As a manufacturer dealing with various steel grades daily, I often hear engineers asking about 4140 steel equivalents. It’s frustrating when material specifications vary across different countries and standards, making it challenging to find the right match.

4140 steel is equivalent to several international grades: SCM440 (Japan), 42CrMo4 (Europe), and 708M40 (UK). This medium carbon chromium-molybdenum alloy steel offers excellent strength, hardness, and wear resistance, making it ideal for manufacturing critical components.

I want to share something important about these equivalents. While they’re similar in composition, small variations in manufacturing processes and exact chemical compositions can affect performance. At PTSMAKE, we carefully select materials based on specific application requirements and regional availability to ensure optimal results.

What Are The Advantages And Disadvantages Of 4140 Steel?

Choosing the right steel grade for manufacturing projects can be overwhelming. With dozens of steel varieties available, many engineers and manufacturers struggle to determine whether 4140 steel is the optimal choice for their specific applications. The wrong decision could lead to component failure or unnecessary costs.

4140 steel is a medium carbon chromium-molybdenum alloy steel that offers an excellent balance of strength, hardness, and toughness. It’s ideal for manufacturing components that require high mechanical strength and wear resistance, though it comes with higher costs and specific processing requirements.

Understanding 4140 Steel Composition

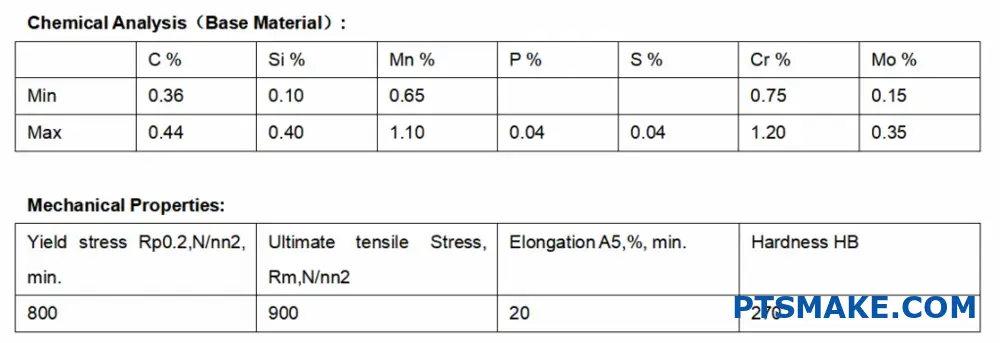

The chemical composition of 4140 steel plays a crucial role in determining its properties. Here’s a detailed breakdown of its primary elements:

| Element | Percentage Range |

|---|---|

| Carbon | 0.38 – 0.43% |

| Chromium | 0.80 – 1.10% |

| Molybdenum | 0.15 – 0.25% |

| Manganese | 0.75 – 1.00% |

| Silicon | 0.15 – 0.35% |

| Phosphorus | 0.035% max |

| Sulfur | 0.040% max |

The presence of austenite in its microstructure contributes significantly to its mechanical properties.

Key Advantages of 4140 Steel

Superior Strength and Hardness

4140 steel demonstrates exceptional strength properties, with a tensile strength ranging from 95,000 to 160,000 PSI depending on the heat treatment. At PTSMAKE, we frequently utilize this material for manufacturing high-stress components that require excellent mechanical properties.

Excellent Machinability

Despite its high strength, 4140 steel offers good machinability. This characteristic makes it particularly suitable for CNC machining processes, which is one of our specialties at PTSMAKE.

Versatile Heat Treatment Options

The material responds well to various heat treatment processes, allowing for customization of properties based on specific application requirements:

- Quenching and tempering

- Normalizing

- Annealing

- Surface hardening

Impressive Wear Resistance

The combination of chromium and molybdenum provides excellent wear resistance, making it ideal for components subject to continuous friction and stress.

Notable Disadvantages of 4140 Steel

Cost Considerations

4140 steel typically costs more than basic carbon steels due to its alloying elements. However, its superior properties often justify the investment for critical applications.

Processing Requirements

Working with 4140 steel demands specific expertise and equipment:

- Requires proper heat treatment procedures

- Needs controlled cooling rates

- Demands specific machining parameters

Limited Weldability

While weldable, 4140 steel requires:

- Preheating before welding

- Controlled cooling after welding

- Specific welding procedures to prevent cracking

Common Applications

Based on my experience at PTSMAKE, 4140 steel excels in various applications:

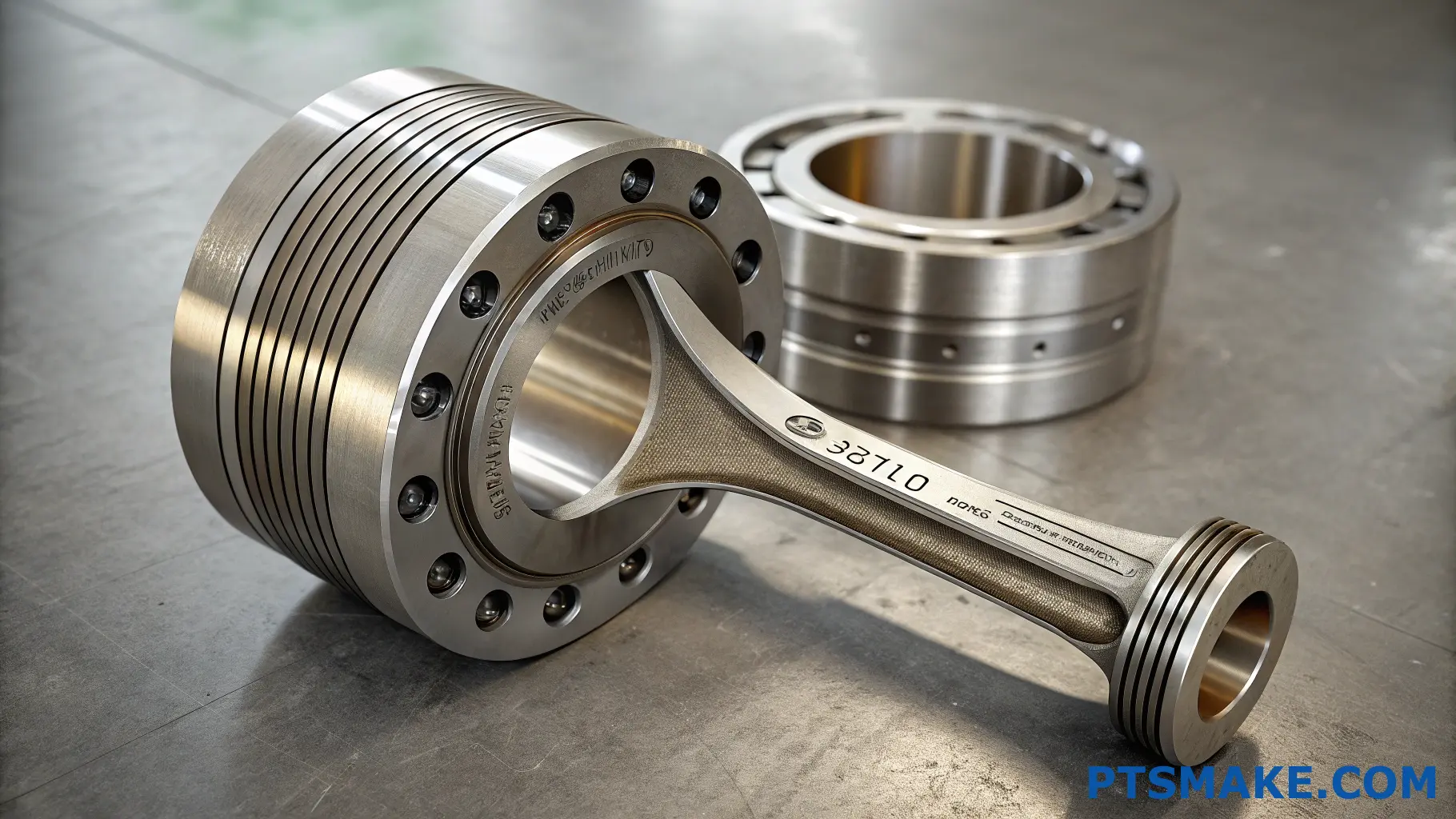

Automotive Components

- Crankshafts

- Connecting rods

- Gear shafts

- Steering components

Industrial Equipment

- Heavy machinery parts

- Power transmission components

- Mining equipment

- Oil and gas industry components

Manufacturing Tools

- Dies

- Molds

- Machinery components

- Heavy-duty fasteners

Performance Considerations

When working with 4140 steel, consider these factors:

| Property | Typical Range |

|---|---|

| Tensile Strength | 95-160 ksi |

| Yield Strength | 60-150 ksi |

| Elongation | 10-18% |

| Hardness | 28-40 HRC |

Quality Control and Testing

At PTSMAKE, we implement rigorous quality control measures for 4140 steel components:

- Material certification verification

- Hardness testing

- Dimensional inspection

- Surface finish analysis

- Heat treatment validation

Cost-Benefit Analysis

When evaluating 4140 steel for your project, consider:

Direct Costs

- Material price

- Processing requirements

- Heat treatment expenses

- Machining time and tooling

Long-term Benefits

- Extended service life

- Reduced maintenance

- Improved performance

- Better reliability

I’ve found that while the initial investment might be higher, the superior properties of 4140 steel often result in lower total ownership costs for critical applications.

Environmental and Storage Considerations

Proper storage and handling of 4140 steel are essential:

- Store in a dry environment

- Protect from corrosive elements

- Maintain proper temperature control

- Use appropriate coating or oil protection when necessary

Through my experience at PTSMAKE, I’ve observed that proper storage significantly impacts the material’s performance and machinability.

What Is 4140 Steel Commonly Used For?

Every day, manufacturers face the challenge of selecting the right material for their critical components. The wrong choice can lead to premature failure, increased maintenance costs, and potentially catastrophic consequences in high-stress applications.

4140 steel is a medium carbon chromium-molybdenum alloy steel widely used in manufacturing critical parts requiring high strength, good toughness, and wear resistance. It’s particularly popular in automotive, aerospace, and heavy machinery applications due to its excellent combination of properties.

Key Properties That Make 4140 Steel Valuable

The value of 4140 steel lies in its unique combination of properties. Having worked with various steel grades in our manufacturing facility, I’ve found that 4140 steel stands out due to its metallurgical stability under varying conditions.

Mechanical Properties

- Tensile Strength: 95,000 – 105,000 PSI

- Yield Strength: 60,000 – 70,000 PSI

- Hardness: 275-320 Brinell (in annealed condition)

Chemical Composition

| Element | Percentage Range |

|---|---|

| Carbon | 0.38-0.43% |

| Chromium | 0.80-1.10% |

| Molybdenum | 0.15-0.25% |

| Manganese | 0.75-1.00% |

| Silicon | 0.15-0.35% |

| Phosphorus | 0.035% max |

| Sulfur | 0.040% max |

Common Applications Across Industries

Automotive Industry

- Crankshafts

- Connecting rods

- Gear shafts

- Spindles

- Steering components

At PTSMAKE, we regularly machine these components for automotive clients, maintaining tight tolerances and ensuring superior surface finishes.

Aerospace Applications

- Landing gear components

- Structural components

- Fasteners

- Support brackets

- Engine mounts

Heavy Machinery and Equipment

- Hydraulic shaft components

- Power transmission parts

- Heavy-duty bolts

- Construction equipment components

- Mining equipment parts

Manufacturing Considerations

Heat Treatment Options

4140 steel responds well to various heat treatment processes:

- Annealing (1500-1600°F)

- Normalizing (1600-1700°F)

- Hardening (1500-1550°F)

- Tempering (varies based on desired hardness)

Machining Characteristics

In my experience overseeing CNC machining operations at PTSMAKE, 4140 steel requires specific considerations:

Cutting Speed Recommendations:

- Turning: 200-300 SFM

- Milling: 150-250 SFM

- Drilling: 100-150 SFM

Tool Selection:

- Carbide tools for most operations

- HSS tools for specialized applications

- Coated tools for improved wear resistance

Surface Treatment Options

The material can be enhanced through various surface treatments:

- Nitriding

- Chrome plating

- Black oxide coating

- Phosphating

- PVD coating

Cost Considerations and Alternatives

When comparing 4140 steel to alternatives, consider these factors:

| Factor | 4140 Steel | Alternative Steels |

|---|---|---|

| Initial Cost | Moderate | Varies |

| Machining Cost | Moderate-High | Depends on grade |

| Heat Treatment Cost | Moderate | Varies |

| Life Cycle Cost | Low | Often higher |

Quality Control and Testing

At PTSMAKE, we implement rigorous testing procedures for 4140 steel components:

Hardness Testing

- Regular Rockwell hardness tests

- Brinell hardness verification

- Microhardness testing when required

Material Verification

- Chemical composition analysis

- Microstructure examination

- Mechanical property testing

Dimensional Inspection

- CMM measurement

- Surface roughness testing

- Geometric tolerancing verification

Best Practices for Design Engineers

When designing with 4140 steel, consider these guidelines:

Design Features

- Maintain appropriate corner radii

- Avoid sharp transitions

- Consider stress concentration factors

- Plan for proper heat treatment allowances

Manufacturing Considerations

- Account for material removal rates

- Plan for proper fixturing

- Consider post-machining operations

- Allow for heat treatment distortion

Cost Optimization

- Design for efficient material usage

- Minimize complex features where possible

- Consider batch sizes for heat treatment

- Plan for optimal tool life

Through our experience at PTSMAKE, we’ve found that successful implementation of 4140 steel components requires careful attention to these factors, ensuring optimal performance and cost-effectiveness in the final application.

Is 4140 Harder Than Mild Steel?

Every day, I receive questions from engineers struggling to choose between 4140 and mild steel for their projects. They’re often confused about the hardness differences and worried about making the wrong material choice that could lead to project failures.

Yes, 4140 steel is significantly harder than mild steel. With proper heat treatment, 4140 steel can achieve a hardness range of 28-32 HRC, while mild steel typically maxes out at 15 HRC. This superior hardness makes 4140 ideal for high-stress applications requiring enhanced wear resistance.

Understanding Material Properties

Chemical Composition Impact

The fundamental difference between 4140 and mild steel lies in their chemical composition. 4140 steel contains significant amounts of chromium and molybdenum, creating a martensitic microstructure1 during heat treatment. I’ve observed that these alloying elements contribute directly to its enhanced hardness capabilities.

| Element | 4140 Steel (%) | Mild Steel (%) |

|---|---|---|

| Carbon | 0.38-0.43 | 0.05-0.25 |

| Chromium | 0.80-1.10 | Trace |

| Molybdenum | 0.15-0.25 | None |

| Manganese | 0.75-1.00 | 0.30-0.60 |

Hardness Testing Methods

At PTSMAKE, we regularly perform various hardness tests to ensure material quality. The three main testing methods we use are:

- Rockwell Hardness (HRC)

- Brinell Hardness (BHN)

- Vickers Hardness (HV)

Practical Applications and Performance

Strength Comparison

4140 steel consistently outperforms mild steel in strength-related properties:

| Property | 4140 Steel | Mild Steel |

|---|---|---|

| Tensile Strength (MPa) | 655-1000 | 340-440 |

| Yield Strength (MPa) | 415-655 | 210-250 |

| Elongation (%) | 15-25 | 20-30 |

Industry-Specific Uses

Automotive Applications

In automotive manufacturing, 4140 steel is preferred for:

- Crankshafts

- Connecting rods

- Drive shafts

- Gear components

Mild steel, however, finds its place in:

- Body panels

- Frame components

- Non-critical structural parts

Manufacturing Considerations

Based on my experience at PTSMAKE, I’ve found that machining 4140 steel requires:

- Higher cutting speeds

- More robust tooling

- Enhanced cooling strategies

These requirements directly impact production costs and timelines. When working with mild steel, standard machining parameters usually suffice.

Heat Treatment Effects

Heat Treatment Response

4140 steel’s response to heat treatment is remarkable:

| Treatment | 4140 Hardness (HRC) | Mild Steel Hardness (HRC) |

|---|---|---|

| Annealed | 16-22 | 10-15 |

| Normalized | 25-30 | 12-17 |

| Quenched & Tempered | 28-32 | 14-18 |

Cost Considerations

While 4140 steel offers superior hardness, it comes at a higher cost:

- Raw material expenses are typically 30-40% higher

- Heat treatment processes add additional costs

- Machining time increases due to material hardness

Wear Resistance and Durability

Surface Wear Characteristics

4140 steel demonstrates superior wear resistance due to:

- Higher carbon content

- Presence of chromium

- Improved hardness after heat treatment

At PTSMAKE, we’ve implemented advanced wear testing procedures to validate material performance under various conditions.

Environmental Factors

Both materials react differently to environmental conditions:

| Factor | 4140 Steel | Mild Steel |

|---|---|---|

| Corrosion Resistance | Moderate | Poor |

| Temperature Stability | Excellent | Fair |

| Impact Resistance | Good | Excellent |

Future Developments and Trends

Material Innovation

The steel industry continues to evolve with:

- New heat treatment processes

- Advanced surface treatments

- Hybrid material solutions

Sustainability Considerations

Modern manufacturing demands increasingly focus on:

- Energy-efficient production methods

- Recyclability

- Carbon footprint reduction

Through working with various clients at PTSMAKE, I’ve noticed a growing trend toward sustainable material choices while maintaining performance requirements.

What Is The Classification Of 4140 Steel?

Every day, I receive inquiries from customers confused about 4140 steel classification. They struggle to understand its grade system and proper applications, which often leads to costly material selection mistakes and project delays.

4140 steel is classified as a medium carbon chromium-molybdenum alloy steel. It belongs to the 41XX series of chromium-molybdenum steels, where ’41’ indicates the alloy type, and ’40’ represents approximately 0.40% carbon content.

Chemical Composition and Properties

The chemical composition of 4140 steel is crucial for understanding its classification. The steel undergoes precise metallurgical processes2 to achieve its distinctive properties. Here’s a detailed breakdown of its chemical composition:

| Element | Percentage Range |

|---|---|

| Carbon | 0.38-0.43% |

| Chromium | 0.80-1.10% |

| Molybdenum | 0.15-0.25% |

| Manganese | 0.75-1.00% |

| Silicon | 0.15-0.35% |

| Phosphorus | 0.035% max |

| Sulfur | 0.040% max |

Standard Designations

At PTSMAKE, we work with various international standards for 4140 steel. The material is recognized differently across global standards:

- AISI/SAE: 4140

- DIN: 42CrMo4

- JIS: SCM440

- BS: 708M40

- GB: 42CrMo

Heat Treatment Classifications

4140 steel can be classified based on its heat treatment condition:

Annealed State (A)

- Hardness: 190-220 HB

- Structure: Ferrite and spheroidized carbides

- Best for machining operations

Quenched and Tempered (Q&T)

- Hardness: 280-320 HB

- Improved strength and toughness

- Optimal for high-stress applications

Industry-Specific Classifications

In my experience working with various industries at PTSMAKE, I’ve observed different classification systems based on application requirements:

Automotive Industry

- Grade H: High-strength applications

- Grade M: Medium-strength applications

- Grade L: Low-stress components

Aerospace Applications

- AMS 6382: Aircraft structural parts

- AMS 6349: Critical components

- AMS 6359: General purpose applications

Quality Classifications

We classify 4140 steel quality levels based on manufacturing processes:

Premium Quality (PQ)

- Stringent control of inclusions

- Enhanced mechanical properties

- Higher cost but better performance

Commercial Quality (CQ)

- Standard manufacturing process

- Acceptable inclusion levels

- Cost-effective option

Form Classifications

4140 steel is available in various forms, each with its own classification:

Bar Stock

- Hot-rolled

- Cold-drawn

- Forged

Plate

- Hot-rolled

- Normalized

- Stress-relieved

Application-Based Classification

The versatility of 4140 steel allows for various application-specific classifications:

Structural Applications

- Class S1: Heavy-duty structural components

- Class S2: Medium-duty frameworks

- Class S3: Light-duty supports

Tools and Dies

- Class T1: High-wear resistance tools

- Class T2: Impact-resistant dies

- Class T3: General-purpose tooling

At PTSMAKE, we regularly process 4140 steel for various applications, maintaining strict adherence to these classifications to ensure optimal performance. Our advanced CNC machining capabilities allow us to work with all forms and conditions of 4140 steel, delivering precise components that meet or exceed customer specifications.

The classification system helps in selecting the right variant of 4140 steel for specific applications. Understanding these classifications is crucial for:

- Proper material selection

- Quality control processes

- Meeting industry standards

- Ensuring component performance

- Cost optimization

Through proper classification understanding, engineers and designers can make informed decisions about material selection, leading to improved product performance and reliability. Our team at PTSMAKE assists customers in selecting the most appropriate 4140 steel classification based on their specific application requirements and performance goals.

What Is The Difference Between 4140 And 410 Stainless Steel?

As a manufacturing professional, I often encounter clients struggling to choose between 4140 and 410 stainless steel for their projects. The confusion stems from their similar numbering and some overlapping properties, leading to costly material selection mistakes and project delays.

The main difference between 4140 and 410 stainless steel lies in their composition and corrosion resistance. 4140 is a chromium-molybdenum alloy steel offering high strength and hardness, while 410 is a martensitic stainless steel providing better corrosion resistance with moderate strength.

Chemical Composition and Properties

The fundamental differences between these steels start with their chemical makeup. Let’s examine their compositions:

| Element | 4140 Steel | 410 Stainless Steel |

|---|---|---|

| Carbon | 0.38-0.43% | 0.15% max |

| Chromium | 0.80-1.10% | 11.5-13.5% |

| Molybdenum | 0.15-0.25% | – |

| Manganese | 0.75-1.00% | 1.00% max |

| Silicon | 0.15-0.35% | 1.00% max |

The presence of higher chromium content in 410 stainless steel creates a protective passivation layer on the surface, providing superior corrosion resistance compared to 4140 steel.

Mechanical Properties Comparison

Both steels offer distinct mechanical properties that make them suitable for different applications:

4140 Steel Characteristics

- Higher tensile strength (95,000 – 115,000 PSI in the annealed condition)

- Superior hardness capability (28-33 HRC)

- Excellent wear resistance

- Good fatigue strength

- Better machinability

410 Stainless Steel Characteristics

- Moderate tensile strength (65,000 – 90,000 PSI in the annealed condition)

- Good hardness potential (25-30 HRC)

- Superior corrosion resistance

- Better oxidation resistance at elevated temperatures

- Moderate wear resistance

Heat Treatment Considerations

Through my experience at PTSMAKE, I’ve observed significant differences in heat treatment responses:

4140 Steel Heat Treatment

- Austenitizing temperature: 1500-1600°F

- Quenching in oil preferred

- Tempering temperature: 400-1200°F

- Excellent hardenability

- Achieves higher hardness levels

410 Stainless Steel Heat Treatment

- Austenitizing temperature: 1700-1850°F

- Air or oil quenching possible

- Tempering temperature: 300-700°F

- Moderate hardenability

- Maintains corrosion resistance after proper heat treatment

Cost and Availability

In my manufacturing experience, these factors significantly impact material selection:

- 4140 steel is generally more cost-effective

- 410 stainless steel commands a premium due to higher chromium content

- Both materials are readily available in standard forms

- Lead times may vary depending on specific grades and dimensions

Application Guidelines

Here’s where each steel type excels:

4140 Steel Applications

- Automotive crankshafts and axles

- Heavy machinery components

- Oil and gas industry tools

- General purpose shafts

- Gear applications

410 Stainless Steel Applications

- Pump shafts in corrosive environments

- Valve components

- Turbine parts

- Kitchen cutlery

- Medical instruments

Performance in Different Environments

Environmental considerations play a crucial role:

4140 Steel Environment Compatibility

- Excellent in oil-lubricated applications

- Good in dry running conditions

- Limited corrosion resistance

- Not recommended for wet or marine environments

- Suitable for high-stress applications

410 Stainless Steel Environment Compatibility

- Good in marine environments

- Excellent in wet conditions

- Moderate chemical resistance

- Suitable for food processing equipment

- Good high-temperature oxidation resistance

Manufacturing Considerations

At PTSMAKE, we’ve developed specific approaches for working with each material:

Machining Characteristics

- 4140 steel offers better machinability

- 410 stainless requires slower cutting speeds

- Both materials need proper cooling during machining

- Tool wear is generally higher with 410 stainless

Welding Considerations

- 4140 requires preheating and post-weld heat treatment

- 410 stainless needs special welding procedures

- Both materials are weldable with proper precautions

- Stress relief after welding is recommended

Quality Control Measures

Proper quality control is essential for both materials:

Testing Requirements

- Hardness testing

- Tensile strength verification

- Microstructure examination

- Corrosion resistance testing (especially for 410)

- Impact strength evaluation

Future Trends and Developments

The industry is seeing interesting developments:

- Advanced heat treatment processes

- Improved surface finishing techniques

- Development of hybrid materials

- Enhanced coating technologies

- More sustainable manufacturing methods

Through careful material selection and proper processing, both 4140 and 410 stainless steel can provide excellent service in their respective applications. The key is understanding their unique properties and limitations to make an informed choice for your specific needs.

Is 4140 The Same As A36?

When sourcing steel materials for manufacturing projects, I often encounter clients who are confused about the differences between 4140 and A36 steel. The misconception that these materials are interchangeable can lead to costly mistakes and project failures.

No, 4140 and A36 are not the same. 4140 is a medium carbon chromium-molybdenum alloy steel known for its high strength and hardness, while A36 is a low carbon structural steel with lower strength but better weldability and formability.

Chemical Composition Differences

The fundamental distinction between these two steels lies in their chemical makeup. At PTSMAKE, we carefully select materials based on their composition to ensure optimal performance for our clients’ projects.

4140 Steel Composition

- Carbon: 0.38-0.43%

- Chromium: 0.80-1.10%

- Molybdenum: 0.15-0.25%

- Manganese: 0.75-1.00%

- Silicon: 0.15-0.35%

- Sulfur: 0.040% max

- Phosphorus: 0.035% max

A36 Steel Composition

- Carbon: 0.26% max

- Manganese: 0.60-0.90%

- Silicon: 0.40% max

- Sulfur: 0.050% max

- Phosphorus: 0.040% max

Mechanical Properties Comparison

The yield strength3 and other mechanical properties vary significantly between these steels, affecting their applications:

| Property | 4140 Steel | A36 Steel |

|---|---|---|

| Tensile Strength (MPa) | 655-1195 | 400-550 |

| Yield Strength (MPa) | 415-1070 | 250 |

| Elongation (%) | 9-16 | 20 |

| Hardness (HB) | 197-341 | 130-180 |

Primary Applications

4140 Steel Applications

- Automotive crankshafts and gears

- Aircraft landing gear components

- Heavy machinery parts

- High-stress mechanical components

- Precision machined parts requiring high strength

A36 Steel Applications

- Structural beams and columns

- Building frameworks

- Bridge components

- General construction

- Basic machine parts

Heat Treatment Capabilities

4140 steel’s response to heat treatment sets it apart from A36. Through my experience at PTSMAKE, I’ve observed these key differences:

4140 Heat Treatment

- Excellent hardenability

- Can be through-hardened

- Suitable for quenching and tempering

- Achievable hardness range: 28-55 HRC

A36 Heat Treatment

- Limited hardenability

- Not typically heat-treated

- Better suited for welding

- Maintains consistent properties

Cost and Availability Considerations

The price difference between these materials can significantly impact project budgets:

| Factor | 4140 Steel | A36 Steel |

|---|---|---|

| Relative Cost | Higher | Lower |

| Market Availability | Moderate | Widely Available |

| Processing Cost | Higher | Lower |

| Lead Time | Longer | Shorter |

Manufacturing Considerations

Based on our manufacturing experience at PTSMAKE, here are key processing differences:

Machinability

- 4140: Requires more robust tooling and specific cutting parameters

- A36: Easier to machine with standard tooling

Welding Characteristics

- 4140: Requires preheating and controlled cooling

- A36: Excellent weldability with minimal preparation

Forming and Fabrication

- 4140: More difficult to form, requires specific techniques

- A36: Easily formed and fabricated

Quality Control Requirements

The inspection and testing requirements differ significantly:

4140 Steel Testing

- Hardness testing

- Tensile strength verification

- Chemical composition analysis

- Microstructure examination

- Heat treatment certification

A36 Steel Testing

- Basic dimensional inspection

- Visual examination

- Simple strength testing

- Mill certification review

Economic Impact on Projects

Choosing between these materials can significantly affect project economics:

| Consideration | 4140 Steel | A36 Steel |

|---|---|---|

| Initial Material Cost | Higher | Lower |

| Processing Cost | Higher | Lower |

| Maintenance Cost | Lower | Higher |

| Service Life | Longer | Shorter |

Understanding these differences is crucial for making informed material selections. At PTSMAKE, we guide our clients through these decisions to ensure optimal material choice for their specific applications, considering both technical requirements and economic constraints.

Is 4140 The Same As 1045?

As a manufacturer, I often encounter clients who are confused about steel grades 4140 and 1045. They struggle to understand their differences and similarities, leading to potential design and manufacturing issues. This confusion can result in costly material selection mistakes and performance problems.

While 4140 and 1045 are both medium carbon steels, they are distinctly different materials. 4140 is a chromium-molybdenum alloy steel with higher hardenability and strength, while 1045 is a plain carbon steel with simpler composition and lower overall performance characteristics.

Chemical Composition Differences

The fundamental distinction between these steels lies in their chemical makeup. 4140 contains additional alloying elements that significantly enhance its properties. Let’s examine their compositions:

| Element | 4140 Steel (%) | 1045 Steel (%) |

|---|---|---|

| Carbon | 0.38-0.43 | 0.43-0.50 |

| Chromium | 0.80-1.10 | – |

| Molybdenum | 0.15-0.25 | – |

| Manganese | 0.75-1.00 | 0.60-0.90 |

| Silicon | 0.15-0.35 | 0.15-0.35 |

| Phosphorus | ≤0.035 | ≤0.040 |

| Sulfur | ≤0.040 | ≤0.050 |

Mechanical Properties Comparison

The hardenability4 characteristics of these steels show significant variations. In my manufacturing experience at PTSMAKE, I’ve observed these key differences:

Strength Properties

| Property | 4140 Steel | 1045 Steel |

|---|---|---|

| Tensile Strength (MPa) | 655-1090 | 570-850 |

| Yield Strength (MPa) | 415-655 | 305-505 |

| Elongation (%) | 10-18 | 12-20 |

| Hardness (HB) | 197-321 | 170-265 |

Heat Treatment Response

4140 steel demonstrates superior heat treatment capabilities due to its alloying elements:

- Better through-hardening properties

- More uniform hardness distribution

- Higher tempering resistance

- Greater dimensional stability

Applications and Use Cases

4140 Steel Applications

- High-stress mechanical components

- Aircraft landing gear parts

- Heavy machinery components

- Automotive crankshafts

- Industrial fasteners

1045 Steel Applications

- General-purpose machine parts

- Axles and shafts

- Construction equipment

- Agricultural implements

- Basic structural components

Cost and Availability Considerations

Through my work at PTSMAKE, I’ve noticed significant cost differences between these materials:

- 4140 typically costs 20-30% more than 1045

- 1045 is more readily available in standard sizes

- 4140 may require longer lead times for specialized sizes

- Bulk ordering can affect pricing significantly

Manufacturing Processes

Machining Characteristics

Both steels can be machined effectively, but there are important distinctions:

| Process | 4140 Steel | 1045 Steel |

|---|---|---|

| Turning | Moderate difficulty | Easier |

| Milling | Requires specific tools | Standard tooling |

| Drilling | Higher tool wear | Normal tool wear |

| Surface finish | Excellent | Good |

Welding Considerations

- 4140 requires pre-heating and controlled cooling

- 1045 can be welded with standard procedures

- Both need proper filler material selection

- Post-weld heat treatment may be necessary

Quality Control Measures

At PTSMAKE, we implement rigorous testing procedures for both materials:

- Hardness testing at multiple points

- Ultrasonic inspection for internal defects

- Chemical composition verification

- Mechanical property validation

Environmental Impact

Both steels offer different environmental considerations:

- 4140 production requires more energy due to alloying

- 1045 has a simpler recycling process

- Both materials are 100% recyclable

- Energy consumption during heat treatment varies

Material Selection Guidelines

When choosing between 4140 and 1045, consider:

- Required strength levels

- Application environment

- Budget constraints

- Manufacturing complexity

- Heat treatment requirements

This comparison demonstrates that while 4140 and 1045 may seem similar, they serve different purposes and offer distinct advantages. At PTSMAKE, we help clients make informed decisions based on their specific requirements, ensuring optimal material selection for each project.

How Does Heat Treatment Affect The Properties Of 4140 Steel?

Heat treating 4140 steel can be a complex process, and many manufacturers struggle to achieve the desired material properties. I’ve seen numerous cases where incorrect heat treatment leads to parts failing prematurely or not meeting specifications, causing costly production delays and material waste.

Heat treatment significantly affects 4140 steel’s properties by altering its microstructure. Through controlled heating and cooling processes, we can enhance its strength, hardness, and toughness while maintaining good machinability. The specific treatment method determines the final mechanical properties.

Understanding the Basics of 4140 Steel Heat Treatment

4140 steel undergoes various heat treatment processes that fundamentally change its mechanical properties. The steel’s response to heat treatment is largely due to its martensite5 formation during the cooling process. At PTSMAKE, we carefully control these processes to achieve optimal results for our clients’ specific applications.

Critical Temperatures and Phases

The heat treatment process involves several critical temperature ranges:

| Temperature Range (°F) | Phase | Purpose |

|---|---|---|

| 1500-1600 | Austenitizing | Transform structure to austenite |

| 800-1300 | Tempering | Reduce hardness, increase ductility |

| 400-700 | Stress Relief | Remove internal stresses |

Common Heat Treatment Methods

Quenching Process

Quenching is perhaps the most crucial step in hardening 4140 steel. The process involves:

- Heating the steel to austenitizing temperature

- Holding at temperature for proper saturation

- Rapid cooling in oil or water

The cooling rate dramatically influences the final hardness and strength properties.

Tempering Effects

After quenching, tempering becomes essential to:

- Reduce internal stresses

- Improve ductility

- Enhance toughness

- Achieve specific hardness requirements

Property Changes Through Heat Treatment

Mechanical Properties

Heat treatment significantly impacts the following properties:

| Property | Before Treatment | After Treatment |

|---|---|---|

| Tensile Strength (ksi) | 95-105 | 140-160 |

| Yield Strength (ksi) | 60-70 | 120-140 |

| Hardness (HRC) | 20-25 | 28-32 |

Microstructural Changes

The heat treatment process creates various microstructural changes:

- Formation of fine pearlite

- Development of tempered martensite

- Carbide distribution

- Grain refinement

Optimization Strategies

Temperature Control

Precise temperature control is crucial for achieving desired properties. At PTSMAKE, we utilize advanced heat treatment equipment with:

- Digital temperature monitoring

- Uniform heating chambers

- Precise cooling rate control

- Automated process management

Time Management

The duration of each heat treatment phase significantly affects the final properties:

| Phase | Optimal Duration | Critical Factors |

|---|---|---|

| Austenitizing | 30-60 minutes | Section size |

| Quenching | 1-5 minutes | Cooling medium |

| Tempering | 2-4 hours | Final hardness |

Industry Applications

Different industries require various property combinations:

Automotive Applications

The automotive industry often requires:

- High fatigue strength

- Good wear resistance

- Excellent toughness

Aerospace Requirements

Aerospace applications demand:

- Superior strength-to-weight ratio

- Consistent properties

- High reliability

Quality Control Measures

To ensure consistent results, we implement:

- Regular equipment calibration

- Material certification verification

- Process parameter monitoring

- Post-treatment testing

Troubleshooting Common Issues

Surface Decarburization

To prevent surface decarburization:

- Use protective atmospheres

- Control heating rates

- Monitor furnace conditions

Distortion Management

Minimize distortion through:

- Proper fixture design

- Uniform heating

- Controlled cooling

- Strategic part orientation

Environmental Considerations

Modern heat treatment processes must consider:

- Energy efficiency

- Emissions control

- Waste reduction

- Resource conservation

At PTSMAKE, we’ve implemented energy-efficient furnaces and recovery systems to minimize environmental impact while maintaining superior quality standards.

Future Trends

The heat treatment of 4140 steel continues to evolve with:

- Advanced process control systems

- Automated handling equipment

- Real-time monitoring capabilities

- Predictive maintenance solutions

Our commitment to staying current with these developments ensures we provide the best possible service to our clients.

What Are The Machining Considerations For 4140 Steel?

Working with 4140 steel can be challenging, especially when precise machining is required. Many manufacturers struggle with tool wear, heat management, and achieving tight tolerances. These issues often lead to increased production costs and project delays.

The key machining considerations for 4140 steel include proper cutting speed selection, tool material choice, cooling strategies, and maintaining optimal feed rates. These factors are crucial because 4140 steel’s high strength and hardness require specific machining parameters to achieve quality results.

Understanding 4140 Steel Properties

Before diving into machining considerations, it’s essential to understand what makes 4140 steel unique. This medium carbon chromium-molybdenum alloy steel exhibits exceptional hardenability6 and strength. At PTSMAKE, we frequently work with 4140 steel for various industrial applications, particularly in aerospace and automotive components.

Chemical Composition

The chemical composition of 4140 steel directly influences its machinability:

| Element | Percentage Range |

|---|---|

| Carbon | 0.38-0.43% |

| Chromium | 0.80-1.10% |

| Molybdenum | 0.15-0.25% |

| Manganese | 0.75-1.00% |

| Silicon | 0.15-0.35% |

| Phosphorus | 0.035% max |

| Sulfur | 0.040% max |

Cutting Speed and Feed Rate Optimization

Speed Selection Guidelines

I’ve found that the optimal cutting speed for 4140 steel varies depending on the machining operation:

- Rough turning: 250-350 SFM

- Finish turning: 300-400 SFM

- Milling: 200-300 SFM

- Drilling: 150-250 SFM

Feed Rate Considerations

Feed rates should be adjusted based on:

- Material condition (annealed vs. heat-treated)

- Depth of cut

- Tool geometry

- Surface finish requirements

Tool Selection and Management

Recommended Tool Materials

For machining 4140 steel, I recommend:

- Carbide tools for general machining

- Ceramic tools for high-speed operations

- HSS tools for simple operations with lower speeds

Tool Geometry Specifications

The right tool geometry is crucial:

- Relief angle: 6-8 degrees

- Rake angle: 5-7 degrees

- Lead angle: 15-30 degrees

Cooling and Lubrication Strategies

Coolant Selection

At PTSMAKE, we use different cooling methods based on specific requirements:

- Water-soluble coolants for general machining

- Straight oils for heavy-duty operations

- Minimum quantity lubrication (MQL) for environmentally conscious projects

Temperature Control Methods

Effective temperature management includes:

- Regular coolant maintenance

- Proper coolant concentration

- Strategic coolant delivery

- Monitoring tool temperature

Surface Finish Considerations

Finishing Parameters

To achieve optimal surface finish:

| Operation | Speed (SFM) | Feed (IPR) | Depth of Cut (inches) |

|---|---|---|---|

| Rough | 300 | 0.015 | 0.100 |

| Semi-finish | 350 | 0.010 | 0.050 |

| Finish | 400 | 0.005 | 0.010 |

Quality Control Measures

Inspection Methods

We implement rigorous quality control:

- In-process measurements

- Post-machining dimensional verification

- Surface roughness testing

- Hardness testing

Common Issues and Solutions

Typical challenges include:

- Tool wear: Regular tool condition monitoring

- Dimensional accuracy: Proper fixturing and temperature control

- Surface finish: Optimized cutting parameters

- Chatter: Improved tool holder rigidity

Heat Treatment Considerations

Pre-machining Treatment

Proper heat treatment before machining can:

- Reduce internal stresses

- Improve machinability

- Ensure dimensional stability

Post-machining Treatment

Consider post-machining heat treatment for:

- Stress relief

- Hardness adjustment

- Enhanced material properties

Cost Optimization Strategies

Tool Life Management

To optimize costs:

- Monitor tool wear patterns

- Implement predictive tool replacement

- Use appropriate cutting parameters

- Select cost-effective tool materials

Production Efficiency

Enhance efficiency through:

- Optimized machining sequences

- Minimal setup changes

- Efficient workpiece handling

- Regular maintenance schedules

At PTSMAKE, we’ve developed comprehensive machining strategies for 4140 steel that ensure consistent quality while maintaining cost-effectiveness. Our experience with various industrial applications has helped us refine these parameters for optimal results.

What Are The Cost Implications Of Using 4140 Steel In Manufacturing?

Many manufacturers struggle with balancing material costs and performance requirements in their projects. The rising prices of steel and the complexity of material selection often leave project managers and engineers wondering if they’re making costly mistakes in their material choices.

4140 steel’s cost implications in manufacturing vary depending on factors like volume, processing requirements, and market conditions. While its initial price is higher than basic carbon steels, the material’s superior properties often lead to long-term cost benefits through improved performance and reduced maintenance needs.

Breaking Down the Initial Material Costs

The upfront cost of 4140 steel is a significant consideration in manufacturing projects. As a chromoly steel7 grade, it typically commands a premium over basic carbon steels. I’ve observed that current market prices can range significantly based on:

Raw Material Pricing Factors

- Global market conditions

- Order quantity

- Material form (bar, plate, tube)

- Supplier relationships

- Geographic location

The following table shows typical price comparisons between 4140 and other common steels:

| Steel Grade | Relative Cost Index | Typical Applications |

|---|---|---|

| 1018 Carbon Steel | 1.0 | General purpose parts |

| 4140 Steel | 1.8-2.2 | High-stress components |

| 4340 Steel | 2.3-2.8 | Aerospace parts |

| Tool Steel | 3.0-4.0 | Cutting tools |

Processing Cost Considerations

The total manufacturing cost extends beyond raw material prices. At PTSMAKE, we’ve identified several processing factors that influence the final cost:

Machining Costs

4140 steel requires specific cutting parameters and tools due to its hardness. Key considerations include:

- Tool wear rates

- Cutting speeds and feeds

- Coolant requirements

- Machine time allocation

Heat Treatment Expenses

The material often requires heat treatment to achieve optimal properties:

- Quenching and tempering costs

- Energy consumption

- Processing time

- Equipment maintenance

Long-term Cost Benefits

Despite higher initial costs, 4140 steel often provides economic advantages over time:

Reduced Maintenance Costs

Components manufactured from 4140 steel typically exhibit:

- Extended service life

- Better wear resistance

- Improved fatigue strength

- Lower replacement frequency

Performance-Related Savings

The material’s superior properties can lead to:

- Reduced downtime

- Lower warranty claims

- Decreased liability risks

- Enhanced product reputation

Industry-Specific Cost Analysis

Different sectors experience varying cost implications when using 4140 steel:

Automotive Industry

- Higher initial tooling costs

- Reduced warranty claims

- Improved safety ratings

- Better fuel efficiency through weight optimization

Heavy Equipment Manufacturing

- Extended component lifespan

- Reduced maintenance intervals

- Higher equipment reliability

- Better resistance to harsh conditions

Cost Optimization Strategies

At PTSMAKE, we implement several strategies to optimize 4140 steel costs:

Design Optimization

- Material usage efficiency

- Part consolidation

- Weight reduction

- Stress distribution analysis

Supply Chain Management

- Strategic supplier partnerships

- Volume purchasing agreements

- Market timing for purchases

- Inventory optimization

Future Cost Considerations

The cost landscape for 4140 steel continues to evolve:

Market Trends

- Raw material availability

- Global trade policies

- Environmental regulations

- Energy costs

Technological Advances

- Improved processing methods

- Advanced heat treatment techniques

- More efficient machining strategies

- Better quality control systems

Our experience at PTSMAKE has shown that successful cost management with 4140 steel requires a comprehensive understanding of both immediate and long-term factors. We consistently work with clients to analyze their specific applications and determine the most cost-effective approach for their projects.

By carefully considering all these aspects, manufacturers can make informed decisions about using 4140 steel in their applications. While the initial investment may be higher, the total cost of ownership often proves more favorable when compared to lower-grade alternatives, especially in critical applications where performance and reliability are paramount.

Learn about the unique structures in steel that enhance strength and durability. ↩

Understand how metals are processed to enhance their properties for optimal performance. ↩

Learn about yield strength differences to choose the right steel for your project. ↩

Understand how hardenability impacts performance and material selection for your manufacturing projects. ↩

Learn about martensite formation to optimize 4140 steel’s heat treatment for enhanced strength and toughness. ↩

Learn about hardenability to improve machining efficiency and achieve better results in 4140 steel applications. ↩

Learn about chromoly’s unique properties for cost-effective manufacturing solutions and enhanced performance. ↩