In our machine shop, I often meet customers who struggle with achieving ultra-precise cuts in tough metals. Many of them have tried various cutting methods but still can’t get the accuracy they need, especially for complex shapes and intricate details.

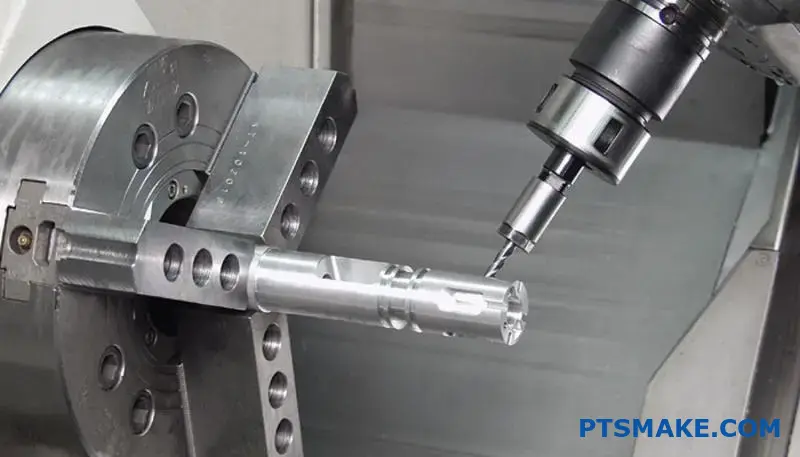

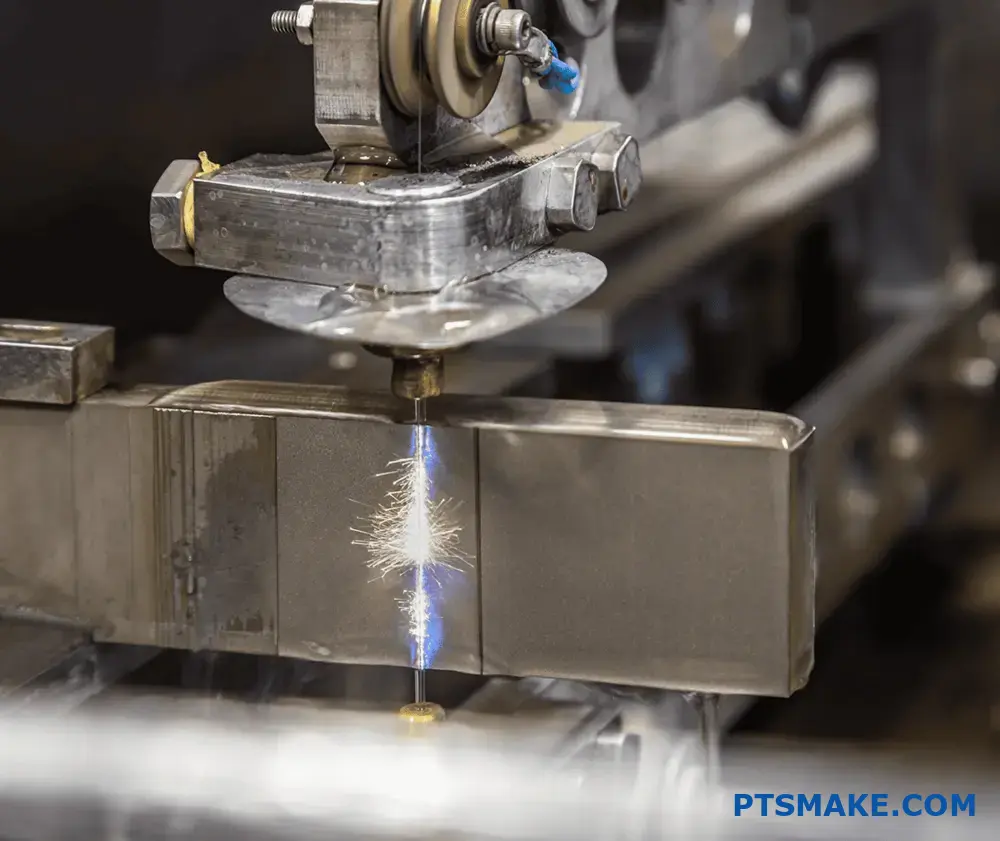

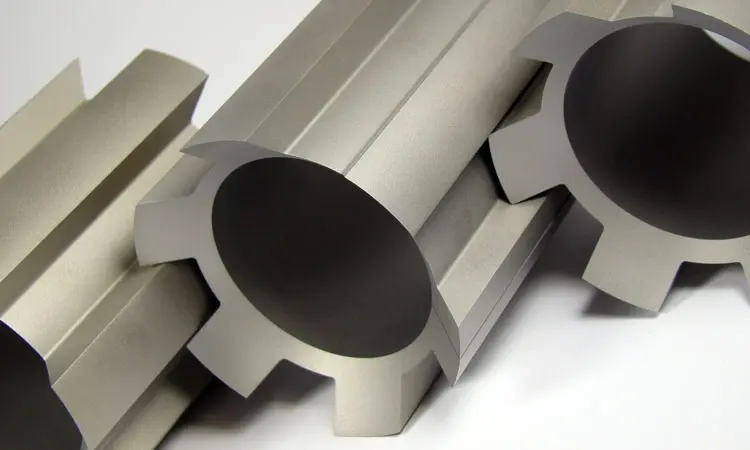

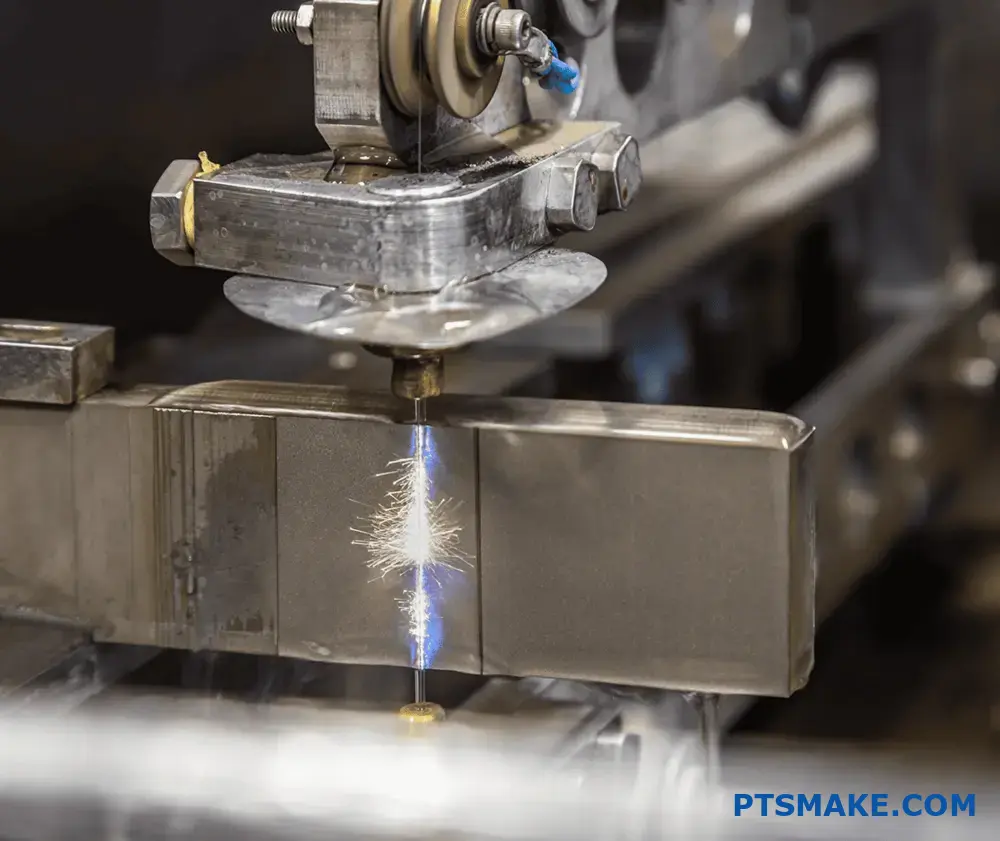

EDM Wire Cutting, also known as Wire EDM or Wire-cut EDM, is a precision machining process that uses electrically charged wire to cut through conductive materials. This method creates highly accurate parts with excellent surface finishes, particularly useful for complex shapes and hard metals.

I know you might be wondering why EDM wire cutting stands out among other machining methods. Let me explain its unique advantages. This technology allows us to cut parts with tolerances as tight as ±0.0001 inches, which is crucial for aerospace components, medical devices, and precision tooling. As the wire never directly contacts the workpiece, we can achieve exceptional accuracy without mechanical stress.

What Thickness Wire Is Used For EDM Cutting?

Have you ever found yourself staring at an EDM wire cutting machine, wondering if you’re using the right wire thickness? This common dilemma can lead to wasted materials, poor surface finishes, and even damaged workpieces when the wrong choice is made.

For EDM wire cutting, the most commonly used wire thickness ranges from 0.1mm to 0.3mm, with 0.25mm being the standard choice for general applications. The selection depends on factors like material thickness, required accuracy, and cutting speed requirements.

Understanding Wire EDM Thickness Options

The selection of wire thickness in EDM cutting plays a crucial role in achieving optimal results. At PTSMAKE, we’ve developed extensive expertise in wire EDM cutting through years of precision manufacturing experience. Let’s explore the various aspects of wire thickness selection.

Common Wire Diameters and Their Applications

| Wire Diameter (mm) | Best Applications | Typical Materials |

|---|---|---|

| 0.10 – 0.15 | Micro-precision parts, jewelry | Precious metals, thin materials |

| 0.20 – 0.25 | General purpose cutting | Steel, aluminum, brass |

| 0.30 – 0.33 | Heavy-duty cutting | Thick materials, carbide |

Factors Influencing Wire Selection

Material Thickness

The thickness of your workpiece significantly impacts wire selection. Thicker materials generally require larger diameter wires to maintain stability during cutting. The kerf width1 produced by the wire must also be considered for precise dimensional accuracy.

Cutting Speed Requirements

Thicker wires typically allow for faster cutting speeds as they can handle higher power inputs without breaking. However, this comes at the cost of reduced precision and wider cutting paths.

Surface Finish Considerations

Wire diameter directly affects surface finish quality:

- Thinner wires (0.1-0.15mm) produce finer surface finishes

- Standard wires (0.25mm) offer good balance between finish and speed

- Thicker wires (0.3mm+) may require additional finishing operations

Economic Considerations

Cost-Performance Analysis

Different wire thicknesses come with varying cost implications:

- Thinner wires are more expensive per meter

- Higher break rates in thin wires increase operational costs

- Thicker wires offer better cost efficiency for rough cutting

Productivity Impact

Wire thickness affects overall productivity through:

- Cutting speed capabilities

- Machine downtime due to wire breaks

- Required number of cutting passes

Application-Specific Guidelines

Aerospace Components

For aerospace applications, we typically recommend:

- 0.25mm wire for general components

- 0.1mm wire for critical, high-precision features

- Multiple cutting passes for superior surface finish

Medical Device Manufacturing

Medical components often require:

- 0.15-0.20mm wire for intricate features

- Strict adherence to surface finish requirements

- Enhanced accuracy for critical dimensions

Automotive Parts

Automotive industry applications usually utilize:

- 0.25-0.30mm wire for robust cutting

- Balance between speed and accuracy

- Cost-effective solutions for high-volume production

Best Practices for Wire Selection

To optimize your EDM wire cutting process:

- Always consider the material properties

- Calculate the required accuracy

- Evaluate the economic factors

- Test different wire sizes for optimal results

- Monitor wire performance during cutting

Performance Optimization Tips

To maximize EDM cutting performance:

- Regular machine maintenance

- Proper wire tension adjustment

- Clean dielectric fluid

- Appropriate power settings

- Correct wire feed rates

Technical Specifications

Essential parameters to consider:

| Parameter | Thin Wire (<0.2mm) | Standard Wire (0.25mm) | Thick Wire (>0.3mm) |

|---|---|---|---|

| Cutting Speed | Slow | Medium | Fast |

| Surface Finish | Excellent | Good | Fair |

| Cost per Meter | High | Medium | Low |

| Break Resistance | Low | Medium | High |

At PTSMAKE, we maintain a comprehensive inventory of various wire thicknesses to meet diverse manufacturing needs. Our experienced engineers can help select the optimal wire thickness for your specific application, ensuring the best balance of accuracy, speed, and cost-effectiveness.

How Accurate is EDM Wire Cut?

Have you ever struggled to achieve ultra-precise cuts in hard metals or complex geometries? The frustration of dealing with traditional machining methods that fall short of your exacting specifications can be overwhelming, especially when your project demands absolute precision.

EDM wire cutting typically achieves accuracies between ±0.0001 to ±0.0003 inches (0.0025 to 0.0076 mm), making it one of the most precise machining processes available for creating intricate parts with exceptional dimensional accuracy.

Understanding EDM Wire Cut Accuracy Factors

The accuracy of EDM wire cutting depends on several critical factors that work together to deliver precise results. In my experience working with various dielectric fluids2 and machine configurations, I’ve identified key elements that influence cutting accuracy:

Machine Stability and Environmental Control

- Temperature control (±1°C variation maximum)

- Vibration isolation systems

- Humidity regulation (45-55% optimal range)

- Clean room conditions where necessary

Wire Properties and Characteristics

The wire electrode’s properties significantly impact cutting accuracy:

| Wire Type | Typical Diameter (mm) | Accuracy Range (μm) | Best Applications |

|---|---|---|---|

| Brass | 0.1 – 0.3 | ±2.5 – 5 | General purpose cutting |

| Zinc-coated | 0.1 – 0.25 | ±2 – 4 | High-speed cutting |

| Tungsten | 0.02 – 0.1 | ±1 – 2.5 | Micro-cutting |

Advanced Control Systems and Monitoring

Modern EDM wire cutting machines employ sophisticated control systems that continuously monitor and adjust cutting parameters:

Real-time Parameter Adjustment

- Wire tension control

- Spark gap monitoring

- Feed rate optimization

- Surface finish tracking

Quality Assurance Measures

At PTSMAKE, we implement comprehensive quality control procedures:

- In-process measurement systems

- Post-cut CMM verification

- Surface roughness testing

- Geometric tolerance validation

Practical Applications and Tolerance Achievements

Different industries require varying levels of precision:

Aerospace Components

- Turbine blade profiles: ±0.005mm

- Fuel injection nozzles: ±0.003mm

- Structural components: ±0.01mm

Medical Device Manufacturing

- Surgical instruments: ±0.004mm

- Implant components: ±0.002mm

- Micro-tools: ±0.001mm

Optimizing EDM Wire Cut Accuracy

To achieve maximum accuracy, consider these essential practices:

Material Preparation

- Proper stress relief

- Surface cleanliness

- Material homogeneity verification

- Proper workpiece mounting

Operating Parameters

| Parameter | Optimal Range | Impact on Accuracy |

|---|---|---|

| Wire Speed | 2-12 m/min | High |

| Power Settings | 2-8 A | Critical |

| Wire Tension | 1200-1800g | Significant |

| Flush Pressure | 0.5-2.0 MPa | Moderate |

Common Accuracy Challenges and Solutions

Understanding potential issues helps maintain consistent accuracy:

Environmental Factors

- Temperature fluctuations

- Vibration interference

- Electromagnetic disturbances

- Humidity variations

Material-Related Issues

- Internal stress

- Non-uniform hardness

- Material impurities

- Thermal expansion

Industry-Specific Requirements

Different sectors have unique accuracy demands:

Automotive Industry

- Transmission components: ±0.008mm

- Engine parts: ±0.005mm

- Tooling components: ±0.003mm

Electronics Manufacturing

- Semiconductor tools: ±0.002mm

- Connector molds: ±0.004mm

- Testing equipment: ±0.003mm

At PTSMAKE, we consistently achieve these tolerances through:

- Regular machine calibration

- Operator training programs

- Environmental monitoring

- Quality control protocols

Future Trends in EDM Wire Cut Accuracy

The industry continues to evolve with:

- AI-powered control systems

- Advanced wire materials

- Improved sensor technology

- Enhanced automation capabilities

These developments promise even greater accuracy levels, potentially reaching sub-micron precision in specialized applications. The combination of traditional expertise and modern technology enables unprecedented levels of precision in EDM wire cutting operations.

What Materials Can Be Cut With EDM Wire?

Have you ever faced the challenge of cutting extremely hard metals or complex shapes that seem impossible with traditional machining methods? Many engineers find themselves stuck when conventional cutting tools fail to deliver the precision they need, especially with demanding materials.

EDM wire cutting can effectively process any electrically conductive material, including hardened steel, titanium, copper alloys, and tungsten carbide. This non-contact machining method uses electrical discharges to remove material, achieving exceptional precision regardless of material hardness.

Commonly Cut Materials in Wire EDM

Wire EDM has revolutionized the way we approach precision cutting in manufacturing. As someone who oversees numerous EDM projects, I’ve compiled a comprehensive list of materials that work well with this technology:

Metals and Alloys

Tool Steels

- D2, M2, and H13 tool steels

- CPM steels

- High-speed steels (HSS)

These materials are extensively used in making cutting tools and dies. The dielectric fluid3 used in the process helps maintain consistent cutting conditions.

Stainless Steels

- 304 and 316 grades

- Precipitation-hardened variants

- Martensitic stainless steels

Advanced Materials

| Material Type | Typical Applications | Advantages of EDM |

|---|---|---|

| Titanium Alloys | Aerospace components | No mechanical stress |

| Inconel | Turbine parts | High precision cuts |

| Carbide | Cutting tools | Perfect for hard materials |

| Brass | Electrical components | Smooth surface finish |

Material Properties That Affect EDM Cutting

Electrical Conductivity

The material’s electrical conductivity directly impacts the cutting efficiency. Materials with higher conductivity typically achieve:

- Faster cutting speeds

- Better surface finish

- More consistent results

Material Thickness

Different materials have varying optimal cutting parameters based on thickness:

| Thickness Range (mm) | Typical Cutting Speed | Power Settings |

|---|---|---|

| 0.5 – 10 | Fast | Low to Medium |

| 10 – 50 | Medium | Medium |

| 50+ | Slow | High |

Heat Treatment Condition

The material’s heat treatment status affects the cutting process:

- Annealed materials often cut more consistently

- Hardened materials may require adjusted parameters

- Post-heat treatment might be necessary

Special Considerations for Different Materials

Composite Materials

When working with composite materials:

- Ensure proper grounding

- Monitor cutting parameters closely

- Consider potential delamination risks

Exotic Alloys

For specialized alloys like Hastelloy or Waspaloy:

- Adjust cutting parameters

- Use appropriate wire types

- Monitor material removal rate

Material-Specific Cutting Parameters

Speed vs. Material Hardness

| Material Hardness (HRC) | Relative Cutting Speed | Wire Type Recommendation |

|---|---|---|

| 20-35 | High | Brass or Coated |

| 35-50 | Medium | Coated or Stratified |

| 50+ | Low | High-Performance Coated |

Surface Finish Considerations

Different materials require specific approaches for optimal surface finish:

- Softer materials might need multiple finishing passes

- Harder materials often achieve better surface finish naturally

- Grain structure impacts final surface quality

Industry-Specific Applications

Aerospace

In aerospace applications, we commonly cut:

- Titanium components

- High-strength aluminum

- Heat-resistant superalloys

Medical

Medical device manufacturing requires:

- Surgical-grade stainless steel

- Titanium implant materials

- Specialized biocompatible alloys

Automotive

Common automotive applications include:

- Tool steel for dies

- Hardened steel components

- Precision transmission parts

Best Practices for Material Selection

To ensure successful EDM wire cutting:

- Verify material conductivity

- Consider material thickness

- Account for heat treatment requirements

- Select appropriate wire type

- Optimize cutting parameters

At PTSMAKE, we maintain strict material handling protocols to ensure optimal results across all EDM wire cutting projects. Our experience with diverse materials allows us to provide precise recommendations for specific applications.

What Are The Advantages And Disadvantages Of Wire Cut EDM?

Have you ever struggled with machining extremely hard materials or creating intricate shapes with tight tolerances? Traditional machining methods often fall short when dealing with complex geometries, leaving engineers frustrated and projects delayed.

Wire Cut EDM (Electrical Discharge Machining) is a non-conventional machining process that uses electrical discharges to remove material, offering unique advantages in precision and capability but also coming with certain limitations in speed and cost.

Core Advantages of Wire Cut EDM

Precision and Accuracy

Wire EDM achieves exceptional accuracy with tolerances as tight as ±0.0001 inches. This level of precision is crucial for industries like aerospace and medical device manufacturing. The process excels in creating complex shapes and intricate details that would be impossible with conventional machining methods.

Material Versatility

One of the most significant advantages is the ability to cut any electrically conductive material, regardless of its hardness. The electrical conductivity4 of the material determines the cutting speed and efficiency. This makes it ideal for:

- Hardened steels

- Titanium alloys

- Carbide materials

- Exotic metals

No Direct Contact

Unlike traditional cutting methods, wire EDM doesn’t make physical contact with the workpiece during machining. This eliminates:

- Mechanical stress

- Tool wear

- Cutting force issues

- Surface deformation

Key Limitations and Challenges

Speed Constraints

The material removal rate in wire EDM is relatively slow compared to conventional machining methods. Here’s a comparative analysis:

| Machining Method | Material Removal Rate (mm³/min) | Surface Finish (Ra) |

|---|---|---|

| Wire EDM | 2-300 | 0.1-0.8 µm |

| CNC Milling | 1000-5000 | 0.4-1.6 µm |

| Conventional Turning | 800-3000 | 0.5-1.8 µm |

Cost Considerations

The operational costs of wire EDM can be higher than traditional machining methods due to:

- Expensive wire consumables

- Higher energy consumption

- Deionized water maintenance

- Longer machining times

Material Limitations

Despite its versatility with conductive materials, wire EDM has some restrictions:

- Cannot machine non-conductive materials

- Requires minimum material thickness

- May cause heat-affected zones in certain materials

Application-Specific Considerations

Industry Applications

Wire EDM finds extensive use in various industries:

Aerospace

- Engine components

- Turbine parts

- Structural elements

Medical

- Surgical instruments

- Implant components

- Custom medical devices

Automotive

- Precision engine parts

- Tool and die making

- Prototype development

Quality and Surface Finish

The process can achieve excellent surface finishes, but several factors affect the final quality:

- Wire diameter selection

- Power settings

- Cutting speed

- Material properties

Environmental Impact

Wire EDM has both positive and negative environmental aspects:

Positive:

- Minimal waste material

- No cutting fluids required

- Lower noise pollution

Negative:

- High energy consumption

- Wire disposal considerations

- Water treatment requirements

Process Optimization Strategies

Parameter Selection

Optimal results require careful consideration of:

- Wire type and diameter

- Power settings

- Wire tension

- Cutting speed

- Flushing pressure

Maintenance Requirements

Regular maintenance is crucial for consistent performance:

- Wire guide alignment

- Filter system cleaning

- Water quality monitoring

- Machine calibration

Cost Reduction Methods

Several strategies can help optimize costs:

- Batch processing similar parts

- Optimizing nesting arrangements

- Minimizing wire consumption

- Implementing automated systems

Future Developments

The wire EDM technology continues to evolve with:

- Advanced control systems

- Improved wire materials

- Better power supply efficiency

- Enhanced automation capabilities

At PTSMAKE, we’ve implemented these advanced wire EDM capabilities to deliver precise, complex parts for our clients across various industries. Our expertise in optimizing wire EDM processes ensures we maintain the balance between quality, cost, and delivery time.

How Does EDM Wire Cutting Compare To Traditional Machining Methods?

Have you ever struggled with machining complex, high-precision parts using traditional methods? When dealing with hardened materials or intricate geometries, conventional machining can lead to tool wear, material waste, and frustrating quality issues.

EDM wire cutting offers superior precision and capability for complex geometries compared to traditional machining methods. This non-contact process can achieve tolerances as tight as ±0.0001 inches while working with any conductive material, regardless of hardness.

Understanding the Core Differences

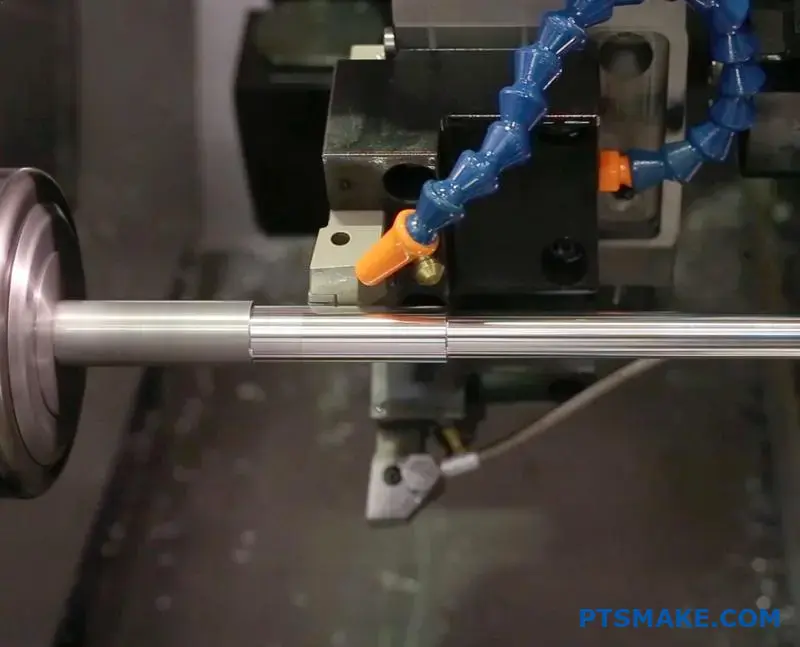

Process Mechanics

Traditional machining relies on physical contact between cutting tools and workpieces, while EDM wire cutting uses electrical discharge to remove material. The dielectric fluid5 in EDM creates a controlled environment for precise material removal without direct tool contact.

Material Capabilities

Traditional machining methods face limitations when working with:

- Hardened materials

- Heat-sensitive components

- Complex geometries

- Extremely thin walls

EDM wire cutting excels in these scenarios because it:

- Works independently of material hardness

- Generates minimal heat affect zone

- Maintains consistent accuracy

- Produces no cutting forces

Performance Comparison

Here’s a detailed comparison of key performance metrics:

| Aspect | EDM Wire Cutting | Traditional Machining |

|---|---|---|

| Surface Finish | Ra 0.1-0.8 μm | Ra 0.4-3.2 μm |

| Tolerance Capability | ±0.0001 inches | ±0.0005 inches |

| Material Hardness Limit | No limit (conductive only) | Limited by tool hardness |

| Setup Time | Longer initial setup | Generally faster setup |

| Production Speed | Slower removal rate | Faster for simple geometries |

Cost Considerations

Initial Investment

EDM wire cutting machines typically require higher initial investment than traditional CNC machines. At PTSMAKE, we’ve carefully balanced our equipment portfolio to offer both options, ensuring cost-effective solutions for different project requirements.

Operating Costs

The operating costs include:

- Wire consumption

- Dielectric fluid maintenance

- Power consumption

- Labor costs

- Maintenance requirements

Traditional machining often involves:

- Cutting tool replacement

- Coolant costs

- Higher power consumption

- More frequent maintenance

Production Economics

The economics of each process depends on:

- Part complexity

- Material properties

- Production volume

- Quality requirements

For instance, when machining hardened steel components with complex geometries, EDM wire cutting often proves more economical despite slower cutting speeds, as it eliminates the need for multiple setups and tool changes.

Application-Specific Advantages

Precision Parts Manufacturing

EDM wire cutting excels in applications requiring:

- Micro-features

- Sharp internal corners

- Thin walls

- Complex profiles

Prototype Development

For prototype development, EDM wire cutting offers:

- Flexibility in design changes

- Minimal tooling requirements

- Consistent accuracy

- Reduced setup modifications

Production Considerations

Key factors influencing process selection:

Part Geometry

- Simple shapes favor traditional machining

- Complex profiles benefit from EDM

Material Properties

- Soft materials work well with traditional methods

- Hardened materials often require EDM

Quality Requirements

- High-precision needs favor EDM

- Standard tolerances suit traditional machining

Integration with Modern Manufacturing

EDM wire cutting complements traditional machining in modern manufacturing environments. At PTSMAKE, we often combine both technologies to optimize production efficiency. For example, we might rough-cut a part using traditional methods before achieving final precision with EDM wire cutting.

Hybrid Manufacturing Approaches

Modern manufacturing often requires a combination of processes:

- Initial shaping with traditional methods

- Precision features via EDM wire cutting

- Final surface finishing as needed

Quality Control Integration

Both processes require different quality control approaches:

- Traditional machining focuses on tool wear monitoring

- EDM wire cutting emphasizes wire condition and electrical parameters

Future Trends

The manufacturing industry continues to evolve with:

- Advanced CNC controls

- Automated wire threading

- Improved cutting speeds

- Enhanced surface finish capabilities

What Surface Finish Quality Can Be Achieved With EDM Wire Cutting?

Have you ever struggled to achieve the perfect surface finish with traditional machining methods? It’s frustrating when your parts show tool marks, scratches, or inconsistent surface quality, especially for high-precision components where every micron matters.

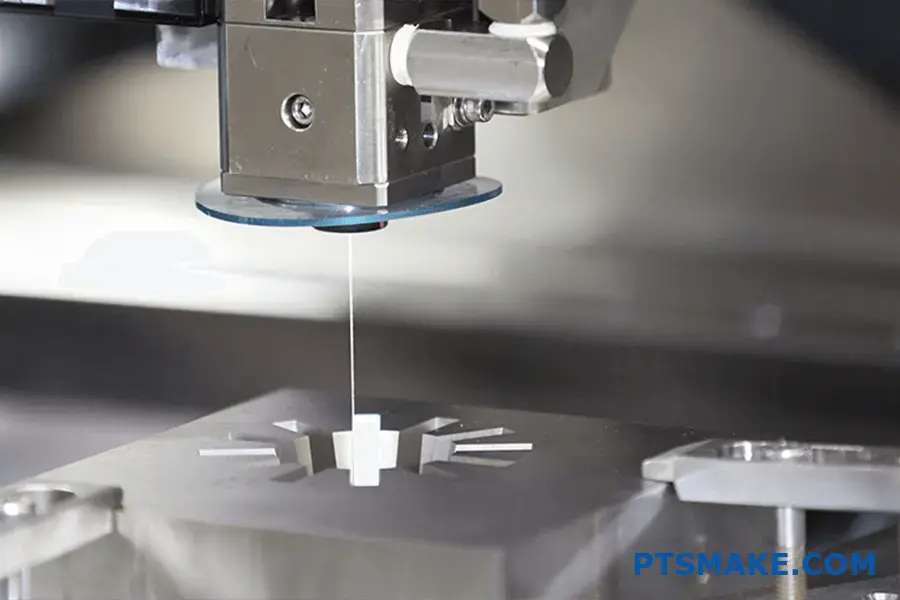

EDM wire cutting can achieve surface finishes as fine as 0.1 μm Ra (0.004 μin), making it ideal for precision components. The process delivers consistent, mirror-like surfaces without mechanical stress or tool marks, particularly valuable for medical and aerospace applications.

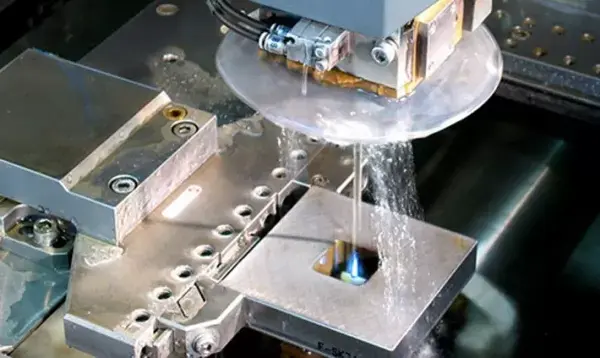

Understanding Surface Finish in Wire EDM

Surface finish quality in wire EDM depends on several key factors. The dielectric fluid6 circulation, wire electrode material, and machine parameters all play crucial roles in achieving the desired surface finish.

Key Parameters Affecting Surface Quality

Power Settings

- Peak current

- Pulse duration

- Pulse frequency

- Gap voltage

Wire Characteristics

- Wire material type

- Wire diameter

- Wire tension

Machine Variables

- Cutting speed

- Flushing pressure

- Wire feed rate

Surface Finish Classification

Different applications require varying levels of surface finish. Here’s a comprehensive breakdown:

| Grade | Ra Value (μm) | Typical Applications |

|---|---|---|

| N12 | 50.0 | Rough cutting |

| N10 | 12.5 | General machining |

| N8 | 3.2 | Semi-finishing |

| N6 | 0.8 | Finishing |

| N4 | 0.2 | Mirror finishing |

Multiple-Pass Strategy for Superior Finish

At PTSMAKE, we implement a strategic multi-pass approach to achieve premium surface finishes:

First Cut (Rough Cut)

- Higher power settings

- Faster cutting speed

- Focuses on material removal

- Ra value typically 3.0-4.0 μm

Second Pass (Semi-Finish)

- Reduced power settings

- Moderate cutting speed

- Removes previous cut marks

- Ra value typically 1.0-2.0 μm

Final Pass (Fine Finish)

- Minimal power settings

- Slow cutting speed

- Ultra-precise surface generation

- Ra value can reach 0.1-0.2 μm

Industry-Specific Requirements

Different industries demand specific surface finish qualities:

Aerospace Components

- Typically requires N6-N4 finish

- Critical for fatigue resistance

- Ensures aerodynamic efficiency

- Maintains structural integrity

Medical Devices

- Often demands N4 finish

- Essential for biocompatibility

- Prevents bacterial growth

- Facilitates sterilization

Mold and Die Industry

- Varies from N8 to N4

- Affects plastic part quality

- Influences material flow

- Impacts tool longevity

Best Practices for Optimal Surface Finish

Wire Selection

- Premium brass wire for general applications

- Zinc-coated wire for enhanced surface finish

- Tungsten wire for ultra-precise cuts

Machine Maintenance

- Regular calibration

- Clean dielectric system

- Proper wire disposal

- Stable environmental conditions

Process Optimization

- Appropriate parameter selection

- Consistent wire tension

- Optimal flushing conditions

- Regular quality checks

Surface Finish Measurement and Verification

To ensure consistent quality, we employ various measurement techniques:

Contact Methods

- Profilometers

- Surface roughness testers

- Stylus instruments

Non-Contact Methods

- Optical microscopes

- 3D surface mapping

- Digital imaging analysis

Common Surface Finish Challenges and Solutions

Wire Breakage Issues

- Solution: Adjust cutting parameters

- Implement proper wire tension

- Ensure clean dielectric fluid

Surface Irregularities

- Solution: Review power settings

- Check flushing effectiveness

- Verify wire condition

Inconsistent Finish

- Solution: Stabilize machine parameters

- Monitor environmental conditions

- Maintain consistent wire feed

Cost Considerations vs. Surface Quality

While achieving superior surface finish is possible, it’s important to balance quality with cost-effectiveness:

Economic Factors

- Machine time

- Wire consumption

- Power usage

- Labor costs

Quality-Cost Trade-offs

- Number of passes required

- Processing speed

- Material specifications

- Final application requirements

How To Choose The Right EDM Wire Cutting Service Provider?

Have you ever received EDM wire-cut parts that failed to meet your specifications? Or worse, dealt with delays that threw your entire production schedule into chaos? These situations can be frustrating and costly, especially when you’re working on time-sensitive projects.

Choosing the right EDM wire cutting service provider requires evaluating their technical capabilities, experience, quality control systems, and customer service. The ideal partner should have advanced equipment, proven expertise, and a track record of delivering precise parts on schedule.

Understanding Technical Capabilities

When selecting an EDM wire cutting service provider, their technical capabilities should be your first consideration. A provider’s equipment and expertise directly impact the quality of your parts.

Machine Specifications

Modern EDM wire cutting machines should feature:

- High-precision positioning systems

- Advanced wire threading capabilities

- Automatic Wire Tension Control7

- Multi-axis cutting capabilities

Material Processing Expertise

The provider should demonstrate expertise in working with various materials:

| Material Type | Typical Applications | Maximum Thickness |

|---|---|---|

| Tool Steel | Dies and Molds | Up to 400mm |

| Carbide | Cutting Tools | Up to 150mm |

| Aluminum | Aerospace Parts | Up to 300mm |

| Copper | Electrical Components | Up to 200mm |

Quality Control Systems

Quality control is crucial in EDM wire cutting. At PTSMAKE, we maintain strict quality standards through:

Inspection Equipment

- CMM machines for dimensional verification

- Surface roughness testers

- Optical measuring systems

Documentation and Certification

- ISO 9001:2015 certification

- Detailed inspection reports

- Material certifications

- Process control documentation

Production Capacity and Lead Times

Consider the provider’s ability to handle your production needs:

Capacity Indicators

- Number of EDM machines

- Operating hours

- Skilled operator availability

- Maintenance schedules

Customer Service and Communication

Effective communication is essential for successful projects. Look for providers that offer:

Communication Channels

- Dedicated project managers

- Regular progress updates

- Technical consultation

- Quick response to queries

Project Management

- Clear timeline commitments

- Transparent pricing

- Problem-solving capabilities

- Change management procedures

Cost Considerations

While price shouldn’t be the only factor, understanding cost structures is important:

| Service Level | Features | Typical Applications |

|---|---|---|

| Standard | Basic cutting services | Simple geometries |

| Premium | Enhanced precision | Complex parts |

| Express | Expedited delivery | Urgent projects |

Industry Experience and Reputation

Evaluate the provider’s standing in the industry:

Key Indicators

- Years in business

- Industry certifications

- Client testimonials

- Portfolio of completed projects

Geographic Location and Logistics

Consider practical aspects of working with the provider:

Location Factors

- Shipping capabilities

- Import/export experience

- Time zone differences

- Local regulations compliance

Environmental and Safety Compliance

Responsible providers maintain:

- Proper waste disposal systems

- Worker safety protocols

- Environmental certifications

- Regular safety audits

Technology Integration

Modern EDM wire cutting services should offer:

Digital Capabilities

- CAD/CAM integration

- Online order tracking

- Digital quality reports

- File transfer systems

Trial Orders and Sampling

Before committing to large projects:

- Request sample parts

- Evaluate surface finish

- Check dimensional accuracy

- Assess communication efficiency

At PTSMAKE, we encourage potential clients to start with small orders to experience our service quality firsthand. This approach helps build trust and ensures we meet your specific requirements before scaling up to larger projects.

By carefully evaluating these aspects, you can select an EDM wire cutting service provider that meets your needs and contributes to your project’s success.

What Maintenance Is Required For EDM Wire Cutting Machines?

Have you ever experienced unexpected breakdowns with your EDM wire cutting machine right in the middle of a critical project? The frustration of production delays and inconsistent cutting quality can be overwhelming, especially when tight deadlines are looming.

EDM wire cutting machines require regular maintenance focused on five key areas: dielectric fluid system, wire drive system, machine guides, electrical components, and mechanical parts. Proper maintenance ensures optimal cutting performance, extends machine life, and prevents costly downtime.

Understanding Dielectric Fluid Maintenance

The dielectric fluid system is crucial for EDM wire cutting operations. Regular maintenance of this system includes:

Filter Replacement

- Checking filter condition weekly

- Replacing filters according to manufacturer specifications

- Monitoring fluid pressure and flow rates

Fluid Quality Control

The conductivity level8 of the dielectric fluid must be maintained within specified ranges for optimal cutting performance. At PTSMAKE, we implement a strict fluid testing schedule:

| Testing Parameter | Frequency | Acceptable Range |

|---|---|---|

| Conductivity | Daily | 10-15 μS/cm |

| pH Level | Weekly | 7.0-8.5 |

| Temperature | Continuous | 20-25°C |

Wire Drive System Maintenance

Wire Feed Mechanism

Regular inspection and cleaning of:

- Wire guides

- Feed rollers

- Tension control system

- Wire collection bin

Tension Adjustment

Proper wire tension is essential for accurate cuts. I recommend checking tension settings:

- Before each new job

- After wire type changes

- When cutting parameters change significantly

Machine Guide Maintenance

Upper and Lower Guide Maintenance

- Daily cleaning of guide surfaces

- Weekly inspection for wear

- Monthly calibration checks

- Quarterly replacement schedule

Alignment Verification

Proper guide alignment ensures cutting accuracy:

| Alignment Check | Method | Frequency |

|---|---|---|

| X-Y Squareness | Test cut | Monthly |

| Z-axis Travel | Dial indicator | Bi-weekly |

| Table Flatness | Level gauge | Monthly |

Electrical Component Care

Power Supply System

- Regular inspection of electrical connections

- Cleaning of power contact points

- Verification of voltage stability

- Testing of emergency stop systems

Control System Maintenance

- Backup of machine parameters

- Software updates installation

- Calibration of measuring systems

- Verification of communication interfaces

Mechanical Components

Machine Structure

- Checking for structural integrity

- Lubricating moving parts

- Inspecting seals and gaskets

- Verifying table movement

Axis System

- Linear guide maintenance

- Ball screw lubrication

- Bearing inspection

- Drive system checks

Preventive Maintenance Schedule

I’ve developed a comprehensive maintenance schedule based on machine usage:

| Component | Daily | Weekly | Monthly | Quarterly |

|---|---|---|---|---|

| Dielectric System | Check levels | Clean tanks | Replace filters | Full system flush |

| Wire System | Clean guides | Check tension | Replace guides | Calibrate feed |

| Electronics | Visual inspection | Test safety | Check connections | Full diagnostic |

| Mechanics | Clean workspace | Lubricate | Align table | Overhaul check |

Documentation and Record Keeping

Maintaining detailed maintenance records is crucial. At PTSMAKE, we document:

- All maintenance activities

- Machine performance data

- Part quality metrics

- Downtime incidents

- Repair histories

Environmental Considerations

Proper maintenance also includes environmental factors:

- Temperature control (20-25°C)

- Humidity regulation (40-60%)

- Dust prevention

- Vibration isolation

Training Requirements

Effective maintenance requires properly trained personnel. Key training areas include:

- Basic machine operation

- Troubleshooting procedures

- Safety protocols

- Emergency response

- Preventive maintenance techniques

Cost Management

Implementing a structured maintenance program helps control costs by:

- Reducing unexpected downtime

- Extending machine life

- Optimizing consumable usage

- Improving part quality

- Minimizing scrap rates

Through systematic maintenance practices at PTSMAKE, we’ve achieved significant improvements in machine reliability and cutting precision. Regular maintenance not only ensures consistent performance but also maximizes the return on investment in EDM wire cutting technology.

Can EDM Wire Cutting Reduce Production Lead Times For Prototyping?

Have you ever faced frustrating delays in your prototyping projects due to complex cutting requirements? Traditional machining methods often struggle with intricate shapes and hard materials, leading to extended production timelines and missed deadlines. These challenges can significantly impact your product development cycle.

EDM wire cutting can significantly reduce production lead times for prototyping by up to 50% compared to conventional machining methods. This technology enables precise cutting of complex shapes in hard materials without mechanical stress, allowing for faster prototype iteration and development.

Understanding EDM Wire Cutting Technology

EDM wire cutting, also known as wire electrical discharge machining, represents a breakthrough in precision manufacturing. This process uses dielectric fluid9 to facilitate controlled electrical discharges between a wire electrode and the workpiece. At PTSMAKE, we’ve integrated this technology into our prototyping services to deliver faster turnaround times while maintaining exceptional accuracy.

Key Components of EDM Wire Cutting

- Wire Electrode

- Dielectric System

- Power Generator

- CNC Control System

- Workpiece Fixturing

Speed Advantages in Prototyping

The efficiency of EDM wire cutting becomes particularly evident when working with:

Complex Geometries

Traditional machining methods often require multiple setups and tool changes for complex shapes. EDM wire cutting can create intricate profiles in a single operation, significantly reducing setup time and overall production duration.

Hard Materials Processing

When working with hardened steels or super alloys, conventional cutting tools may wear quickly or break. EDM wire cutting bypasses these limitations by using electrical erosion rather than mechanical force.

Comparative Analysis of Production Times

| Manufacturing Method | Setup Time | Cutting Speed | Post-Processing | Total Lead Time |

|---|---|---|---|---|

| EDM Wire Cutting | 1-2 hours | 15-30 mm²/min | Minimal | 1-3 days |

| Traditional Milling | 2-4 hours | Varies | Extensive | 3-7 days |

| Laser Cutting | 1 hour | 40-60 mm²/min | Moderate | 2-4 days |

Quality Benefits During Prototyping

Surface Finish Consistency

The controlled erosion process of EDM wire cutting produces consistent surface finishes, typically achieving:

- Surface roughness as low as 0.2μm

- No burrs or mechanical stress

- Uniform texture across all cut surfaces

Dimensional Accuracy

Modern EDM wire cutting machines can achieve:

- Positioning accuracy of ±0.001mm

- Cut width tolerance of ±0.002mm

- Repeatability within 0.001mm

Cost-Effectiveness Considerations

While the initial investment in EDM wire cutting equipment is substantial, the technology offers several cost advantages for prototyping:

Direct Cost Savings

- Reduced labor costs due to automated operation

- Lower tooling expenses compared to conventional machining

- Minimal material waste

- Decreased need for secondary operations

Indirect Cost Benefits

- Faster time-to-market

- Reduced prototype iteration cycles

- Lower risk of errors and scrap

- Improved design validation capability

Application-Specific Advantages

Aerospace Prototypes

The aerospace industry demands extremely precise components with complex geometries. EDM wire cutting excels in creating:

- Turbine components

- Structural brackets

- Heat exchanger parts

- Precision mounting fixtures

Medical Device Development

For medical prototypes, EDM wire cutting provides:

- Sterile surface characteristics

- Complex surgical instrument components

- Implant device parts

- Custom fixture requirements

Best Practices for Optimal Results

To maximize the benefits of EDM wire cutting in prototyping:

Design Optimization

- Consider wire diameter limitations

- Plan for optimal cutting paths

- Include appropriate clearances

Material Selection

- Choose appropriate materials for EDM processing

- Consider conductivity requirements

- Account for material thickness variations

Process Parameters

- Optimize cutting speeds for different materials

- Balance roughing and finishing passes

- Monitor wire tension and feed rates

Integration with Other Manufacturing Processes

EDM wire cutting works effectively alongside:

- CNC milling

- Turning operations

- Heat treatment processes

- Surface finishing methods

This integration capability allows for comprehensive prototyping solutions that combine the strengths of multiple manufacturing processes.

How To Minimize Material Waste In EDM Wire Cutting Processes?

Have you ever watched your material costs soar while running your EDM wire cutting operations? The frustration of seeing expensive materials go to waste, coupled with increasing environmental concerns, can make any manufacturer question their process efficiency.

Material waste in EDM wire cutting can be minimized through strategic part nesting, optimized cutting parameters, and proper maintenance procedures. These techniques can reduce waste by up to 30% while maintaining part quality and production efficiency.

Understanding Material Waste Sources

Primary Waste Contributors

Material waste in EDM wire cutting primarily comes from three sources:

- Poor part nesting

- Excessive kerf width10

- Unnecessary test cuts

Optimization Strategies for Material Conservation

Effective Part Nesting

Part nesting is crucial for material optimization. At PTSMAKE, we use advanced nesting software that considers:

- Part orientation

- Material grain direction

- Common line cutting opportunities

- Scrap minimization

Parameter Optimization

The following table shows recommended cutting parameters for different material thicknesses:

| Material Thickness (mm) | Wire Speed (mm/min) | Wire Tension (N) | Power Setting (A) |

|---|---|---|---|

| 0-10 | 8-12 | 10-12 | 2-4 |

| 10-30 | 6-8 | 12-14 | 4-6 |

| 30-50 | 4-6 | 14-16 | 6-8 |

Maintenance and Quality Control

Regular Machine Maintenance

Proper maintenance ensures consistent cutting performance:

- Daily wire guide inspection

- Weekly filter cleaning

- Monthly calibration checks

- Quarterly preventive maintenance

Quality Control Measures

To maintain optimal material usage:

- Regular dimensional checks

- Surface finish monitoring

- Wire consumption tracking

- Scrap rate analysis

Advanced Techniques for Waste Reduction

Common Line Cutting

This technique involves:

- Sharing cut lines between parts

- Reducing total cutting distance

- Minimizing material waste between parts

Bridge Cutting

Implementation strategies include:

- Strategic bridge placement

- Minimal bridge thickness

- Easy part removal

- Reduced material stress

Material Selection and Handling

Material Grade Selection

Choose appropriate materials based on:

- Application requirements

- Cost considerations

- Machining characteristics

- Surface finish needs

Storage and Handling

Proper material handling involves:

- Climate-controlled storage

- Proper stacking methods

- Regular inventory rotation

- Protected transportation

Technology Integration

CAD/CAM Optimization

Modern software solutions offer:

- Automatic nesting algorithms

- Cutting path optimization

- Material utilization reports

- Simulation capabilities

Machine Learning Applications

Emerging technologies provide:

- Predictive maintenance

- Cutting parameter optimization

- Real-time adjustments

- Waste prediction models

Environmental Considerations

Recycling Programs

Implement effective recycling:

- Sorting by material type

- Proper containment

- Regular collection

- Documentation

Sustainable Practices

Focus on:

- Energy efficiency

- Water conservation

- Waste reduction

- Environmental compliance

Cost Analysis and ROI

Waste Reduction Metrics

| Improvement Area | Potential Savings (%) | Implementation Cost | ROI Timeline |

|---|---|---|---|

| Part Nesting | 15-20 | Low | 1-3 months |

| Parameter Optimization | 10-15 | Medium | 3-6 months |

| Maintenance | 5-10 | Medium | 6-12 months |

Best Practices Implementation

- Regular operator training

- Standard operating procedures

- Quality control checkpoints

- Performance monitoring

- Continuous improvement programs

Future Trends and Innovations

Emerging Technologies

- AI-driven optimization

- Advanced material development

- Improved sensor systems

- Automated material handling

Industry 4.0 Integration

- Real-time monitoring

- Data analytics

- Predictive maintenance

- Connected systems

Click here to learn how kerf width affects your part’s final dimensions and accuracy. ↩

Click to learn more about the role of dielectric fluids in achieving superior EDM cutting accuracy. ↩

Click to learn more about dielectric fluid properties and their impact on EDM cutting performance. ↩

Click here to learn how electrical conductivity affects EDM cutting performance and material selection. ↩

Click to learn more about dielectric fluid’s role in achieving precision cuts. ↩

Click to learn more about dielectric fluid selection and its impact on surface finish quality. ↩

Click to learn how automatic wire tension control ensures optimal cutting precision. ↩

Click to learn more about conductivity measurement techniques for optimal EDM performance. ↩

Click to learn more about how dielectric fluid enhances cutting precision and speed in EDM processes. ↩

Click to learn more about kerf width optimization techniques for maximum material efficiency. ↩