Have you ever received a product with blurry or peeling screen-printed graphics? It’s frustrating when logos fade or text becomes illegible after just a few uses. Poor silkscreen quality not only affects product appearance but can damage brand reputation and lead to customer returns.

Silkscreen printing is a method where ink is transferred through a mesh stencil onto a surface. The process involves creating a screen with blocked and open areas, applying ink, and using a squeegee to press the ink through the mesh onto the material beneath.

I’ve helped many clients optimize their silkscreen processes at PTSMAKE. Let me walk you through the detailed steps and share some practical tips I’ve learned from working with various materials and applications. You’ll discover how to achieve professional-quality results consistently.

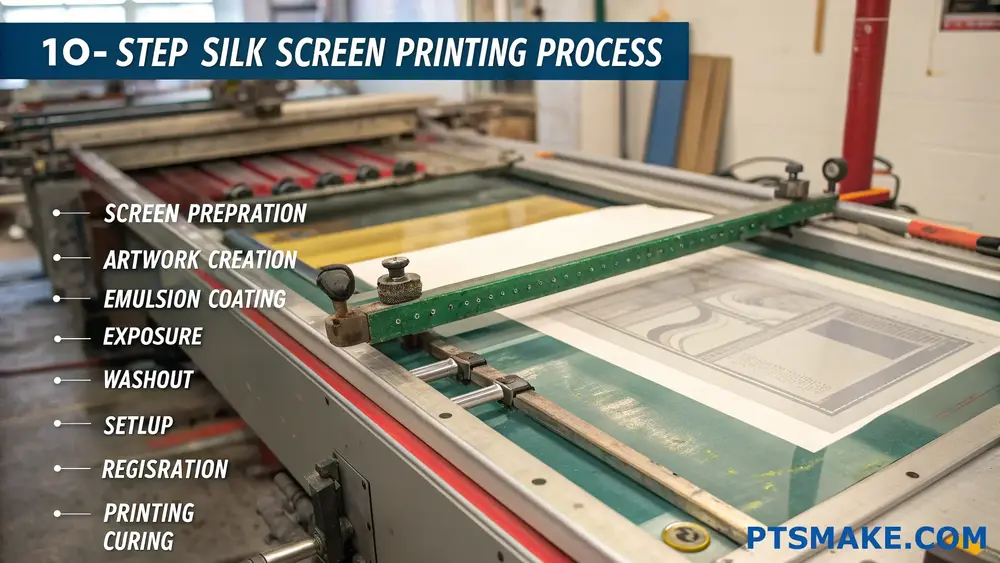

What Are the 10 Steps in Silk Screen Printing?

Have you ever admired the vibrant logos on t-shirts or precise patterns on circuit boards and wondered how they achieve such perfect prints? Many businesses struggle to get consistent, high-quality results in screen printing, often facing issues with blurred edges and uneven coverage.

Silk screen printing involves ten essential steps: screen preparation, artwork creation, emulsion coating, exposure, washout, setup, registration, printing, curing, and cleanup. This systematic process ensures consistent, high-quality prints across various materials and applications.

Understanding the Screen Preparation Process

The foundation of successful screen printing starts with proper screen preparation. At PTSMAKE, we begin by selecting the appropriate mesh count for the project. The mesh count1 determines the amount of ink that passes through the screen, affecting the final print quality.

Mesh Selection Guide

| Application Type | Recommended Mesh Count | Best For |

|---|---|---|

| Textiles | 110-160 | T-shirts, fabrics |

| Electronics | 200-305 | Circuit boards, components |

| Graphics | 160-230 | Posters, signs |

| Fine Details | 305-420 | High-resolution prints |

Creating and Preparing Artwork

The quality of your final print heavily depends on the artwork preparation. I recommend using vector-based designs whenever possible for the sharpest results. The artwork must be properly separated into individual colors and converted to high-contrast positives.

Key Artwork Requirements:

- Minimum line thickness: 0.5pt

- Text size: At least 6pt for positive prints

- Image resolution: 300 DPI minimum

- Color separation: Clear distinction between elements

Emulsion Application Techniques

The emulsion coating process requires precision and consistency. I’ve developed a specific technique that involves:

- Maintaining a 45-degree angle while coating

- Applying even pressure throughout the stroke

- Using two coats on the print side

- Adding one coat on the squeegee side

Exposure and Development Process

This critical phase transforms your artwork into a printable stencil. The exposure time varies based on:

Exposure Variables Table

| Factor | Impact | Consideration |

|---|---|---|

| Emulsion Type | High | Different sensitivities |

| Light Source | Critical | LED vs. UV vs. Metal Halide |

| Screen Color | Medium | Yellow vs. White mesh |

| Coating Thickness | High | Affects cure time |

Setup and Registration Process

Proper setup ensures consistent prints throughout the run. I emphasize the importance of:

- Securing the screen firmly

- Setting off-contact distance

- Adjusting squeegee angle

- Establishing registration marks

The Printing Operation

The actual printing process requires:

Speed and Pressure Control

- Consistent squeegee speed

- Even pressure application

- Proper flood stroke technique

- Clean ink deposit

Curing Methods and Requirements

Different materials require specific curing methods:

Curing Temperature Guide

| Material Type | Temperature Range | Curing Time |

|---|---|---|

| Cotton | 320-350°F | 60-90 seconds |

| Polyester | 270-300°F | 45-60 seconds |

| Paper | 250-300°F | 30-45 seconds |

| Plastics | 150-200°F | 20-30 seconds |

Quality Control and Troubleshooting

Regular quality checks ensure consistent output. Key inspection points include:

- Print opacity

- Registration accuracy

- Color consistency

- Cure completeness

Cleanup and Maintenance

Proper cleanup extends screen life and maintains print quality. Essential steps include:

- Ink removal

- Emulsion reclaiming

- Degreasing

- Proper storage

Advanced Techniques for Special Applications

At PTSMAKE, we’ve developed specialized techniques for challenging applications:

Industrial Applications

- Circuit board printing

- Medical device marking

- Automotive part labeling

This comprehensive process has enabled us to deliver consistent results across various industries, from electronics to textiles. The key is maintaining strict attention to detail at each step while understanding how different variables interact throughout the process.

How Does the Process of Silk Screening Occur?

Have you ever wondered why some printed designs look so vibrant and durable, while others fade quickly? The difference often lies in the printing technique used. Many businesses waste thousands of dollars on inferior printing methods, leading to poor quality results and disappointed customers.

Silk screening, also known as screen printing, is a printing technique where ink is transferred through a mesh screen onto a substrate. The process involves creating a stencil on the screen, applying ink, and using a squeegee to press the ink through the mesh onto the material beneath.

Understanding the Basic Components

Before diving into the process, it’s essential to understand the key components involved in silk screening:

Mesh Screen

The foundation of silk screening starts with the mesh screen. Modern screens use synthetic materials like polyester or nylon, offering different mesh counts for various applications:

| Mesh Count | Best Used For | Print Quality |

|---|---|---|

| 110-160 | Basic designs | Standard |

| 200-230 | Detailed work | High |

| 305-330 | Fine details | Premium |

Frame and Emulsion

The mesh is stretched over a frame, typically made of aluminum or wood. We apply a light-sensitive photoemulsion2 coating to create the stencil. At PTSMAKE, we exclusively use industrial-grade aluminum frames for better durability and consistent results.

The Step-by-Step Process

1. Design Preparation

- Create or convert artwork to single-color layers

- Ensure proper resolution and contrast

- Print design on transparent film

2. Screen Preparation

- Clean the mesh thoroughly

- Apply photoemulsion evenly

- Allow proper drying time in a dark room

3. Exposure and Development

The prepared screen undergoes exposure to UV light, which hardens the emulsion everywhere except where the design blocks the light. The unexposed areas wash away, creating the stencil.

4. Setting Up the Print

- Secure the substrate

- Align the screen precisely

- Test print positioning

5. Printing Execution

This crucial stage requires:

- Proper ink consistency

- Correct squeegee angle (15-25 degrees)

- Even pressure application

- Consistent stroke speed

Advanced Techniques and Considerations

Multi-Color Printing

For complex designs requiring multiple colors:

- Each color needs a separate screen

- Perfect registration is crucial

- Drying time between colors is essential

Quality Control Measures

| Aspect | Check Point | Prevention Method |

|---|---|---|

| Registration | Color alignment | Use registration marks |

| Ink Coverage | Even distribution | Maintain proper pressure |

| Cure Temperature | Complete curing | Monitor heat settings |

Material-Specific Adjustments

Different substrates require specific considerations:

- Textiles: Pre-treatment may be necessary

- Plastics: Surface tension testing

- Metal: Special ink formulations

- Glass: Proper adhesion promoters

Troubleshooting Common Issues

Print Quality Problems

- Uneven ink coverage

- Bleeding or smearing

- Poor detail reproduction

- Color inconsistency

Prevention Strategies

- Regular screen maintenance

- Proper mesh tension

- Consistent ink viscosity

- Environmental control

Industry Applications

The versatility of silk screening makes it valuable across various industries:

Manufacturing Sector

- Product markings

- Warning labels

- Serial numbers

- Brand identifications

Commercial Applications

- Promotional materials

- Signage

- Packaging

- Display graphics

In my experience at PTSMAKE, we’ve successfully implemented silk screening for various industrial applications, particularly in manufacturing identification components. This process has proven especially valuable for clients requiring durable, high-quality markings on their products.

Technical Specifications for Industrial Use

| Application | Ink Type | Curing Method | Durability |

|---|---|---|---|

| Metal Parts | Epoxy-based | Heat cure | 5+ years |

| Plastic Components | UV-resistant | UV exposure | 3-5 years |

| Circuit Boards | Conductive | Thermal | 10+ years |

Environmental Considerations and Modern Adaptations

The industry is evolving with increased focus on:

- Water-based ink systems

- VOC-free solutions

- Energy-efficient curing methods

- Waste reduction practices

Our facility at PTSMAKE has embraced these environmental considerations, implementing sustainable practices while maintaining high-quality standards in our silk screening operations.

What Equipment Is Essential for the Silk Screen Process?

Have you ever tried silk screen printing only to end up with blurry images and uneven color distribution? The frustration of wasting materials and time on failed attempts can be overwhelming, especially when you’re not sure if it’s your technique or equipment that’s causing the problems.

To achieve professional silk screen printing results, you need essential equipment including a quality screen mesh, squeegee, frame, emulsion, exposure unit, wash-out booth, and proper inks. Each piece plays a crucial role in creating sharp, consistent prints.

Basic Screen Printing Equipment

Frame and Mesh

The foundation of silk screen printing starts with a proper frame and mesh combination. At PTSMAKE, we use aluminum frames because they’re lightweight, resistant to warping, and maintain tension better than wooden frames. The mesh count is crucial – higher counts (200-305) work best for detailed designs, while lower counts (110-160) are ideal for bold graphics and thicker inks.

Squeegee Selection

Your squeegee’s durometer (hardness) affects print quality significantly. Here’s a basic guide:

| Durometer Rating | Best Used For | Common Applications |

|---|---|---|

| Soft (60-70) | Heavy deposits, textured surfaces | T-shirts, fabrics |

| Medium (70-80) | General purpose, smooth surfaces | Posters, signs |

| Hard (80-90) | Fine detail, thin deposits | Electronics, precision parts |

Advanced Equipment Requirements

Exposure Unit

A professional exposure unit ensures consistent photopolymer3 curing. While entry-level printers might use sunlight, I recommend investing in a LED exposure unit for repeatable results. These units provide uniform light distribution and precise timing controls.

Washout Booth

A dedicated washout area prevents cross-contamination and maintains workplace cleanliness. The ideal setup includes:

- Pressure washer

- Proper drainage system

- Adequate lighting

- Chemical-resistant surfaces

Quality Control Equipment

Registration Systems

Precise registration is essential for multi-color prints. Modern registration systems include:

- Micro-registration adjustments

- Pin registration

- Registration guides

- Digital alignment tools

Inspection Tools

Quality control equipment ensures consistent output:

- Light table for screen inspection

- Magnifying glass for detail checking

- Durometer gauge for squeegee hardness

- Tension meter for mesh measurement

Storage and Maintenance Equipment

Proper storage extends equipment life and maintains print quality. Essential storage items include:

Screen racks

- Vertical storage to prevent dust accumulation

- Adequate spacing between screens

- Climate-controlled environment

Chemical storage cabinets

- Ventilated storage for inks

- Safe emulsion storage

- Cleaning solution organization

Maintenance tools

- Screen tension meters

- Frame repair tools

- Mesh repair kits

Safety Equipment

Worker safety is paramount in screen printing operations. Required safety equipment includes:

Personal Protection

- Chemical-resistant gloves

- Safety glasses

- Respiratory protection

- Protective aprons

Facility Safety

- Ventilation systems

- Eye wash stations

- First aid kits

- Chemical spill kits

Environmental Control Equipment

Temperature and humidity significantly impact screen printing quality. Essential environmental control equipment includes:

Climate Control Systems

- Air conditioning units

- Dehumidifiers

- Temperature monitors

- Humidity gauges

Air Quality Management

- Ventilation systems

- Air filtration units

- Fume extractors

Ink Management System

Professional ink management ensures consistent results:

| Equipment Type | Purpose | Benefits |

|---|---|---|

| Ink mixing station | Color matching | Consistent color reproduction |

| Viscosity meters | Ink flow control | Uniform coverage |

| Color matching lights | Color accuracy | Professional results |

| Storage systems | Ink preservation | Extended shelf life |

At PTSMAKE, we’ve implemented comprehensive ink management systems that have significantly reduced waste and improved color consistency across production runs.

Digital Support Equipment

Modern screen printing benefits from digital technology:

Design Equipment

- Computer workstations

- Design software

- Color separation tools

- Film output devices

Process Control

- Digital timers

- Automated registration systems

- Quality control cameras

- Production tracking software

How to Ensure Quality Control in the Silk Screen Process?

Have you ever experienced the frustration of receiving silk-screened products with misaligned prints, inconsistent colors, or peeling issues? These quality problems not only waste resources but can also damage your brand’s reputation and lead to costly reprints.

Quality control in silk screen printing requires a systematic approach focusing on pre-press preparation, process monitoring, and post-production inspection. By implementing standardized procedures and regular checkpoints, manufacturers can consistently achieve high-quality results while minimizing defects and waste.

Pre-Production Quality Control

Material Verification

The foundation of quality control starts with proper material selection and verification. At PTSMAKE, we carefully inspect all incoming materials, including:

- Screen mesh quality and tension

- Ink viscosity and color accuracy

- Substrate surface condition

- Emulsion consistency

Equipment Calibration

Regular calibration of printing equipment ensures consistent results. Key aspects include:

- Screen tension measurement

- Squeegee angle and pressure settings

- Registration system alignment

- UV exposure unit calibration

Process Control Measures

Screen Preparation

The screen preparation process directly impacts print quality. Important factors include:

- Proper photoemulsion coating4

- Accurate exposure time

- Complete washout

- Thorough screen drying

Print Parameters Monitoring

Continuous monitoring of printing parameters is essential for maintaining quality. We implement the following control measures:

| Parameter | Control Method | Frequency |

|---|---|---|

| Registration | Visual inspection | Every print |

| Color density | Densitometer reading | Every 100 prints |

| Print clarity | Visual inspection | Every 50 prints |

| Ink viscosity | Viscometer check | Every 2 hours |

Quality Inspection Standards

Visual Inspection Criteria

We establish clear visual inspection standards for:

- Color consistency

- Image sharpness

- Registration accuracy

- Surface finish

- Coverage uniformity

Measurement-Based Quality Control

Quantitative measurements ensure objective quality assessment:

- Color density readings

- Registration tolerance checks

- Adhesion testing

- Curing verification

Documentation and Tracking

Process Documentation

Maintaining detailed records helps identify and resolve quality issues:

- Production parameters

- Material batch numbers

- Equipment settings

- Operator information

- Quality check results

Defect Analysis and Prevention

Understanding common defects helps prevent future issues:

| Defect Type | Common Causes | Preventive Measures |

|---|---|---|

| Color variation | Ink inconsistency | Regular ink mixing |

| Misregistration | Screen tension issues | Tension monitoring |

| Poor adhesion | Inadequate surface prep | Cleaning protocols |

| Image blurring | Improper screen tension | Regular calibration |

Environmental Control

Temperature and Humidity

Maintaining stable environmental conditions is crucial:

- Temperature: 20-25°C

- Relative humidity: 45-55%

- Air filtration

- Dust control

Storage Conditions

Proper storage of materials ensures consistent quality:

- Climate-controlled storage areas

- Protected from direct sunlight

- Organized inventory system

- Regular stock rotation

Training and Standardization

Operator Training

Well-trained operators are essential for quality control:

- Standard operating procedures

- Quality awareness

- Problem-solving skills

- Regular skill assessment

Quality Management System

Implementing a comprehensive quality management system includes:

- Written procedures

- Quality metrics

- Regular audits

- Continuous improvement initiatives

Continuous Improvement

Performance Monitoring

Regular monitoring helps identify areas for improvement:

- Defect rates

- Customer feedback

- Production efficiency

- Material waste

Process Optimization

Continuous improvement efforts focus on:

- Updated procedures

- New technology adoption

- Enhanced training

- Streamlined workflows

What Materials Are Compatible With the Silk Screen Printing Process?

Have you ever struggled to determine which materials would work best for your silk screen printing project? The frustration of wasted materials and failed prints can be overwhelming, especially when you’re working with unique substrates or specialized designs.

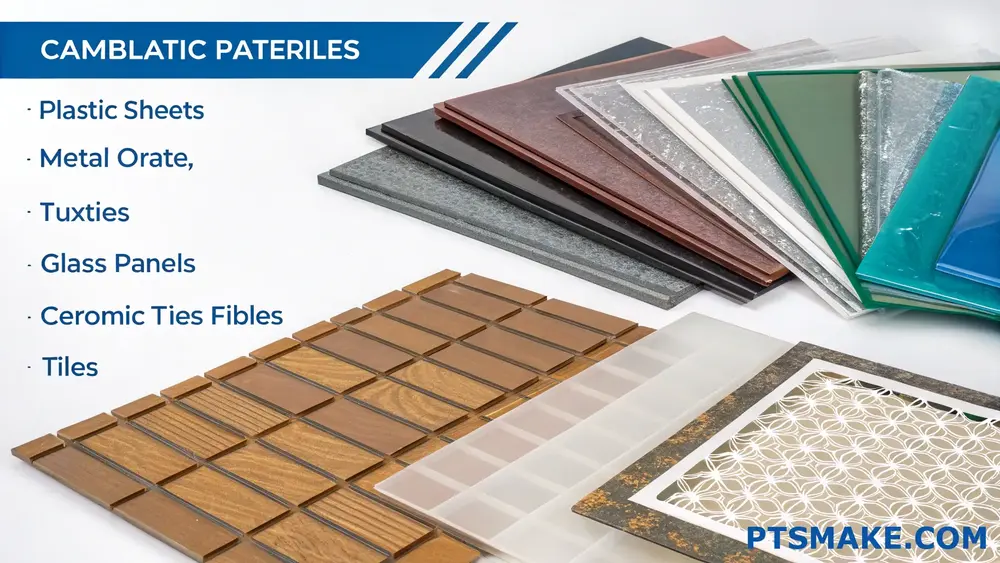

Silk screen printing is compatible with a wide range of materials including plastics, metals, textiles, glass, wood, and ceramics. The key factor is choosing the right ink type and mesh count for each specific substrate to ensure proper adhesion and print quality.

Understanding Material Compatibility

Plastic Materials

When it comes to plastic materials, silk screen printing offers exceptional versatility. At PTSMAKE, we regularly work with various plastic substrates, including:

| Plastic Type | Characteristics | Recommended Ink Type |

|---|---|---|

| ABS | High impact resistance | Solvent-based, UV-curable |

| Polycarbonate | Excellent clarity | UV-curable, epoxy |

| PVC | Flexible, durable | Vinyl, solvent-based |

| Acrylic | Crystal clear | UV-curable, epoxy |

| Polyethylene | Chemical resistant | Special PE inks |

Metal Surfaces

Metal surfaces require specific preparation and ink selection. The success of silk screen printing on metals depends heavily on the surface tension5 and proper pre-treatment methods.

Textile Applications

Natural Fibers

Natural fibers like cotton, silk, and wool respond well to:

- Plastisol inks

- Water-based inks

- Discharge inks

- Specialty metallic inks

Synthetic Fibers

Synthetic materials require different considerations:

- Polyester needs heat-resistant inks

- Nylon demands specific adhesion promoters

- Spandex blends require flexible ink formulations

Glass and Ceramic Materials

These materials present unique challenges but offer excellent printing results when handled correctly:

Glass Considerations

- Must be completely clean and free from oils

- Requires specialized glass inks

- Often needs UV curing

- Benefits from primer application

Ceramic Requirements

- Temperature resistance is crucial

- Ceramic-specific inks needed

- May require post-print firing

- Surface preparation is essential

Wood and Paper Products

Different wood types and paper grades accept screen printing differently:

| Material Type | Special Considerations | Best Practices |

|---|---|---|

| Hardwoods | Grain pattern affects print | Use higher mesh count |

| Softwoods | More ink absorption | Requires sealing |

| Coated Paper | Smooth surface ideal | Fast-drying inks |

| Cardstock | Thickness affects process | Adjust pressure |

Environmental Factors

The success of silk screen printing also depends on:

- Ambient temperature

- Humidity levels

- Proper ventilation

- Storage conditions

- Curing requirements

Material Preparation Techniques

For optimal results, different materials require specific preparation:

Surface Treatment Methods

- Degreasing

- Corona treatment

- Flame treatment

- Chemical etching

- Mechanical abrasion

Quality Control Measures

- Adhesion testing

- Durability assessment

- Color matching

- Print clarity evaluation

At PTSMAKE, we’ve developed specialized processes for each material type, ensuring consistent quality across various substrates. Our experience shows that proper material selection and preparation account for approximately 60% of successful silk screen printing outcomes.

Common Material Challenges

Understanding potential issues helps prevent problems:

Material-Specific Issues

- Static electricity on plastics

- Moisture content in textiles

- Temperature sensitivity

- Surface irregularities

- Ink adhesion problems

Solutions and Preventive Measures

- Using anti-static equipment

- Implementing proper pre-treatment

- Maintaining optimal environmental conditions

- Regular quality control checks

- Continuous process monitoring

The key to successful silk screen printing lies in understanding these material compatibilities and adapting your process accordingly. Through careful material selection and proper preparation techniques, you can achieve exceptional print quality across various substrates.

What Are the Common Defects in Silk Screen Printing and How to Avoid Them?

Have you ever felt frustrated when your silk screen printed parts come back with smudges, uneven coverage, or misaligned patterns? These quality issues not only waste materials and time but can also delay your entire production schedule and damage your brand reputation.

Silk screen printing defects are common manufacturing challenges that can significantly impact product quality. The most frequent issues include ink bleeding, poor adhesion, image distortion, and improper registration. However, these problems can be prevented through proper technique, equipment maintenance, and quality control measures.

Understanding Print Quality Issues

Ink-Related Defects

One of the most challenging aspects of silk screen printing is managing ink-related issues. The rheological properties6 of the ink play a crucial role in print quality. At PTSMAKE, we’ve developed a comprehensive approach to prevent these common defects:

Bleeding and Feathering

- Cause: Ink viscosity too low or excessive pressure

- Solution: Adjust ink consistency and reduce squeegee pressure

- Prevention: Regular viscosity testing before production

Poor Coverage

- Cause: Insufficient ink deposit or improper mesh count

- Solution: Multiple passes or mesh count adjustment

- Prevention: Proper mesh selection based on ink type

Mesh and Screen Issues

The screen’s condition directly affects print quality. Here’s what we monitor:

| Issue | Cause | Solution | Prevention |

|---|---|---|---|

| Screen Tearing | Excessive pressure | Reduce squeegee pressure | Regular screen tension checks |

| Pinholes | Dust or debris | Clean screen thoroughly | Maintain clean room conditions |

| Mesh Marks | Incorrect mesh count | Select appropriate mesh | Test prints before production |

Equipment-Related Problems

Registration Errors

Proper registration is essential for multi-color prints. Common issues include:

Misalignment

- Use registration marks

- Implement automated registration systems

- Regular calibration checks

Shifting

- Secure substrate properly

- Check for equipment vibration

- Maintain consistent pressure

Press Setup Problems

The printing press setup can cause various defects:

| Problem | Indicator | Correction Method |

|---|---|---|

| Off-Contact Height | Blurred edges | Adjust screen height |

| Squeegee Angle | Inconsistent coverage | Modify angle to 75° |

| Print Speed | Smearing | Optimize press speed |

Material and Environmental Factors

Substrate Issues

Different materials require specific approaches:

Surface Treatment

- Proper cleaning procedures

- Surface energy testing

- Application of primers when needed

Storage Conditions

- Temperature control

- Humidity monitoring

- Dust-free environment

Environmental Control

Environmental factors significantly impact print quality:

Temperature Effects

- Maintain 68-75°F (20-24°C)

- Monitor ink viscosity changes

- Adjust drying parameters

Humidity Considerations

- Keep relative humidity at 45-55%

- Use dehumidifiers when necessary

- Store materials properly

Quality Control Measures

Pre-Production Checks

Implementing thorough pre-production procedures:

Material Testing

- Ink viscosity measurement

- Substrate surface energy testing

- Screen tension verification

Equipment Inspection

- Squeegee condition

- Screen cleanliness

- Registration system alignment

Production Monitoring

Continuous monitoring during production:

| Stage | Check Points | Frequency |

|---|---|---|

| Setup | Registration marks | Every job start |

| Running | Print quality | Every 10-15 prints |

| Completion | Final inspection | 100% of prints |

Maintenance and Prevention

Regular Equipment Maintenance

Establishing preventive maintenance schedules:

Daily Tasks

- Clean screens thoroughly

- Check squeegee condition

- Inspect registration system

Weekly Tasks

- Test screen tension

- Clean press components

- Calibrate registration system

Process Documentation

Maintaining detailed records helps prevent recurring issues:

Production Parameters

- Ink specifications

- Press settings

- Environmental conditions

Quality Records

- Defect types and frequency

- Corrective actions taken

- Success rates of solutions

At PTSMAKE, we’ve implemented these comprehensive quality control measures in our silk screen printing processes. Our systematic approach ensures consistent quality and minimal defects, helping our clients achieve their desired results efficiently and cost-effectively.

How Does the Silk Screen Process Compare to Digital Printing for Industrial Applications?

Have you ever faced the challenge of choosing between silk screen and digital printing for your industrial projects? It’s a common dilemma that can significantly impact your product’s quality, cost, and production timeline, yet many professionals struggle to make the right choice.

Silk screen printing generally offers better durability and color vibrancy for industrial applications, while digital printing provides more flexibility for small batches and complex designs. The choice depends on factors like production volume, material requirements, and cost considerations.

Understanding the Fundamental Differences

Process Mechanics

Silk screen printing involves pushing ink through a mesh stencil onto the substrate, while digital printing uses modern printers to directly apply ink to materials. The halftone process7 in silk screening creates a unique dot pattern that contributes to its distinctive appearance and durability.

Material Compatibility

Both methods have different material compatibility profiles:

| Printing Method | Compatible Materials | Durability | Cost per Unit |

|---|---|---|---|

| Silk Screen | Metals, Plastics, Glass, Textiles | High | Lower for large runs |

| Digital | Paper, Vinyl, Some Plastics | Medium | Lower for small runs |

Production Considerations

Volume and Scalability

At PTSMAKE, we’ve observed that silk screen printing becomes more cost-effective as production volumes increase. The initial setup costs are higher, but the per-unit cost decreases significantly with larger runs. Digital printing maintains consistent pricing regardless of volume but may become costly for large productions.

Quality and Precision

When it comes to quality:

Silk Screen Advantages:

- Superior ink coverage

- Better color vibrancy

- Enhanced durability

- Excellent opacity on dark materials

Digital Printing Benefits:

- Higher detail resolution

- Easier color matching

- Smooth gradients

- Quick turnaround times

Cost Analysis and ROI

Setup Costs

The initial investment differs significantly:

| Cost Factor | Silk Screen | Digital Printing |

|---|---|---|

| Equipment | $5,000-$20,000 | $10,000-$100,000 |

| Setup Time | 2-4 hours | 15-30 minutes |

| Material Waste | Higher | Minimal |

Long-term Considerations

The cost-effectiveness depends on:

- Production volume

- Color complexity

- Material requirements

- Production frequency

Environmental Impact

Sustainability Factors

Digital printing generally has a lower environmental impact due to:

- Reduced waste generation

- Lower chemical usage

- More efficient energy consumption

- Fewer material resources needed

Silk screen printing, while traditional, can be optimized for sustainability through:

- Water-based ink options

- Proper waste management

- Recycling of screens

- Efficient cleaning processes

Industry-Specific Applications

Automotive Industry

Silk screen printing excels in:

- Dashboard components

- Control panels

- Warning labels

- Exterior decorative elements

Electronics Manufacturing

Digital printing advantages include:

- Circuit board markings

- Component labeling

- Product identification

- Custom device housings

Quality Control Considerations

Common Quality Issues

Silk Screen Challenges:

- Screen tension maintenance

- Ink consistency

- Registration accuracy

- Edge definition

Digital Printing Concerns:

- Color matching

- Material adhesion

- Print head maintenance

- Resolution consistency

Future Trends and Technologies

Emerging Developments

The industry is evolving with:

- Hybrid printing systems

- Automated quality control

- Smart material handling

- Enhanced ink formulations

Market Predictions

We’re seeing trends toward:

- Increased automation

- Improved sustainability

- Greater customization options

- Enhanced material compatibility

Making the Right Choice

Consider these factors when deciding:

- Production volume requirements

- Material specifications

- Quality expectations

- Budget constraints

- Timeline requirements

- Environmental considerations

Integration with Modern Manufacturing

Both methods can be integrated into modern manufacturing processes:

- Industry 4.0 compatibility

- Automated production lines

- Quality monitoring systems

- Digital workflow management

This comprehensive comparison shows that both silk screen and digital printing have their place in industrial applications. The key is understanding your specific requirements and choosing the method that best aligns with your production goals and constraints.

What Are the Cost Factors in the Silk Screen Printing Process?

Have you ever received a quote for silk screen printing that left you puzzled? Many manufacturers struggle to understand why prices can vary so dramatically between different projects and suppliers. The complexity of cost factors often leads to budget overruns and project delays.

Silk screen printing costs are influenced by multiple factors including setup charges, material selection, quantity, colors used, printing area size, and labor requirements. Understanding these elements helps businesses make informed decisions and optimize their printing expenses.

Material Costs and Their Impact

Screen Mesh Selection

The choice of screen mesh significantly affects both quality and cost. Monofilament polyester8 remains the industry standard, but specialized materials like stainless steel mesh may be required for specific applications. At PTSMAKE, we carefully evaluate mesh requirements to balance cost and performance.

Substrate Materials

The type of material being printed on plays a crucial role in determining costs:

| Material Type | Relative Cost | Typical Applications |

|---|---|---|

| Paper | Low | Posters, Cards |

| Plastics | Medium | Control Panels, Signs |

| Metals | High | Industrial Labels |

| Glass | Very High | Electronic Displays |

Production Volume Considerations

Setup Costs

Initial setup costs remain relatively fixed regardless of order size. These include:

- Screen preparation

- Color matching

- Test prints

- Equipment calibration

Economies of Scale

Larger production runs typically reduce per-unit costs:

| Quantity Range | Cost per Unit | Setup Cost Impact |

|---|---|---|

| 1-100 | High | Major |

| 101-500 | Medium | Moderate |

| 501-1000 | Low | Minor |

| 1000+ | Lowest | Minimal |

Design Complexity Factors

Color Requirements

Each additional color requires:

- Separate screens

- Additional setup time

- More materials

- Extended production time

Image Detail and Resolution

Fine details and precise requirements increase costs through:

- Higher mesh counts

- More careful preparation

- Slower production speeds

- Increased quality control

Labor and Time Considerations

Skill Level Requirements

Different projects require varying levels of expertise:

- Basic single-color prints: Entry-level operators

- Multi-color registration: Experienced technicians

- Precision electronic components: Master printers

Production Speed Variables

Several factors influence production speed:

- Material handling requirements

- Drying time between colors

- Quality inspection needs

- Equipment capabilities

Geographic and Market Factors

Regional Labor Rates

Labor costs vary significantly by location. At PTSMAKE, our strategic location in China allows us to offer competitive pricing while maintaining high quality standards.

Market Competition

Local market conditions affect pricing:

- Number of available suppliers

- Specialization requirements

- Regional demand levels

- Available technology

Quality Control Costs

Inspection Requirements

Quality control measures add to overall costs:

- Visual inspections

- Measurement verification

- Documentation

- Defect analysis

Rejection Rates

Higher quality requirements typically mean:

- More careful production

- Additional inspection points

- Lower production speeds

- Increased material waste

Environmental and Regulatory Compliance

Safety Requirements

Safety measures impact costs through:

- Protective equipment

- Ventilation systems

- Waste handling

- Training programs

Environmental Controls

Environmental considerations include:

- Ink disposal

- Chemical storage

- Air quality management

- Water treatment

Technology and Equipment Factors

Machine Capabilities

Equipment selection affects:

- Production speed

- Quality levels

- Labor requirements

- Setup times

Maintenance Costs

Regular maintenance ensures consistent quality:

- Preventive maintenance

- Repairs

- Calibration

- Replacement parts

Special Requirements

Custom Color Matching

Special color requirements add costs:

- Color development time

- Special ink mixing

- Test runs

- Quality verification

Surface Treatment

Some materials require pre-treatment:

- Cleaning

- Surface activation

- Primer application

- Post-treatment

How to Choose the Right Supplier for Silk Screen Process Projects?

Have you ever received silk screened products that looked nothing like what you expected? The misaligned prints, inconsistent colors, and poor adhesion can turn a promising project into a nightmare. These quality issues not only waste time and money but can also damage your brand’s reputation.

Choosing the right silk screen process supplier requires evaluating their technical capabilities, quality control systems, and industry experience. The ideal partner should demonstrate expertise in screen printing techniques, maintain consistent quality standards, and provide clear communication throughout the project.

Technical Capabilities Assessment

Equipment and Technology

A supplier’s technical foundation directly impacts their ability to deliver quality results. At PTSMAKE, we emphasize the importance of modern equipment for precise silk screen processing. The supplier should have:

- Automatic printing machines for consistent output

- High-quality mesh screens

- Advanced curing equipment

- Color matching systems

- Quality inspection tools

Material Expertise

Understanding different substrate materials and their interaction with inks is crucial. The supplier should be knowledgeable about:

- Various ink types and their applications

- Substrate compatibility

- Surface treatment requirements

- Halftone printing9 techniques

- Curing parameters for different materials

Quality Control Systems

Process Documentation

Reliable suppliers maintain detailed documentation of their processes. Look for:

| Documentation Type | Purpose | Importance |

|---|---|---|

| Standard Operating Procedures | Process standardization | High |

| Quality Control Checklists | Consistency verification | Critical |

| Material Specifications | Input control | Essential |

| Test Reports | Quality validation | Mandatory |

Quality Assurance Methods

Quality control should be systematic and comprehensive, including:

- Pre-production sample approval

- In-process inspections

- Post-production testing

- Color consistency checks

- Adhesion testing

Production Capacity and Flexibility

Volume Management

Understanding a supplier’s production capacity helps ensure they can meet your needs:

- Daily production capability

- Equipment availability

- Workforce capacity

- Production scheduling system

- Rush order handling

Project Scalability

The supplier should demonstrate flexibility in handling:

- Small prototype runs

- Medium-sized orders

- Large production volumes

- Custom requirements

- Schedule adjustments

Communication and Service

Response Time

Effective communication is crucial for project success. Evaluate:

- Quote response time

- Technical query handling

- Sample approval process

- Production updates

- Issue resolution speed

Technical Support

Look for suppliers offering comprehensive technical support:

- Design optimization advice

- Material selection guidance

- Process improvement suggestions

- Troubleshooting assistance

- Quality issue resolution

Cost Structure and Transparency

Pricing Components

Understanding the cost structure helps avoid surprises:

| Cost Element | Description | Impact |

|---|---|---|

| Setup Charges | Initial preparation costs | One-time |

| Material Costs | Ink and substrate expenses | Variable |

| Labor Rates | Production workforce costs | Variable |

| Quality Control | Inspection and testing fees | Fixed |

| Packaging | Protection and shipping prep | Variable |

Value-Added Services

Consider additional services that may benefit your project:

- Design assistance

- Inventory management

- Custom packaging

- Rush delivery options

- Quality certification support

Industry Experience and Reputation

Track Record

Evaluate the supplier’s history and reputation:

- Years in business

- Industry certifications

- Client testimonials

- Project portfolio

- Quality awards

Industry Knowledge

The supplier should demonstrate understanding of:

- Industry standards

- Regulatory requirements

- Environmental regulations

- Safety protocols

- Best practices

At PTSMAKE, we’ve built our reputation on delivering consistent, high-quality silk screen processing services. Our comprehensive quality management system, modern equipment, and experienced team ensure reliable results for every project. We understand that choosing the right supplier is crucial for project success, which is why we maintain transparent communication and provide detailed documentation throughout the process.

Click to learn how different mesh counts affect print quality and when to use each type. ↩

Click to learn more about photoemulsion types and their specific applications in industrial printing. ↩

Click to learn more about photopolymer technology and how it revolutionizes screen printing quality. ↩

Click to learn more about proper emulsion coating techniques for optimal screen printing results. ↩

Click to learn more about surface tension’s critical role in achieving optimal print adhesion. ↩

Click to learn more about ink properties and their impact on print quality. ↩

Click here to learn more about halftone techniques and their impact on print quality. ↩

Click to learn more about advanced mesh materials and their impact on print quality. ↩

Click to learn advanced techniques for achieving precise gradients in screen printing. ↩