Have you ever found yourself puzzled about which steel grade to choose for your manufacturing project? Many engineers and designers struggle with this decision, especially when dealing with low-carbon steel options. The wrong choice can lead to wasted materials and costly production delays.

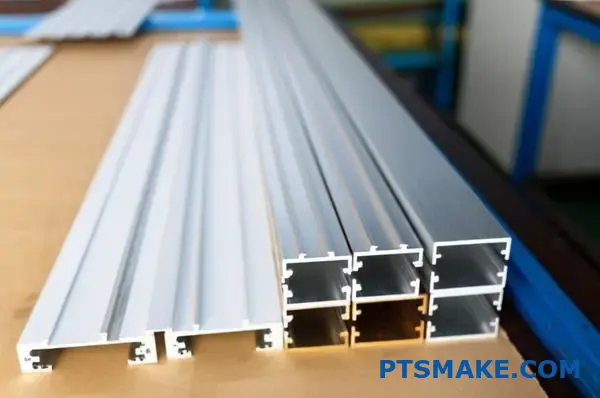

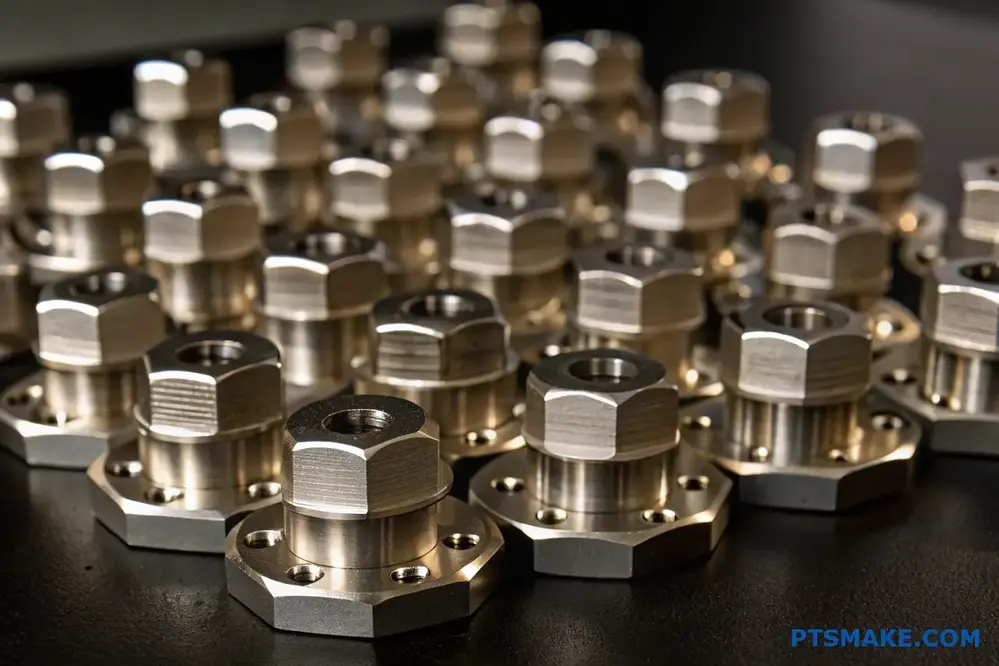

1018 steel is primarily used for general-purpose manufacturing applications that require good strength and machinability. It’s commonly used in shafts, pins, rods, and other machinery parts where high strength isn’t critical but good formability and weldability are essential.

I’ve worked with many clients who choose 1018 steel for their projects, and I understand why it’s such a popular choice. Let me share more detailed insights about this versatile material’s applications and how it can benefit your manufacturing needs. Whether you’re considering it for your next project or just exploring options, you’ll find valuable information in the following sections.

What Is Grade 1018 Steel Equivalent To?

Working with steel grades can be confusing, especially when dealing with international equivalents. Many of my clients struggle to find the right material specifications across different standards, which can lead to costly mistakes in manufacturing and product performance issues.

Grade 1018 steel is equivalent to several international standards, including C15 (European), S15C (Japanese), and 15# (Chinese). It’s a low-carbon steel containing 0.15-0.20% carbon content, making it ideal for general-purpose manufacturing and machining applications.

Understanding 1018 Steel Properties

The composition of 1018 steel makes it one of the most versatile materials in manufacturing. At PTSMAKE, we frequently work with this material due to its excellent metallurgical properties1 and machinability. Here’s a detailed breakdown of its chemical composition:

| Element | Percentage Range |

|---|---|

| Carbon | 0.15-0.20% |

| Manganese | 0.60-0.90% |

| Phosphorus | ≤0.040% |

| Sulfur | ≤0.050% |

| Iron | Balance |

International Equivalents of 1018 Steel

European Standards

- C15 (EN 10084)

- 1.0401 (DIN)

- 080M15 (BS)

Asian Standards

- S15C (JIS G4051 – Japan)

- 15# (GB/T 699 – China)

- SM20C (KS D3752 – Korea)

Mechanical Properties and Applications

1018 steel offers a balanced combination of strength and ductility. Based on my experience at PTSMAKE, these properties make it particularly suitable for:

Typical Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 440-490 MPa |

| Yield Strength | 370-420 MPa |

| Elongation | 15-20% |

| Hardness | 126-167 HB |

Common Applications

Automotive Components

- Shaft components

- Pins and bushings

- General fasteners

Industrial Equipment

- Machine parts

- Structural components

- Support brackets

Consumer Products

- Hardware items

- Tools and fixtures

- Household appliance parts

Manufacturing Considerations

When working with 1018 steel, several factors influence its performance:

Machining Characteristics

- Excellent machinability rating

- Consistent cutting speeds

- Good surface finish potential

- Cost-effective material removal rates

I’ve observed that proper cutting parameters are crucial for optimal results:

| Operation | Speed (SFM) | Feed Rate (IPR) |

|---|---|---|

| Turning | 350-400 | 0.005-0.015 |

| Milling | 300-350 | 0.004-0.012 |

| Drilling | 250-300 | 0.006-0.012 |

Heat Treatment Options

- Carburizing

- Case hardening

- Normalizing

- Stress relieving

Cost and Availability Benefits

1018 steel offers several advantages in terms of procurement:

Wide Availability

- Stocked by most suppliers

- Multiple form factors

- Quick delivery options

Cost Effectiveness

- Competitive pricing

- Efficient machining reduces labor costs

- Minimal waste during processing

Supply Chain Flexibility

- Multiple supplier options

- Standard sizes readily available

- Consistent quality across sources

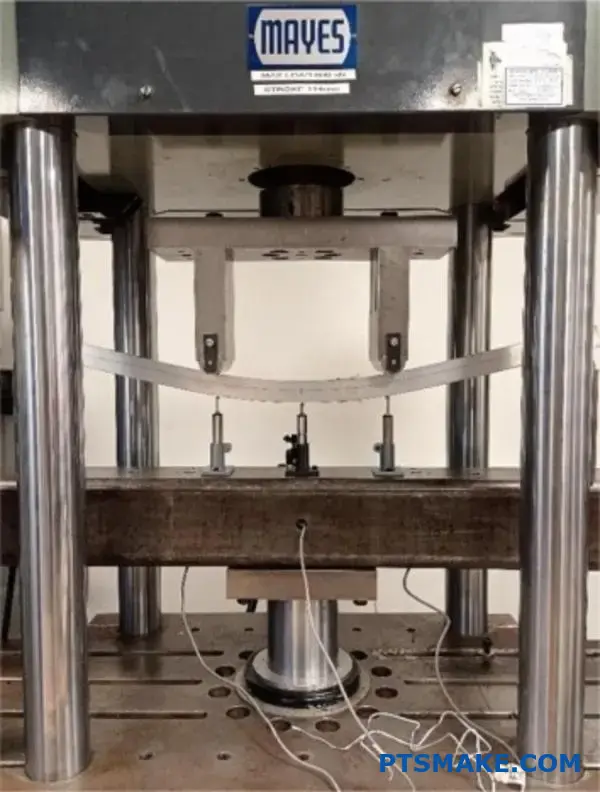

Quality Control Considerations

At PTSMAKE, we implement strict quality control measures for 1018 steel components:

Material Verification

- Chemical composition testing

- Hardness testing

- Microstructure analysis

Dimensional Control

- Precision measurements

- Geometric tolerancing

- Surface finish requirements

Performance Testing

- Load testing where applicable

- Wear resistance verification

- Corrosion resistance checks

Environmental and Safety Aspects

When working with 1018 steel, consider these environmental and safety factors:

Environmental Impact

- Recyclable material

- Lower energy consumption in processing

- Minimal harmful emissions during machining

Safety Considerations

- Standard PPE requirements

- No special handling needed

- Regular machine shop safety protocols apply

Is 1018 Steel the Same as A36?

When selecting steel materials for your manufacturing project, the confusion between 1018 steel and A36 steel can lead to costly mistakes. Many engineers and manufacturers struggle to understand the key differences, which puts their project quality and timeline at risk.

While 1018 steel and A36 steel share some similarities, they are distinct materials with different chemical compositions and mechanical properties. 1018 is a carbon steel with higher carbon content, while A36 is a mild structural steel with lower carbon content but higher manganese levels.

Chemical Composition Differences

The primary distinction between these steels lies in their chemical makeup. In my experience working with various steel grades at PTSMAKE, I’ve noticed that understanding these differences is crucial for material selection.

| Element | 1018 Steel | A36 Steel |

|---|---|---|

| Carbon | 0.15-0.20% | 0.25-0.29% |

| Manganese | 0.60-0.90% | 0.80-1.20% |

| Phosphorus | ≤0.040% | ≤0.040% |

| Sulfur | ≤0.050% | ≤0.050% |

Mechanical Properties Comparison

The yield strength2 variations between these materials significantly impact their performance in different applications.

Strength Characteristics

| Property | 1018 Steel | A36 Steel |

|---|---|---|

| Tensile Strength | 63,800 PSI | 58,000-80,000 PSI |

| Yield Strength | 53,700 PSI | 36,000 PSI |

| Elongation | 15% | 20% |

Workability and Machinability

1018 steel offers superior machinability compared to A36. At PTSMAKE, we’ve found that 1018 steel provides:

- Better surface finish in CNC machining

- More precise dimensional accuracy

- Reduced tool wear during machining

- Improved chip formation and breaking

Applications and Use Cases

1018 Steel Applications

- Precision machined parts

- Shafts and pins

- Automotive components

- General-purpose manufacturing

A36 Steel Applications

- Structural components

- Construction elements

- Building frameworks

- Support beams

Cost and Availability Factors

The price difference between these materials can impact project budgets:

| Factor | 1018 Steel | A36 Steel |

|---|---|---|

| Cost per pound | Higher | Lower |

| Market availability | Widely available | Very common |

| Processing cost | Moderate | Lower |

Heat Treatment Considerations

Both steels respond differently to heat treatment processes:

1018 Steel Heat Treatment

- Carburizing temperature: 1700°F (927°C)

- Case hardening potential

- Better response to surface hardening

A36 Steel Heat Treatment

- Limited heat treatment options

- Primarily used in as-rolled condition

- Welding-friendly properties

Manufacturing Recommendations

Based on our manufacturing experience at PTSMAKE, here are key considerations:

Choose 1018 steel when:

- Precision machining is required

- Surface finish is critical

- Parts need case hardening

- Dimensional accuracy is crucial

Select A36 steel when:

- Structural strength is primary

- Cost is a major factor

- Welding is required

- Large-scale construction is involved

Quality Control Measures

To ensure optimal performance, consider these quality control aspects:

Material Testing:

- Chemical composition verification

- Mechanical property testing

- Hardness testing

- Microstructure analysis

Processing Parameters:

- Temperature control during heat treatment

- Cooling rate monitoring

- Surface finish requirements

- Dimensional tolerance checking

Through my work at PTSMAKE, I’ve learned that successful material selection depends on understanding these nuances. When customers approach us with material selection questions, we always emphasize the importance of considering the entire application context rather than just comparing individual properties.

Will 1018 Steel Rust?

Metal corrosion is a serious concern for manufacturers and engineers. I’ve seen countless projects compromised by unexpected rusting, leading to costly replacements and potential safety hazards. The anxiety around material degradation can keep you awake at night.

Yes, 1018 steel will rust when exposed to moisture and oxygen. As a low-carbon steel, it lacks the corrosion resistance of stainless steel variants, making it susceptible to oxidation. However, various protective measures can significantly extend its service life.

Understanding the Chemistry of 1018 Steel Corrosion

1018 steel undergoes electrochemical oxidation3 when exposed to environmental factors. This process involves several key elements:

Chemical Composition Impact

- Carbon content: 0.14-0.20%

- Manganese: 0.60-0.90%

- Phosphorus: ≤0.040%

- Sulfur: ≤0.050%

The relatively low carbon content makes 1018 steel more susceptible to rust compared to higher carbon steels. At PTSMAKE, we frequently work with various steel grades, and I’ve observed that understanding these compositional differences is crucial for proper material selection.

Factors Accelerating Rust Formation

Several environmental conditions can speed up the rusting process:

Environmental Conditions

| Condition | Impact Level | Prevention Difficulty |

|---|---|---|

| High Humidity | Severe | Moderate |

| Salt Exposure | Severe | High |

| Industrial Atmospheres | Moderate | High |

| Temperature Fluctuations | Moderate | Low |

Protective Measures and Solutions

Surface Treatments

- Zinc Coating (Galvanization)

- Paint Application

- Powder Coating

- Oil-Based Treatments

In our manufacturing facility, we implement various surface treatment methods depending on the specific application requirements. These treatments create a barrier between the steel and corrosive elements.

Design Considerations

When working with 1018 steel, consider these design elements:

- Avoid water traps

- Include drainage paths

- Maintain proper ventilation

- Use protective sacrificial anodes when necessary

Industry Applications and Limitations

Suitable Applications

- Indoor structural components

- Machine parts with regular maintenance

- Temporary fixtures and tooling

- Non-critical components

Applications to Avoid

- Marine environments

- Outdoor exposure without protection

- High-humidity locations

- Chemically aggressive environments

Cost-Benefit Analysis

When comparing 1018 steel with alternatives:

| Material | Initial Cost | Maintenance Cost | Lifespan |

|---|---|---|---|

| 1018 Steel | Low | Moderate | 5-10 years* |

| Stainless Steel | High | Low | 15-20 years* |

| Galvanized Steel | Moderate | Low | 10-15 years* |

*Lifespan varies significantly based on environment and maintenance

Maintenance Best Practices

To extend the life of 1018 steel components:

Regular Inspection

- Check for early signs of rust

- Document problem areas

- Monitor environmental conditions

Preventive Maintenance

- Regular cleaning

- Reapplication of protective coatings

- Moisture control

- Temperature regulation

Real-World Performance Data

Based on our experience at PTSMAKE, we’ve compiled performance data from various applications:

| Application Type | Environment | Average Time to First Rust | Protection Method Used |

|---|---|---|---|

| Indoor Machinery | Controlled | 2-3 years | Oil coating |

| Factory Floor | Semi-exposed | 1-2 years | Paint coating |

| Workshop Tools | Variable | 6-12 months | Regular maintenance |

Future Considerations

The industry is constantly evolving, with new protective technologies emerging:

Emerging Technologies

- Nano-coating solutions

- Smart protective films

- Self-healing materials

- Advanced composite coatings

These innovations might change how we approach rust prevention in 1018 steel applications.

Economic Impact of Proper Material Selection

Making the right choice between 1018 steel and alternatives can significantly impact project costs:

Cost Factors to Consider

- Initial material cost

- Installation expenses

- Maintenance requirements

- Replacement frequency

- Downtime costs

At PTSMAKE, we help clients evaluate these factors to make informed decisions about material selection and protection methods.

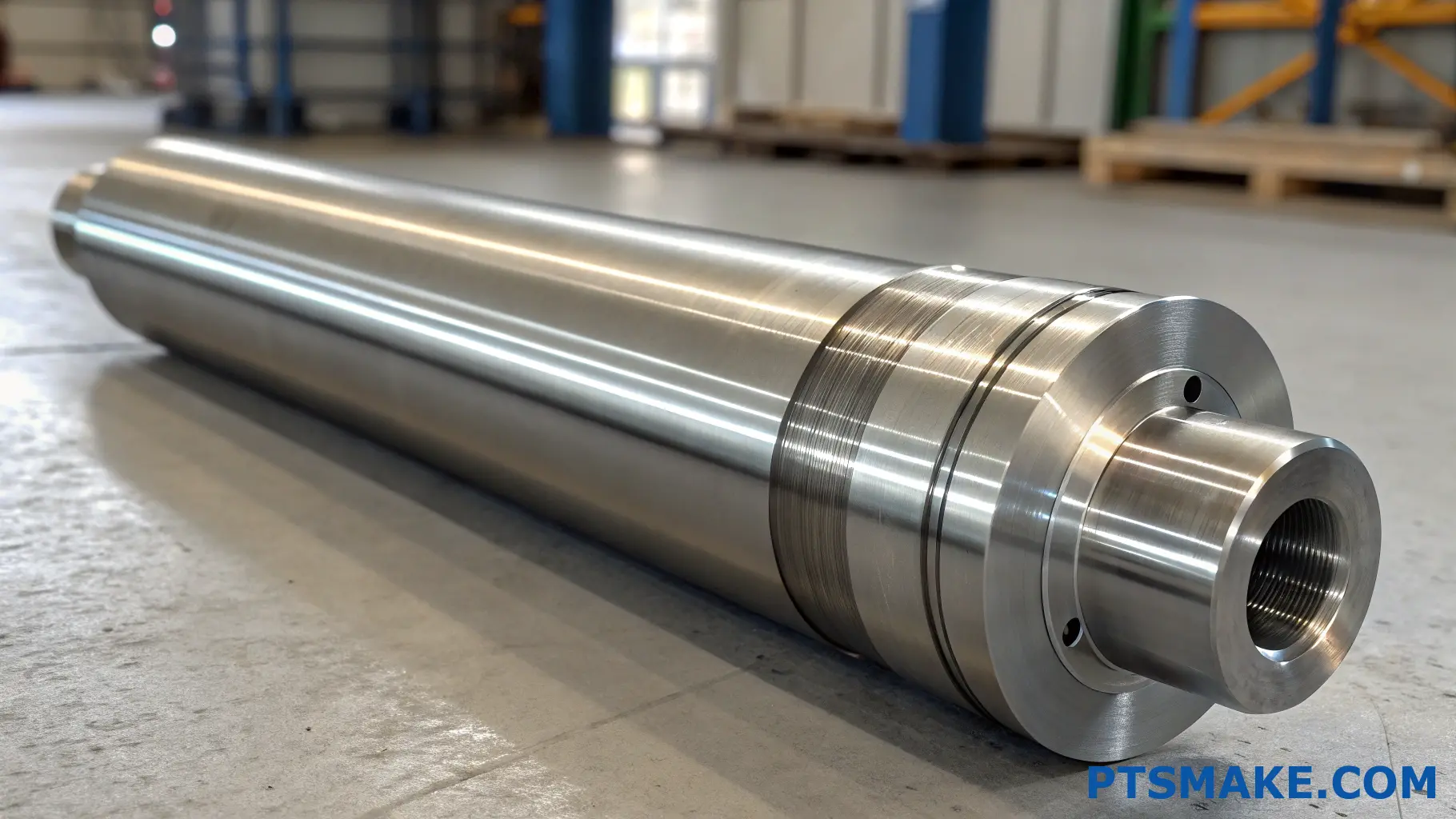

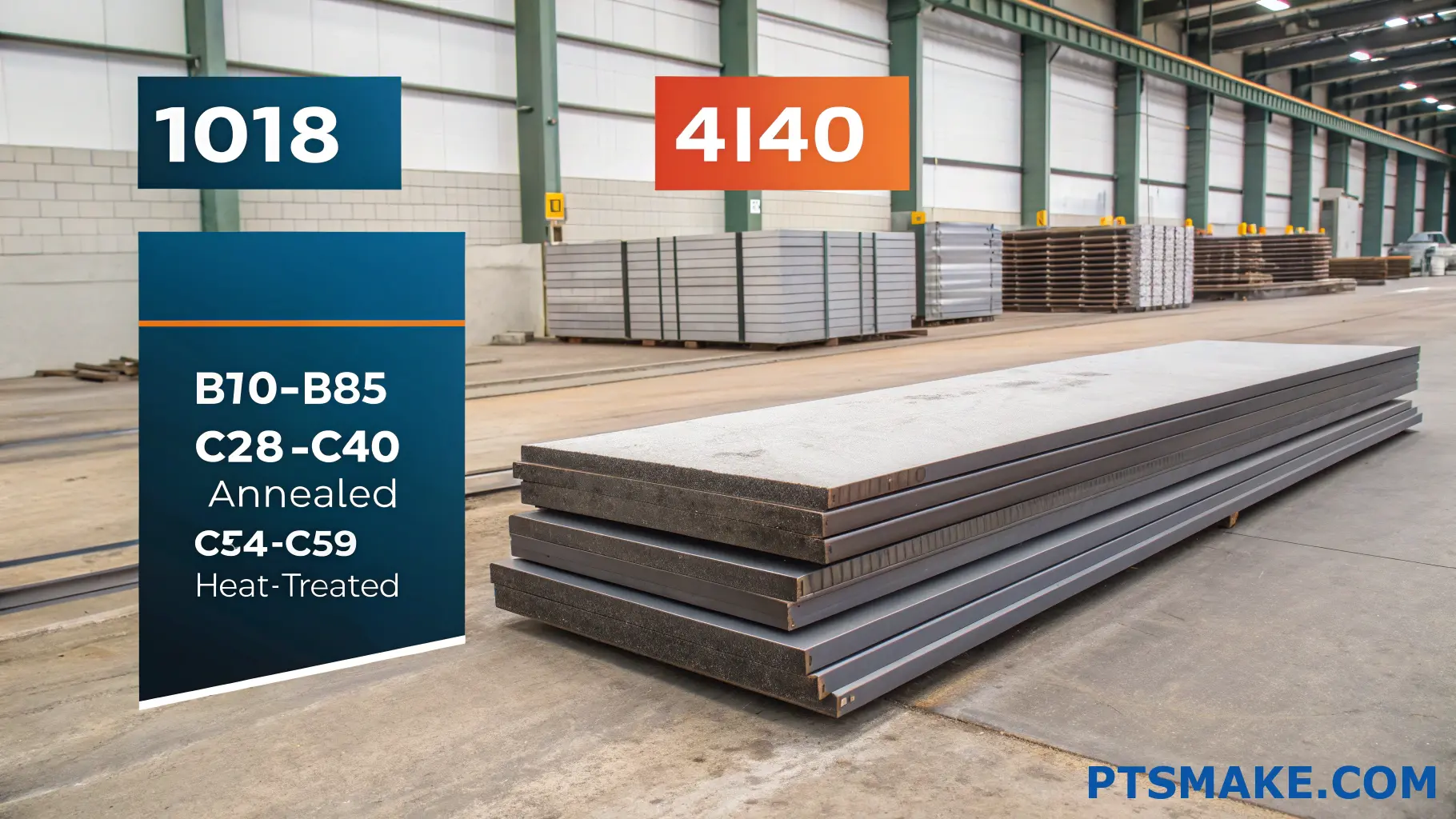

Which Is Harder, 1018 or 4140 Steel?

When selecting steel for machining projects, many engineers and manufacturers struggle with choosing between 1018 and 4140 steel. The confusion often leads to project delays and unnecessary material waste, especially when hardness requirements are critical for the application.

4140 steel is significantly harder than 1018 steel. While 1018 steel typically has a Rockwell hardness of B70-B85, 4140 steel can reach hardness levels of C28-C40 in its annealed state and up to C54-C59 when heat-treated.

Understanding Material Properties

Both 1018 and 4140 steel have distinct characteristics that make them suitable for different applications. The key difference lies in their chemical composition and metallurgical structure4, which directly affects their hardness and machinability.

Chemical Composition Comparison

| Element | 1018 Steel (%) | 4140 Steel (%) |

|---|---|---|

| Carbon | 0.15-0.20 | 0.38-0.43 |

| Manganese | 0.60-0.90 | 0.75-1.00 |

| Chromium | – | 0.80-1.10 |

| Molybdenum | – | 0.15-0.25 |

Hardness Characteristics

1018 Steel Hardness Properties

1018 steel is a low-carbon steel that offers:

- Rockwell hardness of B70-B85 in its standard form

- Limited heat treatment potential

- Good machinability

- Excellent weldability

At PTSMAKE, I’ve worked with numerous projects requiring 1018 steel, particularly for parts that need good machinability without extreme hardness requirements.

4140 Steel Hardness Properties

4140 steel demonstrates superior hardness characteristics:

- Rockwell hardness of C28-C40 in annealed state

- Can reach C54-C59 when properly heat-treated

- Higher wear resistance

- Better fatigue strength

Applications Based on Hardness Requirements

1018 Steel Applications

- General-purpose machining

- Non-critical components

- Structural parts

- Shaft collars

- Spacers

4140 Steel Applications

- Automotive crankshafts

- Heavy-duty axles

- Gears and sprockets

- Tool holders

- High-stress components

Factors Affecting Material Selection

Cost Considerations

| Factor | 1018 Steel | 4140 Steel |

|---|---|---|

| Raw Material Cost | Lower | Higher |

| Machining Cost | Lower | Higher |

| Heat Treatment Cost | Minimal | Significant |

Performance Factors

Understanding the performance requirements is crucial for material selection:

Wear Resistance

- 1018 steel: Moderate wear resistance

- 4140 steel: Superior wear resistance

Fatigue Strength

- 1018 steel: Lower fatigue strength

- 4140 steel: Higher fatigue strength

Impact Resistance

- 1018 steel: Good impact resistance

- 4140 steel: Excellent impact resistance

Machining Considerations

From my experience at PTSMAKE, proper machining parameters are crucial for both materials:

1018 Steel Machining

- Higher cutting speeds possible

- Lower tool wear

- Better surface finish achievable

- More forgiving in terms of cutting parameters

4140 Steel Machining

- Requires lower cutting speeds

- Higher tool wear

- More careful parameter selection needed

- Better cooling required

Heat Treatment Effects

The heat treatment response of these materials varies significantly:

1018 Steel Heat Treatment

- Limited response to heat treatment

- Case hardening possible

- Surface hardness improvement through carburizing

4140 Steel Heat Treatment

- Excellent response to heat treatment

- Through-hardening capability

- Significant strength improvement possible

Making the Right Choice

When selecting between 1018 and 4140 steel, consider:

- Required hardness specifications

- Application requirements

- Budget constraints

- Manufacturing capabilities

- Post-processing needs

At PTSMAKE, we guide our clients through this selection process by:

- Analyzing application requirements

- Considering manufacturing constraints

- Evaluating cost implications

- Assessing quality requirements

The choice between 1018 and 4140 steel ultimately depends on your specific application needs. While 1018 offers good machinability and lower costs, 4140 provides superior hardness and wear resistance. Understanding these differences helps make informed decisions for your manufacturing projects.

Is 1018 Steel Corrosion Resistant?

Working with various steel grades in manufacturing, I often encounter clients concerned about material durability and longevity. Many wonder if their chosen steel will withstand environmental challenges, particularly when it comes to 1018 steel and its resistance to corrosion.

1018 steel has limited corrosion resistance due to its low carbon content and lack of protective alloying elements. Without proper surface treatment or protective coating, it will rust when exposed to moisture and oxygen in normal atmospheric conditions.

Understanding Corrosion Mechanisms in 1018 Steel

When 1018 steel encounters moisture and oxygen, it undergoes electrochemical oxidation5, leading to rust formation. This process accelerates in environments with:

- High humidity levels

- Salt exposure

- Chemical presence

- Temperature fluctuations

Factors Affecting Corrosion Rate

The speed at which 1018 steel corrodes depends on several environmental conditions:

| Environmental Factor | Impact Level | Effect on Corrosion Rate |

|---|---|---|

| Humidity | High | Accelerates rust formation |

| Temperature | Medium | Higher temperatures increase reaction speed |

| Salt Exposure | Very High | Dramatically accelerates corrosion |

| pH Level | High | Acidic environments speed up deterioration |

Protective Measures for 1018 Steel

At PTSMAKE, we implement various protection methods to enhance 1018 steel’s corrosion resistance:

Surface Treatments

Zinc Plating

- Creates protective barrier

- Offers sacrificial protection

- Extends part lifespan

Chrome Plating

- Provides excellent corrosion resistance

- Improves surface hardness

- Enhances aesthetic appeal

Coating Options

Powder Coating

- Durable finish

- Wide color selection

- Environmental friendly

Paint Systems

- Cost-effective

- Easy to maintain

- Multiple layer protection

Industry Applications and Considerations

1018 steel finds extensive use in various applications despite its corrosion limitations:

Suitable Applications

- Indoor mechanical components

- Temporary structural elements

- Non-critical machinery parts

- Training and prototype materials

Applications to Avoid

- Marine environments

- Outdoor exposure

- Chemical processing equipment

- High-moisture locations

Cost-Benefit Analysis

Consider these factors when choosing 1018 steel:

| Factor | Advantage | Disadvantage |

|---|---|---|

| Cost | Lower initial investment | May require additional protection |

| Machinability | Excellent workability | Surface treatments add cost |

| Availability | Readily available | Regular maintenance needed |

| Strength | Good mechanical properties | Limited corrosion resistance |

Maintenance Requirements

To maximize the lifespan of 1018 steel components:

Regular Inspection

- Check for rust spots

- Monitor coating integrity

- Document deterioration patterns

Preventive Measures

- Keep surfaces clean

- Control environmental conditions

- Apply protective oils when appropriate

Alternative Materials

When corrosion resistance is crucial, consider these alternatives:

Stainless Steel Grades

- 304 stainless

- 316 stainless

- 430 stainless

Specialty Alloys

- Inconel

- Hastelloy

- Monel

Through my experience at PTSMAKE, I’ve found that while 1018 steel isn’t inherently corrosion resistant, proper treatment and application can make it suitable for many projects. We often recommend it for indoor applications or situations where regular maintenance is feasible.

Design Considerations

When using 1018 steel in your projects:

Environmental Assessment

- Evaluate exposure conditions

- Consider seasonal changes

- Assess chemical exposure risks

Protection Planning

- Select appropriate coatings

- Design for water drainage

- Include maintenance access

Cost Planning

- Calculate initial material costs

- Factor in protection expenses

- Include maintenance budget

Remember, successful implementation of 1018 steel components requires careful consideration of environmental conditions and appropriate protective measures. At PTSMAKE, we guide our clients through material selection and protection strategies to ensure optimal performance and longevity of their components.

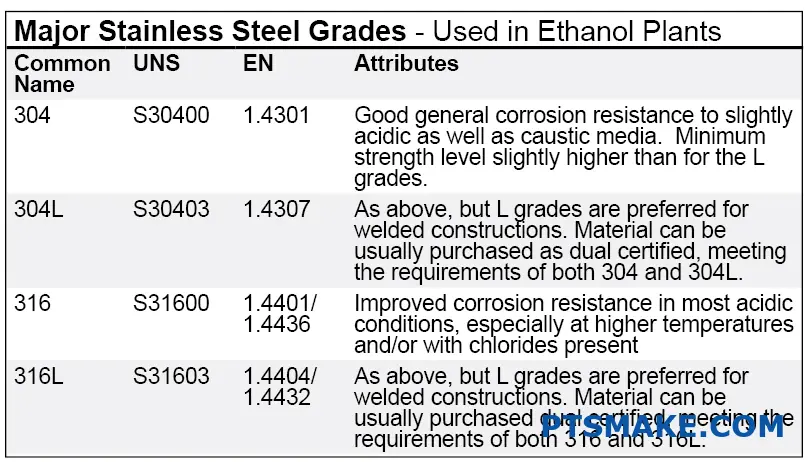

What Is the Best Steel for Not Rusting?

Every day, I see clients struggling with rusted steel components that compromise their product quality and safety. The frustration of dealing with corroded parts not only affects aesthetics but also leads to costly replacements and potential system failures. This is a common challenge that plagues many industries.

The best steel for rust resistance is stainless steel, particularly grades 316 and 304. These types contain high chromium content (at least 10.5%) and form a protective oxide layer that prevents corrosion. While no steel is completely rust-proof, these grades offer superior resistance to corrosion.

Understanding Corrosion Resistance in Steel

The key to understanding rust resistance lies in the steel’s chemical composition. When we talk about passivation6 in steel, we’re referring to the natural formation of a protective oxide layer that shields the metal from further corrosion. At PTSMAKE, we carefully select materials based on their corrosion resistance properties for various applications.

Factors Affecting Rust Resistance

- Chemical composition

- Environmental conditions

- Surface treatment

- Maintenance practices

Common Rust-Resistant Steel Grades

Here’s a detailed comparison of popular rust-resistant steel grades:

| Steel Grade | Chromium Content | Nickel Content | Corrosion Resistance | Common Applications |

|---|---|---|---|---|

| 316 | 16-18% | 10-14% | Excellent | Marine equipment, Chemical processing |

| 304 | 18-20% | 8-10.5% | Very Good | Kitchen equipment, Construction |

| 430 | 16-18% | <1% | Good | Automotive parts, Appliances |

| 1018 | <1% | None | Poor | General construction |

Material Selection Considerations

Environmental Factors

- Temperature exposure

- Chemical exposure

- Moisture levels

- Salt presence

Performance Requirements

- Mechanical properties

- Cost considerations

- Maintenance needs

- Service life expectations

Best Practices for Preventing Rust

Proper Material Selection

- Consider the operating environment

- Evaluate cost vs. performance

- Account for maintenance requirements

Surface Treatments

- Electroplating

- Hot-dip galvanizing

- Powder coating

- Chemical passivation

Design Considerations

- Avoid water traps

- Ensure proper drainage

- Minimize crevices

- Plan for maintenance access

Industry-Specific Applications

Marine Industry

The marine environment demands the highest level of corrosion resistance. At PTSMAKE, we often recommend 316 stainless steel for marine applications due to its excellent resistance to saltwater corrosion.

Food Processing

For food processing equipment, we typically use 304 stainless steel because it offers:

- Excellent corrosion resistance

- Easy cleaning

- Compliance with food safety regulations

Chemical Processing

Chemical processing requires specialized materials. Based on my experience with numerous projects, I recommend:

- 316L for acidic environments

- Duplex stainless steel for high-pressure applications

- Special alloys for extreme conditions

Cost-Effective Solutions

While premium stainless steel grades offer the best protection, they might not always fit within budget constraints. Here are some alternative approaches:

Carbon Steel with Protective Coatings

- More economical initial cost

- Requires regular maintenance

- Suitable for less demanding environments

Low-Alloy Steels

- Better corrosion resistance than carbon steel

- Lower cost than stainless steel

- Good for moderate environments

Hybrid Solutions

- Using stainless steel only for critical components

- Combining different materials strategically

- Optimizing cost vs. performance

Maintenance Guidelines

To maximize the corrosion resistance of any steel:

Regular Cleaning

- Remove surface contaminants

- Use appropriate cleaning agents

- Follow manufacturer recommendations

Periodic Inspection

- Check for early signs of corrosion

- Monitor protective coatings

- Document findings

Preventive Measures

- Apply protective coatings

- Maintain environmental controls

- Address issues promptly

Through our work at PTSMAKE, we’ve found that proper material selection combined with appropriate maintenance can significantly extend the service life of steel components. For specific applications requiring exceptional corrosion resistance, I recommend consulting with our engineering team to develop customized solutions that meet your exact needs.

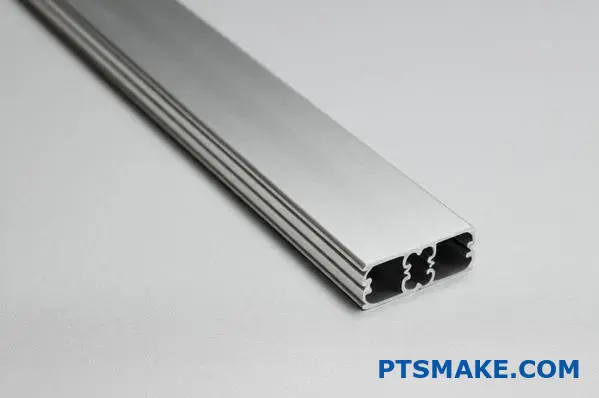

How Does 1018 Steel Perform in CNC Machining Processes?

Working with various steel grades in CNC machining can be challenging, especially when trying to achieve precise tolerances and optimal surface finishes. Many manufacturers struggle to determine the best machining parameters for 1018 steel, leading to wasted materials and increased production costs.

1018 steel performs exceptionally well in CNC machining processes due to its moderate carbon content, good machinability rating, and excellent balance between strength and ductility. It maintains dimensional stability during machining while allowing for relatively high cutting speeds.

Material Properties and Characteristics

1018 steel belongs to the category of low-carbon steels, containing approximately 0.18% carbon. The material exhibits a unique combination of properties that make it particularly suitable for CNC machining operations. During my time overseeing numerous machining projects, I’ve observed that its work hardening rate7 significantly influences machining performance.

The key properties that affect its machinability include:

| Property | Typical Value | Impact on Machining |

|---|---|---|

| Tensile Strength | 440 MPa | Moderate cutting forces required |

| Yield Strength | 370 MPa | Good chip formation |

| Hardness | 126 HB | Excellent tool life |

| Carbon Content | 0.18% | Balanced machining characteristics |

Optimal Cutting Parameters

At PTSMAKE, we’ve developed specific cutting parameters for 1018 steel that consistently deliver superior results:

Speed and Feed Rates

| Operation Type | Cutting Speed (SFM) | Feed Rate (IPR) |

|---|---|---|

| Rough Turning | 350-400 | 0.012-0.020 |

| Finish Turning | 400-450 | 0.004-0.008 |

| Face Milling | 400-500 | 0.006-0.012 |

| End Milling | 350-400 | 0.004-0.008 |

Surface Finish Considerations

The surface finish quality achievable with 1018 steel is one of its standout characteristics. I’ve found that proper cutting tool selection and parameter optimization can consistently achieve:

- Ra values of 32-63 microinches in general turning

- Ra values of 16-32 microinches with optimized finishing passes

- Excellent dimensional stability throughout the machining process

Tool Selection Guidelines

The choice of cutting tools significantly impacts machining performance:

| Tool Type | Recommended Material | Coating |

|---|---|---|

| Turning Tools | Carbide | TiAlN |

| End Mills | Solid Carbide | TiCN |

| Drill Bits | HSS-Co | TiN |

Cost-Effectiveness Analysis

1018 steel offers excellent value in CNC machining applications:

- Lower tool wear compared to higher carbon steels

- Reduced machining time due to good machinability

- Minimal material waste during setup and operation

- Cost-effective material pricing in the market

Production Efficiency Metrics

| Aspect | Performance Rating | Notes |

|---|---|---|

| Tool Life | 8/10 | Extended tool life compared to other steels |

| Cycle Time | 7/10 | Efficient material removal rates |

| Surface Quality | 8/10 | Excellent finish with proper parameters |

| Cost Efficiency | 9/10 | Optimal balance of performance and price |

Common Applications

At PTSMAKE, we frequently machine 1018 steel for various applications:

- Automotive components requiring moderate strength

- General-purpose shafts and pins

- Agricultural equipment parts

- Industrial machinery components

Quality Control Considerations

Maintaining consistent quality in 1018 steel machining requires attention to:

Process Monitoring

- Regular tool wear inspection

- Temperature control during machining

- Dimensional stability checks

- Surface finish verification

Common Challenges and Solutions

| Challenge | Solution |

|---|---|

| Built-up Edge | Increase cutting speed |

| Poor Surface Finish | Adjust feed rates |

| Dimensional Variation | Implement proper cooling |

| Tool Wear | Use recommended coatings |

Environmental Factors

The machining of 1018 steel presents several environmental considerations:

- Recyclability of chips and scrap material

- Proper coolant management

- Energy efficiency in machining operations

- Waste reduction strategies

Future Trends

The future of 1018 steel machining is evolving with technology:

- Implementation of AI-driven parameter optimization

- Development of advanced cutting tool materials

- Integration of sustainable machining practices

- Enhanced monitoring and quality control systems

Through my experience at PTSMAKE, I’ve seen 1018 steel consistently deliver reliable performance in CNC machining operations. Its combination of good machinability, cost-effectiveness, and versatility makes it an excellent choice for many manufacturing applications. While it may not be suitable for every project, understanding its characteristics and optimal machining parameters can help achieve superior results in appropriate applications.

What Are the Cost Benefits of Using 1018 Steel Over Other Grades?

Manufacturing costs keep rising, and many engineers struggle to balance material quality with budget constraints. The pressure to reduce expenses while maintaining product integrity creates significant stress in material selection decisions.

1018 steel offers an excellent balance of cost and performance compared to other grades. Its lower carbon content makes it more economical to machine and form, while still providing adequate strength for many applications, making it a cost-effective choice for various manufacturing projects.

Understanding the Cost Structure of 1018 Steel

The cost advantages of 1018 steel stem from several factors that I’ve observed throughout my experience in manufacturing. The material exhibits excellent machinability8 characteristics, which significantly impacts the overall production costs.

Raw Material Costs

1018 steel typically costs less than higher-grade alternatives due to:

- Simpler composition with lower carbon content

- Widespread availability from suppliers

- Less complex manufacturing process

- Higher production volumes

Processing Cost Comparison

I’ve found that the processing costs for 1018 steel are notably lower compared to other grades. Here’s a detailed breakdown:

| Process Type | 1018 Steel | 4140 Steel | 316 Stainless |

|---|---|---|---|

| Machining Time | Lower | Moderate | Higher |

| Tool Wear | Minimal | Moderate | Significant |

| Heat Treatment | Optional | Required | Rarely Needed |

| Surface Finishing | Simple | Moderate | Complex |

Production Efficiency Benefits

Faster Machining Speeds

1018 steel allows for:

- Higher cutting speeds

- Reduced cycle times

- Less tool wear

- Fewer machine adjustments

Reduced Tool Costs

At PTSMAKE, we’ve noticed significant savings in tooling costs when working with 1018 steel:

- Longer tool life

- Fewer tool changes

- Lower-cost cutting tools

- Reduced maintenance requirements

Applications Where 1018 Steel Provides Cost Advantages

Automotive Components

- Shaft components

- Brackets

- Non-critical structural parts

- Assembly fixtures

Industrial Equipment

- Guide rails

- Support structures

- Mounting brackets

- General fabrication

Cost Comparison Analysis

Direct Material Cost Savings

Based on current market prices:

| Steel Grade | Cost per Pound | Relative Machining Cost | Total Processing Cost |

|---|---|---|---|

| 1018 Steel | $0.75-1.00 | Base (1.0x) | Lowest |

| 4140 Steel | $1.25-1.75 | 1.3x | Moderate |

| 316 Stainless | $2.50-3.00 | 1.8x | Highest |

Quality Considerations vs. Cost

Suitable Applications

1018 steel is ideal for:

- Medium-strength requirements

- Non-critical components

- High-volume production

- Cost-sensitive projects

Performance Trade-offs

Understanding where 1018 steel may not be the best choice:

- High-stress applications

- Corrosive environments

- Safety-critical components

- High-temperature operations

Best Practices for Cost Optimization

Material Selection Strategy

- Evaluate application requirements

- Consider production volume

- Assess environmental conditions

- Calculate total cost of ownership

Manufacturing Process Optimization

At PTSMAKE, we implement several strategies to maximize cost benefits:

- Optimized cutting parameters

- Efficient tool selection

- Strategic batch sizing

- Minimal material waste

Real-World Cost Savings Examples

Case Study: Automotive Bracket Production

- 30% reduction in material costs

- 25% faster machining time

- 40% longer tool life

- 35% overall cost savings

Production Volume Impact

The cost benefits become more pronounced with higher production volumes:

- Reduced setup time per part

- Better material utilization

- Optimized process parameters

- Lower per-unit costs

Environmental and Sustainability Benefits

Energy Efficiency

1018 steel processing typically requires:

- Less energy for machining

- Fewer heat treatment steps

- Simpler finishing processes

- Lower environmental impact

Material Recyclability

- High recycling value

- Lower processing waste

- Simplified recycling process

- Reduced environmental footprint

Future Cost Considerations

The cost benefits of 1018 steel are likely to continue due to:

- Stable supply chains

- Established manufacturing processes

- Ongoing material innovations

- Improved processing technologies

Using 1018 steel can significantly reduce manufacturing costs while maintaining acceptable performance standards for many applications. Through careful consideration of application requirements and proper manufacturing processes, companies can achieve substantial cost savings without compromising product quality.

Can 1018 Steel Be Heat Treated for Enhanced Strength?

Many manufacturers struggle with choosing between heat treating 1018 steel or selecting a different grade entirely. The confusion often leads to costly material selection mistakes and wasted resources in manufacturing processes.

Yes, 1018 steel can be heat treated, but its effectiveness is limited compared to higher carbon steels. While case hardening can improve surface hardness, the low carbon content (0.15-0.20%) restricts the overall strength enhancement potential through traditional heat treatment methods.

Understanding 1018 Steel Composition

1018 steel is a low-carbon steel with a relatively simple composition. At PTSMAKE, we frequently work with this material for various machining projects. The typical composition includes:

| Element | Percentage Range |

|---|---|

| Carbon | 0.15-0.20% |

| Manganese | 0.60-0.90% |

| Phosphorus | ≤0.040% |

| Sulfur | ≤0.050% |

| Iron | Balance |

Heat Treatment Options for 1018 Steel

Case Hardening

The most effective heat treatment method for 1018 steel is carburization9. This process involves adding carbon to the surface layer of the steel at high temperatures. During my experience at PTSMAKE, I’ve observed that case hardening can increase the surface hardness while maintaining a ductile core.

Process Parameters

| Treatment Type | Temperature Range (°F) | Duration | Cooling Method |

|---|---|---|---|

| Carburizing | 1650-1700 | 4-8 hours | Oil quench |

| Normalizing | 1600-1650 | 1-2 hours | Air cool |

| Stress Relief | 1100-1200 | 1-2 hours | Slow cool |

Limitations and Considerations

Carbon Content Restrictions

The low carbon content in 1018 steel presents inherent limitations. Unlike medium or high-carbon steels, 1018 steel’s core hardness won’t significantly increase through conventional heat treatment methods.

Surface Hardness vs. Core Strength

While case hardening can achieve surface hardness up to 50-60 HRC, the core remains relatively soft. This characteristic makes 1018 steel suitable for:

- Parts requiring wear resistance on the surface

- Components needing a tough, ductile core

- Applications with moderate strength requirements

Alternative Approaches

Material Substitution

For applications requiring higher strength throughout the material, consider these alternatives:

| Steel Grade | Carbon Content | Advantages |

|---|---|---|

| 4140 | 0.38-0.43% | Better hardenability |

| 4340 | 0.38-0.43% | Higher strength potential |

| 1045 | 0.43-0.50% | Improved heat treat response |

Surface Treatment Options

When working with 1018 steel, we can recommend several surface treatment alternatives:

- Nitriding

- Induction hardening

- Chrome plating

- Physical Vapor Deposition (PVD)

Real-World Applications

In my manufacturing experience at PTSMAKE, 1018 steel finds extensive use in:

- General-purpose machinery parts

- Automotive components

- Structural applications

- Shaft and axle components

- Pins and fasteners

Cost-Benefit Analysis

When considering heat treatment for 1018 steel, evaluate these factors:

| Factor | Consideration |

|---|---|

| Material Cost | Lower than alloy steels |

| Processing Cost | Moderate |

| Equipment Requirements | Standard heat treat equipment |

| Quality Control | Less critical than high-carbon steels |

Best Practices for Heat Treating 1018 Steel

To achieve optimal results:

- Ensure proper temperature control

- Maintain consistent carburizing atmosphere

- Control cooling rates

- Verify surface hardness after treatment

- Consider post-treatment machining requirements

Quality Control Measures

To maintain consistency in heat-treated 1018 steel parts:

- Regular hardness testing

- Case depth measurements

- Microstructure analysis

- Dimensional verification

- Surface finish inspection

Summary and Recommendations

While 1018 steel can be heat treated, its applications should align with its limitations. For optimal results:

- Use case hardening when surface hardness is the primary requirement

- Consider alternative materials for through-hardening needs

- Implement proper process controls

- Verify results through testing

- Match the material properties to application requirements

Through proper understanding and application, 1018 steel can serve effectively in many manufacturing scenarios, particularly when surface hardness is the primary concern while maintaining core ductility.

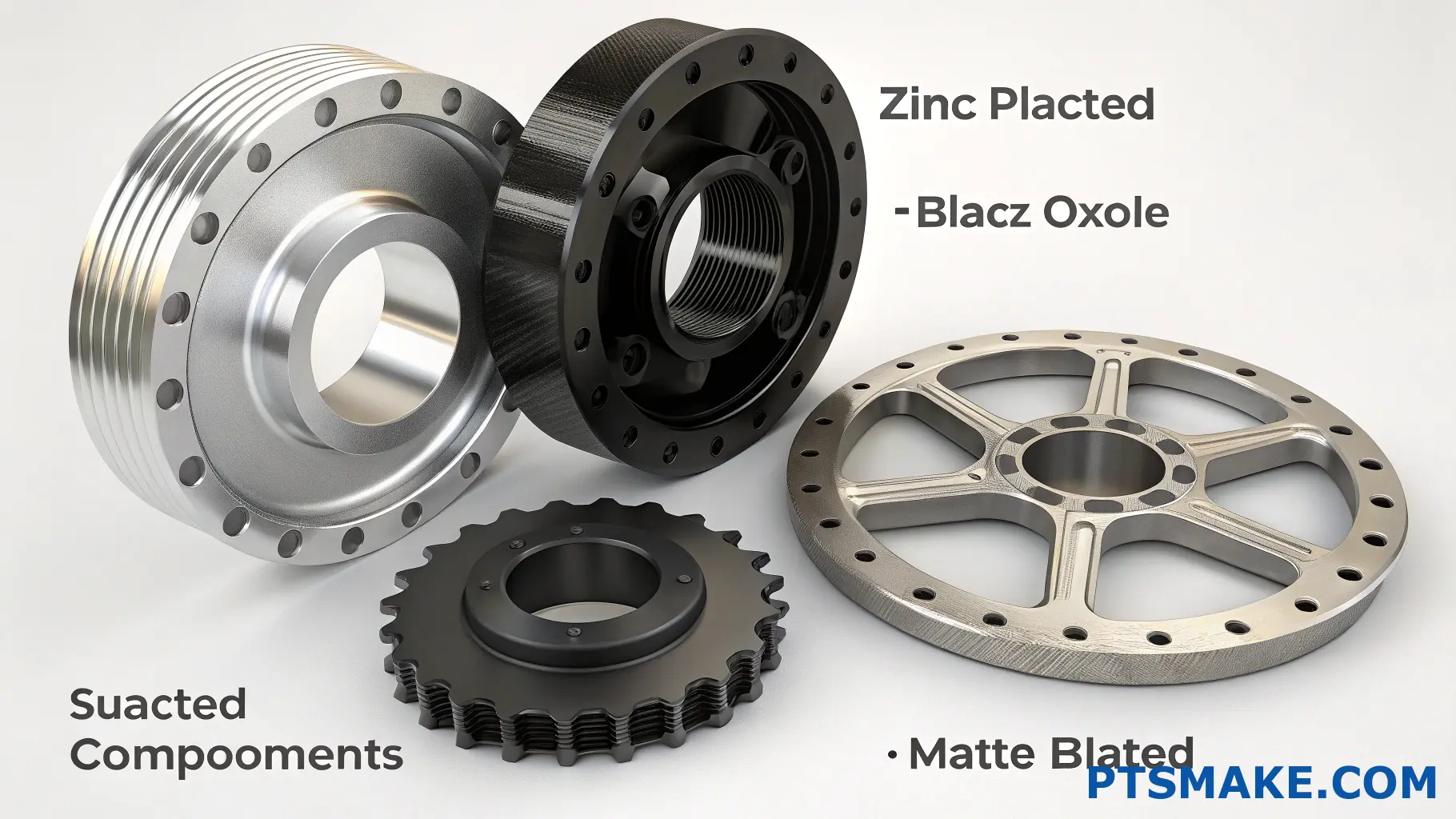

What Surface Treatments Are Recommended for 1018 Steel Components?

Working with 1018 steel components can be challenging when it comes to surface protection. Many manufacturers struggle with premature corrosion and wear issues, leading to shortened component life spans and increased replacement costs. These problems often result in production delays and quality concerns.

The most recommended surface treatments for 1018 steel components include zinc plating, black oxide coating, and carburizing10. These processes enhance corrosion resistance, wear protection, and surface hardness while maintaining the base material’s properties.

Understanding 1018 Steel Properties

1018 steel is widely used in manufacturing due to its excellent machinability and moderate strength. At PTSMAKE, we frequently work with this material for various industrial applications. The material contains approximately 0.18% carbon, making it suitable for many surface treatment options.

Chemical Composition

The chemical composition of 1018 steel plays a crucial role in determining suitable surface treatments:

| Element | Percentage |

|---|---|

| Carbon | 0.15-0.20% |

| Manganese | 0.60-0.90% |

| Phosphorus | 0.040% max |

| Sulfur | 0.050% max |

| Iron | Balance |

Primary Surface Treatment Options

1. Zinc Plating

Zinc plating is one of the most cost-effective surface treatments for 1018 steel. In our manufacturing facility, we’ve implemented both barrel and rack plating processes to accommodate different component sizes. The typical coating thickness ranges from 5-25 microns, providing excellent corrosion resistance.

Benefits of zinc plating include:

- Superior corrosion protection

- Uniform coating thickness

- Attractive appearance

- Cost-effective application

2. Black Oxide Coating

Black oxide coating creates a dark, protective layer that’s particularly popular in automotive and machinery applications. The process involves a chemical reaction that converts the surface iron to magnetite (Fe3O4).

Key advantages include:

- Minimal dimensional change

- Good corrosion resistance when oiled

- Attractive black finish

- Economical application

3. Carburizing

This heat treatment process involves diffusing carbon into the surface layer of 1018 steel. It creates a harder outer layer while maintaining a relatively ductile core.

Advanced Treatment Considerations

Environmental Factors

When selecting surface treatments, consider the following environmental factors:

- Operating temperature

- Exposure to chemicals

- Humidity levels

- UV exposure

Quality Control Measures

| Test Method | Parameter | Acceptance Criteria |

|---|---|---|

| Salt Spray | Corrosion Resistance | 96-240 hours |

| Adhesion | Coating Adhesion | 5B (ASTM D3359) |

| Thickness | Coating Thickness | ±10% of specification |

Application-Specific Recommendations

Automotive Components

For automotive applications, I recommend zinc plating with a chromate conversion coating. This combination provides excellent corrosion resistance and meets most automotive industry standards.

Industrial Machinery

Black oxide coating works well for industrial machinery components, especially when regular maintenance and oiling are part of the service routine.

Outdoor Equipment

For outdoor applications, hot-dip galvanizing offers the best long-term protection against harsh environmental conditions.

Cost-Benefit Analysis

| Treatment Type | Initial Cost | Durability | Maintenance Requirements |

|---|---|---|---|

| Zinc Plating | Moderate | Good | Low |

| Black Oxide | Low | Moderate | Medium |

| Carburizing | High | Excellent | Low |

Implementation Guidelines

Based on my experience at PTSMAKE, successful surface treatment implementation requires:

- Proper surface preparation

- Controlled process parameters

- Post-treatment handling procedures

- Quality inspection protocols

Maintenance Considerations

To maximize the effectiveness of surface treatments:

- Regular inspection schedules

- Proper cleaning procedures

- Touch-up protocols

- Environmental control measures

As a precision manufacturing expert, I’ve found that successful surface treatment of 1018 steel components requires careful consideration of application requirements, environmental conditions, and maintenance capabilities. The right choice depends on balancing performance needs with economic constraints.

Learn how metallurgical properties affect steel performance and suitability for various applications. ↩

Learn about yield strength’s role in material performance and make informed engineering choices. ↩

Learn about the oxidation process that affects rust development in metals for effective prevention. ↩

Learn how the internal structure affects steel properties for better material selection. ↩

Learn about the process leading to rust and how to prevent it effectively. ↩

Learn how passivation can enhance steel’s protection against rust and extend its durability. ↩

Learn how work hardening affects machining performance for better results. ↩

Learn how machinability affects production costs and efficiency in manufacturing processes. ↩

Learn how to enhance the performance of 1018 steel through effective heat treatment processes. ↩

Learn how carburizing enhances durability and wear resistance in steel components for improved performance. ↩