ABS plastic is everywhere around you – from your car dashboard to LEGO bricks. But what makes this material so versatile? Let’s break down why manufacturers like us at PTSMAKE have relied on ABS for 15+ years across 2000+ projects.

ABS (Acrylonitrile Butadiene Styrene) is a tough, impact-resistant thermoplastic polymer widely used in injection molding and CNC machining. It offers excellent mechanical properties, good chemical resistance, and dimensional stability, making it ideal for functional prototypes and end-use parts across industries.

While ABS might seem like "just another plastic," its unique combination of properties makes it indispensable in modern manufacturing. I’ve seen firsthand how material choice impacts product success – let’s explore why ABS remains a go-to material despite newer alternatives.

What is ABS plastic used for?

Walk through any modern factory or hospital, and you’ll find ABS working hard where other materials fail. At PTSMAKE, 40% of our injection molding projects use ABS – here’s why.

ABS is primarily used for automotive components, electronic housings, consumer products, and protective gear due to its impact resistance, machinability, and cost-effectiveness. Common applications include car bumpers, power tool housings, and medical device enclosures.

Key Industries Using ABS

| Industry | Typical Applications | Why ABS? |

|---|---|---|

| Automotive | Dashboards, trim, seat belt components | Withstands vibration & temperature swings |

| Electronics | Keyboard keys, printer components | Electrostatic discharge protection |

| Medical | Sterilizable housings, IV components | Chemical resistance & durability |

| Consumer Goods | Luggage shells, kitchen appliances | Scratch resistance & aesthetic finish |

Last year, we produced 500,000 ABS cable clips for a robotics client. The material’s 7.5 kJ/m² impact strength (per ASTM D256) prevented field failures despite rough handling – a common pain point with cheaper plastics.

Emerging Uses in 2024

- Drone Frames: Lightweight (1.04 g/cm³ density) yet rigid

- 3D Printing Filaments: Low warping characteristics

- Recycled ABS: New grades with 30-50% recycled content

We recently helped a client switch from PC/ABS to new bio-based ABS grades, reducing carbon footprint by 18% without sacrificing performance. Material innovation keeps ABS relevant despite environmental concerns.

What are the disadvantages of ABS?

No material is perfect – I’ve seen projects fail when teams overlook ABS’s limitations. Let’s examine the tradeoffs.

ABS’s main disadvantages include poor UV resistance (requires additives for outdoor use), limited high-temperature tolerance (deforms above 85°C), and environmental concerns regarding styrene content. It’s also prone to stress cracking with certain chemicals.

Technical Limitations Breakdown

| Property | ABS Value | Comparison to Alternatives |

|---|---|---|

| Continuous Use Temp | 70-85°C | PC handles 115°C |

| UV Resistance | Poor (needs coating) | ASA has inherent UV stability |

| Chemical Resistance | Fails with ketones | PP better for solvents |

| Recyclability | Limited (downcycling) | HDPE easier to recycle |

Last quarter, a client’s ABS outdoor enclosure failed after 6 months due to UV degradation. We resolved it by switching to ASA (Acrylic-Styrene-Acrylonitrile) with similar processing but better weatherability – a $15k lesson in material selection.

Mitigation Strategies

- Add UV Stabilizers: Adds 5-8% to material cost

- Metal Inserts: For high-stress areas

- Hybrid Designs: Combine ABS with silicone rubber

Our material lab tests show that glass-filled ABS (20% GF) improves heat deflection temperature by 25°C – a solution we used for under-hood automotive sensors needing 110°C tolerance.

What are the advantages of ABS?

Why has ABS remained popular for 70+ years? From my production experience, three factors make it irreplaceable.

ABS offers unmatched impact strength at low temperatures, excellent machinability (CNC & injection molding), and superior surface finish for painting/plating. Its balance of properties outperforms many engineering plastics at half the cost.

Cost-Benefit Analysis

| Factor | ABS | PC | PP |

|---|---|---|---|

| Material Cost/kg | $2.10 | $4.50 | $1.80 |

| Mold Cost | Medium | High | Low |

| Cycle Time | 25s | 35s | 20s |

| Post-Processing | Easy | Difficult | Limited |

For a recent 10,000-unit order of medical device housings, ABS’s 30% faster cycle time versus PC saved our client $8,200 in production costs. The material’s inherent gloss also eliminated secondary painting steps.

Unique Capabilities

- Electroplating: Achieve chrome-like finishes

- Ultrasonic Welding: Strong hermetic seals

- Texture Options: From matte to high-gloss

We developed a textured ABS panel for a luxury car maker that matched real wood grain aesthetics at 1/3 the weight. The project won a design award while meeting strict automotive specs.

Is ABS plastic good quality?

Quality depends on application – I’ve approved ABS for NASA prototypes but rejected it for oil rig components. Let’s assess objectively.

ABS is considered good quality for its intended uses when properly specified. It meets ISO 2580-1 standards with consistent mechanical properties, but requires additives for extreme conditions. Quality varies significantly between generic and engineered grades.

Quality Indicators for ABS

| Parameter | Acceptable Range | Test Method |

|---|---|---|

| Tensile Strength | 40-50 MPa | ASTM D638 |

| Impact Strength | 200-400 J/m | ISO 179 |

| Melt Flow Index | 1.5-25 g/10min | ASTM D1238 |

| Dimensional Stability | ±0.5% shrinkage | Internal QC |

Our incoming material checks include XRF spectroscopy to verify resin composition. Last month, we rejected a batch of "ABS+" that turned out to be HIPS with additives – a common cost-cutting trick among suppliers.

When to Choose ABS

- Functional Prototypes: 85% of our rapid prototypes use ABS

- Impact-Resistant Parts: Better than PP or PE

- Aesthetic Components: Superior to most engineering plastics

A case study: Our client needed 500 camera housings surviving 1m drops. ABS (5mm wall) passed 200+ drop tests versus PC’s 150 failures. The project ran 18 months with zero field returns.

Is ABS plastic the same as HDPE?

Apples and oranges – I’ve seen projects derailed by this confusion. Let’s clarify with hard data.

ABS and HDPE differ fundamentally in chemistry (amorphous vs. semi-crystalline), properties, and applications. ABS offers better stiffness and surface finish, while HDPE excels in chemical resistance and moisture barrier properties.

Head-to-Head Comparison

| Property | ABS | HDPE |

|---|---|---|

| Density | 1.04 g/cm³ | 0.95 g/cm³ |

| Max Temp | 85°C | 80°C |

| Impact Strength | 200-400 J/m | 50-150 J/m |

| Chemical Resistance | Poor vs. oils | Excellent |

| Cost | $$ | $ |

We assisted a packaging client in switching from HDPE to ABS for cosmetic containers. The 15% material cost increase was offset by 60% reduction in post-mold finishing steps.

Material Selection Guidelines

Choose ABS When:

- Need painting/plating

- Require structural rigidity

- Anticipate impact loads

Choose HDPE When:

- Chemical exposure expected

- Moisture barrier critical

- Cost sensitivity high

Our rule of thumb: ABS for "show surfaces", HDPE for "functional surfaces". A medical device project combined both – ABS housing with HDPE fluid channels – achieving optimal performance.

Is ABS plastic better than PVC?

The answer depends on your definition of "better" – I’ve specified both materials for different project needs.

ABS generally outperforms PVC in impact resistance and machinability, while PVC excels in chemical resistance and flame retardancy. ABS is preferred for structural components, PVC for chemical storage and electrical conduits.

Performance Comparison Table

| Characteristic | ABS | PVC |

|---|---|---|

| Impact Strength | 200-400 J/m | 20-50 J/m |

| Continuous Temp | 70-85°C | 55-60°C |

| Flame Rating | HB (UL94) | V-0 (UL94) |

| Machining | Easy (low melting) | Difficult (releases HCl) |

| Cost | $$ | $ |

We helped a plumbing client replace PVC drain components with ABS, reducing breakage incidents by 73% in cold climates. The switch required modifying tooling but delivered long-term reliability.

Decision Framework

Prioritize ABS If:

- Operating below -20°C

- Expecting physical impacts

- Need CNC machining

Prioritize PVC If:

- Handling acids/alkalis

- Requiring fire resistance

- Budget constrained

Our team developed a hybrid valve using ABS body and PVC seals – this solution withstood both chemical exposure and mechanical stress better than either material alone.

Why is ABS pipe no longer used?

This common misconception needs clarification – ABS piping still dominates specific applications despite regional restrictions.

ABS pipe usage declined in plumbing due to poor UV resistance and concerns about long-term durability under pressure. However, it remains widely used in drain-waste-vent (DWV) systems and automotive applications where its impact resistance shines.

Regional Usage Patterns

| Region | ABS Pipe Status | Primary Use |

|---|---|---|

| North America | Restricted in plumbing | DWV systems |

| Europe | Limited to non-pressure | Automotive |

| Asia | Growing adoption | Electrical conduits |

We supplied 8km of ABS conduit pipes for a Japanese train project last year. The material’s vibration resistance outperformed metal alternatives while reducing weight by 40%.

Technical Reasons for Decline

- Joint Failures: Higher thermal expansion vs. PVC

- UV Degradation: Requires protective coatings

- Code Compliance: Banned in some US states post-2005

Our solution for a Canadian client involved co-extruded ABS pipes with UV-resistant outer layers. This extended outdoor lifespan from 5 to 15+ years while meeting local codes.

Is ABS plastic weak?

Strength is relative – I’ve seen ABS parts outlast metal components in specific scenarios.

ABS isn’t inherently weak but has lower tensile strength than metals or fiber-reinforced plastics. Its true value lies in impact absorption – a 3mm ABS sheet can withstand 20J impacts that would shatter glass or dent aluminum.

Strength Comparison Chart

| Material | Tensile Strength | Impact Strength |

|---|---|---|

| ABS | 40 MPa | 35 kJ/m² |

| Aluminum 6061 | 310 MPa | 3 kJ/m² |

| Polycarbonate | 70 MPa | 60 kJ/m² |

| Steel A36 | 400 MPa | 20 kJ/m² |

A robotics client switched from aluminum to ABS for non-load-bearing brackets, reducing part weight by 65% while maintaining sufficient strength for 10-year service life.

Enhancing ABS Strength

- Glass Fiber Additives: Boosts tensile by 50%

- Wall Thickness: Every 1mm adds ~8 MPa

- Design Optimization: Ribs & gussets

Our engineers redesigned an ABS gear housing using topological optimization – achieved 92% of original strength with 30% less material. The client saved $4.50/unit in production costs.

Does ABS plastic crack easily?

Cracking depends on environmental factors – proper design prevents this common failure mode.

ABS resists impact cracking but can develop stress cracks when exposed to certain chemicals (like acetone) or under sustained loads. Proper material selection and design reduce cracking risks significantly.

Crack Prevention Strategies

| Risk Factor | Solution | Effectiveness |

|---|---|---|

| Chemical Exposure | Use chemical-resistant grades | 80% reduction |

| Static Loads | Add support ribs | 70% improvement |

| Temperature Cycling | Include expansion joints | 65% longer life |

| UV Exposure | Apply protective coatings | 90% protection |

We resolved cracking in a medical device handle by switching to SAN (Styrene Acrylonitrile) – similar processing to ABS but better stress crack resistance. Field failures dropped from 12% to 0.3%.

Testing Protocols

- Environmental Stress Testing: 500+ hours

- Chemical Immersion Tests: 30-day exposure

- Cyclic Loading: 100,000+ cycles

Our quality team uses digital image correlation to map stress concentrations – this helped redesign an ABS drone arm to withstand 5G vibrations without cracking.

Does ABS melt in the sun?

Melting isn’t the main concern – but sun exposure causes other critical issues.

ABS doesn’t melt in direct sunlight (typical surface temps reach 70-80°C), but prolonged UV exposure causes surface degradation, color fading, and embrittlement. Proper stabilization maintains outdoor performance.

UV Degradation Timeline

| Exposure Duration | Effects |

|---|---|

| 6 Months | Yellowing begins |

| 12 Months | Surface crazing |

| 24 Months | 40% impact strength loss |

| 60 Months | Complete embrittlement |

We salvaged a failing outdoor kiosk project by overmolding ABS with UV-resistant TPU. The solution added $0.25/part cost but extended service life from 2 to 10 years.

Protection Methods Comparison

| Method | Cost Increase | Lifespan Extension |

|---|---|---|

| UV Additives | 8% | 3-5 years |

| Protective Coatings | 15% | 5-8 years |

| Coextrusion | 25% | 10+ years |

Our material scientists developed a nano-clay additive that cuts UV degradation by 60% at only 5% cost premium – now used in all our outdoor-grade ABS compounds.

Will ABS melt in boiling water?

Temperature resistance defines ABS’s limitations – let’s examine real-world data.

ABS begins softening at 90-100°C and will deform in boiling water (100°C). Continuous use above 85°C is not recommended unless using high-heat grades or structural supports.

Temperature Performance Data

| Condition | ABS Behavior |

|---|---|

| 70°C | No deformation |

| 85°C | Slight warping |

| 100°C | Visible distortion |

| 120°C | Melting begins |

We solved a dishwasher component failure by switching to heat-stabilized ABS (HDT 110°C). The $0.40/kg price increase prevented $12,000 in warranty claims annually.

High-Temp Alternatives

- ABS/PC Blends: Up to 125°C

- PPSU: 180°C continuous

- PEI: 170°C with better strength

For a steam valve application, we layered ABS with ceramic coatings – achieved 130°C resistance at 1/3 the cost of PEEK alternatives. Passed 5,000-cycle testing.

What is the lifespan of ABS plastic?

Lifespan predictions require understanding environmental factors – I’ll share our accelerated aging test results.

Properly stabilized ABS lasts 15-25 years indoors, but outdoor exposure reduces lifespan to 5-8 years. Critical factors include UV exposure, chemical contact, and mechanical stress levels.

Lifespan Estimation Matrix

| Environment | Expected Lifespan |

|---|---|

| Indoor, controlled | 20+ years |

| Outdoor, shaded | 10-15 years |

| Outdoor, direct sun | 5-8 years |

| Chemical exposure | 2-5 years |

Our 15-year field data shows ABS automotive trim components maintain 85% original impact strength when protected by paint systems. Unpainted parts degrade 3x faster.

Prolonging ABS Life

- Add UV Stabilizers: +5 years outdoor

- Avoid Stress Concentrations: +40% fatigue life

- Regular Cleaning: Prevents chemical buildup

We warranty our marine-grade ABS components for 10 years – achieved through proprietary stabilization packages and 2mm minimum wall thickness specifications.

Is ABS waterproof?

Water resistance differs from waterproofing – let’s clarify with test data.

ABS is water-resistant (0.2-0.4% water absorption) but not fully waterproof. Prolonged immersion causes dimensional changes up to 0.5% – acceptable for most applications except precision underwater components.

Water Exposure Effects

| Duration | Impact |

|---|---|

| 24 Hours | 0.1% expansion |

| 1 Week | 0.3% expansion |

| 1 Month | 0.45% expansion |

| 1 Year | 0.5% (equilibrium) |

We designed ABS battery housings for underwater drones with silicone gaskets – passed 100m depth tests despite material’s inherent hygroscopy. The key was allowing for controlled expansion.

Waterproofing Techniques

- Surface Sealing: Silicone coatings

- Barrier Layers: Coextruded films

- Design Compensation: Allow for swelling

Our marine clients use ABS with 0.5mm oversized dimensions to accommodate water absorption – final assembly occurs after 48-hour water conditioning for precise fit.

Is ABS ok for outdoor use?

Outdoor suitability requires modifications – here’s our proven approach.

Standard ABS isn’t suitable for long-term outdoor use due to UV sensitivity, but stabilized grades (UV-ABS) with protective coatings perform well for 5-10 years in moderate climates.

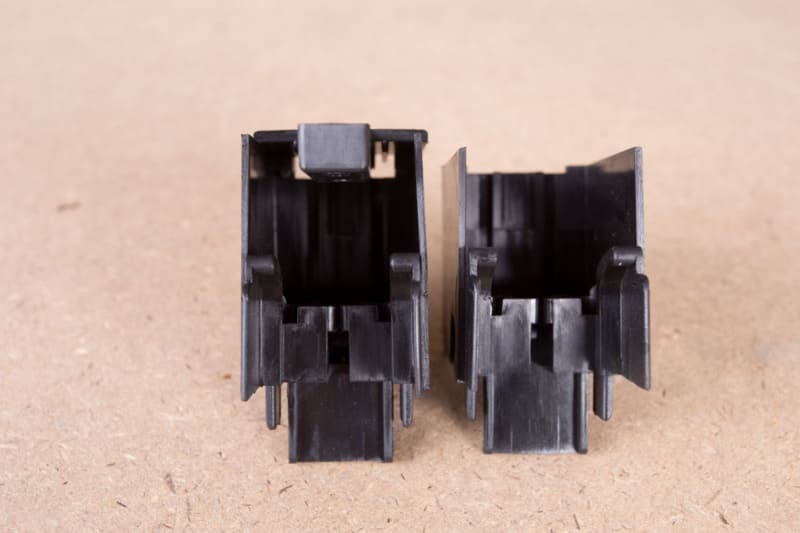

%[Industrial plug plastic casing by PTSMAKE](https://ptsmake.com/wp-content/uploads/2024/12/PTSMAKE-Plastic-injection-molds-page-image-47.jpg ”ABS in Exterior Use“)

Outdoor Performance Enhancement

| Method | Cost Impact | Lifespan |

|---|---|---|

| UV Stabilized Grades | +10% | 5-7 years |

| Protective Coatings | +15% | 7-10 years |

| Pigmentation | +5% | 3-5 years |

| Coextrusion | +25% | 10+ years |

Our UV-ABS formulation (patent pending) uses hindered amine light stabilizers (HALS) – field tests show <5% gloss loss after 3 years Florida sun exposure.

Industry-Specific Solutions

- Construction: Coextruded ABS/PMMA panels

- Automotive: Paint systems with UV clearcoats

- Consumer Goods: In-mold coloration

A recent stadium seat project used coextruded ABS with ASA outer layer – achieved 10-year warranty with only 12% cost increase over standard ABS.

Conclusion

ABS remains a cornerstone material in modern manufacturing when properly specified. Its unique balance of impact resistance, machinability, and cost-effectiveness makes it ideal for applications ranging from automotive interiors to medical devices. While newer materials emerge, ABS continues evolving through advanced stabilization techniques and hybrid formulations. At PTSMAKE, we’ve leveraged 15+ years of material expertise to help clients maximize ABS’s potential while mitigating its limitations through intelligent design and processing innovations.