Have you ever noticed how some metal parts quickly become dull, scratched, or corroded? In the manufacturing industry, I often see clients frustrated when their beautiful aluminum components lose their luster or deteriorate after just a few months of use.

Anodizing creates a durable, corrosion-resistant oxide layer on metal surfaces through an electrochemical process. This treatment enhances the metal’s durability, appearance, and resistance to wear while allowing for custom coloring and improved surface properties.

As a manufacturing professional, I’ve helped many clients improve their products through anodizing. Let me share the key benefits and applications of this versatile surface treatment that can transform ordinary metal parts into exceptional components that last longer and perform better.

What Is the Purpose of Anodization?

Have you ever wondered why some aluminum products maintain their pristine appearance while others quickly deteriorate? Or why certain metal surfaces seem immune to scratches and corrosion while similar items rust away? These challenges can lead to costly replacements and compromised product quality.

Anodization is an electrochemical process that creates a durable, corrosion-resistant oxide layer on metal surfaces, primarily aluminum. This protective coating not only enhances the metal’s durability but also allows for color addition and improved aesthetic appeal.

Understanding the Fundamentals of Anodization

The anodization process involves converting the metal surface into an extremely durable anodic oxide film1. In my experience working with various surface treatment processes at PTSMAKE, I’ve found that this electrochemical process creates a layer that becomes an integral part of the metal rather than just a surface coating.

The Science Behind the Process

The anodization process follows these key steps:

Surface Preparation

- Cleaning and degreasing

- Chemical etching

- Brightening (optional)

Anodizing Bath

- Immersion in electrolyte solution

- Application of electrical current

- Formation of oxide layer

Sealing

- Hot water or chemical sealing

- Pore closure

- Enhanced protection

Benefits of Anodization

Enhanced Durability

The anodized surface provides:

| Benefit | Description |

|---|---|

| Corrosion Resistance | Prevents oxidation and rust formation |

| Wear Resistance | Increases surface hardness |

| Weather Protection | Guards against environmental factors |

| Chemical Stability | Resists reactions with most substances |

Aesthetic Advantages

Anodization offers various aesthetic benefits:

- Color integration possibilities

- Consistent finish across products

- Fade-resistant surface

- Natural metallic appearance preservation

Industrial Applications

Aerospace and Automotive

In the aerospace and automotive sectors, anodized components are crucial for:

- Engine components

- Exterior trim pieces

- Structural elements

- Interior decorative parts

At PTSMAKE, we’ve successfully implemented anodization processes for various automotive clients, ensuring their components meet strict industry standards while maintaining aesthetic appeal.

Consumer Electronics

The electronics industry heavily relies on anodization for:

- Smartphone casings

- Laptop bodies

- Tablet frames

- Portable device housings

Architecture and Construction

Anodized aluminum is extensively used in:

- Building facades

- Window frames

- Door systems

- Decorative panels

Environmental Considerations

Sustainability Benefits

Anodization offers several environmental advantages:

- Non-toxic process

- Recyclable materials

- Long-lasting finish reducing replacement needs

- Minimal waste production

Energy Efficiency

The process contributes to energy efficiency through:

| Aspect | Benefit |

|---|---|

| Heat Reflection | Reduces cooling costs |

| Thermal Barrier | Improves insulation |

| Durability | Minimizes replacement frequency |

| Low Maintenance | Reduces cleaning resource usage |

Quality Control Measures

To ensure consistent anodization results, several factors require monitoring:

Process Parameters

- Temperature control

- Current density

- Solution concentration

- Treatment time

Testing Methods

- Coating thickness measurement

- Seal quality verification

- Corrosion resistance testing

- Color consistency checking

Cost Considerations

While initial anodization costs might seem higher than alternative surface treatments, the long-term benefits often justify the investment:

- Reduced maintenance requirements

- Extended product lifespan

- Decreased replacement frequency

- Enhanced product value

At PTSMAKE, we help clients evaluate these factors to make informed decisions about their surface treatment needs, ensuring they achieve the optimal balance between cost and performance.

What Does the Color of Anodized Aluminum Mean?

Have you ever chosen anodized aluminum parts only to be confused by their various colors? Many engineers find themselves puzzled when selecting the right anodizing color, unsure if it affects the part’s performance or if it’s purely aesthetic.

Anodized aluminum colors aren’t just for decoration – they indicate the coating thickness and level of protection. Type II anodizing typically produces colors like gold, blue, and red, while Type III (hard anodizing) usually results in darker shades of gray or black, offering superior wear resistance.

Understanding Anodizing Color Formation

The coloring process in anodizing is fascinating and complex, involving the formation of a porous oxide layer that can be dyed or left in its natural state. The electrophoretic process2 creates microscopic pores that can accept dyes or be sealed for protection.

Natural vs. Dyed Anodizing Colors

Natural anodizing produces subtle variations:

- Clear/Natural: Slightly translucent appearance

- Light Gray: Common in architectural applications

- Champagne: Popular in consumer electronics

Dyed anodizing offers extensive color options:

| Color | Typical Applications | Durability Rating |

|---|---|---|

| Black | Military equipment | Excellent |

| Blue | Consumer products | Good |

| Red | Sports equipment | Good |

| Gold | Luxury items | Very Good |

Color as a Thickness Indicator

The thickness of the anodized layer directly correlates with its color and protection level:

Type II Anodizing Colors

- Light colors (0.0004" – 0.0007"): Decorative applications

- Medium colors (0.0007" – 0.001"): General purpose use

- Dark colors (0.001" and above): Enhanced protection

Type III Hard Anodizing Colors

- Gray to Black (0.002" – 0.004"): Maximum wear resistance

- Dark Bronze: Industrial applications

- Olive Drab: Military specifications

Industry-Specific Color Standards

Different industries have established specific color requirements:

Aerospace Requirements

- Clear anodizing: Internal components

- Black anodizing: External surfaces

- Color coding: System identification

Military Specifications

- Type III Hard anodizing: Olive drab

- Chemical agent resistant coating (CARC): Specific color ranges

- Color matching to Federal Standard 595

Color Stability Factors

Several factors affect the stability of anodized colors:

Environmental Influences

- UV exposure: Can cause fading

- Chemical exposure: May alter color

- Temperature variations: Impact color consistency

Process Variables

- Voltage control

- Time in bath

- Dye concentration

- Sealing methods

At PTSMAKE, I’ve implemented strict quality control measures to ensure color consistency across production batches. Our advanced anodizing facility maintains precise control over these variables:

Quality Control Measures

| Parameter | Control Method | Tolerance |

|---|---|---|

| Voltage | Digital monitoring | ±0.5V |

| Time | Automated timing | ±30 sec |

| Temperature | Digital control | ±2°F |

| pH Level | Continuous testing | ±0.2 |

Color Selection Guidelines

When selecting anodizing colors, consider:

Functional Requirements

- Wear resistance needs

- Environmental exposure

- Chemical resistance

- Heat dissipation

Aesthetic Considerations

- Brand consistency

- Design integration

- Light reflection

- Color matching

Cost Implications

- Process complexity

- Material requirements

- Production volume

- Quality standards

Testing and Verification

Color consistency requires rigorous testing:

Physical Testing

- Coating thickness

- Color measurement

- Wear resistance

- Impact testing

Quality Assurance

- Spectrophotometer analysis

- Salt spray testing

- Weather resistance

- Adhesion testing

Through our experience at PTSMAKE, we’ve found that successful color anodizing requires a deep understanding of both the technical process and aesthetic requirements. We maintain detailed process controls and quality checks to ensure consistent results across all projects.

Can You Re-Anodise Aluminium?

Have you ever noticed your anodized aluminum parts losing their luster or showing signs of wear? It’s frustrating when these expensive components start looking dull or scratched, especially in high-end products where aesthetics matter as much as functionality.

Yes, aluminum can be re-anodized, but the process requires completely stripping the existing anodized layer first. The success depends on the part’s condition, previous anodizing quality, and proper surface preparation before re-anodizing.

Understanding the Re-Anodizing Process

The re-anodizing process isn’t as straightforward as simply applying a new coating. It involves several critical steps that require careful attention to detail. At PTSMAKE, we’ve developed a systematic approach to ensure optimal results.

Step 1: Initial Assessment

Before beginning the re-anodizing process, we must evaluate:

- Surface condition

- Previous anodizing thickness

- Presence of damage or corrosion

- Original material composition

Step 2: Stripping the Original Coating

The existing anodized layer must be completely removed using a chemical stripping solution3. This process requires:

| Stripping Parameter | Typical Range | Critical Considerations |

|---|---|---|

| Temperature | 20-30°C | Must maintain consistency |

| Time | 30-60 minutes | Depends on coating thickness |

| Solution pH | 8.5-9.5 | Regular monitoring required |

Common Challenges in Re-Anodizing

Surface Imperfections

Re-anodizing might reveal underlying surface defects that were previously hidden. We address this through:

- Mechanical polishing

- Chemical etching

- Surface preparation techniques

Material Loss Considerations

Each re-anodizing cycle removes a small amount of base material. The typical material loss includes:

- 0.0254mm during stripping

- 0.0127mm during new anodizing

- Additional loss from surface preparation

Quality Control Measures

To ensure successful re-anodizing, we implement:

Thickness Testing

- Using eddy current measurements

- Destructive testing on sample pieces

- Regular calibration checks

Adhesion Testing

- Cross-hatch testing

- Impact resistance evaluation

- Salt spray testing

Industry Applications

Re-anodizing serves various industries:

Aerospace Components

- Control surfaces

- Interior trim pieces

- Structural components

Automotive Parts

- Wheel components

- Engine accessories

- Decorative trim

Consumer Electronics

At PTSMAKE, we frequently handle re-anodizing projects for:

- Smartphone housings

- Laptop enclosures

- Tablet frames

Cost-Benefit Analysis

Consider these factors when deciding on re-anodizing:

| Factor | Benefits | Limitations |

|---|---|---|

| Cost | 40-60% less than replacement | Varies with complexity |

| Time | Faster than new production | Requires careful scheduling |

| Quality | Can match original specs | May reveal hidden defects |

Environmental Impact

Re-anodizing offers several environmental benefits:

- Reduces waste material

- Decreases energy consumption

- Minimizes raw material usage

- Supports sustainable manufacturing

Best Practices for Maintaining Anodized Surfaces

To extend the life of anodized surfaces:

- Regular cleaning with pH-neutral solutions

- Avoid harsh chemicals or abrasives

- Protect from extreme environmental conditions

- Address damage promptly

When to Consider Re-Anodizing

The best candidates for re-anodizing are:

- Parts with cosmetic damage

- Components with worn surfaces

- Items requiring color changes

- Products with minor surface corrosion

Technical Specifications

For optimal re-anodizing results, we maintain:

| Parameter | Specification | Tolerance |

|---|---|---|

| Bath Temperature | 20±1°C | ±1°C |

| Current Density | 1.5 A/dm² | ±0.2 A/dm² |

| Coating Thickness | 20 microns | ±2 microns |

Can You Anodise Cast Aluminium?

Have you ever struggled with surface treating your cast aluminum parts, only to find disappointing results? The varying silicon content and porosity in cast aluminum can make achieving a consistent, attractive anodized finish feel like an impossible task.

Yes, cast aluminum can be anodized, but the results may be less predictable and aesthetically pleasing compared to wrought aluminum. The success largely depends on the casting method, silicon content, and porosity level of the specific cast aluminum alloy.

Understanding the Challenges of Cast Aluminum Anodizing

The anodizing process for cast aluminum presents unique challenges that require careful consideration. The main factors affecting the anodizing quality include:

Silicon Content Impact

Cast aluminum typically contains higher levels of silicon than wrought aluminum alloys. When the silicon content exceeds 7%, the eutectic phase4 formation during casting can significantly impact the anodizing results. Silicon particles remain unaffected during anodizing, creating potential weak spots in the protective layer.

Porosity Considerations

Cast aluminum inherently contains microscopic pores and voids that can affect the anodizing process:

| Porosity Level | Impact on Anodizing | Recommended Solution |

|---|---|---|

| Low (0-2%) | Minor impact, good finish possible | Standard anodizing process |

| Medium (2-5%) | Moderate impact, may need special preparation | Modified pre-treatment required |

| High (>5%) | Significant impact, poor finish likely | Consider alternative surface treatments |

Pre-treatment Requirements

Proper surface preparation is crucial for successful cast aluminum anodizing:

Chemical Cleaning

- Degreasing to remove oils and contaminants

- Alkaline etching to create a uniform surface

- Desmutting to remove oxidation and residues

Mechanical Preparation

- Light sanding or blast cleaning may be necessary

- Surface imperfections must be addressed before anodizing

- Careful handling to prevent contamination

Optimizing Anodizing Parameters

The standard anodizing process needs modification for cast aluminum:

Temperature Control

Maintaining precise temperature control during anodizing is essential:

| Process Stage | Optimal Temperature Range | Critical Considerations |

|---|---|---|

| Pre-treatment | 20-25°C | Affects cleaning effectiveness |

| Anodizing | 18-22°C | Influences coating quality |

| Sealing | 90-95°C | Determines durability |

Current Density Adjustments

Lower current densities often produce better results with cast aluminum:

- Start with 1.0-1.5 A/dm²

- Monitor voltage rise carefully

- Adjust based on alloy composition

Quality Control Measures

Implementing robust quality control procedures ensures consistent results:

Testing Methods

- Coating thickness measurements

- Seal quality verification

- Corrosion resistance testing

Common Defects and Solutions

| Defect Type | Possible Causes | Preventive Measures |

|---|---|---|

| Spotty Finish | High silicon content | Modify pre-treatment |

| Poor Adhesion | Surface contamination | Enhanced cleaning |

| Uneven Color | Porosity variations | Adjusted process parameters |

Alternative Surface Treatments

When anodizing results are unsatisfactory, consider these alternatives:

Powder Coating

- Excellent coverage of surface imperfections

- Wide range of color options

- Good durability

Chemical Conversion Coating

- Simpler process than anodizing

- More forgiving of surface variations

- Suitable for most cast alloys

At PTSMAKE, we’ve developed specialized processes for treating cast aluminum components. Our experience has shown that successful anodizing of cast aluminum requires:

- Thorough material analysis

- Customized pre-treatment procedures

- Carefully controlled process parameters

- Comprehensive quality testing

The key to achieving acceptable results lies in understanding the specific characteristics of your cast aluminum components and adjusting the anodizing process accordingly. While the process may be more challenging than anodizing wrought aluminum, with proper preparation and control, satisfactory results are achievable for many applications.

How Does Anodizing Affect Aluminum Alloy Strength?

Have you ever questioned whether anodizing your aluminum parts might compromise their structural integrity? It’s a common concern that keeps many engineers awake at night, especially when dealing with critical components where strength cannot be compromised.

Anodizing typically has minimal impact on aluminum alloy strength. While the process can slightly reduce fatigue strength by 10-15%, it generally maintains or even improves the base material’s tensile strength through enhanced surface hardness and corrosion resistance.

Understanding the Relationship Between Anodizing and Strength

The impact of anodizing on aluminum alloy strength is complex and multifaceted. At PTSMAKE, we regularly handle anodized aluminum components for various industries, and I’ve observed that the relationship between anodizing and strength depends on several key factors.

Surface Layer Formation

The anodizing process creates a protective oxide layer through electrochemical conversion5 of the aluminum surface. This layer typically ranges from 5 to 30 microns in thickness, depending on the type of anodizing process used. The formation of this layer affects different aspects of the material’s strength properties:

| Layer Type | Thickness Range | Primary Benefits | Impact on Strength |

|---|---|---|---|

| Type I | 2-7 microns | Basic protection | Minimal impact |

| Type II | 5-18 microns | Decorative finish | Slight reduction |

| Type III | 13-50 microns | Maximum hardness | Moderate reduction |

Mechanical Property Changes

The anodizing process influences various mechanical properties of aluminum alloys:

Tensile Strength

- Generally maintains or slightly improves

- Surface hardness increases significantly

- Core material properties remain largely unchanged

Fatigue Strength

- May decrease by 10-15%

- Impact varies with coating thickness

- More pronounced in thin sections

Wear Resistance

- Substantially improves

- Surface becomes more durable

- Better resistance to abrasion

Optimizing Anodizing Parameters for Strength

To maintain optimal strength properties while achieving desired surface characteristics, several factors need careful consideration:

Temperature Control

The anodizing bath temperature significantly affects the final strength properties:

- Optimal range: 18-22°C

- Higher temperatures can weaken the coating

- Lower temperatures may result in incomplete conversion

Current Density Management

Proper current density control is crucial for maintaining strength:

| Current Density (A/dm²) | Effect on Coating | Impact on Strength |

|---|---|---|

| 1.0-1.5 | Soft coating | Minimal reduction |

| 1.5-2.0 | Standard coating | Balanced properties |

| 2.0-3.0 | Hard coating | Maximum durability |

Industry-Specific Considerations

Different industries require varying approaches to balancing anodizing and strength requirements:

Aerospace Applications

In aerospace components, where strength is critical:

- Tight control of coating thickness

- Regular testing of mechanical properties

- Specialized sealing processes

- Documentation of all parameters

Automotive Components

For automotive parts, we focus on:

- Optimized coating thickness

- Balanced wear resistance

- Cost-effective solutions

- High-volume consistency

Medical Devices

Medical applications require:

- Biocompatibility

- Precise dimensional control

- Enhanced surface properties

- Strict quality control

Practical Solutions for Strength Maintenance

Based on our experience at PTSMAKE, here are key strategies to maintain strength during anodizing:

Pre-treatment Optimization

- Proper cleaning procedures

- Controlled etching

- Minimal material removal

- Surface preparation quality

Process Control

- Continuous monitoring

- Regular bath analysis

- Temperature maintenance

- Current density adjustment

Post-treatment Considerations

- Proper sealing methods

- Quality inspection

- Strength testing

- Surface finish verification

Quality Assurance Measures

To ensure consistent strength properties:

| Test Method | Parameter Measured | Frequency |

|---|---|---|

| Tensile Testing | Ultimate strength | Per batch |

| Hardness Testing | Surface hardness | Daily |

| Coating Thickness | Layer uniformity | Per part |

| Salt Spray | Corrosion resistance | Weekly |

Future Developments

The field of aluminum anodizing continues to evolve:

- New electrolyte compositions

- Advanced process control systems

- Improved sealing methods

- Enhanced coating properties

This comprehensive understanding of anodizing’s effects on aluminum alloy strength enables us to deliver optimal solutions for our clients’ specific requirements, ensuring both surface protection and structural integrity.

What Are the Cost Benefits of Anodizing in Manufacturing?

Have you ever wondered why some manufacturers hesitate to implement anodizing processes despite their clear benefits? The initial investment and process complexity often make companies question whether the cost is truly justified, leading to potentially missed opportunities for long-term savings.

Anodizing offers significant cost benefits in manufacturing through extended product lifespan, reduced maintenance requirements, and improved durability. While the initial investment may be higher than traditional coating methods, the long-term savings typically outweigh the upfront costs.

Understanding the Economic Value of Anodizing

The cost benefits of anodizing extend far beyond simple surface protection. As the President of PTSMAKE, I’ve analyzed the economic impact of anodizing across various manufacturing scenarios. The process involves creating a protective oxide layer through electrochemical passivation6, which provides multiple cost advantages.

Direct Cost Savings

Reduced Maintenance Expenses

- Lower cleaning costs due to dirt-resistant surfaces

- Minimal need for repainting or surface refinishing

- Decreased frequency of part replacement

Extended Product Lifespan

Traditional surface treatments often require periodic renewal, but anodized surfaces maintain their properties for years. This durability translates to significant cost savings over time.

Operational Cost Benefits

The following table illustrates the comparative maintenance costs between anodized and non-anodized components:

| Maintenance Aspect | Anodized Parts | Non-Anodized Parts |

|---|---|---|

| Annual Cleaning | 1-2 times | 4-6 times |

| Surface Refinishing | Every 8-10 years | Every 2-3 years |

| Replacement Rate | 10-15 years | 3-5 years |

| Labor Costs | Minimal | Moderate to High |

Production Efficiency Improvements

Streamlined Manufacturing Process

At PTSMAKE, we’ve observed that anodizing can actually reduce overall production steps compared to alternative finishing methods. The process is:

- Highly automated

- Consistently repeatable

- Quality-controlled through precise parameters

Energy Conservation Benefits

Anodized products often require less energy in their lifecycle:

- Reduced cleaning energy requirements

- Lower replacement production needs

- Minimal ongoing maintenance energy consumption

Environmental Cost Savings

Regulatory Compliance

Anodizing helps manufacturers meet environmental regulations without costly alternatives:

- Reduced waste disposal costs

- Lower environmental compliance expenses

- Minimal hazardous material handling requirements

Sustainable Manufacturing Benefits

The long-term environmental benefits translate to cost savings:

- Decreased carbon footprint

- Reduced raw material consumption

- Lower waste management costs

Industry-Specific Cost Advantages

Different sectors experience unique cost benefits from anodizing:

Aerospace Applications

- Enhanced corrosion resistance reduces replacement frequency

- Lightweight protection saves fuel costs

- Extended component lifespan reduces maintenance intervals

Automotive Manufacturing

- Improved wear resistance decreases warranty claims

- Reduced friction saves on operational costs

- Decorative durability maintains vehicle value

Consumer Electronics

- Better heat dissipation extends device life

- Improved scratch resistance reduces returns

- Enhanced aesthetics increases market value

Quality-Related Cost Benefits

Reduced Defect Rates

Anodizing provides consistent quality that reduces:

- Manufacturing rejects

- Customer returns

- Warranty claims

Enhanced Product Value

The improved quality justifies premium pricing:

- Higher perceived value

- Increased customer satisfaction

- Strong brand reputation

Long-term Financial Impact

ROI Analysis

Based on our experience at PTSMAKE, anodizing typically shows positive ROI within:

- 12-18 months for high-volume products

- 18-24 months for specialized applications

- 2-3 years for architectural applications

Lifecycle Cost Comparison

When comparing total lifecycle costs:

- Anodized products show 30-40% lower total ownership costs

- Maintenance savings offset initial investment

- Replacement costs are significantly reduced

Market Competitiveness

Pricing Strategy Benefits

Anodizing enables:

- Premium product positioning

- Higher profit margins

- Competitive differentiation

Customer Satisfaction Impact

Improved product performance leads to:

- Reduced customer complaints

- Increased repeat business

- Enhanced brand loyalty

The cost benefits of anodizing in manufacturing are substantial when viewed holistically. While the initial investment may seem higher, the long-term financial advantages make it a smart choice for manufacturers focused on quality and sustainability.

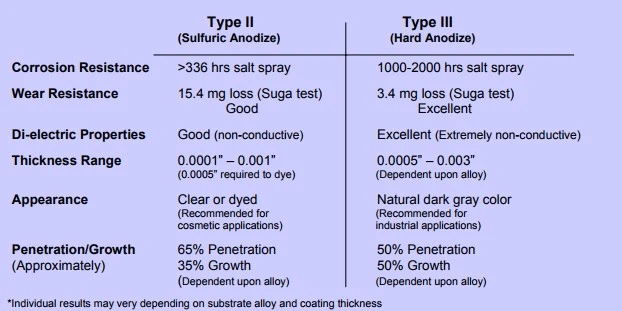

What’s the Difference Between Type II and Type III Anodizing?

Have you ever struggled to choose between Type II and Type III anodizing for your aluminum parts? The confusion is real – making the wrong choice could lead to premature part failure or unnecessary costs in your manufacturing process.

The main difference lies in their coating thickness and application. Type II anodizing creates a thinner layer (0.0004" to 0.001") suitable for indoor use, while Type III produces a thicker coating (0.001" to 0.004") ideal for harsh environments and high wear applications.

Understanding the Fundamentals of Type II and Type III Anodizing

Type II and Type III anodizing are two distinct processes that create protective oxide layers on aluminum surfaces. While both methods follow similar basic principles, their characteristics and applications differ significantly. At PTSMAKE, we regularly work with both types to meet various customer requirements.

The process involves immersing aluminum parts in an electrolytic solution7 where electrical current passes through, creating an oxide layer. The key differences emerge in the processing parameters and resulting properties.

Coating Thickness Comparison

The coating thickness is one of the most notable differences between these two types:

| Anodizing Type | Coating Thickness Range | Common Applications |

|---|---|---|

| Type II | 0.0004" – 0.001" | Indoor use, decorative finishes |

| Type III | 0.001" – 0.004" | Outdoor use, high wear resistance |

Characteristics and Properties

Type II Anodizing

- Moderate wear resistance

- Excellent for dyeing and decorative purposes

- Cost-effective solution

- Suitable for indoor applications

- Maintains closer dimensional tolerances

- Popular in consumer electronics and architectural components

Type III Anodizing

- Superior wear resistance

- Enhanced corrosion protection

- Higher hardness values

- Ideal for outdoor and harsh environments

- Slightly more dimensional growth

- Common in aerospace and military applications

Performance Factors

Hardness Comparison

Type III anodizing typically achieves hardness values between 65-70 on the Rockwell C scale, while Type II usually ranges from 40-45. This significant difference in hardness directly impacts wear resistance and durability.

Environmental Resistance

Both types offer different levels of environmental protection:

| Factor | Type II | Type III |

|---|---|---|

| UV Resistance | Moderate | Excellent |

| Salt Spray Resistance | 250-500 hours | 1000+ hours |

| Chemical Resistance | Good | Excellent |

| Temperature Resistance | Up to 150°F | Up to 200°F |

Cost Considerations

The cost difference between Type II and Type III anodizing can be significant:

- Type II is generally 20-30% less expensive

- Processing time for Type II is shorter

- Energy consumption is lower for Type II

- Type III requires more sophisticated equipment

- Material preparation requirements are more stringent for Type III

Making the Right Choice

The selection between Type II and Type III anodizing should be based on:

Application Requirements

- Environmental exposure

- Wear resistance needs

- Expected service life

- Aesthetic requirements

- Budget constraints

Industry Standards

Different industries have specific requirements:

| Industry | Typical Choice | Reason |

|---|---|---|

| Aerospace | Type III | Maximum durability required |

| Consumer Electronics | Type II | Cost-effective, adequate protection |

| Outdoor Equipment | Type III | Weather resistance needed |

| Indoor Fixtures | Type II | Decorative finish priority |

Technical Considerations

Surface Preparation

Proper surface preparation is crucial for both types, but Type III demands more stringent requirements:

- Surface cleanliness

- Absence of contaminants

- Proper alloy selection

- Surface finish requirements

Processing Parameters

The processing parameters vary significantly:

| Parameter | Type II | Type III |

|---|---|---|

| Temperature | 70°F | 32°F |

| Current Density | 10-20 ASF | 25-50 ASF |

| Processing Time | 30-60 minutes | 60-120 minutes |

Quality Control Measures

At PTSMAKE, we implement rigorous quality control measures for both processes:

- Thickness testing

- Seal quality verification

- Wear resistance testing

- Corrosion resistance testing

- Color consistency checks (for dyed finishes)

The choice between Type II and Type III anodizing ultimately depends on your specific application requirements. While Type II offers a cost-effective solution for less demanding applications, Type III provides superior protection for harsh environments and high-wear situations.

Can Anodizing Improve CNC Machined Part Durability?

Have you ever faced frustrating issues with your aluminum CNC machined parts corroding or wearing out too quickly? It’s a common challenge that can lead to costly replacements and production delays, potentially compromising your project’s success and budget.

Yes, anodizing significantly improves CNC machined part durability by creating a protective oxide layer that enhances corrosion resistance, wear resistance, and surface hardness while offering aesthetic benefits through various color options.

Understanding the Science Behind Anodizing

Anodizing transforms the surface of aluminum through an electrochemical process8 that creates a durable, corrosion-resistant oxide layer. At PTSMAKE, we’ve refined our anodizing techniques to ensure optimal protection for our clients’ parts. This process involves several key stages:

The Three-Step Anodizing Process

Surface Preparation

- Cleaning and degreasing

- Chemical etching

- Brightening (if required)

Anodizing Bath

- Immersion in electrolyte solution

- Application of electrical current

- Formation of oxide layer

Sealing

- Hot water or chemical sealing

- Pore closure

- Final protection

Benefits of Anodizing CNC Machined Parts

Enhanced Corrosion Protection

The anodized layer acts as a barrier against environmental factors:

| Protection Type | Benefit |

|---|---|

| Chemical Resistance | Prevents damage from acids and alkalis |

| Weather Resistance | Guards against outdoor exposure |

| Salt Spray Protection | Ideal for marine applications |

Improved Wear Resistance

The hard oxide layer significantly enhances surface durability:

| Property | Before Anodizing | After Anodizing |

|---|---|---|

| Surface Hardness | 65-95 Brinell | 250-400 Brinell |

| Wear Resistance | Moderate | High |

| Scratch Resistance | Low | Excellent |

Types of Anodizing Finishes

Type I Anodizing

- Chromic acid process

- Thin coating (0.00002-0.0001 inches)

- Excellent for parts requiring tight tolerances

Type II Anodizing

- Sulfuric acid process

- Medium coating (0.0002-0.001 inches)

- Most common for general applications

Type III Anodizing (Hard Anodizing)

- Modified sulfuric acid process

- Thick coating (0.001-0.004 inches)

- Highest wear resistance

Considerations for Anodizing CNC Parts

Design Considerations

- Allow for coating thickness

- Consider part geometry

- Plan for electrical contact points

- Account for dimensional changes

Material Selection Impact

Different aluminum alloys respond differently to anodizing:

| Alloy Series | Anodizing Response | Best Applications |

|---|---|---|

| 6061 | Excellent | General purpose |

| 7075 | Very Good | Aerospace |

| 2024 | Fair | Requires special care |

Quality Control in Anodizing

At PTSMAKE, we maintain strict quality control measures:

Pre-treatment Inspection

- Surface cleanliness

- Material verification

- Dimensional checking

Process Monitoring

- Temperature control

- Current density

- Processing time

- Solution concentration

Post-treatment Testing

- Coating thickness

- Seal quality

- Appearance

- Corrosion resistance

Cost-Benefit Analysis

While anodizing adds to the initial cost, it often proves economical in the long run:

| Factor | Without Anodizing | With Anodizing |

|---|---|---|

| Initial Cost | Lower | Higher |

| Maintenance Cost | Higher | Lower |

| Replacement Frequency | More Frequent | Less Frequent |

| Lifetime Value | Lower | Higher |

Industry-Specific Applications

Different industries benefit from anodizing in unique ways:

Aerospace

- Lightweight corrosion protection

- High wear resistance

- Electrical insulation properties

Medical Devices

- Biocompatibility

- Easy sterilization

- Clean appearance

Consumer Electronics

- Aesthetic appeal

- Scratch resistance

- Heat dissipation

Environmental Impact and Sustainability

Modern anodizing practices focus on environmental responsibility:

- Reduced water consumption

- Recycling of chemicals

- Energy-efficient processes

- Minimal waste generation

Click to learn more about the chemical composition and formation of anodic oxide layers. ↩

Click to learn more about the science behind anodizing color formation and process control. ↩

Click here to learn about advanced chemical stripping techniques and solutions for optimal results. ↩

Click to learn more about how phase formations affect metal surface treatments. ↩

Click to learn more about the science behind electrochemical conversion in anodizing processes. ↩

Click to learn more about this critical process that can transform your manufacturing efficiency. ↩

Click here to learn more about the electrochemical process and optimize your anodizing results. ↩

Click to learn more about this critical process that can extend your parts’ lifespan significantly. ↩