Have you ever struggled with metal parts that look dull, rough, or inconsistent? Many engineers and product designers face this frustrating challenge when trying to achieve a professional finish. I’ve seen how poor surface finishing can impact both aesthetics and functionality.

Bead blasting is a surface treatment process that uses tiny glass beads propelled at high pressure against a material’s surface to create a clean, uniform, and matte finish. This method effectively removes surface contaminants and creates an even texture.

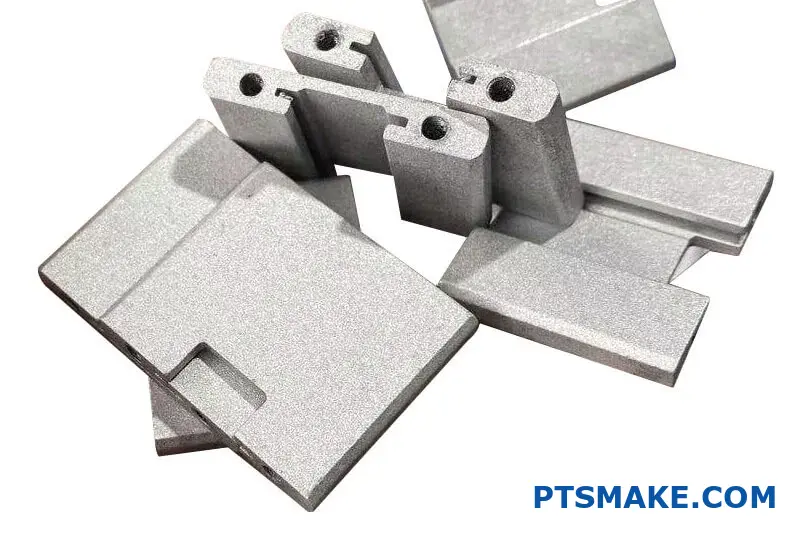

I want to share some insider knowledge about bead blasting that could change how you approach surface finishing. As a manufacturing professional at PTSMAKE, I’ve seen how this technique can transform ordinary parts into premium-looking components. Let me show you why this process might be exactly what your project needs.

What Is The Purpose Of Bead Blasting?

Have you ever struggled with parts that look uneven, rough, or lack that professional finish? Maybe you’ve received components with stubborn surface contaminants or inconsistent textures that affect both appearance and functionality. These surface finish challenges can seriously impact your product’s quality and market appeal.

Bead blasting is a specialized surface treatment process that propels tiny glass beads at high pressure against a material’s surface to clean, smooth, and enhance its appearance. This versatile finishing method effectively removes surface contaminants while creating a uniform, satin-like finish.

Understanding the Core Benefits of Bead Blasting

Bead blasting serves multiple purposes in manufacturing, making it an invaluable process for various industries. The technique employs pneumatic acceleration1 to propel glass beads against surfaces, offering several key advantages:

Surface Cleaning and Preparation

The process excels at removing:

- Surface oxidation

- Paint and old coatings

- Rust and corrosion

- Manufacturing residues

- Oil and grease deposits

Aesthetic Enhancement

Bead blasting creates consistent surface finishes that are:

- Uniformly matte

- Professionally appealing

- Free from visual defects

- Ideal for product presentation

Applications Across Industries

Automotive Manufacturing

In automotive applications, bead blasting proves essential for:

- Engine component restoration

- Chassis part preparation

- Transmission housing finishing

- Custom part enhancement

Aerospace Components

The aerospace industry relies heavily on bead blasting for:

| Application | Purpose | Benefits |

|---|---|---|

| Turbine Parts | Surface preparation | Enhanced durability |

| Landing Gear | Contamination removal | Improved safety |

| Structural Components | Finish uniformity | Better inspection capability |

| Control Surfaces | Coating preparation | Superior adhesion |

Medical Device Manufacturing

Medical applications require exceptional cleanliness and finish quality:

- Surgical instrument preparation

- Implant surface treatment

- Medical equipment maintenance

- Device component finishing

Technical Considerations

Material Compatibility

Different materials respond uniquely to bead blasting:

| Material | Recommended Pressure | Bead Size |

|---|---|---|

| Aluminum | 40-60 PSI | 70-140 mesh |

| Stainless Steel | 60-80 PSI | 50-100 mesh |

| Titanium | 70-90 PSI | 40-80 mesh |

| Plastic | 20-40 PSI | 100-170 mesh |

Process Parameters

At PTSMAKE, we carefully control several key parameters:

- Blast pressure

- Media size and type

- Nozzle distance

- Impact angle

- Treatment duration

Quality Control Measures

To ensure consistent results, we implement:

- Regular media inspection

- Equipment calibration

- Surface roughness testing

- Visual inspection protocols

- Documentation of parameters

Environmental and Safety Considerations

Modern bead blasting requires attention to:

- Dust collection systems

- Proper ventilation

- Operator protection

- Media recycling

- Waste management

Cost-Efficiency Analysis

Bead blasting offers economic advantages through:

- Reduced manual finishing time

- Improved part longevity

- Decreased rejection rates

- Enhanced product value

- Lower maintenance costs

Industry Standards and Specifications

We adhere to various standards including:

- NADCAP requirements

- ISO surface finish specifications

- ASTM testing methods

- Military specifications

- Industry-specific requirements

Future Trends and Innovations

The field continues to evolve with:

- Automated blasting systems

- Advanced media materials

- Precision control technology

- Environmental improvements

- Process optimization tools

Through our extensive experience at PTSMAKE, we’ve refined our bead blasting processes to deliver exceptional results. Our state-of-the-art equipment and skilled technicians ensure that each component receives the precise treatment needed for optimal performance and appearance.

How Does Bead Blasting Affect Material Durability?

Have you ever noticed how some metal parts suddenly show signs of premature wear after surface treatment? It’s frustrating when components that should last for years begin deteriorating months after bead blasting, leaving you questioning whether this finishing process was the right choice.

Bead blasting significantly impacts material durability by altering surface characteristics. This process can either enhance or compromise material longevity depending on factors like blast media selection, pressure settings, and material properties. When properly executed, it creates a uniform surface finish that can improve wear resistance.

Understanding the Mechanical Effects

Surface Modification Process

Bead blasting fundamentally changes the material’s surface structure through controlled work hardening2. At PTSMAKE, we’ve observed that the impact of glass or ceramic beads creates microscopic deformations on the surface. This process compresses the outer layer of the material, resulting in a more densified surface structure.

Impact on Surface Properties

The effects of bead blasting on surface properties can be categorized into several key aspects:

| Property | Effect | Impact on Durability |

|---|---|---|

| Surface Roughness | Increased micro-texture | Enhanced coating adhesion |

| Hardness | Improved surface hardness | Better wear resistance |

| Residual Stress | Compressive stress induction | Increased fatigue life |

| Material Density | Surface layer compression | Higher impact resistance |

Critical Factors Affecting Material Performance

Media Selection Impact

The choice of blasting media plays a crucial role in determining the final surface characteristics. Glass beads produce a smoother finish compared to ceramic beads, while maintaining material integrity. Working with various aerospace clients, I’ve found that material-specific media selection directly correlates with component longevity.

Process Parameters

Several key parameters influence the outcome:

Blast Pressure

- Low pressure: Minimal surface modification

- Medium pressure: Optimal surface enhancement

- High pressure: Risk of material degradation

Treatment Duration

- Short duration: Insufficient surface modification

- Optimal duration: Uniform surface properties

- Extended duration: Possible material damage

Material Compatibility Considerations

Long-term Effects on Different Materials

Metals and Alloys

Most metals respond positively to bead blasting when properly executed. Aluminum components show improved corrosion resistance, while steel parts demonstrate enhanced wear characteristics. At PTSMAKE, we’ve developed specific protocols for different metal types to maximize durability benefits.

Composite Materials

Composite materials require special attention during bead blasting. The process can strengthen surface layers but may compromise internal structure if not carefully controlled. Our experience with aerospace components has shown that modified parameters are essential for composite materials.

Optimization Strategies for Enhanced Durability

Surface Preparation Requirements

Proper surface preparation significantly impacts the success of bead blasting:

| Preparation Step | Purpose | Effect on Durability |

|---|---|---|

| Cleaning | Contaminant removal | Prevents surface defects |

| Inspection | Defect identification | Ensures uniform treatment |

| Temperature control | Process stability | Maintains material properties |

Quality Control Measures

Implementing strict quality control measures ensures consistent results. This includes:

- Regular media inspection and replacement

- Pressure monitoring systems

- Surface roughness measurements

- Post-treatment inspection protocols

Industrial Applications and Considerations

Aerospace Components

In aerospace applications, where safety and reliability are paramount, bead blasting must meet stringent requirements. The process enhances fatigue resistance and surface finish without compromising structural integrity.

Automotive Parts

Automotive components benefit from improved wear resistance and better coating adhesion after bead blasting. The uniform surface finish also contributes to better performance in high-stress applications.

Medical Devices

Medical device manufacturing requires precise surface finishing. Bead blasting creates biocompatible surfaces while maintaining strict dimensional tolerances. This is particularly important for implantable devices where surface properties directly impact biological responses.

Environmental and Safety Aspects

Process Control Parameters

Maintaining environmental controls during bead blasting is essential for both worker safety and material quality:

- Dust collection systems

- Proper ventilation

- Personal protective equipment

- Regular equipment maintenance

Sustainability Considerations

Modern bead blasting operations should focus on sustainable practices:

- Media recycling programs

- Energy-efficient equipment

- Waste reduction strategies

- Environmental impact monitoring

What Industries Commonly Use Bead Blasted Components?

Have you ever wondered why some metal parts have that distinctive matte, uniform finish? Or perhaps you’ve encountered situations where regular surface finishes just don’t meet your product’s requirements for both aesthetics and functionality?

Bead blasted components are widely used across multiple industries including medical, aerospace, automotive, and electronics. This surface treatment process creates a uniform, matte finish that enhances both aesthetic appeal and functional performance while reducing surface imperfections.

Medical Industry Applications

The medical industry demands the highest standards of cleanliness and precision in their equipment. The surface roughness3 achieved through bead blasting plays a crucial role in medical device manufacturing. At PTSMAKE, we regularly process components for:

Surgical Instruments

- Scalpel handles

- Forceps

- Retractors

- Surgical clamps

These instruments require specific surface characteristics to:

- Prevent glare during procedures

- Enhance grip security

- Facilitate proper sterilization

- Maintain professional appearance

Aerospace Industry Requirements

The aerospace sector relies heavily on bead blasted components for both functional and aesthetic purposes. Critical applications include:

External Components

- Turbine blades

- Wing components

- Fuselage panels

- Landing gear parts

Interior Components

- Cabin fixtures

- Control panels

- Seat adjustment mechanisms

- Storage compartment hardware

Automotive Industry Applications

In the automotive industry, bead blasting serves both decorative and functional purposes:

| Component Type | Primary Purpose | Secondary Benefits |

|---|---|---|

| Engine Parts | Heat dissipation | Corrosion resistance |

| Exhaust Systems | Aesthetic finish | Temperature regulation |

| Brake Components | Friction improvement | Wear resistance |

| Suspension Parts | Surface preparation | Durability enhancement |

Electronics Industry Usage

The electronics industry utilizes bead blasted components for:

Heat Management

- Heat sinks

- Cooling fins

- Thermal management systems

- Electronic enclosures

Aesthetic Applications

- Device housings

- Control panels

- Interface components

- Display frames

Consumer Products

The consumer goods sector extensively uses bead blasted finishes for:

Kitchen Appliances

- Coffee makers

- Toasters

- Refrigerator handles

- Microwave panels

Home Hardware

- Door handles

- Cabinet pulls

- Light fixtures

- Bathroom accessories

Industrial Equipment

Manufacturing equipment often requires bead blasted components for:

Machine Components

- Control panels

- Safety guards

- Operating handles

- Access panels

Processing Equipment

- Mixing vessels

- Storage tanks

- Transport containers

- Processing equipment frames

Architecture and Construction

The construction industry utilizes bead blasted finishes for:

Exterior Applications

- Handrails

- Elevator doors

- Façade elements

- Security gates

Interior Features

- Door hardware

- Decorative panels

- Signage

- Lighting fixtures

At PTSMAKE, we’ve optimized our bead blasting processes to meet the specific requirements of each industry. Our experience has shown that different applications require varying levels of surface finish and material removal. We carefully select the appropriate media size and blast pressure to achieve the desired results for each component.

The versatility of bead blasting makes it an excellent choice for components that require:

- Uniform surface finish

- Enhanced material properties

- Improved adhesion for subsequent coatings

- Professional appearance

- Functional performance improvements

When selecting bead blasting for your components, consider these key factors:

- Material compatibility

- Required surface finish

- Component geometry

- End-use environment

- Regulatory requirements

Our manufacturing facility employs advanced bead blasting equipment and precise quality control measures to ensure consistent results across all industries we serve. This commitment to quality has enabled us to maintain long-term partnerships with leading companies in various sectors.

How Much Does Bead Blasting Cost?

Have you ever received a quote for bead blasting services and found yourself questioning the wide range of prices? It’s frustrating when you’re trying to budget for your project, but every supplier seems to have a different pricing structure, leaving you uncertain about what’s fair and reasonable.

The cost of bead blasting typically ranges from $50 to $150 per hour, or $1 to $5 per square foot, depending on factors like material type, surface area, complexity, and finish requirements. Small parts might cost as little as $25, while large components can exceed $500.

Understanding the Cost Breakdown

Material Factors

Material type significantly influences bead blasting costs. Different materials require specific media types and processing times. Here’s a breakdown of common materials and their relative costs:

| Material Type | Cost Range (per sq ft) | Processing Time |

|---|---|---|

| Aluminum | $1.50 – $3.00 | Fast |

| Steel | $2.00 – $4.00 | Medium |

| Stainless Steel | $2.50 – $5.00 | Longer |

| Cast Iron | $2.00 – $3.50 | Medium |

Size and Complexity

The surface complexity4 of your parts plays a crucial role in determining the final cost. Simple flat surfaces are easier and quicker to process, while intricate geometries with multiple angles require more time and attention. At PTSMAKE, we’ve developed specialized techniques to handle complex geometries efficiently while maintaining quality standards.

Surface Area Considerations

The total surface area requiring treatment directly impacts cost. Larger items generally cost less per square foot due to economies of scale, though they may have higher total costs. Here’s what typically affects surface area pricing:

- Setup time requirements

- Equipment size needed

- Material handling complexity

- Coverage requirements

Additional Cost Factors

Media Selection

Different blasting media affect both cost and finish quality:

| Media Type | Cost per lb | Durability | Application |

|---|---|---|---|

| Glass Beads | $0.50-$1.00 | Medium | General purpose |

| Ceramic Beads | $1.50-$2.50 | High | Premium finish |

| Plastic Media | $2.00-$3.00 | Low | Delicate surfaces |

| Steel Shot | $0.75-$1.25 | Very High | Heavy duty |

Labor and Equipment Costs

Professional bead blasting requires skilled operators and specialized equipment. Labor rates typically range from $50-$100 per hour, while equipment costs factor into overhead expenses.

Quantity Considerations

Volume significantly impacts per-unit costs:

- Single prototype: Higher per-unit cost

- Small batch (10-50 units): Moderate cost reduction

- Large production (100+ units): Significant economies of scale

Industry-Specific Pricing

Automotive Applications

Automotive parts often require specific surface finishes and careful handling:

- Engine components: $75-$150 per part

- Body panels: $2-$4 per square foot

- Wheel restoration: $50-$100 per wheel

Aerospace Requirements

Aerospace applications demand higher precision and documentation:

- Small components: $100-$200 per batch

- Structural elements: $3-$6 per square foot

- Certification documentation: Additional $50-$100

Industrial Equipment

Industrial equipment often requires heavy-duty processing:

- Machine frames: $2.50-$4.50 per square foot

- Tooling components: $75-$200 per piece

- Large assemblies: Custom pricing based on complexity

Cost Optimization Strategies

Project Planning

To optimize costs, consider:

- Grouping similar parts together

- Preparing surfaces beforehand

- Specifying exact requirements

- Planning for proper packaging

Quality vs. Cost Balance

Understanding the relationship between quality and cost helps in making informed decisions:

| Quality Level | Cost Premium | Best For |

|---|---|---|

| Standard | Base price | Non-critical parts |

| Premium | +25-50% | Visible surfaces |

| Precision | +50-100% | Critical components |

Volume Discounts

Typical volume discount structures:

| Quantity | Discount |

|---|---|

| 1-10 pieces | Standard pricing |

| 11-50 pieces | 10-15% off |

| 51-100 pieces | 15-25% off |

| 100+ pieces | Custom pricing |

At PTSMAKE, we understand the importance of balancing cost with quality. Our automated processes and efficient workflows help maintain competitive pricing while ensuring consistent results. We recommend discussing your specific requirements with us to receive accurate pricing tailored to your project needs.

What Is Bead Blasted Stainless Steel?

Have you ever struggled to achieve that perfect, uniform matte finish on stainless steel parts? Many manufacturers find themselves puzzled by surface finishing options, especially when their projects demand both aesthetic appeal and functional durability.

Bead blasted stainless steel is a surface finishing method where tiny glass beads are propelled at high pressure against stainless steel surfaces to create a uniform, satin-like matte finish. This process not only enhances aesthetics but also improves material durability and corrosion resistance.

Understanding the Bead Blasting Process

When it comes to surface finishing, bead blasting stands out as one of the most versatile methods. The process involves using compressed air to propel small spherical media, typically glass beads, against the surface of stainless steel. The abrasive impingement5 creates microscopic dimples that collectively form a consistent matte finish.

Equipment Components

The basic setup for bead blasting includes:

- Blast cabinet or room

- Air compressor

- Media delivery system

- Collection and recycling system

- Protective equipment

Media Selection

The choice of blasting media significantly impacts the final finish:

| Media Type | Size Range | Surface Finish | Best Used For |

|---|---|---|---|

| Glass Beads | 40-400 mesh | Satin matte | Decorative finishes |

| Ceramic Beads | 50-200 mesh | Smooth matte | Heavy-duty applications |

| Plastic Beads | 60-300 mesh | Gentle matte | Delicate parts |

Benefits of Bead Blasted Stainless Steel

Enhanced Surface Properties

The bead blasting process offers several advantages:

- Improved corrosion resistance

- Better paint adhesion

- Reduced surface imperfections

- Uniform appearance

- Stress relief in surface layers

Aesthetic Advantages

At PTSMAKE, we’ve observed that bead blasted finishes are particularly popular in:

- Consumer electronics

- Medical devices

- Architectural applications

- High-end machinery

- Aerospace components

Technical Considerations

Surface Roughness Control

The final surface roughness depends on several factors:

- Blast pressure

- Media size

- Distance from workpiece

- Angle of impact

- Duration of treatment

Quality Assurance Measures

To ensure consistent results, we implement:

| Parameter | Monitoring Method | Acceptable Range |

|---|---|---|

| Air Pressure | Digital gauge | 30-90 PSI |

| Media Size | Sieve analysis | ±10% variation |

| Surface Finish | Profilometer | Ra 0.8-3.2 µm |

Industrial Applications

Medical Industry

In medical device manufacturing, bead blasted stainless steel is crucial for:

- Surgical instruments

- Implant components

- Medical equipment housings

- Laboratory equipment

Aerospace Sector

The aerospace industry relies on bead blasted finishes for:

- Turbine components

- Control surfaces

- Interior cabin elements

- Landing gear parts

Consumer Products

Many consumer products benefit from this finish:

- Kitchen appliances

- Bathroom fixtures

- Electronic device housings

- Decorative panels

Best Practices and Recommendations

Process Optimization

To achieve optimal results:

- Clean surfaces thoroughly before blasting

- Maintain consistent air pressure

- Use fresh, properly sized media

- Control blast angle and distance

- Monitor process parameters continuously

Common Issues and Solutions

| Issue | Cause | Solution |

|---|---|---|

| Uneven Finish | Inconsistent pressure | Regulate air supply |

| Surface Damage | Excessive pressure | Adjust blast parameters |

| Contamination | Poor media maintenance | Regular media replacement |

Environmental and Safety Considerations

Worker Protection

Essential safety measures include:

- Proper ventilation systems

- Personal protective equipment

- Regular equipment maintenance

- Safety training programs

Environmental Impact

Sustainable practices we implement:

- Media recycling systems

- Dust collection

- Proper waste disposal

- Energy-efficient equipment

At PTSMAKE, we maintain strict quality control standards for all bead blasting operations, ensuring consistent results that meet or exceed industry specifications. Our advanced facility and experienced team handle projects ranging from prototype development to high-volume production runs.

How Does Bead Blasting Compare To Other Surface Finishes?

Have you ever struggled with choosing the right surface finish for your metal parts? The overwhelming number of finishing options can leave you second-guessing your decision, especially when quality and aesthetics both matter for your project.

Bead blasting stands out among surface finishing methods by offering a uniform, matte appearance while improving surface quality. This process uses high-pressure glass beads to create a consistent finish, making it ideal for both aesthetic and functional applications in manufacturing.

Understanding the Basics of Surface Finishing

Surface finishing plays a crucial role in determining both the appearance and functionality of manufactured parts. When comparing bead blasting to other finishing methods, we need to consider several key factors:

Material Compatibility

Different materials respond uniquely to various finishing processes. While bead blasting works exceptionally well with metals, other methods like electropolishing6 might be more suitable for specific applications. At PTSMAKE, we carefully evaluate material properties before recommending a finishing method.

Surface Characteristics Comparison

| Finishing Method | Surface Texture | Cost Level | Processing Time | Durability |

|---|---|---|---|---|

| Bead Blasting | Matte, Uniform | Moderate | Quick | High |

| Sandblasting | Rough, Textured | Low | Quick | Medium |

| Polishing | Smooth, Glossy | High | Long | Medium |

| Brushing | Linear, Striated | Moderate | Medium | High |

Advantages of Bead Blasting

Consistent Finish Quality

Bead blasting provides remarkable consistency across large surface areas. The uniform bombardment of glass beads creates an even, aesthetically pleasing finish that’s difficult to achieve with manual methods.

Cost-Effectiveness

While initial setup costs exist, bead blasting proves economical for large production runs. The process requires minimal manual intervention and delivers consistent results, reducing rework and quality control costs.

Environmental Considerations

Unlike chemical finishing processes, bead blasting is environmentally friendly. The glass beads can be recycled multiple times, and the process doesn’t produce harmful chemical waste.

Applications Across Industries

Automotive Components

In automotive manufacturing, bead blasting helps prepare surfaces for coating and improves part aesthetics. Engine components, chassis parts, and decorative elements often undergo this treatment.

Aerospace Requirements

The aerospace industry demands precise surface finishing for critical components. Bead blasting helps achieve specific roughness requirements while maintaining tight tolerances.

Medical Device Manufacturing

For medical devices, surface finish affects both functionality and sterilization capabilities. Bead blasting creates surfaces that are easy to clean and maintain.

Comparing Surface Roughness Values

| Surface Treatment | Ra Value (μm) | Common Applications |

|---|---|---|

| Bead Blasting | 0.8 – 3.2 | General purpose |

| Mirror Polishing | 0.1 – 0.2 | Optical devices |

| Brushing | 0.4 – 1.6 | Decorative parts |

| Shot Peening | 2.5 – 5.0 | Stress relief |

Process Control and Quality Assurance

When performing bead blasting at our facility, we maintain strict control over several parameters:

- Bead size selection

- Air pressure adjustment

- Distance from workpiece

- Blasting angle

- Duration of treatment

This attention to detail ensures consistent results across production runs.

Cost Considerations and ROI

The return on investment for bead blasting depends on various factors:

Direct Costs

- Equipment and maintenance

- Media (glass beads) replacement

- Labor requirements

- Energy consumption

Indirect Benefits

- Improved product quality

- Reduced rejection rates

- Enhanced customer satisfaction

- Longer product lifespan

Maintenance and Longevity

To maintain optimal bead blasting performance:

- Regular equipment inspection

- Proper media storage

- Consistent pressure monitoring

- Regular filter replacement

- Routine calibration checks

Future Trends in Surface Finishing

The surface finishing industry continues to evolve with:

- Automated process control systems

- Advanced media compositions

- Real-time quality monitoring

- Integration with Industry 4.0 principles

In comparing bead blasting to other surface finishes, it’s essential to consider the specific requirements of your application. While bead blasting excels in many scenarios, some applications might benefit from alternative methods or combinations of different finishing techniques.

What Are The Maintenance Requirements For Bead Blasted Surfaces?

Have you ever noticed your bead blasted surface losing its uniform appearance over time? It’s frustrating when these carefully treated surfaces start showing signs of wear, oxidation, or uneven patches, potentially compromising both aesthetics and functionality.

Maintaining bead blasted surfaces requires regular cleaning, protection from corrosion, and periodic reapplication of surface treatments. The key maintenance tasks include gentle cleaning with non-abrasive materials, applying protective coatings, and avoiding harsh chemicals that could damage the finish.

Understanding Daily Maintenance Requirements

Proper maintenance of bead blasted surfaces starts with daily care. At PTSMAKE, we recommend implementing a structured maintenance schedule that includes:

Regular Cleaning Protocol

- Use mild, pH-neutral cleaners

- Apply soft, lint-free cloths

- Avoid abrasive cleaning tools

- Clean in the direction of the grain

- Rinse thoroughly with clean water

- Dry immediately to prevent water spots

Protection Against Environmental Factors

Environmental protection is crucial for maintaining the passivation layer7 that forms on bead blasted surfaces. The following measures help preserve surface integrity:

- Install protective covers when not in use

- Control humidity levels in storage areas

- Minimize exposure to harsh weather conditions

- Apply appropriate protective coatings

- Monitor for signs of oxidation

Long-term Maintenance Strategies

Periodic Inspection Schedule

Regular inspections help identify potential issues before they become serious problems. Here’s a recommended inspection timeline:

| Inspection Type | Frequency | Key Check Points |

|---|---|---|

| Visual Check | Weekly | Surface uniformity, discoloration |

| Detailed Inspection | Monthly | Oxidation signs, wear patterns |

| Professional Assessment | Quarterly | Coating integrity, surface damage |

| Complete Evaluation | Annually | Overall condition, maintenance needs |

Professional Maintenance Services

When working with precision components at PTSMAKE, we emphasize the importance of professional maintenance services. These services typically include:

- Surface analysis and evaluation

- Deep cleaning treatments

- Protective coating reapplication

- Repair of damaged areas

- Quality assessment and documentation

Preventive Maintenance Measures

Storage Requirements

Proper storage is essential for maintaining bead blasted surfaces:

- Store in climate-controlled environments

- Use appropriate packaging materials

- Avoid direct contact between surfaces

- Implement proper handling procedures

- Maintain inventory rotation systems

Chemical Treatment Protocols

The following chemical treatments help maintain surface quality:

| Treatment Type | Purpose | Application Frequency |

|---|---|---|

| Passive Films | Corrosion resistance | Every 6 months |

| Anti-oxidation Coatings | Oxidation prevention | Annually |

| Protective Sealants | Surface protection | As needed |

| Cleaning Solutions | Regular maintenance | Weekly |

Troubleshooting Common Issues

Surface Degradation Prevention

To prevent surface degradation:

- Monitor environmental conditions

- Address contamination immediately

- Use appropriate cleaning agents

- Maintain proper pH levels

- Document maintenance procedures

Repair Procedures

When damage occurs, follow these repair steps:

- Assess damage extent

- Clean affected areas

- Apply appropriate treatments

- Monitor repair results

- Update maintenance records

Industrial Application Considerations

Different industries require specific maintenance approaches:

Aerospace Requirements

- Strict cleanliness standards

- Regular surface testing

- Documented maintenance procedures

- Specialized coating applications

- Quality control measures

Medical Device Specifications

- Sterile cleaning protocols

- Biocompatibility maintenance

- Regular sanitization

- Contamination prevention

- Validation procedures

Cost-Effective Maintenance Strategies

Implementing cost-effective maintenance involves:

- Developing preventive maintenance schedules

- Training maintenance personnel

- Using appropriate materials and tools

- Documenting procedures and results

- Evaluating maintenance effectiveness

Budget Planning

Consider these factors when planning maintenance budgets:

| Cost Category | Frequency | Typical Expenses |

|---|---|---|

| Regular Cleaning | Weekly | Supplies, labor |

| Professional Services | Quarterly | Specialist fees |

| Protective Treatments | Semi-annual | Materials, application |

| Emergency Repairs | As needed | Repair costs |

At PTSMAKE, we’ve developed comprehensive maintenance programs that help our clients maximize the lifespan of their bead blasted components while minimizing maintenance costs. Our experience shows that proper maintenance not only preserves surface quality but also extends component life and reduces long-term expenses.

How Does Bead Blasting Improve Corrosion Resistance?

Have you ever noticed your metal parts deteriorating faster than expected, despite regular maintenance? The constant battle against corrosion can be frustrating, especially when traditional surface treatments fall short of providing adequate protection for your valuable components.

Bead blasting significantly improves corrosion resistance by creating a uniform, microscopically textured surface that enhances protective coating adhesion and forms a consistent passive layer. This mechanical process removes contaminants and creates an ideal surface profile for superior corrosion protection.

Understanding the Science Behind Bead Blasting and Corrosion

The Mechanical Process

The foundation of bead blasting lies in its mechanical impact on metal surfaces. When glass or ceramic beads strike the surface at high velocities, they create a work-hardened8 layer that fundamentally alters the metal’s surface properties. At PTSMAKE, we’ve optimized this process through precise control of:

- Bead size selection

- Impact velocity

- Coverage patterns

- Treatment duration

Surface Profile Modification

Bead blasting creates a unique surface topology that enhances corrosion resistance in several ways:

- Uniform Surface Texture

- Increased Surface Area

- Improved Coating Adhesion

- Stress Relief in Surface Layers

The Role of Surface Preparation

Contaminant Removal

The effectiveness of bead blasting in improving corrosion resistance starts with thorough surface preparation:

| Contaminant Type | Removal Efficiency | Impact on Corrosion Resistance |

|---|---|---|

| Oxides | 95-99% | High |

| Oil and Grease | 90-95% | Significant |

| Scale Deposits | 85-95% | Moderate to High |

| Paint Residues | 98-100% | Substantial |

Surface Activation

Bead blasting activates the metal surface through:

- Creation of fresh metal surfaces

- Enhanced reactivity for protective coatings

- Improved surface energy characteristics

- Optimized molecular bonding potential

Enhanced Coating Performance

Adhesion Mechanics

The relationship between bead blasting and coating adhesion is crucial:

| Surface Treatment | Coating Adhesion Strength | Long-term Durability |

|---|---|---|

| Bead Blasted | Excellent (>95%) | 8-10 years |

| Non-Blasted | Fair (60-70%) | 3-5 years |

| Chemical Etched | Good (80-85%) | 5-7 years |

Protective Layer Formation

The process creates ideal conditions for:

- Uniform coating application

- Enhanced paint adhesion

- Improved primer penetration

- Consistent protective layer formation

Industry-Specific Applications

Aerospace Components

In aerospace applications, corrosion resistance is critical. Bead blasting provides:

- Enhanced fatigue resistance

- Improved stress distribution

- Superior surface finish

- Extended component life

Marine Equipment

Marine environments present unique challenges that bead blasting helps address:

- Salt spray resistance

- Underwater protection

- Extended maintenance intervals

- Enhanced coating durability

Quality Control Measures

Surface Profile Measurement

At PTSMAKE, we implement rigorous quality control:

| Test Parameter | Acceptable Range | Frequency |

|---|---|---|

| Surface Roughness | 1.5-4.0 Ra | Every batch |

| Profile Depth | 38-75 μm | Daily |

| Coverage | 98-100% | Continuous |

Performance Validation

Regular testing ensures optimal results:

- Salt spray testing

- Adhesion testing

- Surface energy measurement

- Microscopic inspection

Environmental Considerations

Sustainable Practices

Bead blasting offers environmental benefits:

- Reduced chemical usage

- Lower waste generation

- Recyclable media

- Minimal environmental impact

Health and Safety

Important safety measures include:

- Dust collection systems

- Proper ventilation

- Protective equipment

- Regular air quality monitoring

Cost-Benefit Analysis

Long-term Value

The investment in bead blasting pays off through:

| Benefit | Cost Savings | ROI Timeline |

|---|---|---|

| Extended Part Life | 30-40% | 1-2 years |

| Reduced Maintenance | 25-35% | 6-12 months |

| Improved Performance | 20-30% | 1-3 years |

Operational Efficiency

Bead blasting improves operational efficiency by:

- Reducing downtime

- Minimizing rework

- Extending maintenance intervals

- Improving product reliability

What Safety Precautions Are Needed For Bead Blasting Operations?

Have you ever wondered why some surface finishing operations seem to have such strict safety protocols? When it comes to bead blasting, even a minor oversight in safety measures can lead to serious health risks and workplace accidents that could have been easily prevented.

Bead blasting operations require comprehensive safety measures including proper PPE, ventilation systems, enclosed cabinets, regular equipment maintenance, and thorough operator training. These precautions protect workers from respiratory hazards, flying particles, and other potential workplace dangers.

Essential Personal Protective Equipment (PPE)

Respiratory Protection

Working with bead blasting requires robust respiratory protection due to the fine particles generated during the process. At PTSMAKE, we ensure our operators wear NIOSH-certified respirators9 suitable for the specific media being used. These respirators must be properly fitted and regularly maintained to ensure maximum protection.

Eye and Face Protection

Safety goggles alone aren’t sufficient for bead blasting operations. We implement full-face shields that protect against:

- Ricocheting media

- Airborne particles

- Dust contamination

- Chemical splashes

Body Protection

Proper body protection includes:

| Protection Type | Purpose | Replacement Frequency |

|---|---|---|

| Heavy-duty gloves | Prevent abrasions and cuts | Every 3 months or when worn |

| Blast suits | Full body protection | Annually or when damaged |

| Steel-toed boots | Foot protection | Every 12-18 months |

| Hearing protection | Noise reduction | Every 6 months |

Workplace Engineering Controls

Ventilation Requirements

Proper ventilation is crucial for maintaining a safe working environment. The system should:

- Provide adequate air exchanges

- Include dust collection systems

- Maintain negative pressure in the blast cabinet

- Filter particulates effectively

Equipment Safety Features

The blast cabinet must include:

- Emergency stop buttons

- Automatic shutdown systems

- Pressure relief valves

- Proper sealing mechanisms

Operational Safety Procedures

Pre-operation Checks

Before starting any bead blasting operation, operators must:

| Check Point | Action Required | Frequency |

|---|---|---|

| Equipment integrity | Visual inspection | Daily |

| Air pressure | Gauge verification | Every session |

| Media condition | Quality assessment | Weekly |

| Safety interlocks | Functionality test | Daily |

During Operation Protocols

Maintaining safety during operation involves:

- Constant monitoring of pressure levels

- Regular checks of media flow

- Verification of ventilation system performance

- Immediate reporting of any abnormalities

Environmental Safety Considerations

Waste Management

Proper disposal of used media and collected dust is essential. We implement:

- Designated disposal containers

- Regular waste collection schedules

- Proper labeling of hazardous materials

- Environmental compliance documentation

Containment Measures

To prevent environmental contamination:

- Use sealed cabinets

- Maintain proper filtration systems

- Regular cleaning of work areas

- Proper storage of unused media

Training and Documentation

Operator Certification

All operators must complete:

- Initial safety training

- Equipment operation certification

- Regular refresher courses

- Emergency response training

Record Keeping

Maintain detailed records of:

- Training completion

- Equipment maintenance

- Safety inspections

- Incident reports

Emergency Response Procedures

First Aid Measures

Immediate response protocols for:

- Eye injuries

- Skin abrasions

- Respiratory issues

- Chemical exposure

Emergency Shutdown

Clear procedures for:

- Equipment shutdown

- Area evacuation

- Emergency services notification

- Incident reporting

Regular Maintenance and Inspection

Equipment Maintenance

Scheduled maintenance includes:

| Component | Inspection Frequency | Maintenance Tasks |

|---|---|---|

| Blast nozzles | Weekly | Check for wear, replace if needed |

| Air lines | Monthly | Inspect for leaks, test pressure |

| Filters | Bi-weekly | Clean or replace as needed |

| Cabinet seals | Monthly | Check integrity, replace if worn |

Safety System Verification

Regular testing of:

- Emergency stops

- Pressure relief systems

- Ventilation effectiveness

- Safety interlocks

At PTSMAKE, we’ve implemented these comprehensive safety measures across our bead blasting operations, resulting in an excellent safety record. Our commitment to safety extends beyond mere compliance – it’s about creating a culture where safety is everyone’s priority.

Can Bead Blasting Be Combined With Other CNC Machining Processes?

Have you ever received CNC machined parts that looked perfect dimensionally but lacked that professional, uniform finish? Or maybe you’ve struggled to achieve consistent surface treatments across complex geometries? These challenges can significantly impact your product’s final appearance and functionality.

Yes, bead blasting can be effectively combined with other CNC machining processes. This surface treatment method can be integrated before, during, or after various CNC operations to enhance both aesthetic appeal and functional properties of machined components.

Understanding the Integration of Bead Blasting in CNC Manufacturing

The Strategic Timing of Bead Blasting

The timing of when to apply bead blasting in your manufacturing process can significantly impact the final result. At PTSMAKE, we carefully evaluate each project to determine the optimal sequence. Here’s how we approach different scenarios:

| Process Stage | Benefits | Considerations |

|---|---|---|

| Pre-machining | Removes surface contaminants | May affect dimensional accuracy |

| Mid-process | Targets specific areas | Requires careful masking |

| Post-machining | Ensures uniform finish | Final step in most cases |

Compatibility with Different Materials

The effectiveness of combining bead blasting with CNC machining varies depending on the material being processed. The material hardness scale10 plays a crucial role in determining the appropriate blasting parameters.

Common Combined Applications

Aerospace Components

In aerospace applications, we often combine bead blasting with precision CNC milling. This combination helps achieve:

- Enhanced surface roughness for better coating adhesion

- Improved fatigue resistance

- Consistent appearance across complex geometries

Medical Device Manufacturing

Medical components require exceptional cleanliness and precise surface finishes. The integration process typically involves:

- Initial CNC machining for dimensional accuracy

- Controlled bead blasting for specific surface requirements

- Final precision machining for critical features

Best Practices for Combined Processing

Quality Control Measures

When combining processes, maintaining quality requires:

- Regular inspection between operations

- Documented procedures for each step

- Calibrated measuring equipment

- Controlled environment for consistent results

Process Parameter Optimization

Success in combining these processes depends on carefully controlled parameters:

| Parameter | Impact | Control Method |

|---|---|---|

| Blast Pressure | Surface texture | Digital pressure monitoring |

| Media Size | Finish consistency | Regular media screening |

| Exposure Time | Material removal | Automated timing systems |

| Nozzle Distance | Pattern uniformity | Fixed mounting fixtures |

Industry-Specific Considerations

Automotive Applications

In automotive manufacturing, we’ve found that combining these processes can:

- Improve wear resistance of engine components

- Enhance oil retention on bearing surfaces

- Create decorative finishes on visible parts

Electronics Housing Manufacturing

For electronic enclosures, the combination offers:

- Better EMI shielding properties

- Improved heat dissipation

- Enhanced paint adhesion for cosmetic finishes

Cost-Efficiency Analysis

Production Volume Considerations

The integration of bead blasting with CNC machining affects costs differently based on production volume:

| Volume Level | Cost Impact | Efficiency Gain |

|---|---|---|

| Prototype | Higher per-unit | Faster iteration |

| Small Batch | Moderate | Improved quality |

| Mass Production | Lower per-unit | Streamlined process |

Equipment Investment

Implementing combined processes requires:

- Multi-purpose CNC machinery

- Dedicated blasting equipment

- Material handling systems

- Quality control instruments

Environmental and Safety Considerations

Dust Control and Collection

Proper implementation requires:

- Advanced filtration systems

- Regular maintenance schedules

- Proper disposal procedures

- Environmental compliance monitoring

Worker Safety Protocols

Essential safety measures include:

- Personal protective equipment

- Regular training programs

- Environmental monitoring

- Emergency response procedures

Future Trends and Innovations

The integration of bead blasting with CNC machining continues to evolve with:

- Automated process control systems

- Advanced media composition development

- Improved surface finish measurement techniques

- Integration with digital manufacturing systems

Click to learn how air pressure technology enhances surface finishing quality. ↩

Click to learn more about work hardening and its crucial role in material enhancement. ↩

Click here to learn optimal surface roughness parameters for different applications. ↩

Click here to learn about how surface complexity affects your project costs and timeline. ↩

Click to learn more about surface treatment physics and optimization techniques. ↩

Click to learn advanced surface treatment techniques for optimal manufacturing results. ↩

Click to learn more about surface protection through passive film formation and maintenance techniques. ↩

Click here to learn advanced surface treatment techniques that can maximize your parts’ lifespan. ↩

Click here to learn about respirator certification standards and selection guidelines. ↩

Click to learn more about material hardness testing methods and their importance in manufacturing. ↩