Have you ever struggled with machining stainless steel components that consistently fail to meet specifications? Many manufacturers face this challenge daily, dealing with tool wear, poor surface finishes, and dimensional inaccuracies. The complexity of working with this demanding material can lead to costly production delays and quality issues that impact your bottom line.

Stainless steel machining is a specialized manufacturing process that involves cutting, shaping, and forming stainless steel using precision tools and equipment. This process requires specific techniques, tools, and expertise to achieve accurate results while maintaining the material’s corrosion-resistant properties.

Understanding the Basics of Stainless Steel

Stainless steel is a remarkable material that contains at least 10.5% chromium, forming a protective oxide layer that makes it highly resistant to corrosion. When we machine stainless steel, we must consider its unique properties:

| Property | Characteristic | Impact on Machining |

|---|---|---|

| Hardness | High work-hardening rate | Requires specific cutting speeds |

| Thermal Conductivity | Poor heat dissipation | Needs proper cooling strategies |

| Tensile Strength | High strength levels | Demands robust tooling |

| Surface Finish | Gummy nature | Requires sharp tools |

Essential Machining Methods

In my experience at PTSMAKE, I’ve found that successful stainless steel machining relies on several key methods:

CNC Milling

- Face milling for flat surfaces

- End milling for complex geometries

- Profile milling for contoured shapes

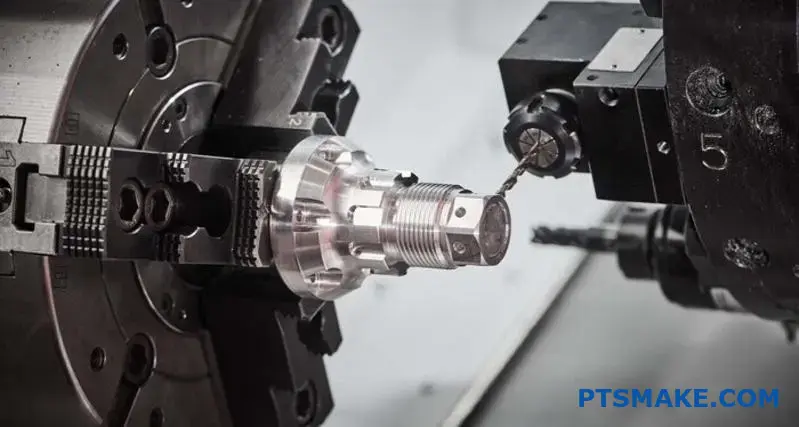

CNC Turning

- External turning for cylindrical shapes

- Internal boring for holes

- Threading for fastener applications

Industry Applications

Stainless steel machined parts serve crucial roles across various sectors:

Medical Industry

- Surgical instruments

- Implant components

- Medical device housings

Aerospace

- Engine components

- Structural elements

- Fastening systems

Food Processing

- Processing equipment

- Storage containers

- Mixing components

Critical Parameters for Success

The key to achieving precision in stainless steel machining lies in controlling these essential parameters:

Cutting Speed

- Lower speeds than carbon steel

- Consistent feed rates

- Proper depth of cut

Tool Selection

- Carbide tools for most applications

- Ceramic tools for high-speed operations

- Coated tools for improved wear resistance

Common Challenges and Solutions

Working with stainless steel presents several challenges that require specific solutions:

Heat Management

- Solution: Implement proper cooling strategies

- Use high-pressure coolant systems

- Maintain optimal cutting speeds

Tool Wear

- Solution: Select appropriate tool materials

- Regular tool condition monitoring

- Implement proper tool rotation schedules

Surface Finish

- Solution: Use sharp, properly coated tools

- Maintain consistent cutting parameters

- Apply appropriate cutting fluids

Quality Control Measures

To ensure consistent quality in stainless steel machining, we implement:

Dimensional Inspection

- Regular CMM measurements

- In-process gauging

- Final inspection protocols

Surface Quality Checks

- Roughness measurements

- Visual inspection

- Material integrity verification

Economic Considerations

The cost-effectiveness of stainless steel machining depends on:

Material Selection

- Grade appropriate for application

- Stock size optimization

- Material certification requirements

Production Planning

- Batch size optimization

- Tool life management

- Setup time reduction

Quality Management

- Inspection requirements

- Documentation needs

- Certification costs

By understanding these fundamental aspects of stainless steel machining, manufacturers can better prepare for the challenges and opportunities this process presents. At PTSMAKE, we’ve developed comprehensive strategies to overcome these challenges while maintaining high-quality standards and cost-effectiveness in our machining operations.

Why is Stainless Steel Difficult to Machine?

Every manufacturer knows the headache of machining stainless steel. I’ve seen countless projects delayed and tools destroyed because teams underestimated its challenges. The material’s unique properties make it a fortress against conventional machining approaches, leading to excessive tool wear and production delays.

Stainless steel’s machining difficulties stem from its high tensile strength, work-hardening tendency, and low thermal conductivity. These properties cause rapid tool wear, excessive heat buildup, and challenging chip formation during machining processes.

Understanding Work Hardening

Work hardening is perhaps the most significant challenge when machining stainless steel. During cutting operations, the material’s surface becomes harder due to plastic deformation. This creates a vicious cycle – the harder the surface becomes, the more force needed to cut it, which in turn causes more hardening.

| Work Hardening Effects | Impact on Machining |

|---|---|

| Surface Hardening | Increased tool wear |

| Strain Rate Sensitivity | Variable cutting forces |

| Microstructure Changes | Unpredictable material behavior |

| Heat Generation | Reduced tool life |

Thermal Conductivity Issues

The low thermal conductivity of stainless steel creates significant heat management challenges. Unlike aluminum or regular steel, stainless steel retains most of the heat generated during machining. This heat concentration leads to:

- Accelerated tool wear

- Built-up edge formation

- Dimensional accuracy problems

- Poor surface finish quality

High Cutting Forces Required

Stainless steel’s high strength and toughness demand greater cutting forces compared to other materials. This requirement affects:

| Factor | Impact |

|---|---|

| Power Consumption | Higher energy costs |

| Machine Stability | Increased vibration risks |

| Tool Selection | Need for stronger tools |

| Production Speed | Slower feed rates needed |

Tool Wear Mechanisms

The combination of work hardening and heat generation creates multiple tool wear mechanisms:

- Abrasive wear from hard particles

- Adhesive wear due to material sticking

- Diffusion wear at high temperatures

- Notch wear at cutting depths

Surface Finish Challenges

Achieving quality surface finishes on stainless steel requires careful consideration of:

| Parameter | Consideration |

|---|---|

| Cutting Speed | Must balance heat generation |

| Feed Rate | Affects surface roughness |

| Tool Geometry | Impacts chip formation |

| Coolant Application | Critical for heat management |

Chip Control Problems

Stainless steel tends to form long, stringy chips that can:

- Wrap around tools

- Damage workpiece surfaces

- Create safety hazards

- Reduce machining efficiency

Material Grade Variations

Different stainless steel grades present varying machining challenges:

| Grade Type | Specific Challenges |

|---|---|

| Austenitic | Highest work hardening |

| Martensitic | Tool wear issues |

| Ferritic | Better machinability |

| Duplex | Extreme toughness |

Critical Process Parameters

Success in machining stainless steel depends on controlling several key parameters:

- Cutting speed selection

- Feed rate optimization

- Depth of cut management

- Tool geometry design

- Coolant strategy implementation

Economic Implications

The difficulties in machining stainless steel directly impact manufacturing costs:

- Higher tool replacement frequency

- Increased machining time

- Greater energy consumption

- More frequent machine maintenance

- Higher skilled operator requirements

Tool Selection Considerations

Proper tool selection is crucial and should account for:

| Factor | Requirement |

|---|---|

| Coating Type | Heat and wear resistance |

| Substrate Material | Toughness and hardness |

| Edge Preparation | Stability and strength |

| Geometry | Chip control and cutting forces |

In my experience at PTSMAKE, successful stainless steel machining requires a comprehensive understanding of these challenges and a systematic approach to addressing them. The key lies in careful planning, proper tool selection, and precise control of machining parameters. While the material presents significant challenges, understanding these fundamental aspects helps ensure successful outcomes in stainless steel machining operations.

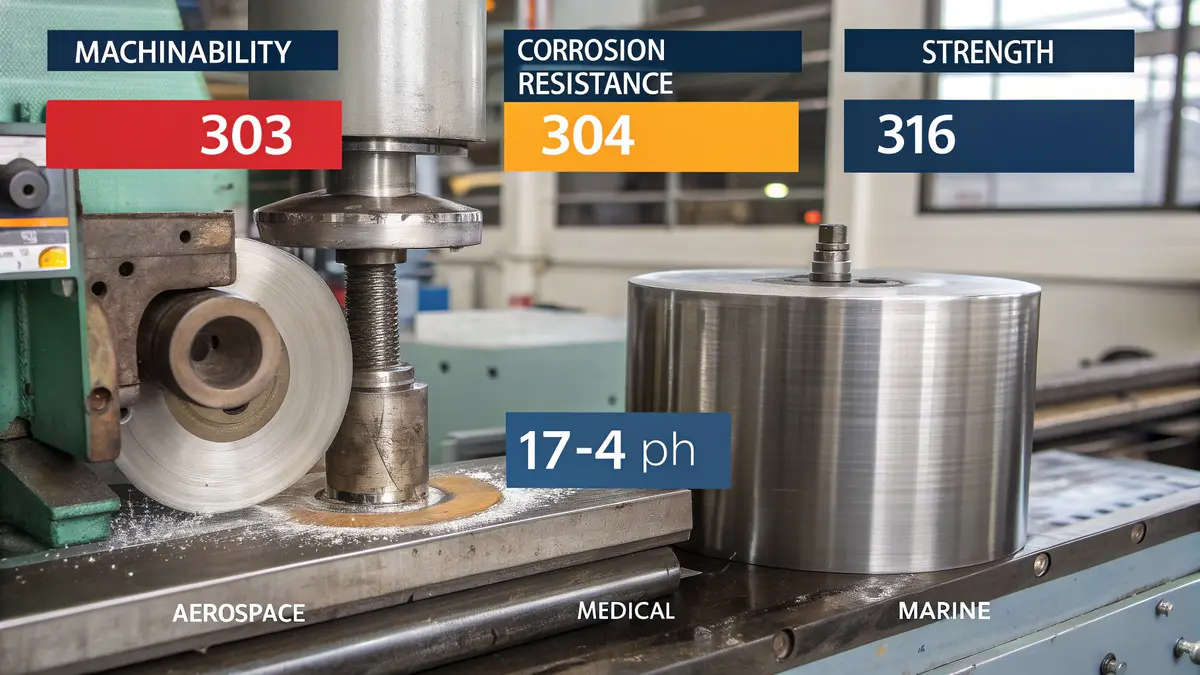

What Are the Common Grades of Stainless Steel Used in Machining?

Choosing the right stainless steel grade for machining can be overwhelming. With numerous grades available and each having distinct properties, many manufacturers struggle to determine which type best suits their specific application. The wrong choice can lead to increased tooling costs, longer production times, and compromised part quality.

The most common grades of stainless steel used in machining are 303, 304, 316, and 17-4 PH. Each grade offers unique characteristics that make them suitable for different applications, with 303 being the most machinable and 316 offering the highest corrosion resistance.

Understanding 303 Stainless Steel

303 stainless steel is often considered the go-to choice for machining operations. Its excellent machinability comes from added sulfur content, which helps break chips during cutting operations. I’ve found that 303 typically machines 40% faster than 304, making it ideal for high-volume production runs.

Key characteristics of 303 include:

- Sulfur content: 0.15% minimum

- Excellent machinability

- Good corrosion resistance

- Lower cost per part due to faster machining

However, the added sulfur slightly reduces its corrosion resistance compared to 304. For most applications, this trade-off is acceptable when considering the significant improvement in machinability.

The Versatility of 304 Stainless Steel

304 is the most widely used stainless steel grade globally, and for good reason. It offers an excellent balance of corrosion resistance, strength, and moderate machinability. While not as easy to machine as 303, it provides superior corrosion resistance and better weldability.

A comparison of key properties:

| Property | 304 Rating | Common Applications |

|---|---|---|

| Corrosion Resistance | Excellent | Food Processing Equipment |

| Strength | Good | Medical Devices |

| Machinability | Moderate | Chemical Processing |

| Weldability | Excellent | Kitchen Equipment |

316 Stainless Steel: The Corrosion Fighter

316 stainless steel contains molybdenum, which significantly enhances its corrosion resistance, particularly against chlorides. While it’s more challenging to machine than 303 or 304, its superior properties make it essential for specific applications.

Important considerations for 316:

- Higher material cost

- Requires slower cutting speeds

- Superior chemical resistance

- Ideal for marine environments

The Power of 17-4 PH Stainless Steel

17-4 PH (precipitation-hardening) stainless steel offers unique advantages through its heat-treatment capability. In my experience working with aerospace clients, this grade is crucial when high strength and moderate corrosion resistance are required.

Machining tips for 17-4 PH:

- Use sharp, coated carbide tools

- Maintain rigid setup and tooling

- Apply adequate cooling

- Consider material condition (solution treated vs. aged)

Best Machining Practices for Different Grades

Each grade requires specific machining parameters for optimal results:

| Grade | Cutting Speed (SFM) | Feed Rate | Coolant Requirement |

|---|---|---|---|

| 303 | 400-500 | High | Moderate |

| 304 | 300-400 | Medium | Heavy |

| 316 | 250-350 | Medium | Heavy |

| 17-4 PH | 200-300 | Low | Heavy |

Material Selection Considerations

When selecting stainless steel grades for machining, consider these factors:

- End-use environment

- Required mechanical properties

- Production volume

- Cost constraints

- Surface finish requirements

For critical applications, I always recommend conducting material testing before full production. This approach has saved many clients from costly mistakes and ensures optimal performance in the final application.

Cost-Efficiency Analysis

The total cost of machining different grades involves more than just material prices:

| Grade | Material Cost | Machining Time | Tool Life | Overall Cost |

|---|---|---|---|---|

| 303 | Moderate | Low | Long | Lowest |

| 304 | Moderate | Medium | Medium | Moderate |

| 316 | High | High | Short | Highest |

| 17-4 PH | Very High | Medium | Medium | High |

In conclusion, selecting the right stainless steel grade requires balancing machinability, performance requirements, and cost considerations. Understanding these common grades and their characteristics helps ensure successful machining operations and optimal part performance.

What are the Key Machining Techniques for Stainless Steel?

Machining stainless steel can be a real challenge for many manufacturers. I’ve seen numerous projects delayed or compromised due to improper machining techniques, resulting in tool wear, poor surface finish, and dimensional inaccuracies. The material’s high strength, work hardening tendency, and low thermal conductivity make it particularly demanding to machine correctly.

The key machining techniques for stainless steel include CNC milling, CNC turning, drilling, and grinding. Success depends on selecting proper cutting parameters, using appropriate tooling, and maintaining optimal cutting conditions with suitable cooling strategies.

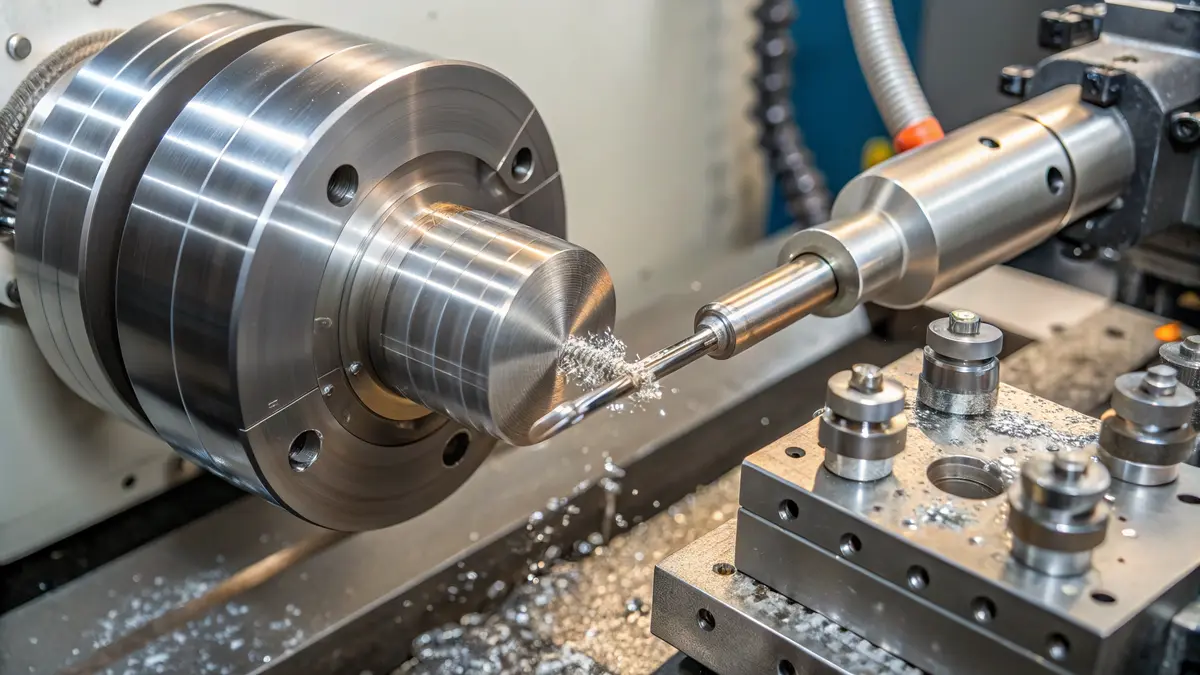

CNC Milling Techniques for Stainless Steel

When it comes to CNC milling stainless steel, the right approach makes all the difference. At PTSMAKE, we use these proven parameters for optimal results:

- Cutting Speed: 100-150 surface feet per minute (SFM) for austenitic stainless

- Feed Rate: 0.004-0.008 inches per tooth

- Depth of Cut: Maximum 0.125 inches for roughing, 0.02 inches for finishing

Using climb milling rather than conventional milling reduces work hardening and extends tool life. We always ensure rigid tool holding and minimal tool overhang to prevent chatter.

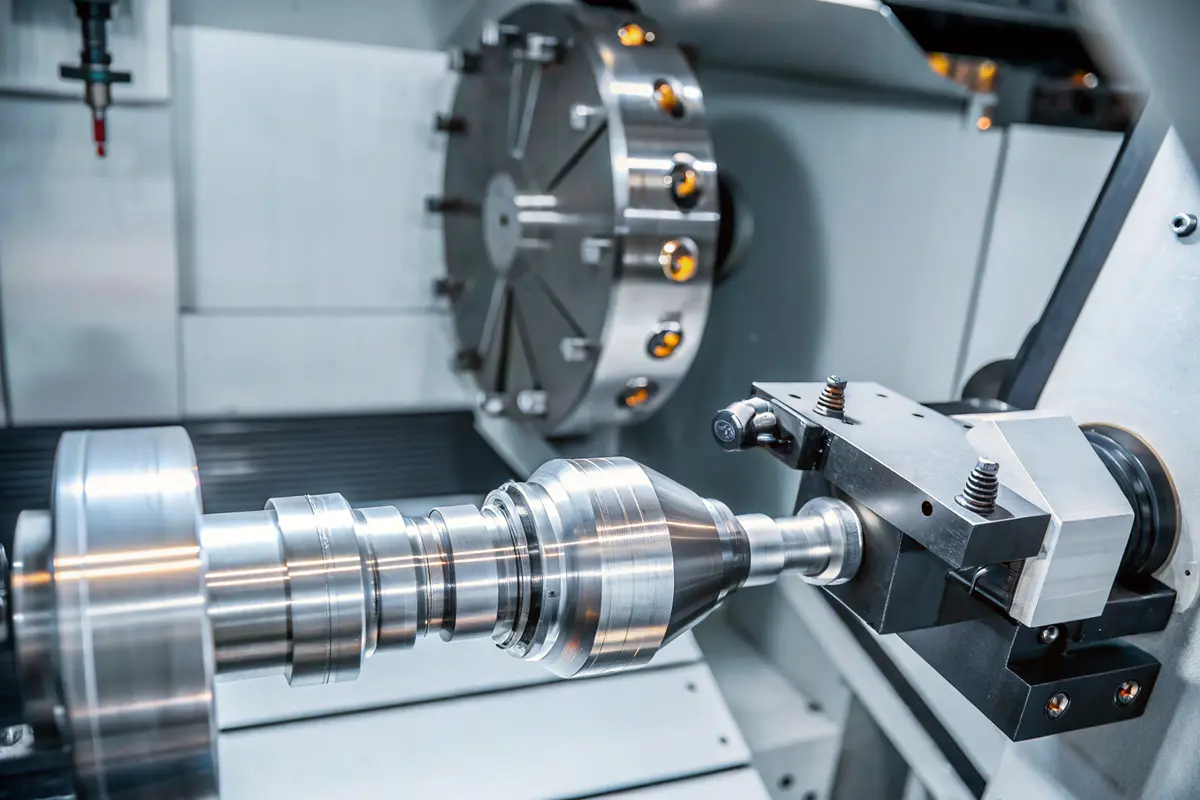

CNC Turning Operations

Turning stainless steel requires special attention to these key factors:

| Parameter | Recommended Range | Notes |

|---|---|---|

| Cutting Speed | 250-350 SFM | Higher for finishing |

| Feed Rate | 0.005-0.015 ipr | Depends on surface finish |

| Depth of Cut | 0.040-0.200 inches | Material dependent |

| Tool Geometry | 5-15° relief angle | Positive rake recommended |

Drilling Techniques

Drilling stainless steel presents unique challenges. We follow these guidelines:

- Use shortened drill lengths when possible

- Start with pilot holes for deeper holes

- Maintain constant feed rate

- Apply sufficient cutting fluid pressure

Recommended drilling parameters:

- Speed: 20-30 SFM

- Feed: 0.002-0.004 inches per revolution

- Peck drilling cycles for holes deeper than 3x diameter

Surface Grinding Considerations

Surface grinding is crucial for achieving tight tolerances. Our approach includes:

Wheel Selection

- Aluminum oxide wheels for general purpose

- CBN wheels for high-production runs

- 60-80 grit size for roughing

- 120-150 grit for finishing

Grinding Parameters

- Wheel speed: 5000-6000 surface feet per minute

- Table speed: 50-60 feet per minute

- Depth of cut: 0.0005-0.001 inches per pass

Cutting Fluid Selection and Application

Proper cutting fluid is essential for stainless steel machining:

Types of Cutting Fluids

- Water-soluble oils for general purpose

- Straight oils for heavy-duty operations

- Synthetic fluids for high-speed applications

Application Methods

- Flood cooling for general operations

- Through-tool cooling for deep holes

- Mist application for light cuts

Tool Selection and Management

Choosing the right tools significantly impacts machining success:

Tool Materials

- Carbide grades with TiAlN coating

- Ceramic tools for high-speed operations

- HSS tools for simple operations

Tool Life Management

- Regular wear monitoring

- Predetermined tool change intervals

- Proper tool storage and handling

Process Optimization Strategies

For optimal results, we implement these strategies:

Parameter Optimization

- Start conservative and increase gradually

- Monitor tool wear and surface finish

- Adjust based on actual results

Quality Control

- Regular dimensional checks

- Surface finish monitoring

- Tool wear inspection

Production Efficiency

- Minimize setup time

- Optimize tool paths

- Reduce non-cutting time

By implementing these techniques and maintaining strict attention to detail, we consistently achieve excellent results in stainless steel machining. The key is understanding how each parameter affects the outcome and making appropriate adjustments based on real-time feedback from the machining process.

Remember, successful stainless steel machining requires a balanced approach. While high productivity is important, it shouldn’t come at the expense of tool life or part quality. Regular monitoring and adjustment of machining parameters ensure optimal results and consistent quality.

What Tools and Equipment Are Best for Stainless Steel Machining?

Stainless steel machining presents significant challenges in our manufacturing processes. Many machinists struggle with rapid tool wear, poor surface finish, and inconsistent results when working with this demanding material. These issues not only lead to increased production costs but also cause frustrating delays and quality concerns.

The best tools for stainless steel machining include carbide cutting tools with specialized coatings, rigid CNC machines with high spindle power, and advanced cutting inserts designed specifically for stainless steel. Proper coolant delivery systems and tool holders are also essential for optimal performance.

Carbide Cutting Tools: The Foundation of Success

In my experience at PTSMAKE, carbide tools have proven to be the most reliable choice for stainless steel machining. We primarily use solid carbide end mills with these key features:

- Micro-grain carbide composition for enhanced wear resistance

- Variable helix angles to reduce chatter

- Higher rake angles for better chip evacuation

- Specialized edge preparation to prevent premature tool failure

The right carbide grade is crucial. For stainless steel applications, we recommend grades with 10-12% cobalt content, which provides an optimal balance between hardness and toughness.

Cutting Tool Coatings: A Game-Changing Element

Modern coating technologies have revolutionized stainless steel machining. Here’s a detailed breakdown of the most effective coatings:

| Coating Type | Benefits | Best Applications |

|---|---|---|

| AlTiN | High heat resistance, excellent hardness | High-speed machining |

| TiCN | Good wear resistance, lower friction | Medium-duty operations |

| ZrN | Chemical stability, reduced built-up edge | Finishing operations |

| TiAlN | Superior oxidation resistance | Heavy roughing |

Advanced CNC Machine Requirements

The success of stainless steel machining heavily depends on machine capabilities. Essential features include:

High Spindle Power

- Minimum 15 HP for small to medium parts

- 25+ HP for larger components

- High-torque capabilities at lower speeds

Rigid Construction

- Heavy-duty base casting

- Linear guides with high preload

- Robust spindle bearings

Thermal Stability

- Temperature-controlled spindle

- Coolant-through capabilities

- Thermal compensation systems

Tool Holders and Workholding Solutions

Proper tool holding is critical for stainless steel machining. We recommend:

- Hydraulic tool holders for better runout control

- Heat-shrink holders for high-speed applications

- Heavy-duty milling chucks for maximum rigidity

Coolant Delivery Systems

Effective coolant management is crucial when machining stainless steel:

High-Pressure Coolant Systems

- 1000+ PSI for deep hole drilling

- 300-500 PSI for general milling operations

- Through-tool coolant delivery

Coolant Selection

- Oil-based coolants for heavy cutting

- Water-soluble emulsions for general purpose

- Minimum quantity lubrication (MQL) for specific applications

Insert Selection and Geometry

The right insert geometry can significantly impact tool life and surface finish:

- Positive rake angles for reduced cutting forces

- Strong edge preparation for interrupted cuts

- Chip breaker geometry for improved chip control

- Corner radius selection based on surface finish requirements

Tool Life Monitoring and Management

To optimize tool performance, we implement these strategies:

Regular Tool Inspection

- Measure wear patterns

- Monitor cutting forces

- Track tool life systematically

Tool Life Optimization

- Adjust cutting parameters based on wear analysis

- Implement predictive tool change schedules

- Document performance metrics

Process Parameters Optimization

Success in stainless steel machining requires careful attention to cutting parameters:

| Parameter | Recommendation | Impact |

|---|---|---|

| Speed | 30-40% lower than carbon steel | Reduces heat generation |

| Feed | Moderate to heavy | Prevents work hardening |

| Depth of Cut | Consistent engagement | Maintains tool life |

| Entry Angle | 45° when possible | Reduces shock loading |

By implementing these tool and equipment recommendations, we’ve consistently achieved excellent results in stainless steel machining. The key is to maintain a systematic approach to tool selection, machine setup, and process optimization while always considering the specific requirements of your application.

How to Prevent Work Hardening in Stainless Steel Machining?

Working with stainless steel can be a real headache in machining operations. I’ve seen countless projects where work hardening has led to premature tool wear, poor surface finish, and even complete part failures. This issue becomes even more frustrating when tight tolerances are required, as the hardened layer can cause dimensional inconsistencies.

To prevent work hardening in stainless steel machining, maintain consistent cutting forces, use proper tool geometry with positive rake angles, and implement effective cooling strategies. Keep cutting speeds moderate, ensure continuous cuts when possible, and select appropriate tool coatings for better heat management.

Understanding Work Hardening Mechanics

Work hardening occurs when mechanical stress causes the material’s crystal structure to change, resulting in increased hardness and strength. In stainless steel, this phenomenon is particularly pronounced due to its austenitic structure. The material can become up to 50% harder than its original state, making subsequent cuts increasingly difficult.

The primary triggers for work hardening include:

- Excessive cutting forces

- Heat buildup during machining

- Inconsistent chip formation

- Tool deflection

- Inappropriate cutting parameters

Tool Geometry Optimization

The right tool geometry plays a crucial role in preventing work hardening. Here’s what I recommend based on extensive testing:

| Tool Parameter | Recommended Value | Purpose |

|---|---|---|

| Rake Angle | 10-15° positive | Reduces cutting forces |

| Relief Angle | 8-12° | Prevents rubbing |

| Edge Prep | Sharp to light hone | Clean cutting action |

| Tool Nose Radius | 0.015-0.032" | Balances strength and heat generation |

Cutting Parameters Selection

Proper cutting parameters are essential for maintaining consistent cutting forces:

| Parameter | Recommendation | Rationale |

|---|---|---|

| Cutting Speed | 100-150 SFM | Balances heat generation |

| Feed Rate | 0.004-0.008 IPR | Maintains chip control |

| Depth of Cut | 0.040-0.080" | Prevents work hardening |

| Step Over | 30-40% of tool diameter | Ensures stable cutting |

Cooling Strategy Implementation

Effective cooling is crucial for preventing work hardening. I recommend implementing these strategies:

High-Pressure Coolant

- Use pressures above 1000 PSI

- Direct coolant precisely at the cutting edge

- Maintain consistent coolant temperature

Through-Tool Cooling

- Enables better heat removal

- Improves chip evacuation

- Reduces thermal shock

Material-Specific Considerations

Different stainless steel grades require specific approaches:

| Grade | Special Considerations | Recommended Approach |

|---|---|---|

| 304 | Highly prone to work hardening | Use lower speeds, higher feeds |

| 316 | Moderate work hardening tendency | Standard parameters with good cooling |

| 410 | Less prone to work hardening | Can use more aggressive cuts |

Tool Coating Selection

The right coating can significantly impact work hardening prevention:

AlTiN Coatings

- Excellent heat resistance

- Reduces friction

- Extends tool life

TiCN Coatings

- Good for interrupted cuts

- Maintains sharp cutting edge

- Resists built-up edge formation

Process Monitoring and Adjustment

Regular monitoring helps prevent work hardening:

Surface Finish Indicators

- Increasing roughness

- Burnished areas

- Inconsistent texture

Tool Wear Signs

- Accelerated wear patterns

- Built-up edge formation

- Changes in cutting sound

Power Consumption

- Sudden increases in power draw

- Inconsistent power usage

- Higher than normal baseline

Best Practices for Success

To ensure consistent results:

Machining Strategy

- Use climb milling when possible

- Maintain constant chip load

- Avoid light cuts that rub instead of cut

Tool Path Planning

- Minimize tool engagement variations

- Avoid sudden direction changes

- Plan for continuous cutting when possible

Setup Considerations

- Ensure rigid workpiece clamping

- Minimize overhang

- Use the shortest possible tool lengths

Through implementing these strategies, we’ve achieved consistent success in preventing work hardening across various stainless steel applications. Remember that prevention is always better than dealing with already hardened material, as corrective measures often result in increased costs and production delays.

What Are the Best Cooling and Lubrication Methods?

Machining stainless steel without proper cooling is like running a marathon in the desert without water. The intense heat generated during the cutting process can quickly destroy expensive cutting tools and compromise part quality. I’ve seen countless machinists struggle with premature tool wear and poor surface finishes simply because they overlooked this critical aspect.

The most effective cooling methods for machining stainless steel combine flood cooling for general operations and mist cooling for high-speed applications. The choice of cutting fluid is equally important – synthetic or semi-synthetic coolants with high lubricity and heat dissipation properties deliver the best results.

Understanding the Importance of Cooling in Stainless Steel Machining

When machining stainless steel, about 80% of the energy used in cutting transforms into heat. This heat concentrates at the cutting edge and workpiece interface. Without proper cooling, the cutting tool can reach temperatures exceeding 800°C, leading to rapid tool wear and potential workpiece damage.

The three main functions of cooling systems are:

- Heat removal from the cutting zone

- Lubrication between the tool and workpiece

- Chip evacuation from the cutting area

Types of Cooling Methods

Flood Cooling

This traditional method remains the most widely used cooling technique in stainless steel machining. Here’s why it’s effective:

- Provides consistent temperature control

- Ensures excellent chip evacuation

- Creates a protective barrier between tool and workpiece

- Offers good surface finish quality

However, flood cooling requires proper maintenance of the coolant system and regular fluid replacement to maintain its effectiveness.

Mist Cooling (MQL – Minimum Quantity Lubrication)

This modern approach uses a fine spray of coolant mixed with compressed air:

- Reduces coolant consumption by up to 95%

- Ideal for high-speed machining operations

- Environmentally friendly option

- Better visibility of the cutting zone

Cryogenic Cooling

For specialized applications, liquid nitrogen cooling offers unique advantages:

- Extremely low temperatures (-196°C)

- Extends tool life significantly

- Ideal for difficult-to-machine materials

- Leaves no residue on parts

Selecting the Right Cutting Fluid

The choice of cutting fluid significantly impacts machining performance. Here’s a comprehensive comparison:

| Fluid Type | Advantages | Best Applications | Concentration Range |

|---|---|---|---|

| Synthetic | High heat dissipation, clean operation | High-speed machining | 5-10% |

| Semi-synthetic | Good lubricity, moderate cost | General purpose | 6-12% |

| Soluble Oil | Excellent lubrication, good cooling | Heavy cutting | 8-15% |

| Straight Oil | Maximum lubricity | Low-speed operations | 100% |

Optimization Strategies for Cooling Systems

Pressure and Flow Rate

The effectiveness of cooling depends heavily on proper delivery:

- Use high-pressure cooling (1000+ PSI) for deep holes and difficult cuts

- Maintain consistent flow rates based on operation type

- Position nozzles correctly to target the cutting zone

Maintenance Requirements

Regular maintenance ensures optimal cooling performance:

- Monitor coolant concentration weekly

- Check pH levels regularly (ideal range: 8.5-9.5)

- Filter chips and contaminants continuously

- Replace coolant when biological growth becomes evident

Advanced Cooling Techniques

Through-Tool Cooling

This method delivers coolant directly through the cutting tool:

- Ensures coolant reaches critical areas

- Improves tool life by up to 50%

- Enables higher cutting speeds

- Particularly effective for deep hole drilling

Dual-Channel Cooling

Some modern systems use separate channels for cooling and lubrication:

- Optimizes both cooling and lubrication functions

- Reduces overall fluid consumption

- Provides better control over process parameters

Practical Implementation Tips

Based on my experience working with various cooling methods, here are key considerations:

Start with the basics:

- Use high-quality coolant

- Maintain proper concentration

- Clean the system regularly

Monitor these critical parameters:

- Coolant pressure

- Flow rate

- Temperature

- Concentration levels

Consider these factors when choosing a cooling method:

- Material characteristics

- Cutting parameters

- Tool geometry

- Production volume

Remember, the best cooling method often combines different techniques based on specific application requirements. The key is finding the right balance between cooling effectiveness, cost efficiency, and environmental impact.

How to Achieve High Precision in Stainless Steel Machining?

Achieving precision in stainless steel machining is a constant challenge that many manufacturers face. I’ve witnessed countless projects fail due to poor accuracy control, resulting in scrapped parts, missed deadlines, and frustrated customers. The complexity of stainless steel’s properties makes this challenge even more daunting, as even minor variations can lead to significant deviations.

To achieve high precision in stainless steel machining, manufacturers must focus on three critical areas: maintaining machine stability, implementing systematic tool wear monitoring, and conducting regular quality control inspections with advanced metrology equipment.

Machine Stability Fundamentals

Machine stability forms the foundation of precision machining. At PTSMAKE, we’ve implemented several key measures to ensure optimal stability:

Temperature Control

- Maintain workshop temperature at 20°C ±1°C

- Install thermal sensors on critical machine components

- Use coolant temperature control systems

- Implement warm-up cycles before precision operations

Vibration Management

- Install anti-vibration mounts

- Regular maintenance of spindle bearings

- Use vibration monitoring systems

- Proper foundation isolation

Tool Wear Monitoring Systems

Tool wear significantly impacts machining accuracy. Our approach includes:

Real-time Monitoring Methods

- Acoustic emission sensors

- Power consumption monitoring

- Cutting force measurement

- Visual inspection systems

| Monitoring Parameter | Measurement Method | Impact on Precision |

|---|---|---|

| Cutting Force | Dynamometer | Direct correlation with tool wear |

| Power Consumption | Amp Meter | Indicates tool condition |

| Acoustic Emission | Sensors | Early detection of wear |

| Surface Finish | Visual/Tactile | Final quality indicator |

Quality Control Protocol

Our comprehensive quality control system ensures consistent precision:

Measurement Equipment

- Coordinate Measuring Machines (CMM)

- Optical measurement systems

- Surface roughness testers

- Digital micrometers

Inspection Frequency

We’ve established a structured inspection schedule:

| Production Stage | Inspection Type | Frequency |

|---|---|---|

| Setup | First Article | Every new setup |

| Production | In-process | Every 10 parts |

| Final | CMM | 100% inspection |

| Post-process | Surface finish | Sample basis |

Process Parameter Optimization

Achieving high precision requires careful parameter selection:

Cutting Parameters

- Reduced cutting speeds (20-30% lower than carbon steel)

- Controlled feed rates

- Appropriate depth of cut

- Rigid workpiece clamping

Coolant Management

- High-pressure coolant delivery

- Regular coolant concentration monitoring

- Filtered and temperature-controlled coolant

- Strategic coolant nozzle positioning

Environmental Controls

Environmental factors play a crucial role in maintaining precision:

Workshop Environment

- Climate-controlled facility

- Air filtration systems

- Regular cleaning schedules

- Controlled humidity levels

Material Handling

- Temperature stabilization before machining

- Proper storage conditions

- Minimal handling during processing

- Clean workpiece surfaces

Statistical Process Control

We implement comprehensive SPC methods:

Data Collection

- Automated measurement recording

- Real-time data analysis

- Trend monitoring

- Process capability studies

| Control Chart Type | Application | Action Limits |

|---|---|---|

| X-bar Chart | Dimensional control | ±3σ |

| R Chart | Process variation | Upper control limit |

| Individual Chart | Critical features | ±2σ |

Continuous Improvement

Our precision machining process constantly evolves through:

Regular Reviews

- Monthly performance analysis

- Customer feedback integration

- Technology updates

- Staff training programs

Documentation

- Detailed process instructions

- Quality control records

- Maintenance logs

- Calibration certificates

This comprehensive approach to precision stainless steel machining has enabled us to consistently achieve tolerances within ±0.01mm. The key is maintaining a systematic approach to all aspects of the machining process, from environmental control to final inspection. By following these guidelines and continuously monitoring and improving our processes, we can ensure reliable, high-precision results in stainless steel machining operations.

What Are the Applications of Machined Stainless Steel Parts?

Many manufacturers struggle to find the right material for their critical components that demand both durability and precision. The challenge becomes even more complex when these parts need to resist corrosion, maintain stability under extreme temperatures, and meet strict industry regulations. Without the right material choice, products can fail prematurely or face regulatory compliance issues.

Machined stainless steel parts are versatile components used across multiple industries, from aerospace to medical devices. These parts offer exceptional corrosion resistance, durability, and precision, making them ideal for demanding applications where reliability and performance are crucial.

Aerospace Industry Applications

The aerospace sector heavily relies on machined stainless steel parts for critical components. I’ve worked with numerous aerospace clients at PTSMAKE, and these parts are essential for:

- Engine components and turbine blades

- Landing gear mechanisms

- Structural supports and fasteners

- Hydraulic system components

- Control surface actuators

The high strength-to-weight ratio and excellent heat resistance of stainless steel make it perfect for these demanding applications.

Medical Device Manufacturing

In medical applications, stainless steel’s biocompatibility and sterilization capabilities are invaluable. Common applications include:

| Medical Component | Key Requirements | Benefits of Stainless Steel |

|---|---|---|

| Surgical Instruments | Precision, Sterilization | Corrosion resistance, Durability |

| Implants | Biocompatibility, Strength | Long life, Body fluid resistance |

| Diagnostic Equipment | Reliability, Cleanability | Easy maintenance, Stability |

| Medical Fixtures | Precision, Durability | Dimensional stability, Wear resistance |

Automotive Components

The automotive industry uses machined stainless steel parts extensively. Key applications include:

- Exhaust system components

- Fuel injection systems

- Engine valve components

- Sensor housings

- Brake system components

These parts must withstand high temperatures, pressure, and constant exposure to corrosive substances.

Food and Beverage Processing Equipment

Stainless steel’s corrosion resistance and ease of cleaning make it ideal for food processing:

- Mixing vessels

- Conveyor systems

- Cutting and processing tools

- Storage tanks

- Filtration systems

Chemical Processing Industry

The chemical industry requires materials that can withstand aggressive environments:

| Application | Environmental Challenge | Stainless Steel Solution |

|---|---|---|

| Pump Components | Chemical exposure | Superior corrosion resistance |

| Valve Bodies | High pressure | Structural integrity |

| Heat Exchangers | Temperature extremes | Thermal stability |

| Reactor Vessels | Multiple stressors | Overall durability |

Marine Applications

Marine environments are particularly challenging due to constant salt water exposure:

- Propeller shafts

- Deck hardware

- Underwater sensors

- Navigation equipment

- Fasteners and fittings

Electronics Industry

The electronics sector uses machined stainless steel for:

- Equipment housings

- Heat sinks

- EMI shielding components

- Mounting brackets

- Connector shells

Oil and Gas Equipment

The oil and gas industry requires particularly robust components:

- Wellhead components

- Valve systems

- Pressure vessels

- Pipeline fittings

- Subsea equipment

Quality Considerations Across Applications

When manufacturing these components, several factors are crucial:

Material Selection

- Grade selection based on application

- Certification requirements

- Cost considerations

Manufacturing Process

- Precision machining capabilities

- Surface finish requirements

- Complex geometry handling

Quality Control

- Dimensional accuracy

- Material properties verification

- Surface finish inspection

At PTSMAKE, we maintain strict quality control measures to ensure each component meets industry-specific requirements:

| Industry | Critical Requirements | Quality Measures |

|---|---|---|

| Aerospace | AS9100 certification | 100% inspection |

| Medical | FDA compliance | Validated processes |

| Automotive | IATF 16949 standards | Statistical process control |

| Food Processing | FDA/USDA standards | Material traceability |

Through working with diverse industries, I’ve observed that the success of stainless steel applications depends heavily on understanding specific industry requirements and maintaining strict quality control throughout the manufacturing process. Each application requires careful consideration of material grade selection, manufacturing processes, and quality control measures to ensure optimal performance in its intended use.

How to Reduce Costs While Maintaining Quality?

In today’s manufacturing landscape, the rising costs of machining stainless steel pose a significant challenge. Tool wear accelerates rapidly, material prices continue to climb, and production expenses seem to multiply with each passing quarter. Many manufacturers find themselves caught between maintaining quality standards and managing escalating costs, leading to shrinking profit margins.

The key to reducing costs while maintaining quality in stainless steel machining lies in a comprehensive approach combining optimized cutting parameters, advanced tooling solutions, waste reduction strategies, and lean manufacturing principles. These methods can decrease expenses by 15-30% without compromising part quality.

Optimizing Cutting Parameters

Proper cutting parameter selection forms the foundation of cost-effective machining. Through careful testing and monitoring at PTSMAKE, we’ve identified these critical factors:

| Parameter | Impact on Cost | Recommended Optimization |

|---|---|---|

| Cutting Speed | Direct effect on tool life | Use optimal speed ranges for specific grades |

| Feed Rate | Influences surface finish and tool wear | Balance between productivity and wear |

| Depth of Cut | Affects power consumption and tool stress | Maintain consistent engagement |

| Coolant Usage | Impacts tool life and surface quality | Use high-pressure cooling when possible |

Advanced Tooling Solutions

Investing in modern cutting tools might seem expensive initially, but the long-term benefits are substantial:

Coated Carbide Tools

- Extended tool life (up to 200% longer)

- Higher cutting speeds possible

- Better surface finish quality

Multi-functional Tools

- Reduced setup time

- Fewer tool changes

- Lower inventory costs

Waste Reduction Strategies

Minimizing waste directly impacts the bottom line:

Material Optimization

- Nesting parts efficiently

- Using remnant materials strategically

- Implementing material tracking systems

Process Waste Reduction

- Optimizing programming for minimal scrap

- Regular maintenance to prevent defects

- Quality control at source

Lean Manufacturing Implementation

The application of lean principles specifically for stainless steel machining includes:

Just-in-Time Production

- Reduced inventory costs

- Better cash flow management

- Minimized storage requirements

Value Stream Mapping

- Identifying inefficiencies

- Eliminating non-value-adding activities

- Streamlining workflow

Cost Monitoring and Analysis

Regular monitoring of key cost indicators helps maintain control:

| Cost Factor | Monitoring Method | Target Improvement |

|---|---|---|

| Tool Consumption | Usage tracking per part | 15-20% reduction |

| Material Utilization | Scrap rate analysis | 10-15% improvement |

| Machine Uptime | OEE measurements | 5-10% increase |

| Labor Efficiency | Time studies | 10-15% enhancement |

Technology Integration

Modern technology plays a crucial role in cost reduction:

CAM Software Optimization

- Better toolpath strategies

- Reduced cycle times

- Improved surface finish

Machine Monitoring Systems

- Real-time performance tracking

- Predictive maintenance

- Energy consumption optimization

Quality Assurance Integration

Maintaining quality while reducing costs requires:

In-Process Monitoring

- Early detection of issues

- Reduced scrap rates

- Consistent quality output

Statistical Process Control

- Data-driven decision making

- Trend analysis

- Continuous improvement

At PTSMAKE, we’ve successfully implemented these strategies across our production floor. For instance, by optimizing cutting parameters and implementing advanced tooling solutions, we achieved a 25% reduction in machining costs for a complex stainless steel medical component while maintaining tight tolerances of ±0.01mm.

The key is to view cost reduction not as a one-time effort but as an ongoing process of continuous improvement. By systematically addressing each aspect of the machining process, from tool selection to waste reduction, significant cost savings can be achieved without compromising the quality standards that our customers expect and deserve.

Remember that successful cost reduction in stainless steel machining requires a balanced approach. While it’s tempting to focus solely on immediate cost-cutting measures, the long-term view should always prioritize maintaining quality standards. This ensures sustainable cost reduction that doesn’t compromise your reputation or lead to expensive quality issues down the line.