Are you struggling to find a material that can withstand extreme temperatures and harsh chemicals? Traditional plastics often fail under demanding conditions, leaving engineers frustrated and projects delayed.

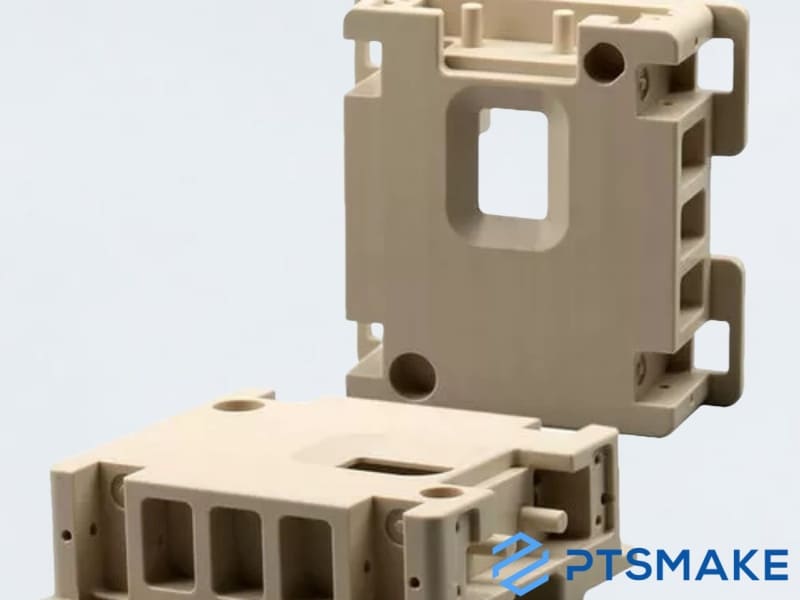

PEEK injection molding is a manufacturing process that uses polyetheretherketone (PEEK), a high-performance thermoplastic, to create complex parts with exceptional strength, heat resistance, and chemical resistance for demanding applications.

I’ve worked with countless materials at PTSMAKE, and I can tell you that PEEK stands in a league of its own. If you’re designing parts for aerospace, medical, or automotive applications, you’ll want to understand what makes PEEK injection molding different from standard plastic processing. Let me walk you through the essentials of this remarkable material and process that’s changing how we approach high-performance components.

What Are The Benefits Of Using PEEK Material In Injection Molding?

Have you ever struggled with finding the right material for demanding applications? Are you tired of components failing under extreme conditions? Traditional plastics often fall short when faced with high temperatures, harsh chemicals, or severe mechanical stress.

PEEK (Polyetheretherketone) offers exceptional benefits in injection molding for high-performance applications. This semi-crystalline thermoplastic polymer delivers outstanding thermal stability, chemical resistance, mechanical strength, and biocompatibility, making it ideal for aerospace, automotive, medical, and industrial components requiring extreme durability.

Understanding PEEK Material

PEEK has emerged as one of the most versatile high-performance thermoplastics in the manufacturing industry. As someone who has worked with countless engineering materials, I can confidently say that PEEK stands out for its remarkable property profile. This semi-crystalline polymer belongs to the polyaryletherketone family and offers a unique combination of properties that make it suitable for applications where other plastics simply can’t compete.

PEEK’s molecular structure consists of aromatic rings connected by ether and ketone linkages, giving it inherent stability. This structure is responsible for its exceptional resistance to thermal degradation, allowing it to maintain its properties at continuous service temperatures of up to 250°C (482°F). Few other thermoplastics can match this level of performance.

Exceptional Thermal Properties

One of the most significant advantages of PEEK in injection molding is its thermal stability. When working with clients in industries like aerospace or automotive, I often recommend PEEK for components that must withstand extreme temperatures. Its glass transition temperature of approximately 143°C and melting point around 343°C make it suitable for applications where other plastics would deform or degrade.

| Property | Value | Benefit |

|---|---|---|

| Continuous Service Temperature | Up to 250°C (482°F) | Maintains properties in high-temperature environments |

| Glass Transition Temperature | ~143°C (289°F) | Retains rigidity at elevated temperatures |

| Melting Point | ~343°C (649°F) | Allows for high-temperature processing |

| Thermal Conductivity | 0.25 W/m·K | Better heat dissipation than many polymers |

These thermal properties make PEEK particularly valuable in applications like electrical insulators, bearing components, and under-hood automotive parts. At PTSMAKE, we’ve successfully implemented PEEK solutions for clients seeking materials that can withstand thermal cycling without dimensionally changing or losing strength.

Superior Chemical Resistance

Another remarkable benefit of PEEK is its resistance to a wide range of chemicals. In my experience working with industrial clients, chemical compatibility is often a critical factor in material selection. PEEK resists degradation from most organic and inorganic chemicals, including acids, bases, hydrocarbons, and steam.

This chemical inertness1 makes PEEK an excellent choice for applications in chemical processing equipment, oil and gas extraction, and semiconductor manufacturing. The material’s stability means components won’t swell, crack, or lose mechanical properties when exposed to harsh environments.

Mechanical Strength and Durability

PEEK offers an impressive combination of mechanical properties that few other thermoplastics can match. With a tensile strength of 90-100 MPa and a modulus of elasticity around 3.6 GPa, it delivers metal-like performance in a lightweight package.

What makes PEEK particularly valuable in injection molding is that these properties are maintained across a wide temperature range. Even after thousands of hours at elevated temperatures, PEEK components retain their dimensional stability and mechanical integrity.

In my work with aerospace clients, PEEK has proven ideal for structural components that must withstand high mechanical loads while offering weight savings compared to metals. Its excellent fatigue resistance and low wear rate also make it perfect for moving parts in applications where lubrication may be limited.

Biocompatibility for Medical Applications

For medical device manufacturers, PEEK offers a compelling combination of biocompatibility and mechanical properties. It’s one of the few high-performance polymers that has been extensively tested and approved for long-term implantable devices.

PEEK’s radiolucency (transparency to X-rays) makes it particularly valuable for spinal implants and other orthopedic applications. Its elastic modulus is close to that of human bone, reducing stress shielding effects that can occur with metal implants.

At PTSMAKE, we maintain strict quality controls when processing PEEK for medical applications, ensuring that all components meet the rigorous standards required for this industry.

Processing Considerations

While PEEK offers exceptional benefits, it does require specific processing techniques to achieve optimal results. The high melting temperature necessitates processing equipment capable of reaching temperatures around 370-400°C. Mold temperatures typically need to be maintained at 170-200°C to ensure proper crystallization and to achieve the best mechanical properties.

Despite these challenges, our team at PTSMAKE has developed expertise in processing PEEK efficiently, allowing us to deliver high-quality components with tight tolerances and excellent surface finishes.

What Is PEEK Used For?

Have you ever faced the challenge of finding a material that can withstand extreme temperatures while maintaining its structural integrity? Or struggled with components failing prematurely when exposed to harsh chemicals? The search for an ideal high-performance material can be frustrating and costly, especially when standard plastics like PVC or ABS simply can’t handle demanding environments.

PEEK (Polyetheretherketone) is a high-performance thermoplastic used in aerospace, medical, automotive, and electronics industries due to its exceptional heat resistance (up to 480°F/250°C), chemical resistance, mechanical strength, and biocompatibility, making it ideal for demanding applications where other plastics fail.

Key Applications of PEEK Material

PEEK has revolutionized manufacturing across multiple industries. In my work with clients at PTSMAKE, I’ve observed firsthand how this remarkable polymer solves complex engineering challenges. Let me walk you through the major applications where PEEK truly shines.

Aerospace Industry Applications

The aerospace sector demands materials that are lightweight yet incredibly durable. PEEK components help reduce aircraft weight while withstanding extreme conditions. Modern aircraft use PEEK for:

- Brackets and fasteners that maintain structural integrity despite temperature fluctuations

- Electrical connectors that resist vibration and provide excellent insulation

- Interior components that meet strict flame retardancy requirements

- Fuel system components that resist jet fuel and hydraulic fluids

One fascinating aspect is PEEK’s ability to replace metal parts while providing a 60-70% weight reduction. This translates directly to fuel savings over an aircraft’s lifetime. When we produce aerospace components at PTSMAKE, we maintain tolerances as tight as ±0.001" to ensure perfect fit and function.

Medical and Healthcare Uses

PEEK’s biocompatibility makes it a standout material in the medical field. The human body typically accepts PEEK implants without rejection, and the material can be sterilized repeatedly without degradation. Key medical applications include:

- Spinal implants and vertebral spacers

- Dental implants and prosthetics

- Orthopedic screws and plates

- Medical device components and surgical instruments

The material’s radiolucency (allowing X-rays to pass through) provides another advantage – doctors can monitor healing around PEEK implants without the imaging interference that metal creates. Its modulus of elasticity2 closely matches human bone, reducing stress shielding that can lead to bone deterioration around implants.

Automotive and Transportation Applications

Modern vehicles incorporate PEEK components to improve performance and durability. Examples include:

- Transmission systems components

- Thrust washers and bearings

- Brake system components

- Fuel system parts resistant to modern biofuels

PEEK’s ability to function reliably from -65°F to 480°F (-54°C to 250°C) makes it ideal for under-hood applications where temperatures fluctuate dramatically. Additionally, its resistance to automotive fluids means parts maintain their integrity for the vehicle’s lifetime.

Oil and Gas Industry Applications

Few environments are as harsh as those found in oil and gas extraction. PEEK excels here due to its:

- Resistance to hydrogen sulfide and other corrosive compounds

- Ability to withstand high pressures in downhole applications

- Excellent performance in subsea equipment

- Reliability in high-temperature, high-pressure (HTHP) environments

When producing components for this sector at PTSMAKE, we often reinforce PEEK with carbon fiber to enhance its already impressive pressure resistance and dimensional stability.

Electronics and Semiconductor Applications

The electronics industry leverages PEEK’s electrical properties and temperature resistance for:

| Application | Benefits of PEEK |

|---|---|

| Circuit board components | High dielectric strength and low outgassing |

| Connectors and insulators | Dimensional stability at high temperatures |

| Semiconductor handling equipment | Chemical resistance to cleaning agents |

| Wafer handling components | Minimal particle generation and contamination |

I’ve noticed electronics manufacturers increasingly specify PEEK for components in plasma etching equipment, where few other materials can withstand the aggressive conditions.

Specialized PEEK Formulations

Beyond standard PEEK, specialized formulations enhance performance for specific applications:

Carbon Fiber Reinforced PEEK

Adding carbon fiber increases:

- Mechanical strength by up to 60%

- Stiffness by up to 150%

- Dimensional stability under load

- Wear resistance in dynamic applications

This reinforced variant is particularly valuable in precision mechanical components that must maintain exact dimensions under stress.

Glass Fiber Reinforced PEEK

Glass fiber reinforcement provides:

- Improved electrical insulation properties

- Enhanced creep resistance

- Better impact strength

- Reduced thermal expansion

At PTSMAKE, we recommend glass-filled PEEK for electrical components requiring long-term reliability in fluctuating temperatures.

When clients approach me with particularly challenging applications, understanding these specialized formulations helps us recommend the right variant for their specific needs. PEEK’s versatility across industries demonstrates why it remains one of the most valuable engineering plastics in modern manufacturing.

Is PEEK Material Expensive?

Have you ever been shocked by the price tag when sourcing PEEK material for your project? Maybe you’ve wondered if there are more cost-effective alternatives that won’t compromise your design. The sticker shock of PEEK can be paralyzing, especially when you’re trying to balance performance requirements with budget constraints.

Yes, PEEK material is expensive, typically costing $75-$200 per pound, making it 10-20 times more costly than common engineering plastics. This high price reflects its exceptional thermal resistance (up to 480°F), outstanding chemical resistance, and superior mechanical properties that few other thermoplastics can match.

What Factors Determine PEEK Material Cost?

When considering the cost of PEEK (Polyetheretherketone), multiple factors come into play. Having worked with this material for numerous projects, I’ve identified several key elements that influence its pricing structure.

Raw Material and Production Complexity

The base ingredients for PEEK are expensive petrochemicals that require sophisticated processing. The manufacturing process involves high temperatures (typically around 400°C) and specialized equipment that can withstand these extreme conditions. This manufacturing complexity contributes significantly to the final cost.

Additionally, the polymerization3 process for PEEK requires precise control and specialized catalysts, further driving up production costs. Only a limited number of chemical companies worldwide have the capability to produce high-quality PEEK resin, creating a relatively constrained supply chain.

Grade Variations and Their Price Impact

PEEK comes in various grades, each with different price points:

| PEEK Grade Type | Approximate Cost ($/lb) | Key Features |

|---|---|---|

| Unfilled PEEK | $75-120 | Basic grade, no additives |

| Glass-filled PEEK | $85-150 | Enhanced rigidity, dimensional stability |

| Carbon-filled PEEK | $100-180 | Improved wear resistance, strength |

| Medical/Implant Grade | $150-200+ | Ultra-pure, biocompatible |

The specialized grades command premium prices because they undergo additional processing and testing. For medical applications, the material must meet strict regulatory requirements, which adds substantial costs to the certification process.

Comparison with Other Engineering Plastics

To put PEEK’s cost in perspective, let’s compare it with other common engineering plastics:

| Material | Approximate Cost ($/lb) | Relative Cost to PEEK |

|---|---|---|

| PEEK | $75-200 | 1x (baseline) |

| PEI (Ultem) | $30-50 | 0.25-0.4x |

| PPS | $15-25 | 0.1-0.2x |

| Nylon | $5-15 | 0.03-0.1x |

| ABS | $3-5 | 0.02-0.03x |

As you can see, PEEK can be 10-20 times more expensive than common engineering plastics like ABS or Nylon. However, at PTSMAKE, we’ve found that clients who need PEEK’s extreme performance characteristics often find the cost justified when considering the total lifecycle cost of their components.

Is the High Cost of PEEK Justified?

Performance-to-Cost Analysis

When evaluating whether PEEK’s high cost makes sense for your application, it’s essential to consider the performance benefits:

Extended Service Life: PEEK parts typically last significantly longer than parts made from lower-cost materials, especially in harsh environments.

Reduced Maintenance: The exceptional durability often translates to fewer replacements and less downtime.

Weight Reduction: PEEK’s strength-to-weight ratio can allow for lighter components, which may offer energy savings in certain applications.

Temperature Resistance: Few other plastics can match PEEK’s ability to perform continuously at temperatures up to 480°F (250°C).

In a recent aerospace project at PTSMAKE, we replaced a metal component with a PEEK alternative. Despite the higher material cost, the client achieved a 40% weight reduction and eliminated a costly surface treatment process, resulting in overall cost savings.

Cost Optimization Strategies

If you’re considering PEEK but concerned about costs, here are some strategies I recommend:

Selective Application: Use PEEK only for components that genuinely require its extreme properties.

Design Optimization: Work with experienced engineers to minimize material usage through efficient design.

Composite Approaches: Consider over-molding PEEK only in critical areas while using less expensive materials elsewhere.

Material Reclamation: For high-volume production, establish a system to reclaim and reuse production scrap.

At PTSMAKE, we work closely with clients to implement these strategies, often helping them achieve the performance benefits of PEEK while minimizing cost impact through thoughtful design and manufacturing approaches.

Future Cost Trends for PEEK Material

Industry analysts project that PEEK prices will remain relatively stable, with perhaps a gradual decrease as manufacturing technology improves and production volumes increase. However, because of the inherent complexity of producing this high-performance polymer, it will likely remain a premium-priced material for the foreseeable future.

Some promising developments include new production methodologies and increasing competition among suppliers, which may help moderate prices. The growing adoption of PEEK in various industries is also driving economies of scale that could eventually translate to cost benefits.

Factors That Influence PEEK Injection Molding Pricing

Have you ever received a quote for PEEK injection molding that left you shocked? Or wondered why PEEK parts cost significantly more than those made from standard plastics like ABS or polypropylene? Many engineers face this pricing confusion when first exploring high-performance thermoplastics.

PEEK injection molding costs typically range from $5-15 per part for high-volume production (10,000+ units) to $50-150 per part for low volumes (under 500 units). Material costs account for 60-70% of total expenses, with PEEK resin priced between $80-150 per kilogram depending on grade and supplier.

Material Grade and Quality Variations

PEEK comes in various grades, each with different price points that significantly impact your overall project costs. During my years working with clients at PTSMAKE, I’ve observed that material selection is often the most substantial cost factor in PEEK projects.

Standard vs. Medical Grade PEEK

Standard industrial PEEK typically costs $80-100 per kilogram, while medical-grade PEEK certified for implantable devices can reach $120-150 per kilogram or more. This price difference isn’t just about purity – medical PEEK requires extensive documentation, traceability, and testing that adds to its cost structure.

For example, one of our medical device clients initially specified implantable-grade PEEK for a surgical instrument that wouldn’t actually remain in the body. By switching to medical-grade (but not implantable) PEEK, they reduced material costs by 25% without compromising performance or regulatory compliance.

Filled vs. Unfilled PEEK

PEEK can be enhanced with various fillers that modify its properties and price:

| PEEK Type | Approximate Cost/kg | Key Properties | Best Applications |

|---|---|---|---|

| Unfilled PEEK | $80-100 | Excellent chemical resistance, base mechanical properties | General industrial components |

| Carbon-filled PEEK | $100-130 | Enhanced stiffness, improved wear resistance | Bearings, gears, structural components |

| Glass-filled PEEK | $90-115 | Improved dimensional stability, higher strength | Precision components, electrical insulators |

| PEEK with additives | $85-120 | Custom properties (flame retardant, ESD, etc.) | Specialized applications |

While filled grades cost more initially, they often allow for thinner walls and less material usage, potentially offsetting the higher per-kilogram price. I always recommend analyzing the total part cost rather than just material price.

Part Design Complexity

The design complexity of your PEEK components dramatically influences tooling and processing costs. PEEK’s high processing temperature (around 370-400°C) and crystalline nature make it less forgiving than standard plastics, requiring special considerations.

Wall Thickness Considerations

PEEK parts with thin walls (under 0.8mm) require precise rheological4 control during injection, often necessitating specialized high-pressure equipment and more expensive tool steel grades. I’ve found that optimizing wall thickness can reduce both cycle time and reject rates, significantly impacting per-part costs.

One aerospace client saved nearly 30% on part costs by redesigning critical wall junctions from 0.7mm to 1.1mm, which allowed for faster cycle times and reduced scrap rates from 8% to under 2%.

Tolerance Requirements

PEEK maintains exceptional dimensional stability, making it ideal for high-precision applications. However, achieving tight tolerances increases costs:

- Standard tolerances (±0.1-0.2mm): Base pricing

- Precision tolerances (±0.05-0.1mm): 15-25% cost premium

- Ultra-precision tolerances (<±0.05mm): 30-50%+ cost premium

When working with precise PEEK components, I often recommend clients to specify tight tolerances only on critical features, leaving non-functional areas with standard tolerances to balance cost and performance.

Production Volume Economics

Production volume has a profound impact on per-part pricing due to the amortization of tooling costs and production efficiencies.

Tooling Investment

PEEK injection molding requires specialized tooling due to its high processing temperatures and abrasive nature (especially when filled with glass or carbon). Typical mold costs for PEEK components range from:

- Simple parts: $15,000-$30,000

- Medium complexity: $30,000-$60,000

- Complex parts: $60,000-$120,000+

At PTSMAKE, we’ve developed strategies to reduce these costs for clients needing small-to-medium runs, including hybrid tooling approaches and modular mold designs that can be adapted for different part variations.

Economic Production Quantities

The relationship between production quantity and per-part cost follows a typical curve:

| Production Quantity | Typical Per-Part Cost | Notes |

|---|---|---|

| Prototype (1-10 parts) | $200-500+ | Often machined rather than molded |

| Low volume (10-500) | $50-150 | High tooling amortization per part |

| Medium volume (500-5,000) | $20-50 | Better economies of scale |

| High volume (5,000-50,000) | $10-20 | Efficient production runs |

| Mass production (50,000+) | $5-15 | Optimal cost efficiency |

For projects requiring under 100 parts, I typically recommend considering CNC machining instead of injection molding, as the breakeven point for PEEK parts often falls between 100-300 units depending on part complexity.

Processing Parameters and Quality Control

The specialized processing requirements for PEEK contribute significantly to its cost structure. PEEK requires higher injection temperatures, specialized equipment, longer cycle times, and more rigorous quality control than standard plastics.

Equipment Requirements

Not all injection molding machines are suitable for PEEK processing. The material requires:

- High-temperature capability (up to 400°C)

- Abrasion-resistant barrels and screws

- Precise temperature control systems

- Higher injection pressures

These specialized requirements mean PEEK processing is typically 30-50% more expensive than standard plastic injection molding on an hourly machine rate basis.

Quality Control Costs

For critical PEEK applications, quality control adds another layer of cost:

- In-process monitoring: 5-10% of production costs

- Non-destructive testing: 10-15% additional for critical components

- Full traceability and documentation: 10-20% premium for regulated industries

These factors collectively explain why PEEK injection molding commands premium pricing compared to standard thermoplastics. However, when factoring in PEEK’s exceptional performance over the entire product lifecycle, the total cost of ownership often makes it the more economical choice for demanding applications.

What Temperature Is Needed For PEEK Molding?

Have you ever struggled with failed PEEK molding attempts, watching expensive material go to waste because the temperature wasn’t quite right? Or perhaps you’ve noticed warped parts, incomplete fills, or material degradation that left you wondering what went wrong with your temperature settings?

PEEK molding requires processing temperatures between 370-400°C (698-752°F) for the melt and mold temperatures of 170-200°C (338-392°F). These precise temperature controls are critical because PEEK has a narrow processing window, with its glass transition temperature at 143°C and melting point at 343°C.

The Critical Role of Temperature in PEEK Processing

Temperature control is perhaps the most crucial factor in successful PEEK molding. As a high-performance thermoplastic, PEEK (Polyetheretherketone) demands precise thermal management throughout the entire molding process. In my experience at PTSMAKE, where we regularly process PEEK for aerospace and medical clients, even minor temperature variations can lead to significant quality issues.

The challenge with PEEK lies in its semi-crystalline structure and high melting point. Unlike standard plastics, PEEK requires careful heating through several temperature zones to achieve optimal crystallinity5 and mechanical properties. Let me break down the essential temperature requirements for different stages of PEEK molding:

Barrel Temperature Profile for PEEK

The barrel temperature profile must be carefully controlled to properly melt PEEK without degrading it. Here’s a typical temperature profile I recommend:

| Barrel Zone | Temperature Range (°C) | Temperature Range (°F) | Function |

|---|---|---|---|

| Feed Zone | 335-345°C | 635-653°F | Initial heating |

| Compression Zone | 355-370°C | 671-698°F | Primary melting |

| Metering Zone | 370-390°C | 698-734°F | Final melt homogenization |

| Nozzle | 380-400°C | 716-752°F | Delivery to mold |

These temperatures may need adjustment based on specific part geometry, wall thickness, and grade of PEEK being processed. For medical-grade PEEK with higher purity requirements, we typically stay at the lower end of these ranges to minimize the risk of degradation.

Mold Temperature Requirements

Mold temperature is equally critical and often overlooked by novice processors. PEEK requires significantly higher mold temperatures than conventional plastics:

| Application Type | Mold Temperature Range (°C) | Mold Temperature Range (°F) | Effect on Properties |

|---|---|---|---|

| Standard PEEK parts | 170-190°C | 338-374°F | Balanced crystallinity |

| High-strength applications | 190-220°C | 374-428°F | Enhanced crystallinity, higher strength |

| Amorphous PEEK requirements | <143°C | <290°F | Reduced crystallinity, improved toughness |

At PTSMAKE, we’ve found that maintaining mold temperatures around 180-200°C provides the best balance of processability and mechanical properties for most applications. Using oil-heated mold temperature controllers rather than electric heaters often provides more stable and uniform temperature distribution.

Common Temperature-Related Issues in PEEK Molding

Incorrect temperature settings can manifest in several ways:

Too Low Processing Temperature

When PEEK is processed below optimal temperature:

- Incomplete filling of the mold cavity

- Increased internal stress

- Poor bonding between layers

- Excessive wear on equipment due to high viscosity

- Reduced crystallinity and inferior mechanical properties

Too High Processing Temperature

Excessive temperatures can cause:

- Material degradation and discoloration

- Release of volatile compounds

- Reduced molecular weight

- Excessive flash at parting lines

- Increased cycle times due to longer cooling requirements

Inconsistent Temperature Control

Temperature fluctuations during processing can lead to:

- Varying part dimensions

- Inconsistent crystallinity

- Unpredictable mechanical properties

- Increased reject rates

Special Considerations for PEEK Drying

Before even reaching the molding stage, proper drying of PEEK is essential. PEEK must be dried at 150°C (302°F) for a minimum of 3-4 hours. Inadequate drying can cause cosmetic issues, voids, and reduced mechanical properties. At PTSMAKE, we often extend drying times to 6-8 hours for critical applications to ensure complete moisture removal.

Temperature Monitoring Technology

Modern PEEK processing requires advanced temperature monitoring:

- Infrared temperature sensors in the barrel

- Embedded thermocouples in the mold

- Real-time temperature data logging and analysis

- Thermal imaging for mold surface temperature verification

These technologies allow us to maintain tight control over the entire thermal profile of the molding process, ensuring consistent part quality even during long production runs.

Advanced Temperature Considerations for Filled PEEK

When working with filled PEEK variants (carbon fiber, glass fiber, etc.), temperature requirements change slightly:

| PEEK Type | Temperature Adjustment | Reason |

|---|---|---|

| Carbon Fiber PEEK | +5 to 10°C higher barrel temperature | Fibers increase viscosity |

| Glass-Filled PEEK | +5 to 15°C higher mold temperature | Promotes better fiber wetting |

| PEEK with PTFE | -5 to 10°C lower barrel temperature | PTFE has lower heat stability |

At PTSMAKE, we’ve developed customized temperature profiles for different filled PEEK formulations based on extensive testing and production experience.

Comparing PEEK Injection Molding with Other High-Performance Polymers: Which Delivers the Best Results?

Have you ever found yourself torn between different high-performance polymers for your critical application? That frustrating moment when you’re balancing cost against performance, heat resistance against chemical stability, and manufacturability against mechanical strength—all while trying to meet tight project deadlines?

PEEK injection molding generally outperforms other high-performance polymers like PPS, PEI, and PPSU in extreme environments requiring exceptional heat resistance (up to 260°C), chemical stability, and mechanical strength. However, its higher cost and processing complexity make alternatives better choices for less demanding applications.

Key Performance Criteria for High-Temperature Polymers

When evaluating high-performance polymers for injection molding, I typically focus on several critical factors that determine their suitability for advanced applications. These polymers aren’t just commodities—they’re specialized materials designed to excel in extreme conditions where standard plastics would fail.

Temperature Resistance Comparison

Temperature resistance remains one of the most defining characteristics of high-performance polymers. In my experience at PTSMAKE, this is often the first specification clients ask about.

PEEK leads the pack with continuous use temperatures of approximately 260°C (500°F), significantly outperforming PPS (Performance Polysulfone) at 220°C, PEI (Polyetherimide) at 170°C, and PPSU (Polyphenylsulfone) at 180°C. This superior heat resistance makes PEEK the go-to choice for applications in aerospace components, semiconductor manufacturing, and oil and gas equipment.

Mechanical Properties Analysis

Beyond temperature, the mechanical properties of these polymers vary considerably:

| Polymer | Tensile Strength (MPa) | Flexural Modulus (GPa) | Impact Strength (kJ/m²) |

|---|---|---|---|

| PEEK | 90-100 | 3.6-4.2 | 7.5-8.5 |

| PPS | 70-85 | 3.3-3.8 | 2.5-4.0 |

| PEI | 85-100 | 3.0-3.5 | 5.3-6.0 |

| PPSU | 70-80 | 2.4-2.7 | 6.5-7.5 |

PEEK’s exceptional tensile strength coupled with its impressive impact resistance gives it versatility across diverse applications. I’ve seen PEEK parts maintain structural integrity in conditions that would cause other polymers to fail catastrophically.

Chemical Resistance and Environmental Stability

Chemical Compatibility Profiles

The chemical resistance profile6 of each polymer plays a crucial role in material selection for corrosive environments. PEEK demonstrates remarkable resilience against most industrial chemicals, acids, and hydrocarbons, even at elevated temperatures.

PPS offers comparable chemical resistance against acids but shows some vulnerability to certain bases and chlorinated solvents. PEI and PPSU have good chemical resistance but generally cannot match PEEK in harsh chemical environments, especially at higher temperatures.

For medical applications requiring sterilization, PEEK’s ability to withstand repeated autoclaving, gamma radiation, and chemical sterilization makes it exceptionally valuable. I’ve worked with medical device manufacturers who specifically request PEEK for components that will undergo hundreds of sterilization cycles.

Water Absorption and Dimensional Stability

Water absorption affects dimensional stability and mechanical properties:

- PEEK: 0.1-0.3%

- PPS: 0.02-0.05%

- PEI: 0.25-0.4%

- PPSU: 0.3-0.6%

PPS actually outperforms PEEK in this category with minimal water absorption, making it preferable for applications where precise dimensional stability is critical in humid environments. However, when all factors are considered together, PEEK’s overall performance envelope still makes it preferable for most extreme applications.

Processing Considerations and Manufacturing Challenges

Material Cost Comparison

The cost factor cannot be ignored when comparing these polymers:

| Polymer | Relative Cost (Base: Standard Engineering Polymers = 1) |

|---|---|

| PEEK | 15-20x |

| PPS | 6-8x |

| PEI | 8-10x |

| PPSU | 7-9x |

PEEK’s cost premium represents a significant consideration. At PTSMAKE, I often advise clients to carefully evaluate whether their application truly requires PEEK’s extreme performance or if another high-performance polymer might provide adequate properties at a lower cost.

Processing Parameters and Equipment Requirements

Processing these polymers presents varying degrees of difficulty:

- PEEK requires higher processing temperatures (370-400°C) and specialized equipment with all-metal hot runner systems

- PPS processes at lower temperatures (310-330°C) but requires careful drying

- PEI needs intermediate processing temperatures (340-370°C)

- PPSU processes at 330-360°C with moderate equipment requirements

The higher processing temperatures for PEEK translate to greater equipment demands, more energy consumption, and specialized tooling considerations. We’ve invested in advanced injection molding systems specifically designed to handle PEEK and other high-temperature polymers, which many manufacturers haven’t done.

Application-Specific Selection Criteria

Your specific application requirements should ultimately drive material selection. For aerospace components exposed to extreme temperatures and mechanical stress, PEEK remains the preferred choice despite its cost. For electrical components requiring excellent dimensional stability and good heat resistance at a more moderate price point, PPS often proves more suitable.

Medical implants benefit from PEEK’s biocompatibility and mechanical properties that closely match human bone. Chemical processing equipment may use PPSU for its excellent hydrolysis resistance when extreme temperature resistance isn’t needed.

At PTSMAKE, we work closely with clients to identify the optimal material based on a comprehensive analysis of performance requirements, manufacturing constraints, and cost considerations, rather than defaulting to the highest-performing polymer regardless of necessity.

What Are The Key Considerations For Designing PEEK Injection Molded Parts?

Have you ever designed a PEEK component only to face expensive mold rework or production failures? It’s frustrating when a high-performance material like PEEK doesn’t deliver because of preventable design issues. Many engineers don’t realize that standard plastic design rules simply don’t apply to this specialized polymer.

Designing PEEK injection molded parts requires careful attention to wall thickness uniformity, proper draft angles, appropriate gate locations, controlled cooling conditions, and consideration of material shrinkage rates. These factors are critical because PEEK’s high processing temperature (370-400°C) and semi-crystalline nature create unique molding challenges.

Understanding PEEK’s Unique Properties for Design Optimization

PEEK (Polyetheretherketone) is a high-performance thermoplastic with exceptional mechanical properties, chemical resistance, and temperature stability. However, these same qualities make it challenging to process through injection molding. When designing parts for PEEK injection molding, you must understand how its material properties impact manufacturability.

One of the most critical aspects is managing PEEK’s high melting point (343°C) and processing temperature (370-400°C). These extreme temperatures affect everything from gate design to cooling strategy. Unlike conventional plastics, PEEK experiences significant crystallization7 during cooling, which causes dimensional changes. This crystallization process must be carefully controlled to maintain part accuracy.

Wall thickness is another crucial consideration. I recommend maintaining uniform wall thickness throughout your design whenever possible. Variations greater than 15% can lead to sink marks, warpage, and internal stresses. For PEEK components, optimal wall thickness typically ranges between 1.0-3.0mm, depending on part requirements.

Critical Design Elements for PEEK Parts

Draft Angles and Surface Finishes

Draft angles are non-negotiable with PEEK. Due to its high processing temperature and subsequent crystallization, PEEK has a tendency to stick to mold surfaces. I’ve found that minimum draft angles of 1° are necessary for textured surfaces, while smooth surfaces require at least 0.5° draft. For deeper ribs or features over 25mm in depth, consider increasing draft angles to 2-3° to ensure reliable ejection.

Surface finish selection also impacts moldability. Highly polished surfaces (SPI A1-A3) can cause part sticking, while textured surfaces may help with release but add complexities to flow and filling. At PTSMAKE, we typically recommend a moderate finish (SPI B1-B3) for most PEEK applications as a balanced approach.

Gate Design and Location

Gate design significantly influences the quality of PEEK parts. The high viscosity of molten PEEK requires careful consideration of gate type, size, and location. For precision parts, I recommend:

| Gate Type | Advantages | Disadvantages | Best Applications |

|---|---|---|---|

| Sub-gate | Excellent cosmetics, automatic detachment | Complex mold design, expensive | Medical implants, electronic connectors |

| Edge gate | Good flow control, simple design | Visible gate vestige | Structural components, brackets |

| Hot tip | Minimal vestige, good for automation | Requires hot runner system | High-volume production parts |

| Fan gate | Reduces warpage in flat parts | Larger vestige area | Thin-walled components, covers |

Gate location should be strategically planned to ensure balanced filling and to minimize weld lines. For complex geometries, flow simulation analysis is invaluable to predict and address potential issues before cutting steel.

Material Considerations and Processing Parameters

Reinforcements and Additives

PEEK can be modified with various fillers to enhance specific properties:

- Glass fiber (typically 10-30%): Improves dimensional stability and stiffness

- Carbon fiber (typically 10-30%): Enhances mechanical strength and reduces warpage

- PTFE or graphite (5-15%): Reduces friction for bearing applications

- Carbon nanotubes (1-3%): Improves electrical conductivity

Each reinforcement alters the flow characteristics and shrinkage rates of PEEK. For glass-filled grades, I recommend increasing draft angles by an additional 0.5° per 10% of filler content to accommodate the reduced flow and increased abrasiveness.

Shrinkage Compensation and Tolerances

PEEK’s crystallization behavior causes significant shrinkage during cooling (approximately 1.0-1.3% for unfilled grades). This shrinkage must be accurately predicted and compensated for in the mold design. Material suppliers provide shrinkage data, but it’s important to understand that actual shrinkage can vary based on:

- Part geometry and wall thickness

- Processing conditions (melt and mold temperatures)

- Reinforcement content

- Crystallinity level

For critical dimensions, I typically recommend planning for ±0.2mm tolerances for the first inch and ±0.05mm for each additional inch. Tighter tolerances are possible but will require more sophisticated process controls and potentially secondary operations.

Design Features to Avoid with PEEK

My experience at PTSMAKE has shown that certain design features consistently cause problems with PEEK molding:

- Sharp corners: Always use appropriate radii (minimum 0.5mm) to reduce stress concentration

- Thick sections: Areas exceeding 4mm can lead to voids, sinks, and extended cycle times

- Abrupt thickness transitions: Use gradual transitions with a maximum ratio of 3:1

- Undercuts: While possible, they increase complexity and cost significantly

- Long, thin ribs: Keep rib height-to-thickness ratio below 3:1 to prevent filling and ejection issues

Economic Considerations for PEEK Part Design

PEEK is an expensive material (often $75-100/kg), making material efficiency a key economic consideration. Design strategies that minimize material usage while maintaining performance are critical:

- Implement ribbing instead of solid sections

- Consider coring out non-functional volumes

- Use simulation to optimize wall thickness for strength-to-weight ratio

- Evaluate whether all portions of the component require PEEK’s performance properties

Additionally, mold design for PEEK typically requires higher-grade steels, more precise temperature control systems, and more robust ejection mechanisms than standard plastics. These factors increase tooling costs but are essential for successful long-term production.

How To Ensure Quality Control In PEEK Injection Molding Projects?

Have you ever received PEEK components that didn’t meet specifications, causing project delays and budget overruns? Or struggled with inconsistent part quality despite using premium materials? These quality control challenges can transform promising PEEK projects into costly nightmares.

Quality control in PEEK injection molding requires a systematic approach including material validation, optimized processing parameters, advanced inspection techniques, and comprehensive documentation. Implementing these controls ensures dimensional accuracy, mechanical integrity, and consistency across production runs.

Understanding the Unique Quality Challenges of PEEK Injection Molding

When working with polyetheretherketone (PEEK), quality control takes on heightened importance. This high-performance thermoplastic demands specialized approaches due to its unique processing characteristics. With a glass transition temperature of 143°C and melting point around 343°C, PEEK requires precise processing conditions to achieve optimal results.

The primary quality challenges I’ve encountered with PEEK injection molding include:

- Material degradation from improper drying or excessive heat exposure

- Dimensional instability due to high shrinkage rates (approximately 1-1.5%)

- Voids and weak weld lines from insufficient packing pressure

- Surface imperfections resulting from processing temperature fluctuations

- Crystallinity variations8 affecting mechanical properties and dimensional stability

At PTSMAKE, we’ve developed comprehensive quality control protocols specifically for PEEK materials, ensuring consistent results even for the most demanding applications.

Pre-Production Quality Control Measures

Material Validation Testing

Before any PEEK resin enters our machines, we implement rigorous material validation procedures:

- Certificate of Analysis (CoA) verification for each batch

- Moisture content testing (PEEK requires <0.02% moisture)

- Melt flow index testing to verify processing characteristics

- DSC (Differential Scanning Calorimetry) testing to confirm thermal properties

Design for Manufacturability (DFM) Analysis

Quality begins with design. Our engineering team reviews each PEEK component design to identify potential manufacturing issues:

- Wall thickness uniformity analysis to prevent warping

- Gate location optimization to minimize flow-related defects

- Draft angle verification for clean ejection

- Cooling channel layout assessment to ensure uniform cooling

These pre-production measures significantly reduce quality issues before the first part is produced.

In-Process Quality Control Techniques

Critical Processing Parameter Monitoring

PEEK processing windows are narrower than conventional plastics. We implement real-time monitoring of:

| Processing Parameter | Typical Range | Monitoring Method |

|---|---|---|

| Barrel Temperature | 360-400°C | Thermocouple array with digital logging |

| Mold Temperature | 170-200°C | Infrared thermal mapping |

| Injection Pressure | 100-140 MPa | Pressure transducers with data recording |

| Holding Time | 10-20 seconds | Automated cycle time verification |

| Cooling Time | 10-30 seconds | Temperature-based adaptive control |

First Article Inspection (FAI)

Each production run begins with comprehensive first article inspection:

- Full dimensional verification using CMM (Coordinate Measuring Machine)

- Visual inspection under magnification for surface defects

- Weight comparison against theoretical calculations

- Functional testing where applicable

Only after FAI approval does full production commence, ensuring quality from the first part.

Post-Production Quality Verification

Statistical Process Control (SPC)

We implement SPC techniques for ongoing quality monitoring, including:

- X-bar and R charts for critical dimensions

- Capability analyses (Cpk > 1.33 for critical features)

- Trend analysis to identify process drift before defects occur

Advanced Material Testing

For PEEK components with critical performance requirements, we offer:

- DSC testing to verify crystallinity percentage

- FTIR (Fourier-Transform Infrared Spectroscopy) for material composition

- Mechanical property testing (tensile, flexural, impact)

- Environmental stress testing for application-specific conditions

Documentation and Traceability Systems

Comprehensive documentation is essential for effective quality control. Our system includes:

Batch Control and Part Traceability

Each PEEK component can be traced back to:

- Original material lot number

- Processing conditions and parameters

- Quality control results and approvals

- Machine and operator information

Quality Reporting and Analysis

We provide detailed quality reports showing:

- Dimensional results with statistical analysis

- Process parameter charts showing stability

- Non-conformance details with root cause analysis

- Corrective actions implemented

This documentation not only verifies quality but allows continuous improvement over time.

Building a Quality Control Partnership

The most effective quality control systems involve close collaboration between our team and yours. I recommend:

- Early involvement of our quality team in design discussions

- Joint development of critical-to-quality (CTQ) characteristics

- Regular review of process capability data

- Shared continuous improvement initiatives

In my experience, when clients actively participate in quality planning, we consistently achieve superior results for PEEK components.

Learn how chemical compatibility affects your material selection and performance. ↩

Learn how this material property affects implant performance and patient outcomes. ↩

Learn how this chemical process affects PEEK’s final properties and cost. ↩

Technical term describing how molten plastic flows during processing. ↩

Click to learn about crystallinity’s critical impact on PEEK performance. ↩

Learn how chemicals affect polymer performance in critical applications. ↩

Learn about crystallization’s impact on PEEK part design and how to control it. ↩

Learn how crystallinity impacts your PEEK parts’ performance and reliability. ↩