener requirements

- Outer diameter: Typically 2-2.5 times the inner diameter

- Height: Usually determined by fastener length and assembly requirements

Structural Considerations

- Support ribs: Adding gussets when boss height exceeds 3 times its diameter

- Wall thickness: Maintaining 60% of nominal wall thickness for supporting features

- Draft angles: Incorporating 1-2° draft for proper molding

Material Flow and Thickness Guidelines

The relationship between wall thickness and material flow significantly impacts part quality. Here’s a detailed breakdown:

| Feature Type | Recommended Thickness | Purpose |

|---|---|---|

| Main Wall | 100% (nominal) | Base reference |

| Ribs | 50-70% of nominal | Prevent sink marks |

| Bosses | 60-80% of nominal | Structural integrity |

| Gussets | 50-60% of nominal | Support features |

Optimizing for Manufacturing

At PTSMAKE, I emphasize these key considerations for successful rib and boss implementation:

Sink Mark Prevention

- Strategic rib placement

- Proper thickness ratios

- Gradual transitions at intersections

Moldability Enhancement

- Adequate draft angles

- Proper venting locations

- Optimized cooling channel placement

Structural Integrity

- Load distribution analysis

- Stress concentration prevention

- Material flow optimization

Common Design Mistakes to Avoid

Through experience, I’ve identified several critical errors that should be avoided:

Geometric Issues

- Excessive rib height without proper support

- Insufficient draft angles

- Sharp corners causing stress concentration

Material Considerations

- Improper thickness ratios leading to sink marks

- Inadequate flow paths causing fill issues

- Poor gate location affecting part strength

Manufacturing Challenges

- Complex geometries preventing proper cooling

- Insufficient support for tall features

- Inadequate ejection considerations

Impact on Part Performance

Well-designed ribs and bosses contribute significantly to part performance:

Structural Benefits

- Enhanced flexural rigidity

- Improved impact resistance

- Better load distribution

Material Efficiency

- Reduced material usage

- Lower part weight

- Improved cost-effectiveness

Quality Improvements

- Better dimensional stability

- Reduced warpage

- Consistent part appearance

Integration with Other Design Elements

Successful implementation requires consideration of:

Assembly Requirements

- Clearance for tools

- Accessibility for fasteners

- Alignment features

Environmental Factors

- Temperature effects

- Chemical exposure

- UV resistance

Production Considerations

- Cycle time optimization

- Tool maintenance

- Quality control requirements

The strategic use of ribs and bosses represents a crucial aspect of plastic part design, requiring careful balance between structural requirements and manufacturing constraints. These features, when properly implemented, significantly enhance part performance while maintaining efficient material usage and manufacturability.

How do gate locations impact plastic injection molding?

When manufacturing injection molded parts, many clients come to me frustrated with visible defects and quality issues in their products. These problems often trace back to one critical yet frequently overlooked aspect – gate location. Poor gate placement can turn a perfect design into a costly manufacturing nightmare.

Gate location serves as the entry point for molten plastic into the mold cavity. Its placement significantly influences material flow, part quality, and production efficiency. Proper gate positioning helps prevent common defects like weld lines, air traps, and uneven filling while ensuring optimal part aesthetics and structural integrity.

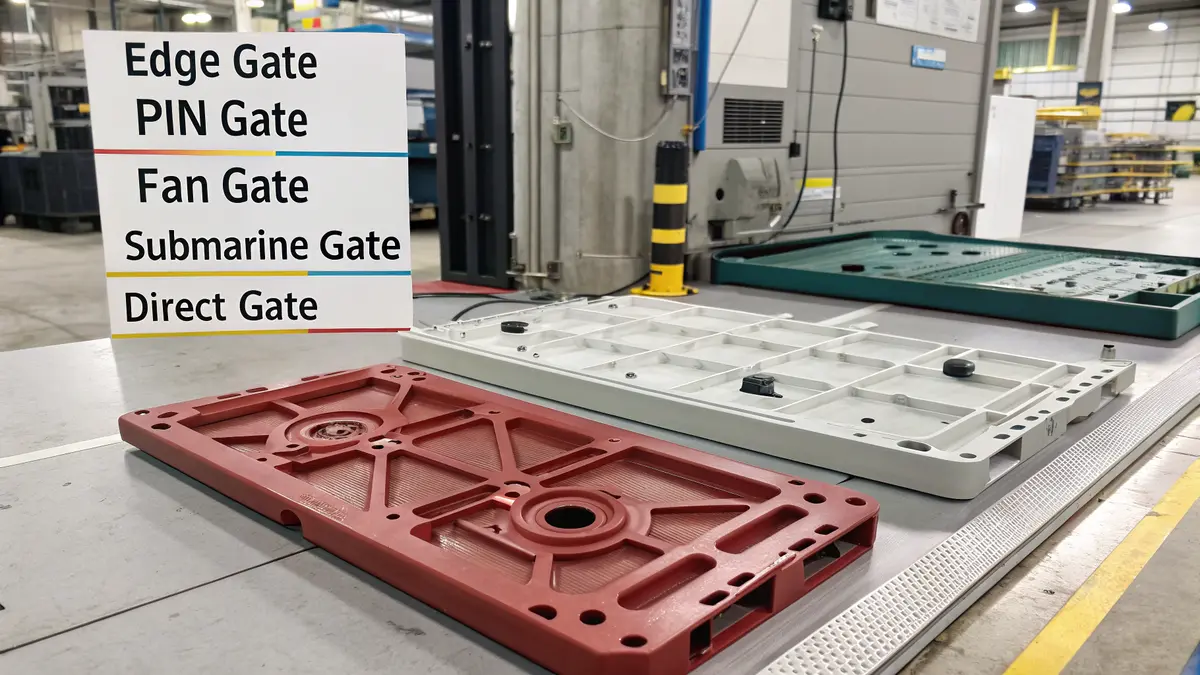

Understanding Gate Types and Their Applications

Different gate types serve various purposes in injection molding. I’ve categorized the main types based on their applications:

| Gate Type | Best Applications | Advantages | Limitations |

|---|---|---|---|

| Edge Gate | Flat parts, basic geometries | Easy to remove, good for automation | Limited to side entry |

| Pin Gate | Small parts, precise filling | Minimal gate mark, good for circular parts | Size limitations |

| Fan Gate | Wide, flat parts | Even material distribution | Difficult gate removal |

| Submarine Gate | High-volume production | Automatic degating | Complex tool design |

| Direct Gate | Large parts, thick sections | Simple design, efficient filling | Visible gate mark |

Critical Factors in Gate Location Selection

The success of your injection molded part heavily depends on several key factors when determining gate location:

Part Geometry Considerations

The rheological behavior7 of plastic material during injection requires careful analysis of part geometry. I always consider:

- Flow length to thickness ratio

- Natural flow paths

- Geometric transitions

- Wall thickness variations

Material Flow Requirements

Different materials have unique flow characteristics that influence gate placement:

- Crystalline vs. amorphous materials

- Melt viscosity

- Thermal sensitivity

- Flow length capabilities

Quality and Aesthetic Requirements

Gate location directly impacts visual and structural qualities:

- Visible surfaces

- Structural integrity zones

- Cosmetic requirements

- Weld line positioning

Impact on Common Molding Defects

Gate location significantly influences various molding defects:

Air Traps and Venting

Proper gate placement helps prevent:

- Trapped air pockets

- Burn marks

- Incomplete filling

- Surface defects

Weld Lines Management

Strategic gate positioning helps control:

- Weld line location

- Strength at meeting points

- Visual appearance

- Structural integrity

Flow-Related Issues

Optimal gate location addresses:

- Short shots

- Hesitation marks

- Flow marks

- Jetting

Advanced Considerations for Complex Parts

Complex parts require additional analysis:

Multi-Cavity Molds

For multi-cavity applications, consider:

- Balanced filling

- Runner system design

- Cavity-to-cavity consistency

- Production efficiency

High-Precision Components

Critical applications demand attention to:

- Dimensional stability

- Minimal warpage

- Precise material control

- Uniform shrinkage

At PTSMAKE, we utilize advanced mold flow analysis software to optimize gate locations. This scientific approach helps us:

- Predict material flow patterns

- Identify potential defect areas

- Optimize cooling efficiency

- Enhance overall part quality

Impact on Production Efficiency

Proper gate location affects various production aspects:

Cycle Time Optimization

- Faster filling times

- Efficient cooling

- Reduced pressure requirements

- Better material distribution

Maintenance Considerations

- Easy gate removal

- Reduced wear on mold components

- Simplified cleaning procedures

- Extended tool life

By carefully considering these factors and utilizing advanced simulation tools, we consistently achieve optimal results in injection molding projects. Our systematic approach to gate location selection has helped numerous clients overcome challenging manufacturing issues and achieve superior product quality.

How can shrinkage be managed in plastic part design?

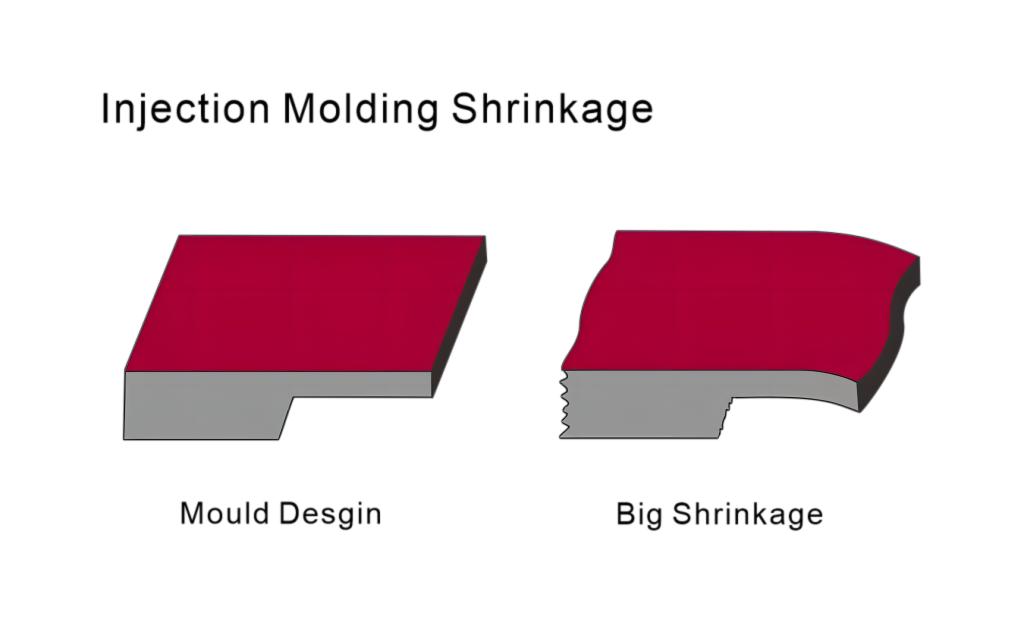

Struggling with dimensional accuracy in plastic parts? I’ve seen countless manufacturers face costly rework and production delays due to unexpected shrinkage issues. When not properly managed, shrinkage can turn a perfect design into a rejected batch, causing headaches for everyone involved.

Managing shrinkage in plastic part design requires a comprehensive approach combining precise mold design adjustments, careful material selection, and optimized processing parameters. By understanding and accounting for material-specific shrinkage rates, manufacturers can ensure dimensional accuracy and part quality.

Understanding Material Shrinkage Characteristics

Different plastic materials exhibit varying volumetric shrinkage8 behavior during cooling. At PTSMAKE, we’ve developed a systematic approach to material selection based on shrinkage characteristics. Here’s a breakdown of common plastic materials and their typical shrinkage rates:

| Material Type | Linear Shrinkage Rate (%) | Shrinkage Uniformity |

|---|---|---|

| ABS | 0.4-0.7 | High |

| Polypropylene | 1.2-2.0 | Medium |

| Polyethylene | 1.5-3.0 | Low |

| Polycarbonate | 0.5-0.7 | High |

| Nylon | 0.8-2.0 | Medium |

Design Compensation Strategies

The key to managing shrinkage starts with proper design compensation. I recommend implementing these essential strategies:

Wall Thickness Optimization

- Maintain uniform wall thickness throughout the part

- Avoid sudden thickness transitions

- Design with recommended thickness ranges for specific materials

Draft Angle Considerations

- Increase draft angles by 1-2° to account for shrinkage

- Apply additional draft for deeper parts

- Consider material-specific shrinkage when calculating draft angles

Process Parameter Optimization

Control over processing parameters significantly impacts shrinkage management:

Mold Temperature Control

- Maintain consistent mold temperature

- Use appropriate cooling channel design

- Monitor temperature variations across the mold

Injection Pressure Settings

- Optimize holding pressure duration

- Adjust injection speed based on material characteristics

- Balance filling and packing phases

Advanced Cooling System Design

Proper cooling system design is crucial for uniform shrinkage:

Cooling Channel Layout

- Position channels for uniform heat removal

- Maintain consistent channel diameter

- Ensure proper channel spacing

Cooling Time Optimization

- Calculate minimum cooling time based on wall thickness

- Consider material thermal properties

- Monitor part temperature at ejection

Material-Specific Considerations

Different materials require specific approaches:

Crystalline Materials

- Allow for higher shrinkage rates

- Implement longer cooling times

- Consider gate location carefully

Amorphous Materials

- Monitor cooling rate consistency

- Maintain appropriate mold temperature

- Control packing pressure precisely

Quality Control Measures

Implementing robust quality control procedures ensures consistent results:

Dimensional Monitoring

- Regular part measurements

- Statistical process control implementation

- Documentation of shrinkage patterns

Process Documentation

- Record optimal processing parameters

- Maintain material-specific setting logs

- Document successful shrinkage compensation strategies

Common Troubleshooting Solutions

When shrinkage issues arise, consider these solutions:

Dimensional Issues

- Adjust mold dimensions based on measured shrinkage

- Modify cooling system layout

- Review material selection

Warpage Problems

- Balance cooling across the part

- Adjust processing temperatures

- Modify wall thickness design

At PTSMAKE, we’ve successfully implemented these strategies across numerous projects. Our experience shows that effective shrinkage management requires a holistic approach combining design expertise, material knowledge, and process control. By carefully considering each aspect of the manufacturing process, we consistently achieve tight tolerances and high-quality parts that meet or exceed customer specifications.

Understanding and managing shrinkage is not just about applying standard compensation factors – it requires a deep understanding of material behavior, process dynamics, and design principles. Through careful attention to these details and continuous monitoring of results, we can effectively control shrinkage and produce high-quality plastic parts that consistently meet dimensional requirements.

What special features should be considered in plastic part design?

Designing plastic parts with special features can be a daunting challenge. Many engineers struggle with balancing functionality and manufacturability, often leading to costly design revisions or production delays. The complexity of these features can make the difference between a successful product and a manufacturing nightmare.

Special features in plastic part design require careful consideration of manufacturing constraints and end-use requirements. Key elements include snap fits, living hinges, undercuts, and textured surfaces, each serving specific functional purposes while demanding precise design attention to ensure successful production.

Understanding Snap Fits

Snap fits are essential features that revolutionize assembly processes. I’ve found that successful snap fit design requires careful attention to several key factors:

- Material Selection: Different materials exhibit varying degrees of flexibility and strength

- Engagement Angle: Typically between 30-45 degrees for optimal performance

- Retention Force: Must balance easy assembly with secure holding power

- Wall Thickness: Critical for preventing stress concentration and breakage

The key to successful snap fit design lies in the strain rate9 calculation, which determines the material’s behavior during assembly.

Living Hinge Design Considerations

Living hinges offer unique advantages in plastic part design:

Design Parameters

- Thickness: Usually 0.2-0.3mm for optimal flexibility

- Material Selection: Polypropylene (PP) is preferred due to its excellent fatigue resistance

- Radius: Sharp corners must be avoided to prevent stress concentration

Performance Factors

| Factor | Requirement | Impact |

|---|---|---|

| Flex Life | >1 million cycles | Product longevity |

| Operating Temperature | -20°C to 80°C | Environmental stability |

| Mold Flow | Parallel to hinge | Structural integrity |

Managing Undercuts Effectively

Undercuts present unique challenges in injection molding:

Types of Undercuts

External Undercuts

- Require side actions or slides

- Impact cycle time and tool cost

Internal Undercuts

- Need collapsible cores

- Affect part ejection mechanics

Design Strategies

- Minimize depth where possible

- Consider split line location carefully

- Evaluate alternative designs that might eliminate undercuts

Surface Texturing Techniques

Surface textures serve both aesthetic and functional purposes:

Texture Categories

Functional Textures

- Anti-slip properties

- Light diffusion

- Wear resistance

Aesthetic Textures

- Leather grain

- Wood grain

- Geometric patterns

Design Guidelines

- Draft angle must increase with texture depth

- Pattern orientation should align with mold opening

- Depth-to-width ratio must be considered for proper filling

Material Selection Impact

The choice of material significantly influences special feature performance:

| Material | Snap Fit Performance | Living Hinge Capability | Texture Retention |

|---|---|---|---|

| PP | Excellent | Excellent | Good |

| ABS | Good | Poor | Excellent |

| PC | Very Good | Poor | Very Good |

| POM | Excellent | Poor | Fair |

Manufacturing Considerations

To ensure successful production:

Tool Design

- Proper venting

- Cooling channel layout

- Gate location optimization

Process Parameters

- Injection pressure control

- Temperature management

- Cooling time optimization

Quality Control

- Dimensional verification

- Functional testing

- Visual inspection

Cost Optimization Strategies

I recommend considering these factors for cost-effective design:

Design Simplification

- Reduce complexity where possible

- Combine features when feasible

- Standardize dimensions

Material Selection

- Balance cost with performance

- Consider recycled materials

- Optimize material usage

Manufacturing Efficiency

- Minimize cycle time

- Reduce secondary operations

- Optimize tool design

Maintenance and Longevity

For long-term success:

Regular Tool Maintenance

- Monitor wear points

- Clean venting channels

- Check alignment features

Quality Monitoring

- Track dimensional stability

- Monitor feature performance

- Document wear patterns

Process Optimization

- Fine-tune parameters

- Monitor cycle times

- Adjust as needed

Through careful consideration of these special features and their implementation requirements, we at PTSMAKE ensure optimal design and manufacturing outcomes. Our approach combines technical expertise with practical experience to deliver parts that meet both functional requirements and manufacturing constraints.

Understand how crystallinity impacts plastic properties for better material selection. ↩

Learn about how stress concentration affects part performance and design optimization techniques. ↩

Understand material moisture absorption effects to ensure optimal performance and durability in part design. ↩

Learn about parting lines to enhance mold efficiency and improve part quality in injection molding. ↩

Learn how wall thickness influences crystallization for better plastic part quality. ↩

Learn about stress reduction techniques that enhance the strength of your plastic part designs. ↩

Understanding rheological behavior enhances injection molding, improving flow characteristics and product quality. ↩

Learn about how shrinkage affects mold design and part quality for improved production outcomes. ↩

Understand strain rate for better material performance during assembly processes. ↩